Patents

Literature

39results about How to "Improve attachment quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

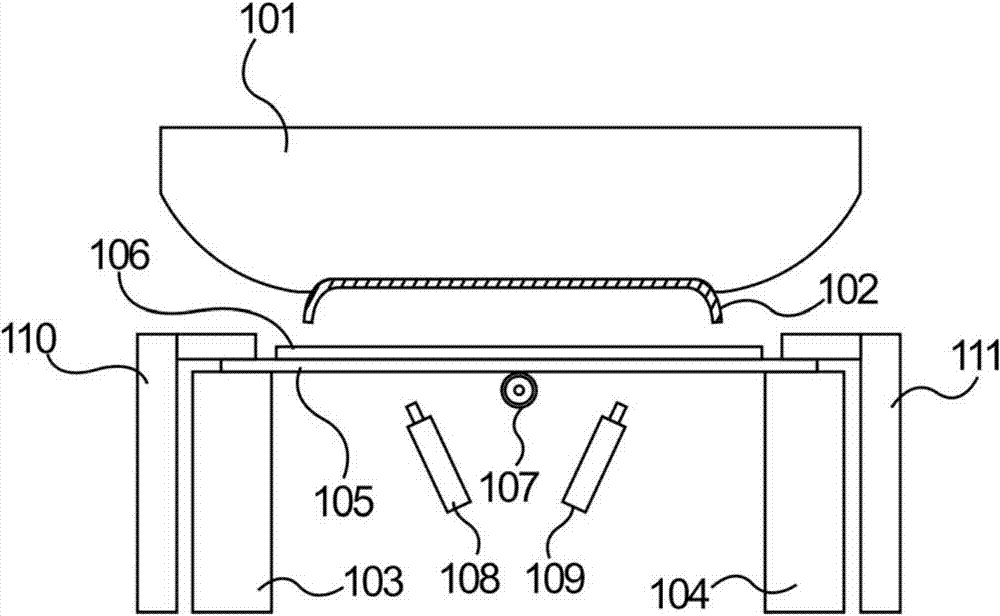

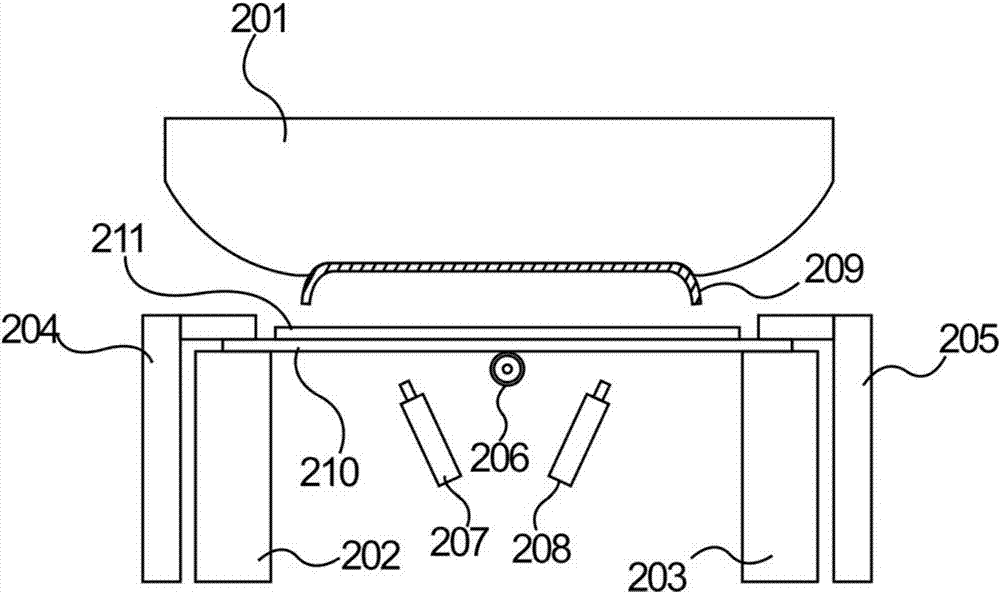

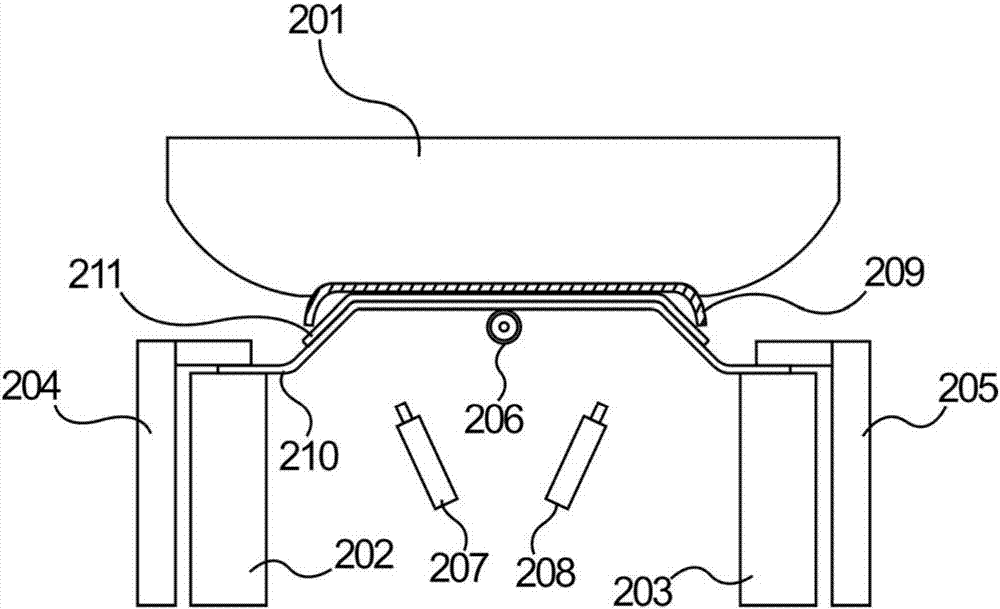

