Turnover device

A flipping device and flipping part technology, applied in packaging and other directions, can solve the problems of uneven patch, increased consumption, skewed attaching part, etc., and achieve the effect of good attaching quality, simple structure and high attaching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

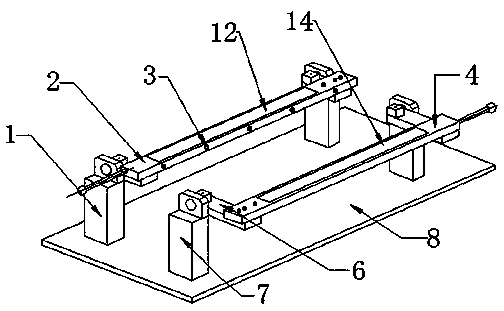

[0024] Such as figure 1 As shown, the turning device includes a frame 8 and a first turning part 1 and a second turning part 7 which are sequentially arranged on the frame 8, each turning part has a superimposed surface, and the first turning part 1 and the second turning part The overlapping surfaces of the parts 7 can be turned over and attached to each other.

[0025] The first reversing part 1 comprises a first placement platform 2 and an adsorption device, the adsorption device comprises an adsorption hole 3 and a negative pressure device arranged on the first placement platform 2, and the negative pressure device comprises an adsorption chamber fixedly connected with the first placement platform 2 (not shown in the figure) and an air pump (not shown in the figure), and the adsorption chamber and the air pump are connected by an air guide tube (not shown in the figure). The first placement platform 2 is also provided with a positioning block (not shown in the figure).

...

Embodiment 2

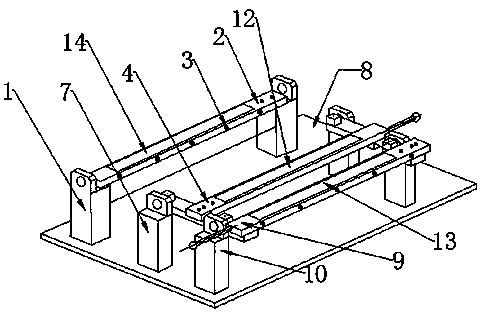

[0030] Such as figure 2 As shown, the turning device includes a frame 8 and a first turning part 1, a second turning part 7 and a third turning part 10 which are sequentially arranged on the frame 8, each turning part has a superimposed surface, and the first turning part The superimposed surfaces of the part 1 and the second reversed part 7 can be reversed and bonded to each other, and the superimposed surfaces of the second reversed part 7 and the third reversed part 10 can be reversed and bonded to each other.

[0031] The first reversing part 1 comprises a first placement platform 2 and an adsorption device, the adsorption device comprises an adsorption hole 3 and a negative pressure device arranged on the first placement platform 2, and the negative pressure device comprises an adsorption chamber fixedly connected with the first placement platform 2 and the air pump, the adsorption chamber and the air pump are connected by an air guide tube. The first placement platform...

Embodiment 3

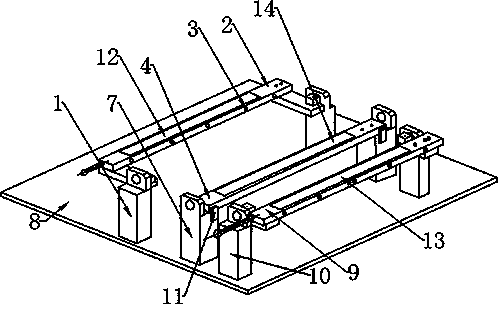

[0039]The rest are the same as in Embodiment 2, the difference is that the first turning part 1 includes a first adsorption device, and the first adsorption device includes an adsorption hole and a negative pressure device arranged on the first placement table 2, and the negative pressure device includes the same as the first suction device. A placement table 2 is fixedly connected to the adsorption chamber and the air pump, and the adsorption chamber and the air pump are connected by an air duct.

[0040] The second placement table 4 is also provided with a second fast positioning and a pneumatic clamping mechanism.

[0041] The working principle of the turning mechanism is as follows:

[0042] The first placement platform 2 is provided with a first positioning block, the patch 12 is placed on the first placement platform 2, the adsorption device is turned on, and the patch 12 is adsorbed on the first placement platform 2 due to negative pressure. The second placement table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com