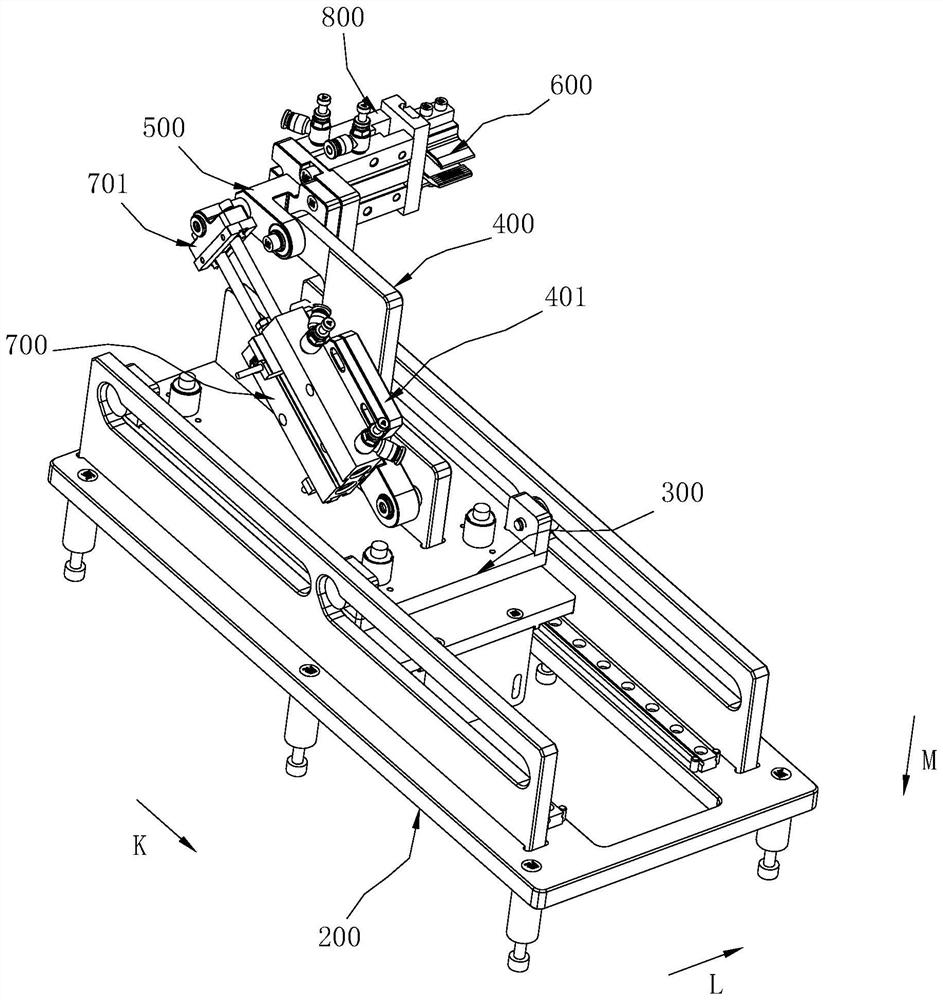

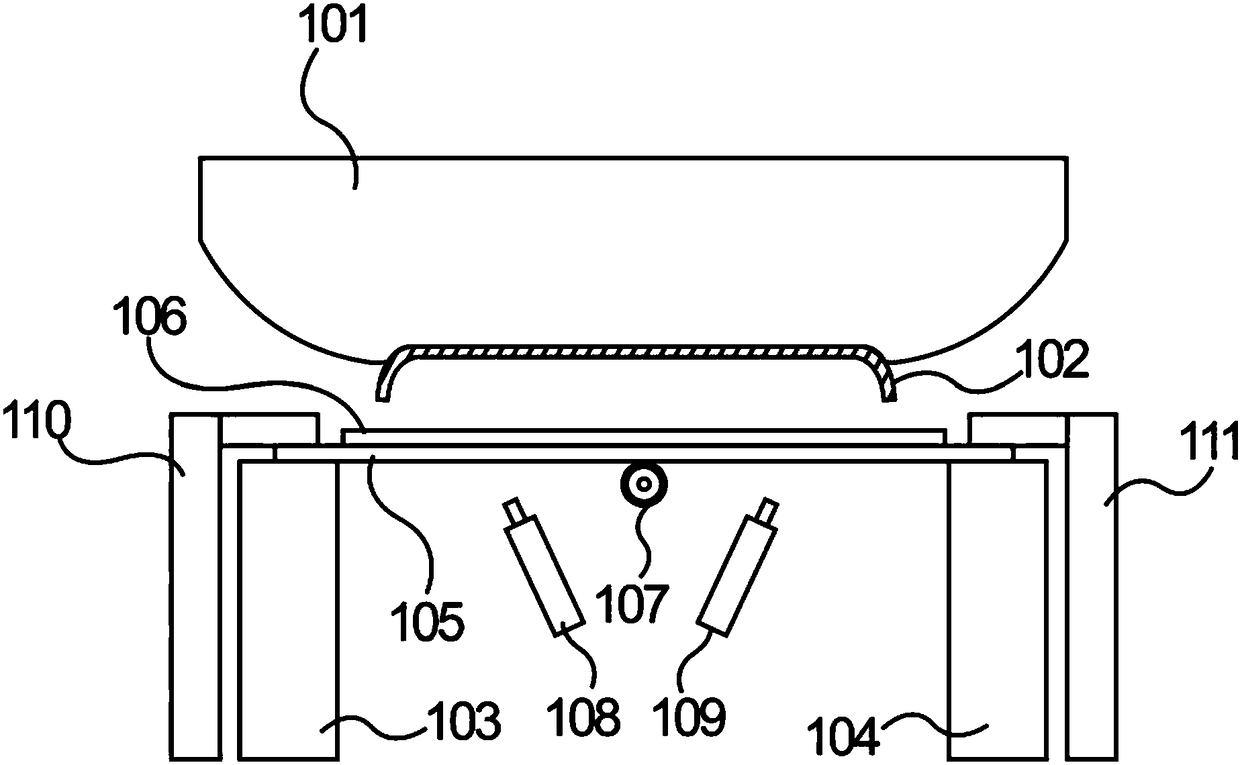

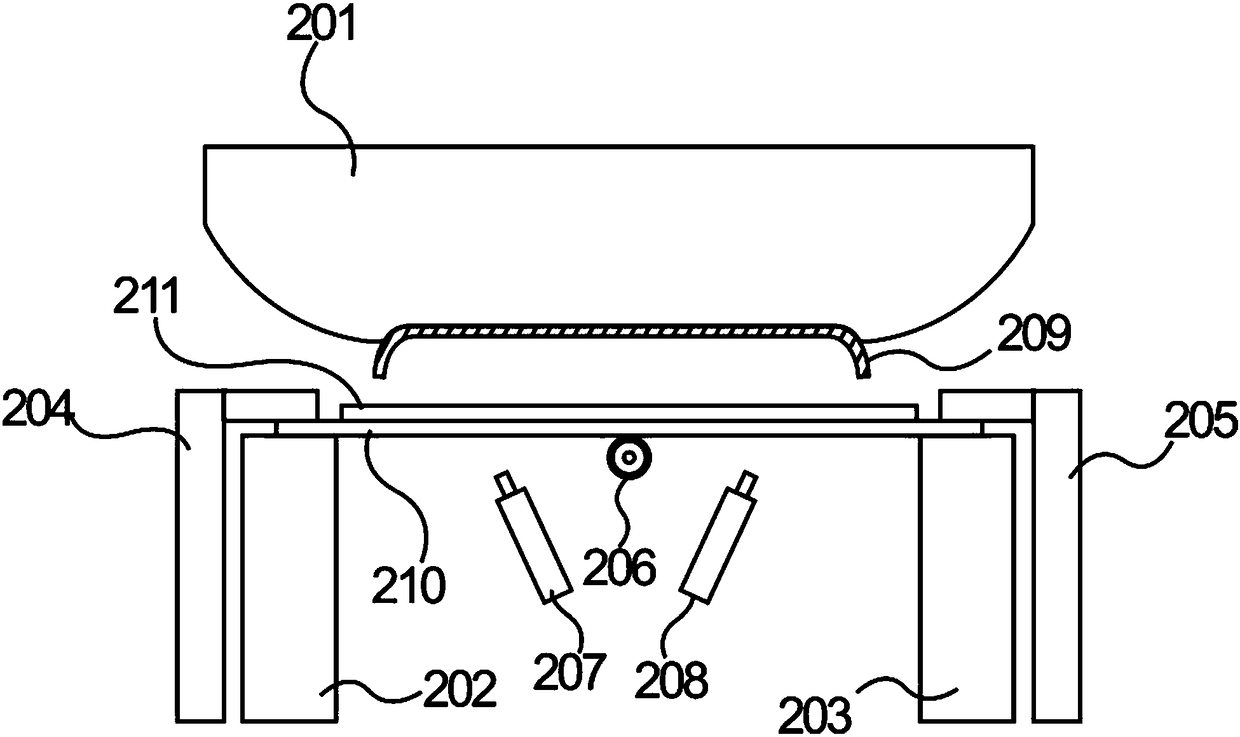

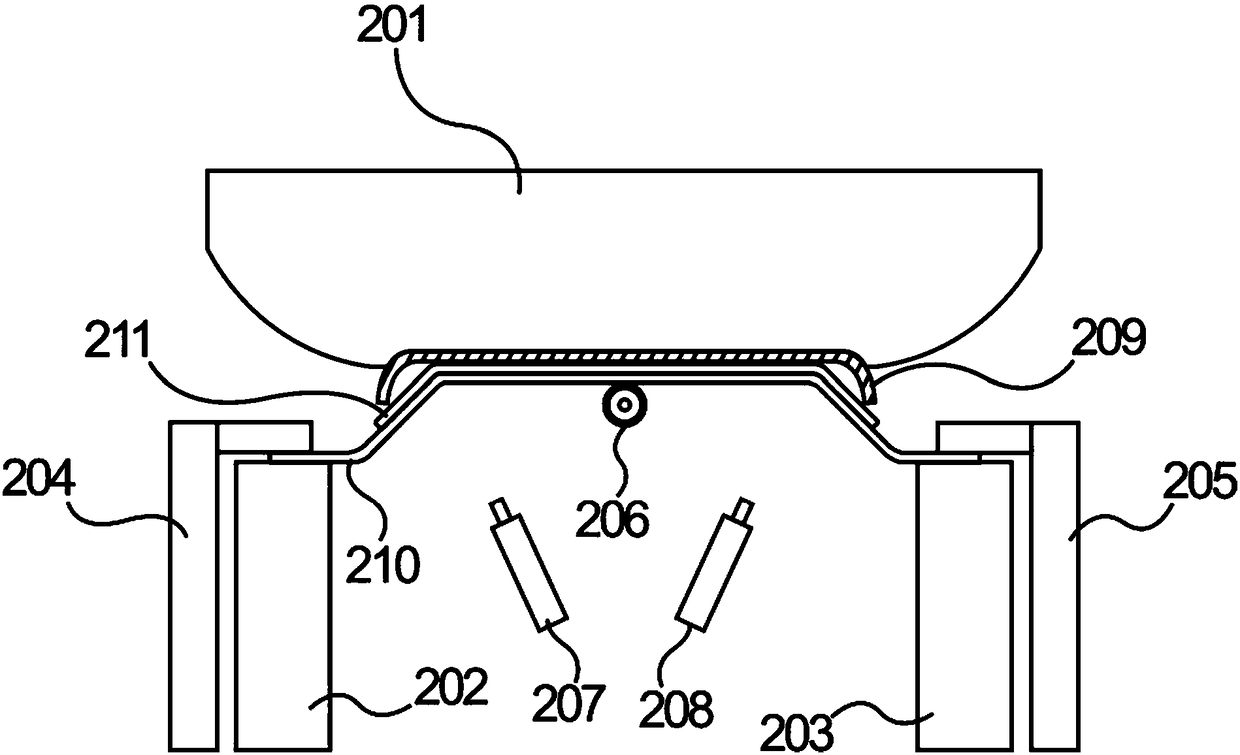

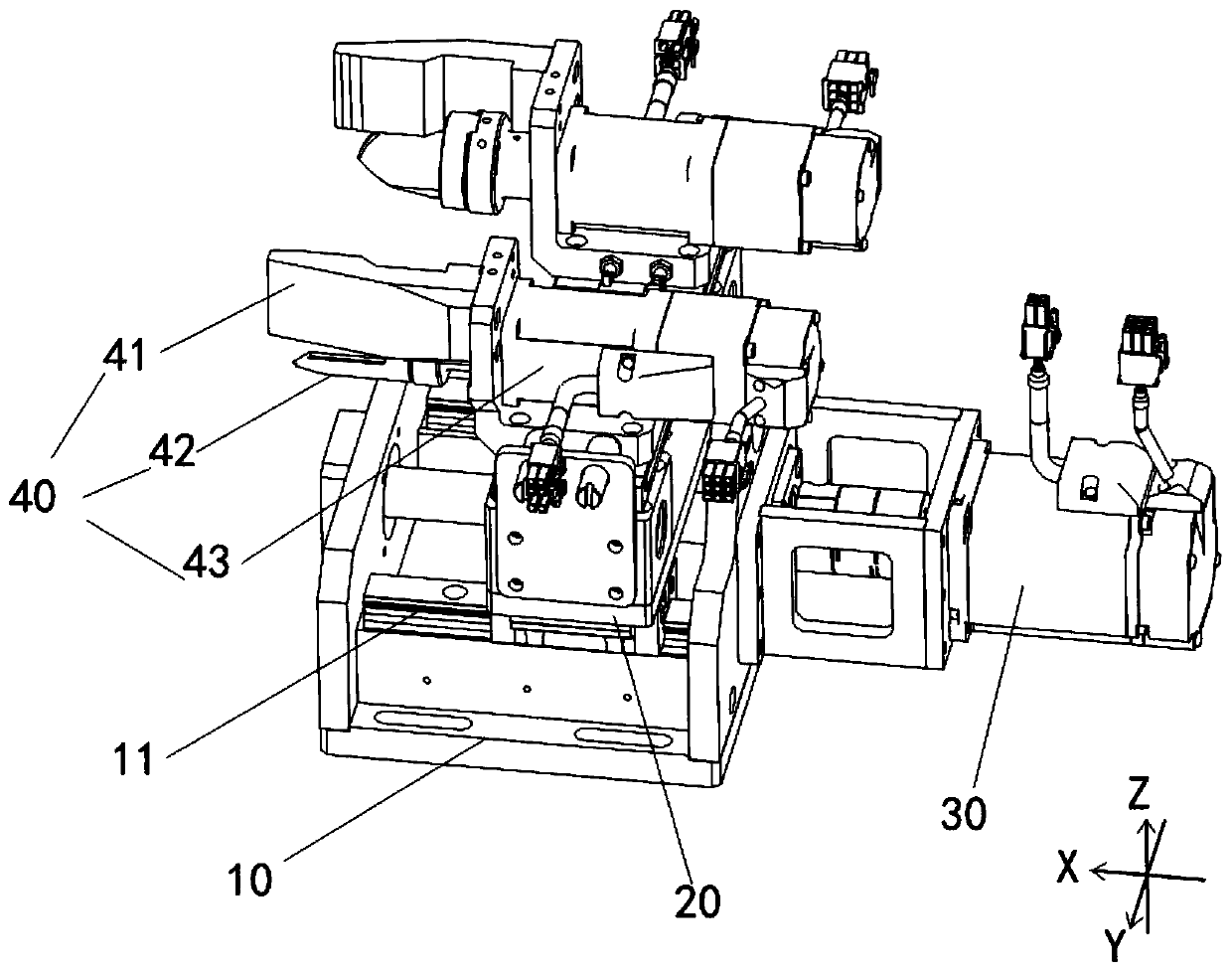

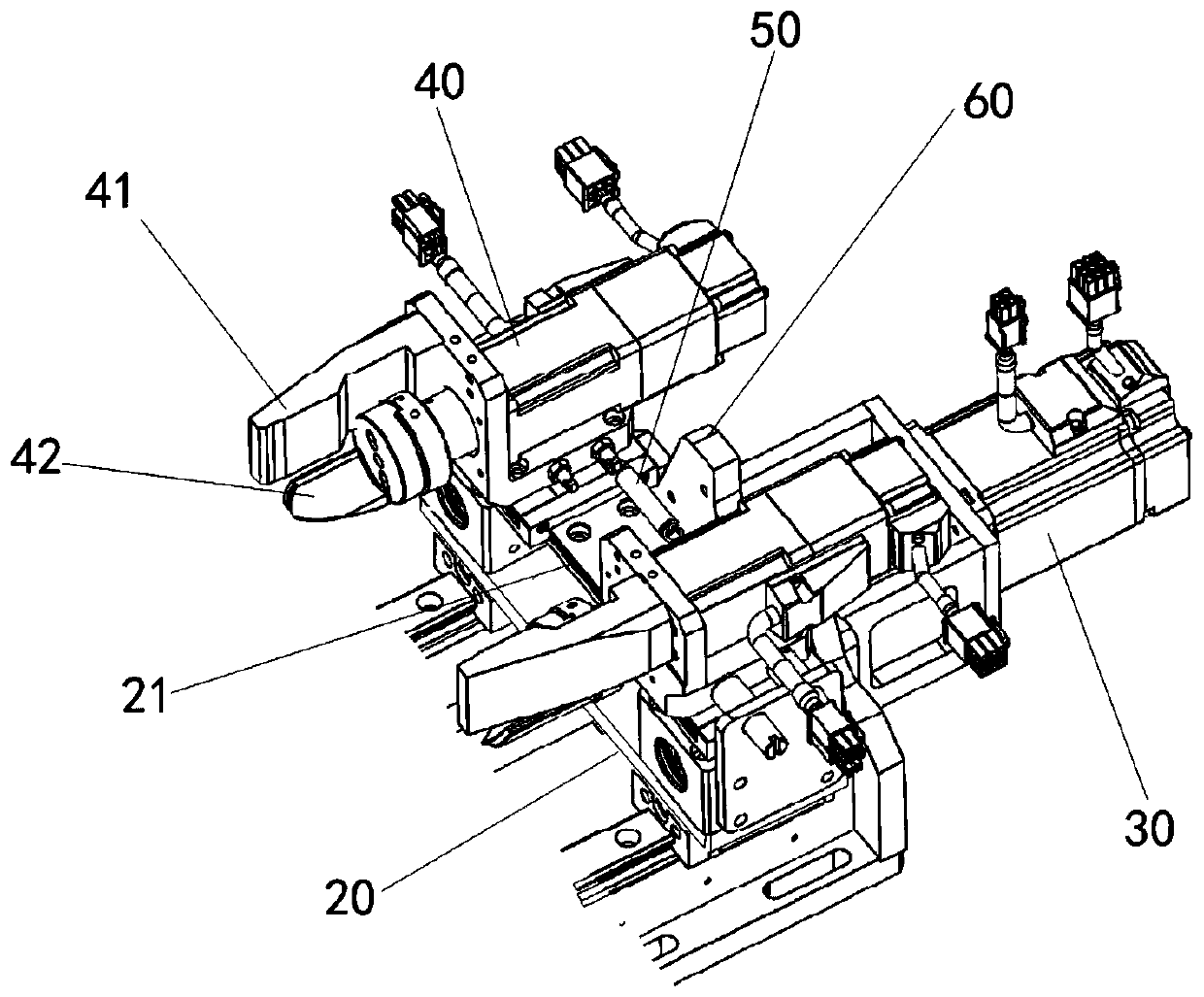

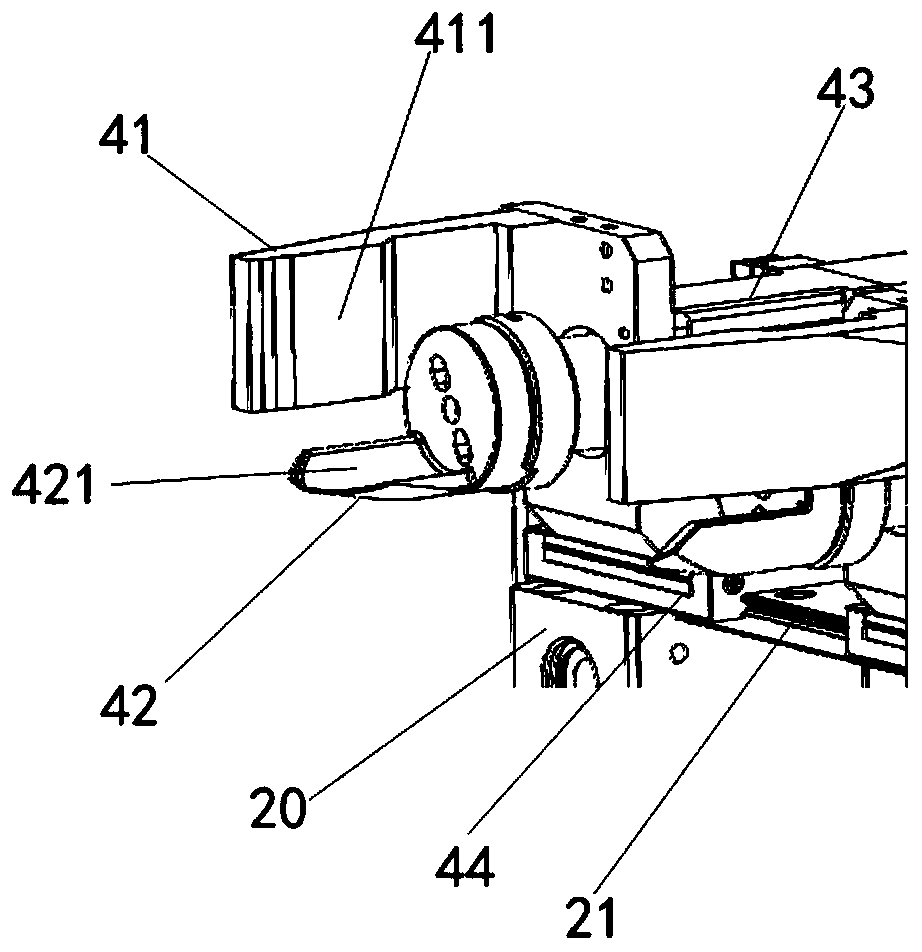

Flexible display panel attachment device and attachment method thereof

ActiveCN107039604AImprove attachment qualitySolid-state devicesSemiconductor/solid-state device manufacturingFlexible displayCover glass

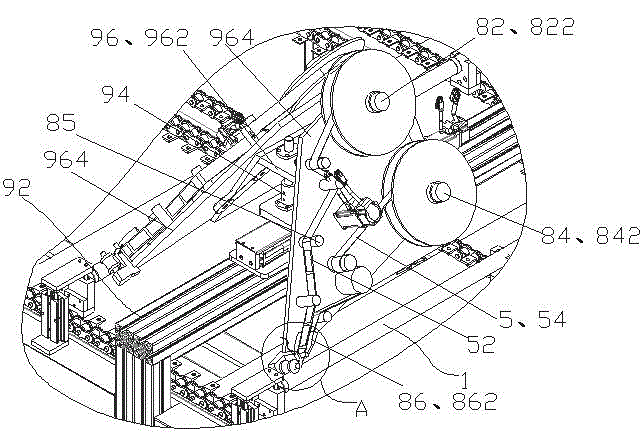

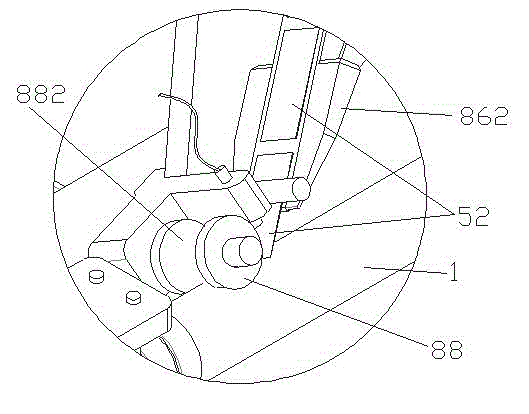

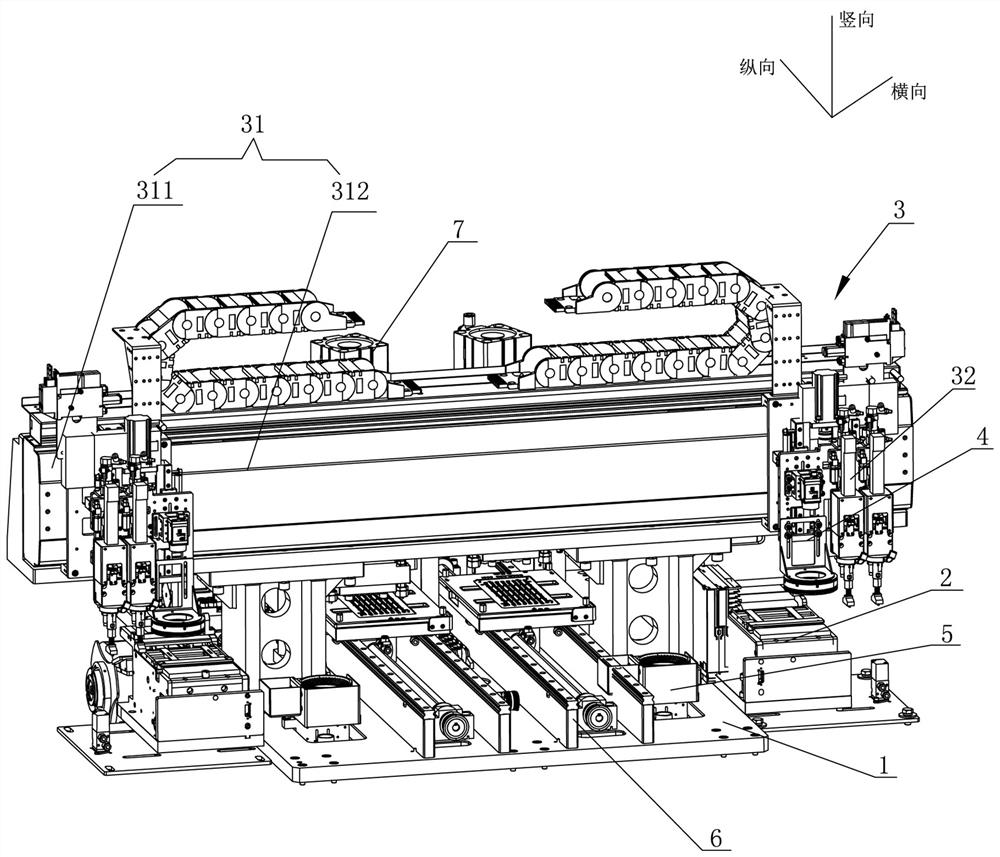

The invention provides a flexible display panel attachment device, comprising an imitation jig, a first adsorption platform, a second adsorption platform, a first pressure claw assembly, a second pressure claw assembly, a roll shaft, a first blower gun and a second blower gun. A part of a flexible display layer is attached to the main body part of a cover glass by rolling of the roll shaft, and then the flexible display layer area that the roll shaft cannot touch is blown by the blower guns, so that the flexible display layer area is attached to the bent part of the cover glass, the flexible OLED display layer is attached to the surface of the cover glass having large radian and small fillet edge, and the attachment quality of the flexible OLED display layer is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

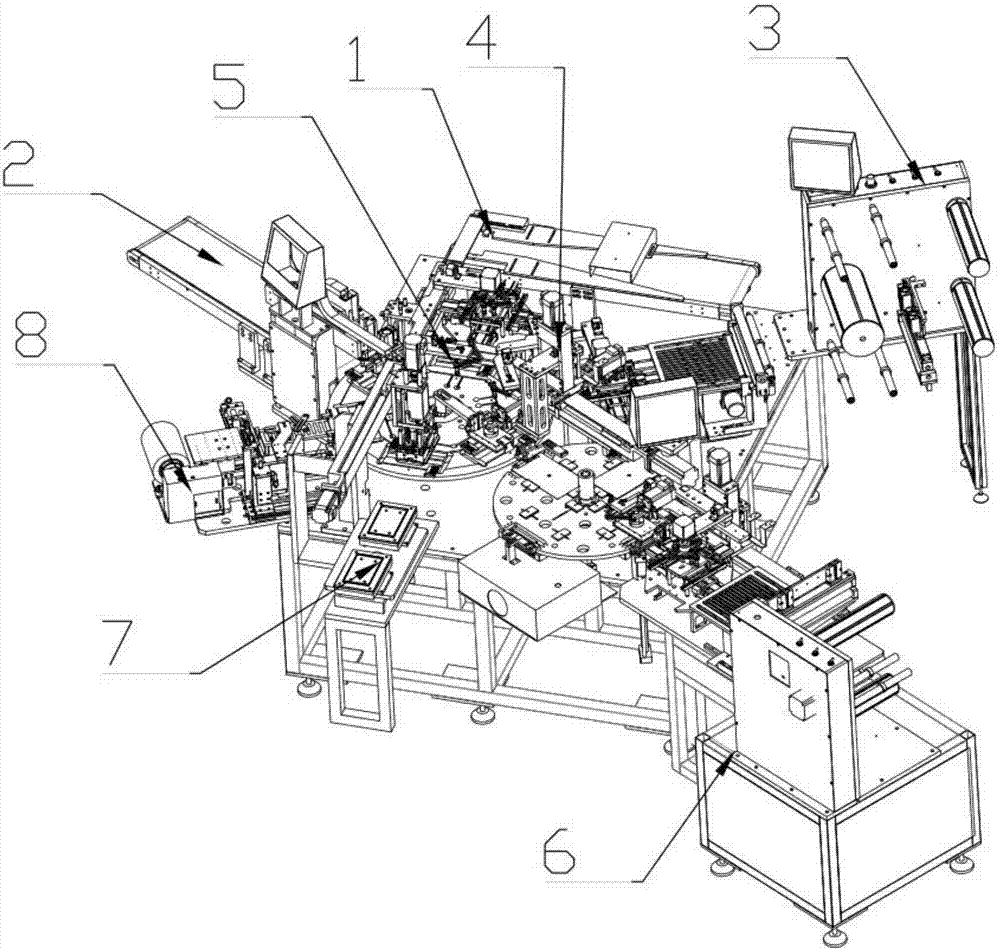

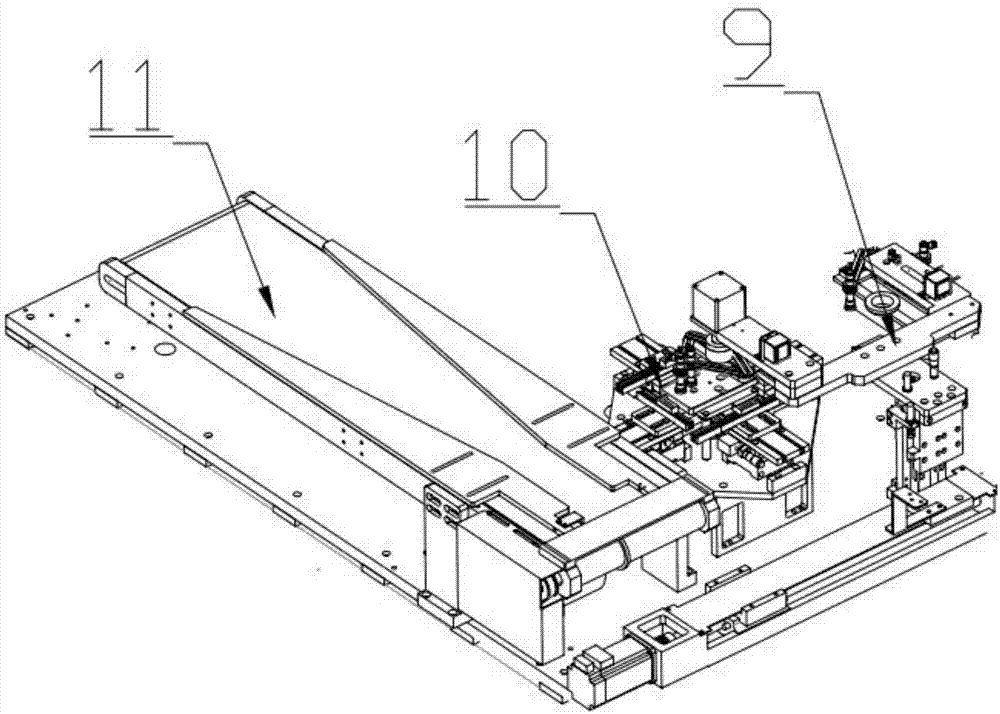

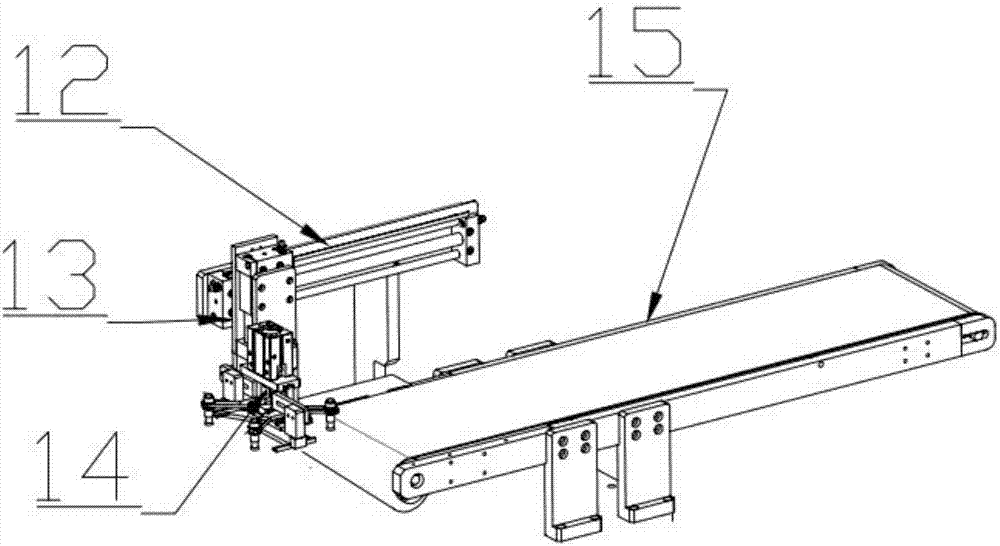

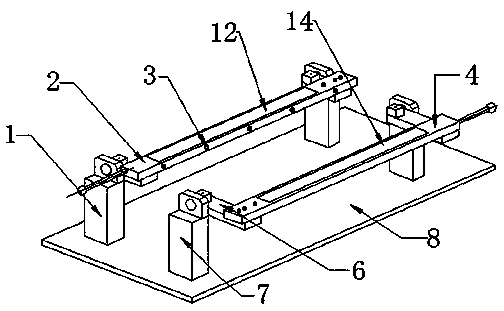

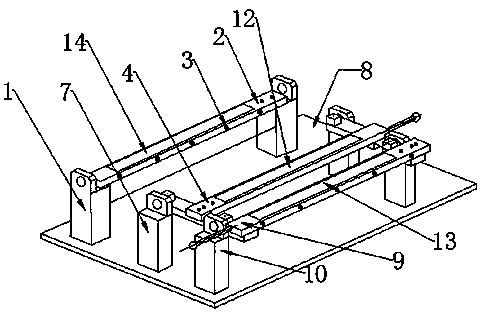

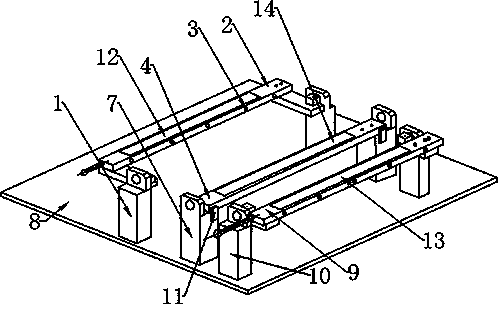

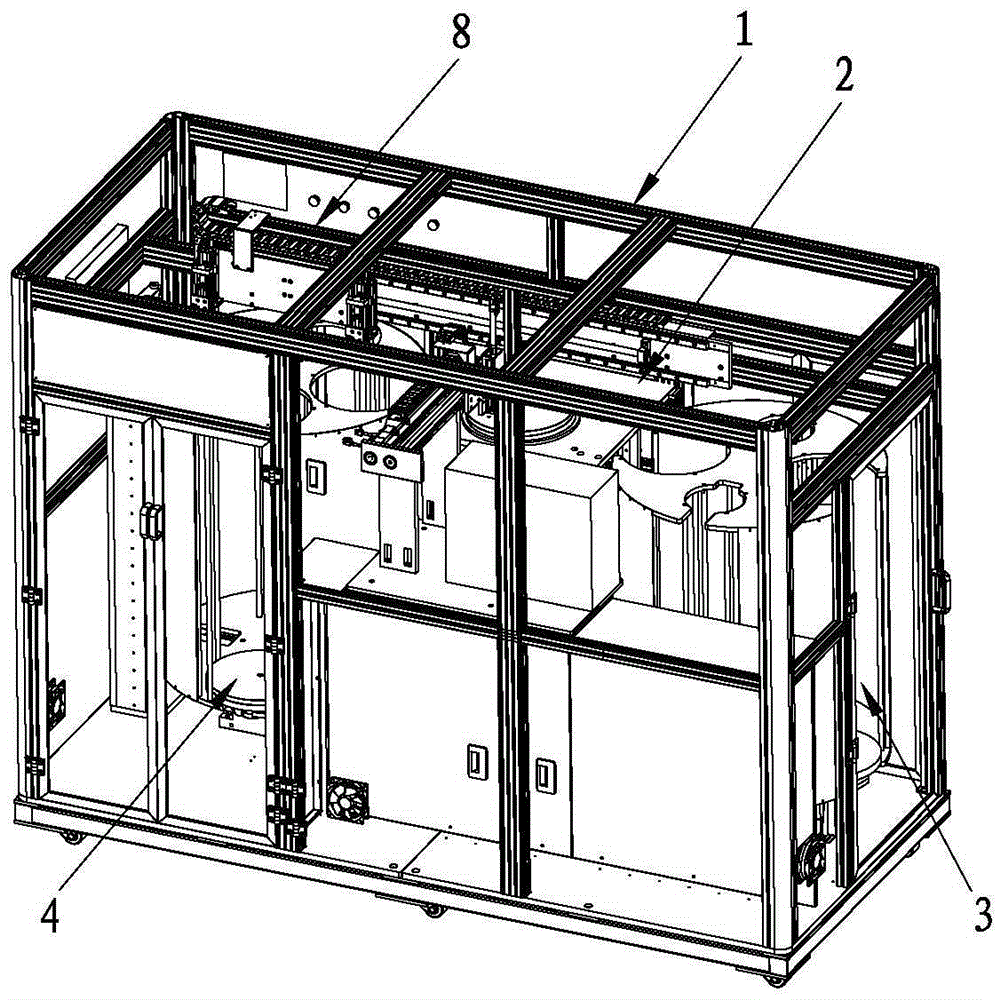

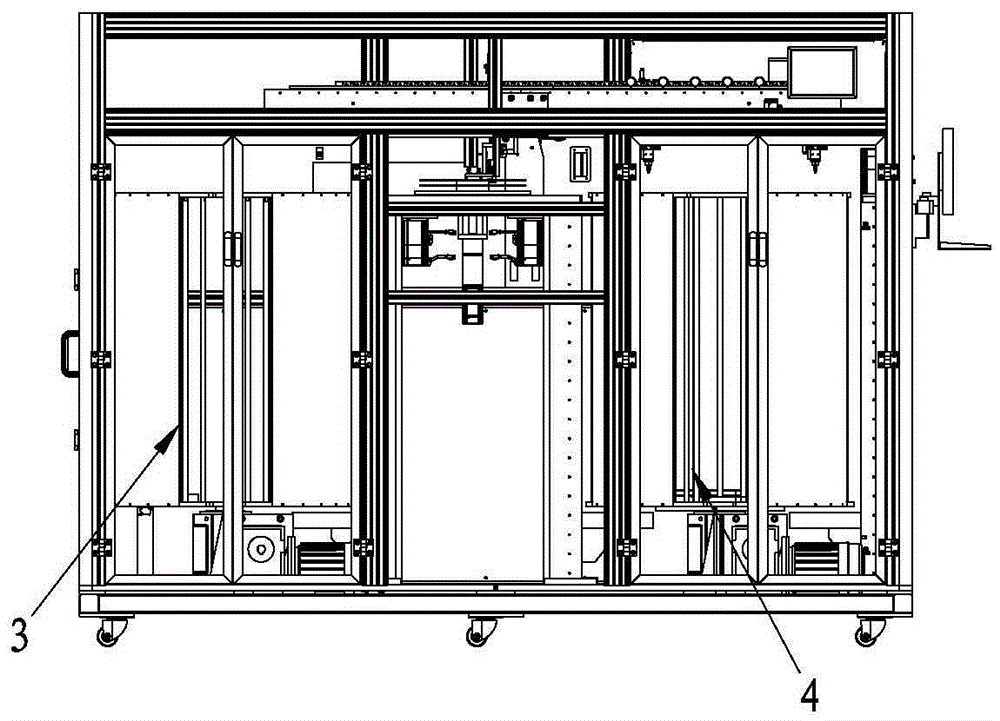

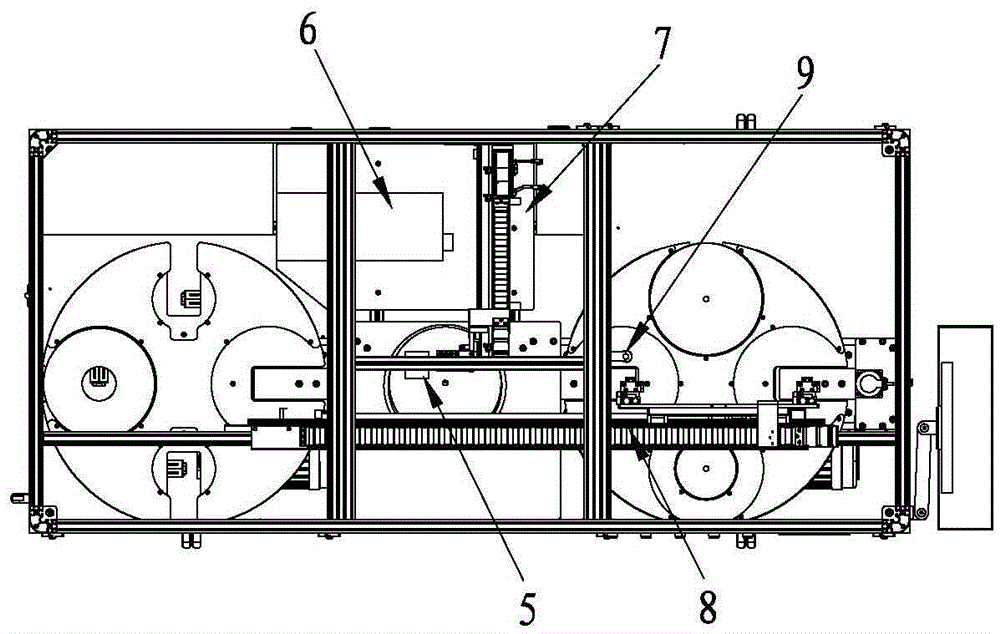

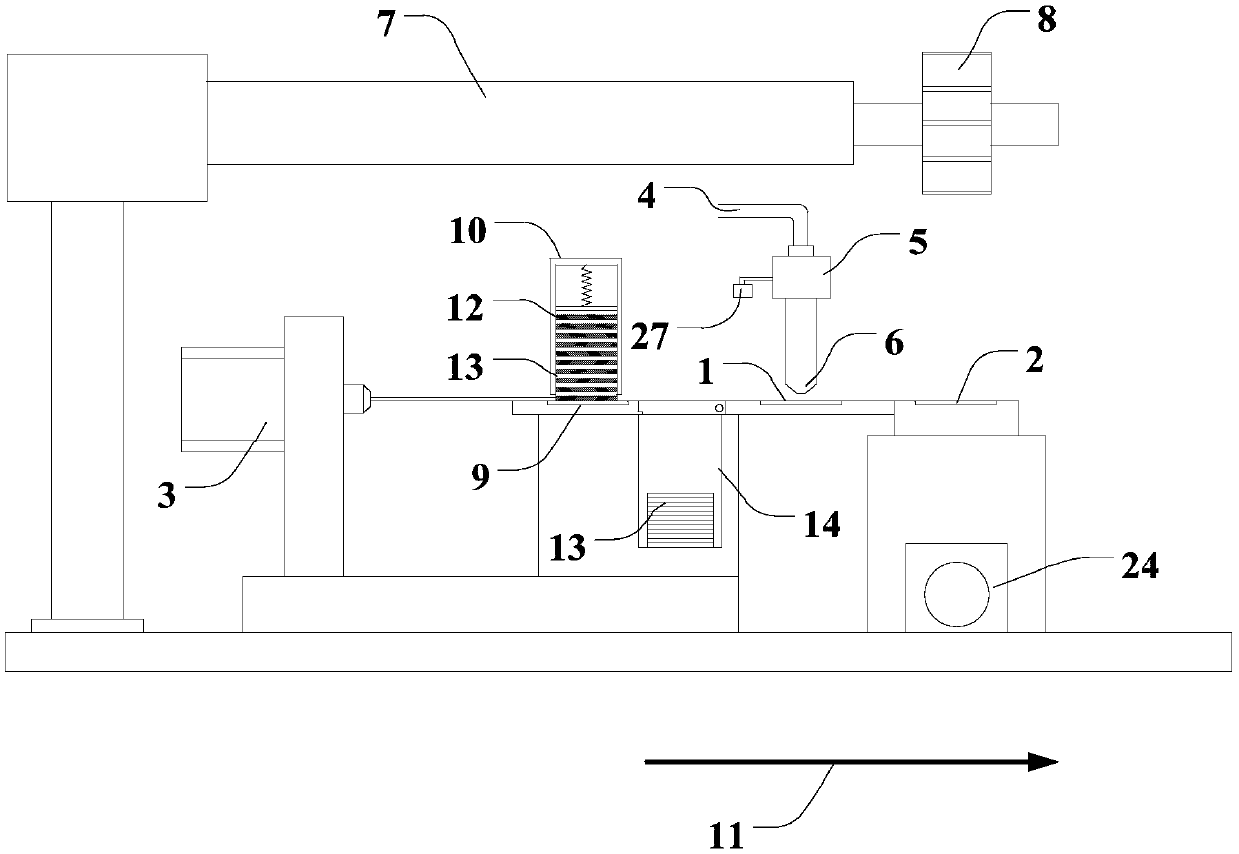

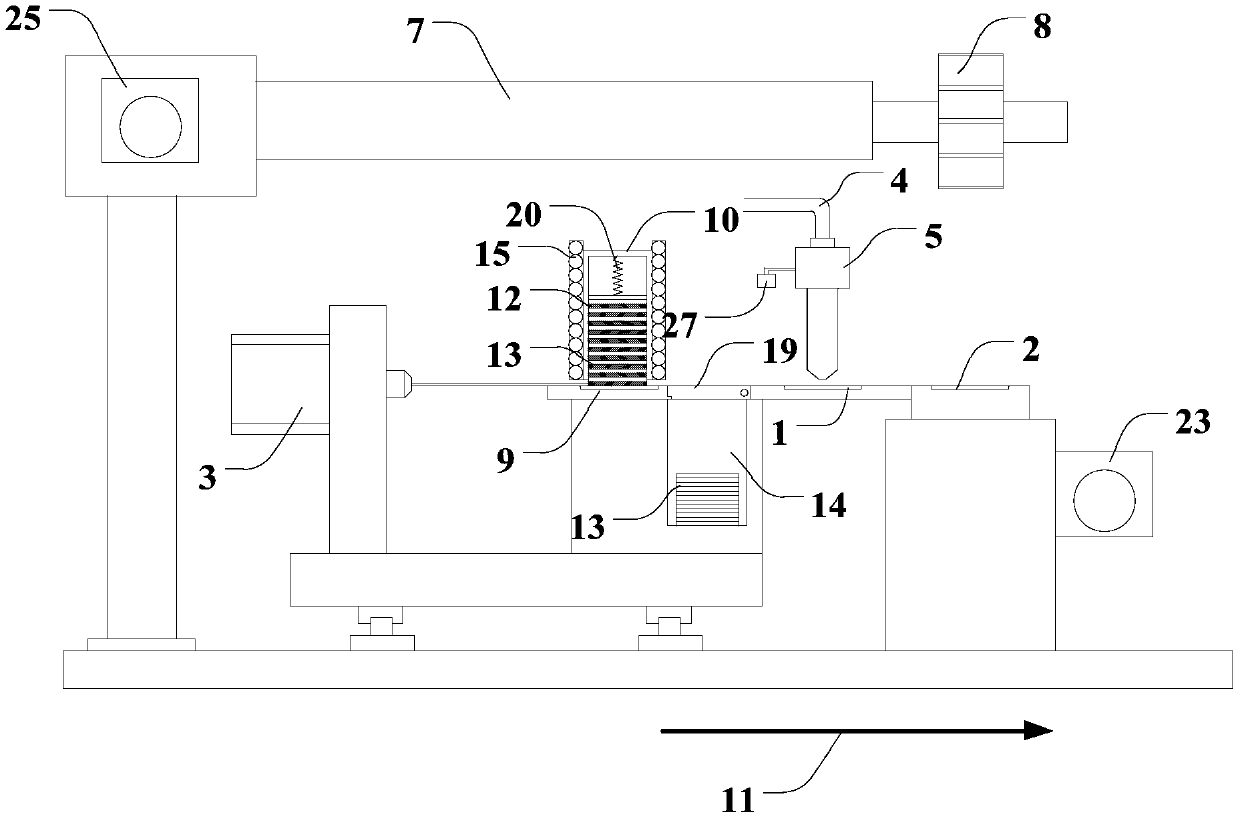

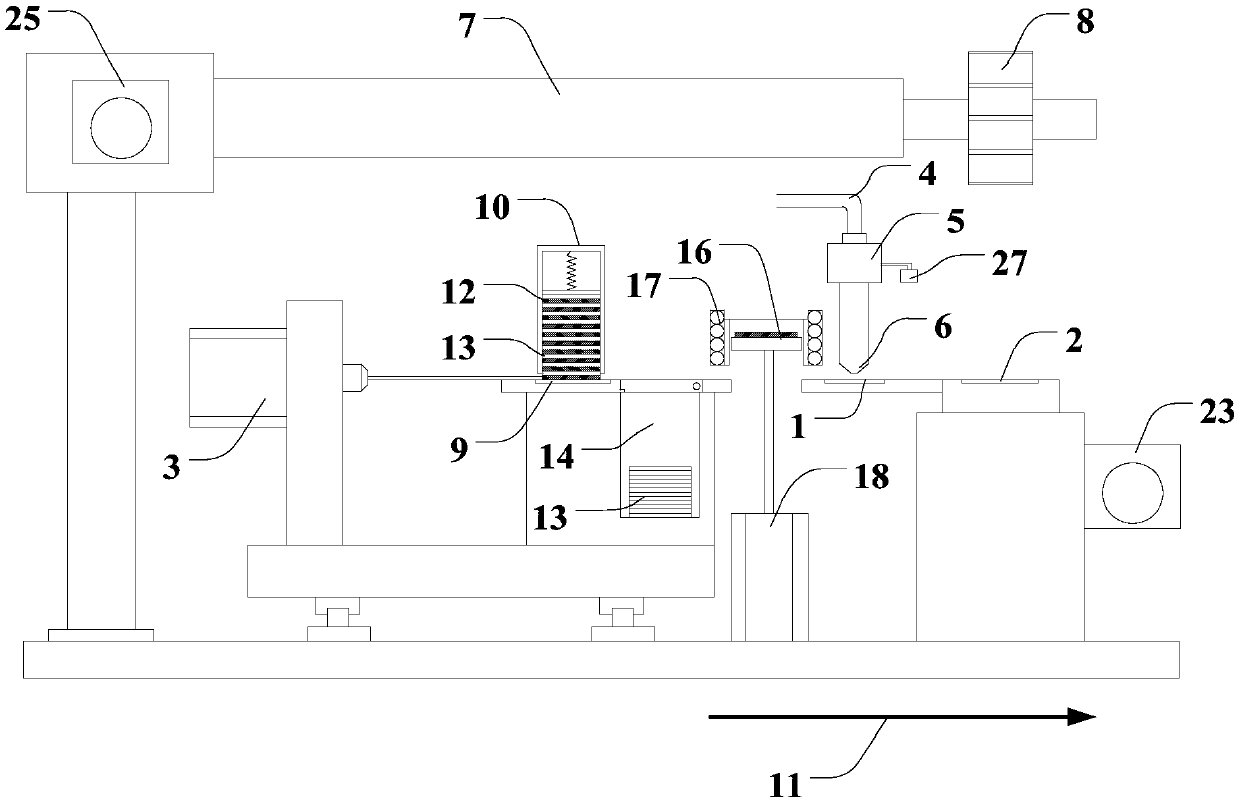

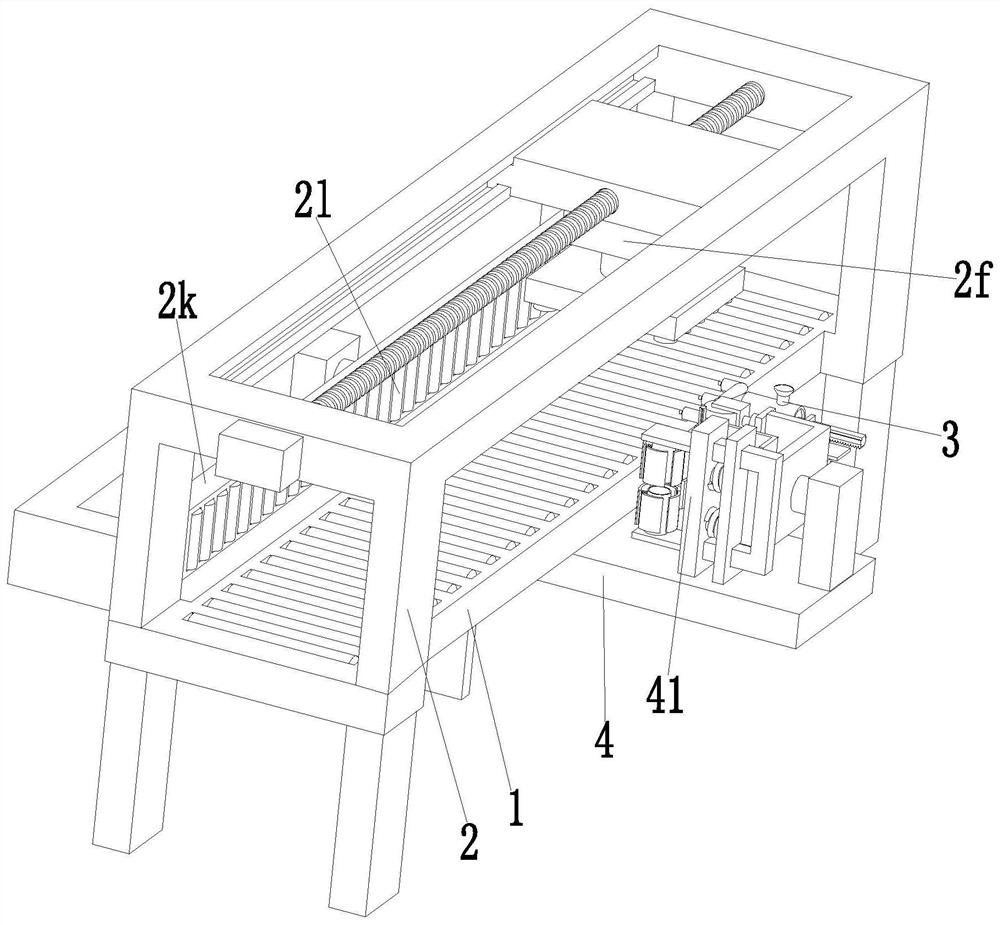

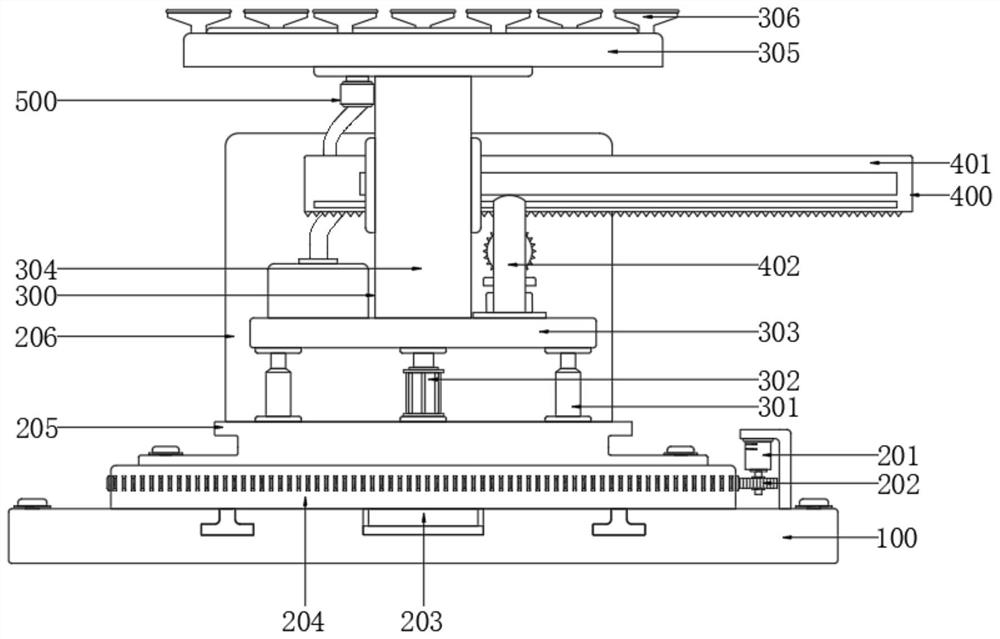

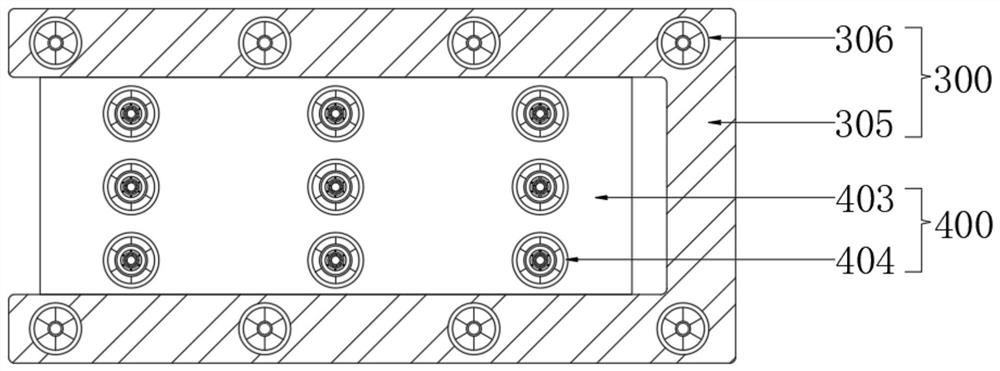

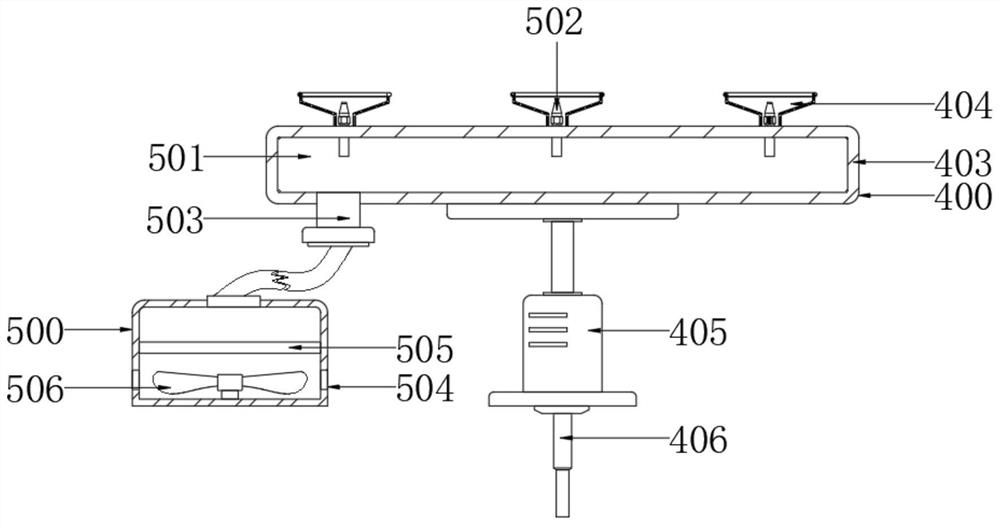

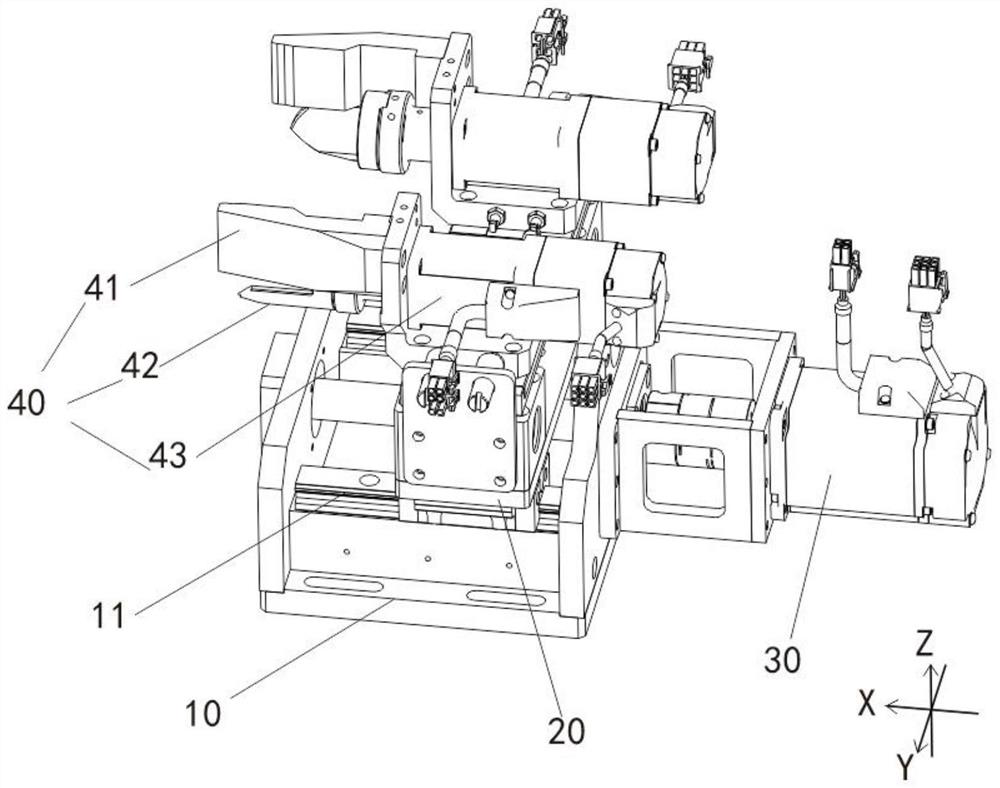

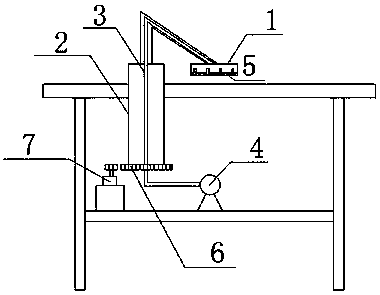

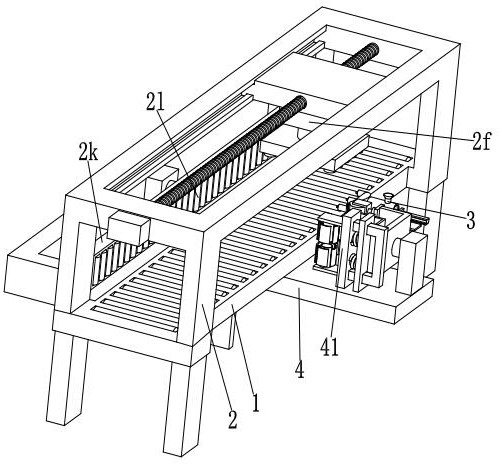

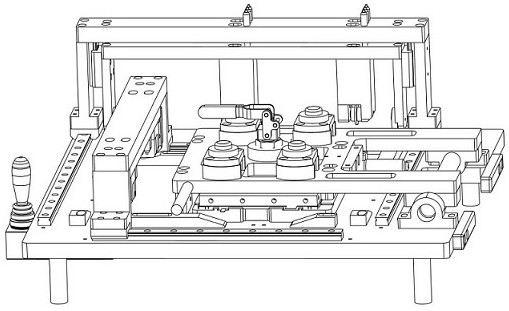

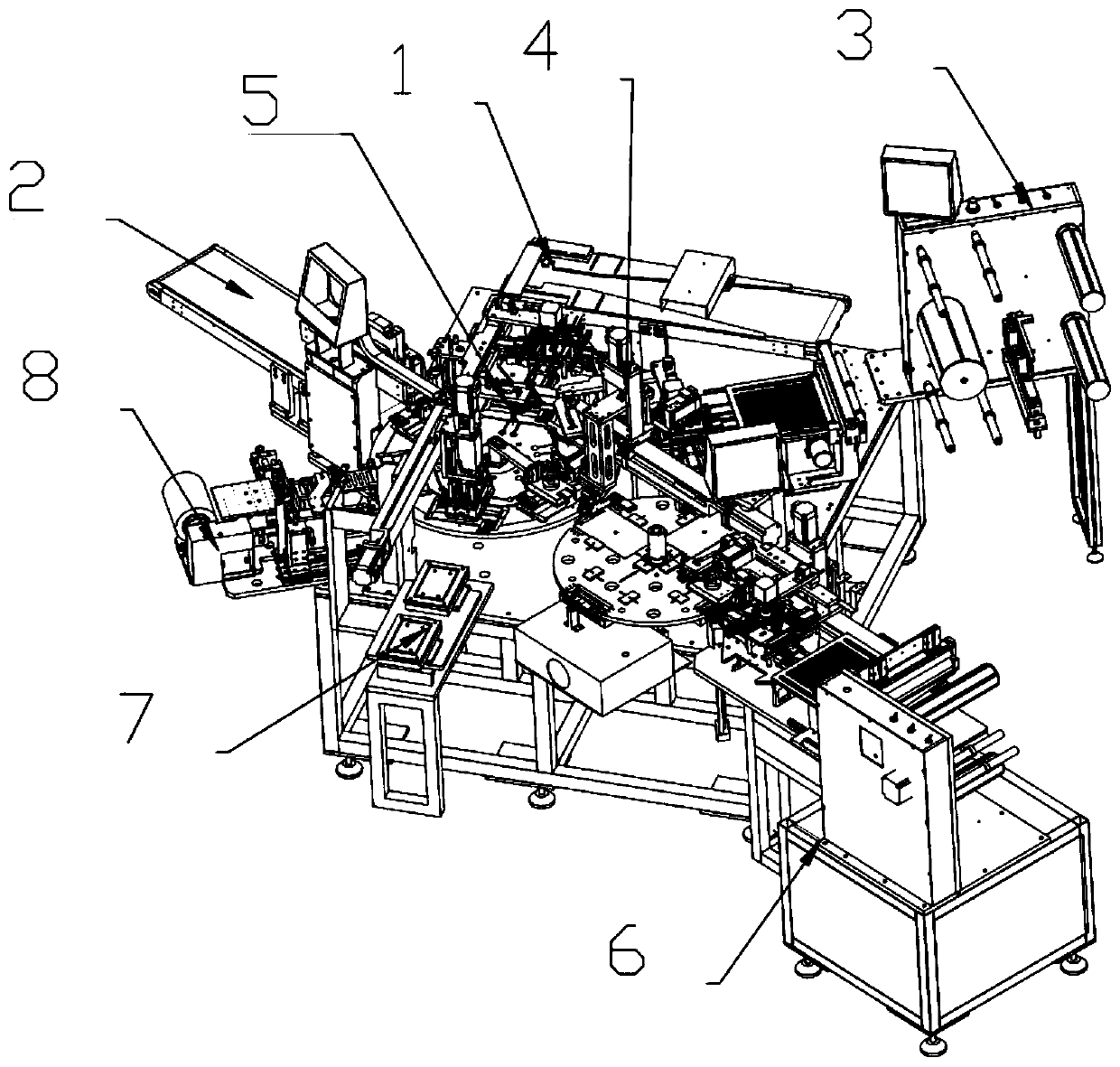

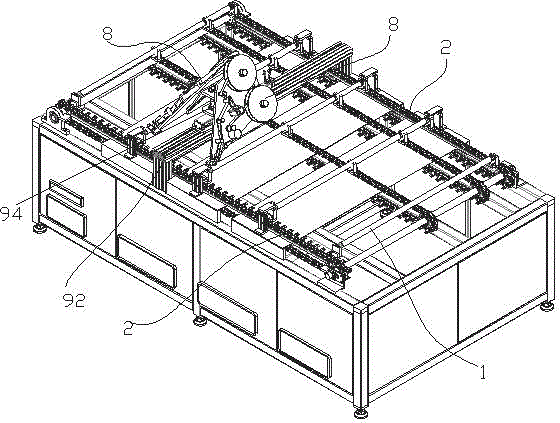

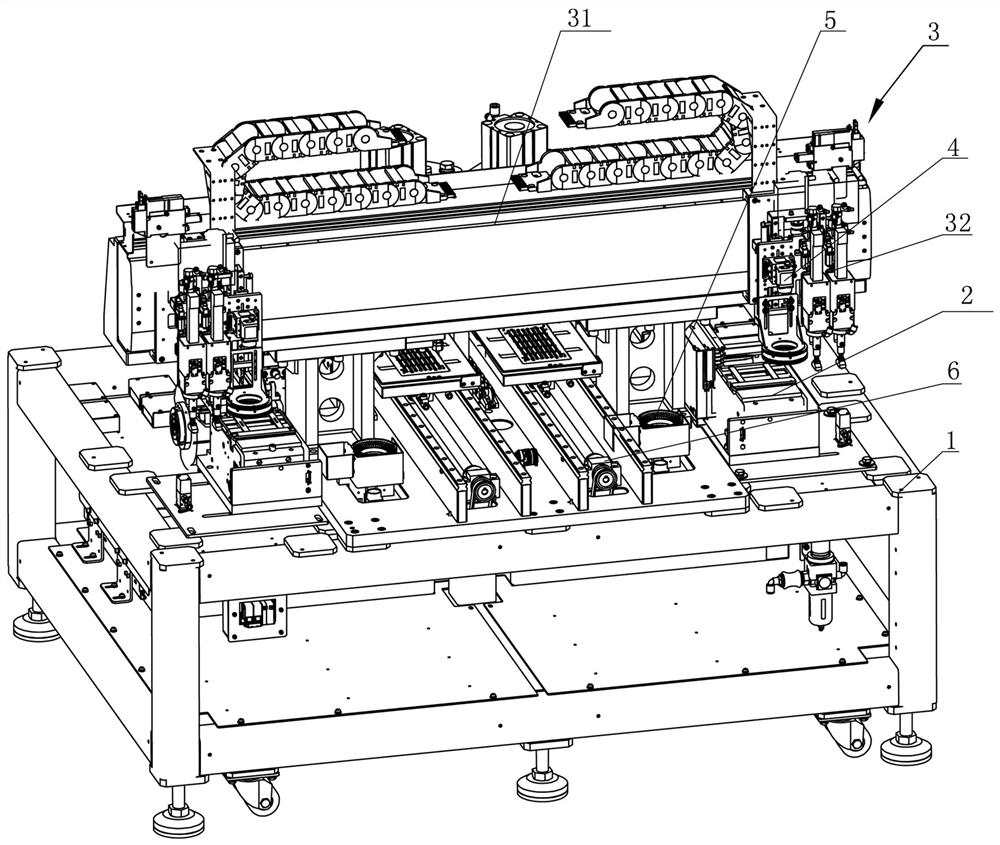

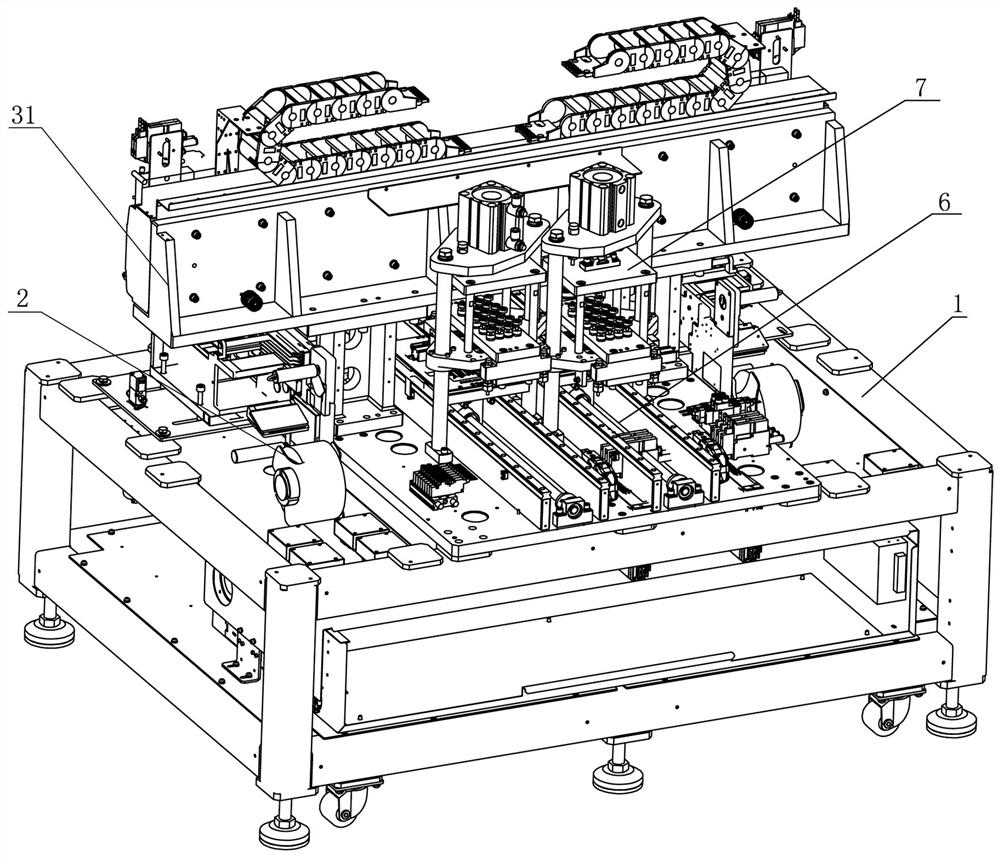

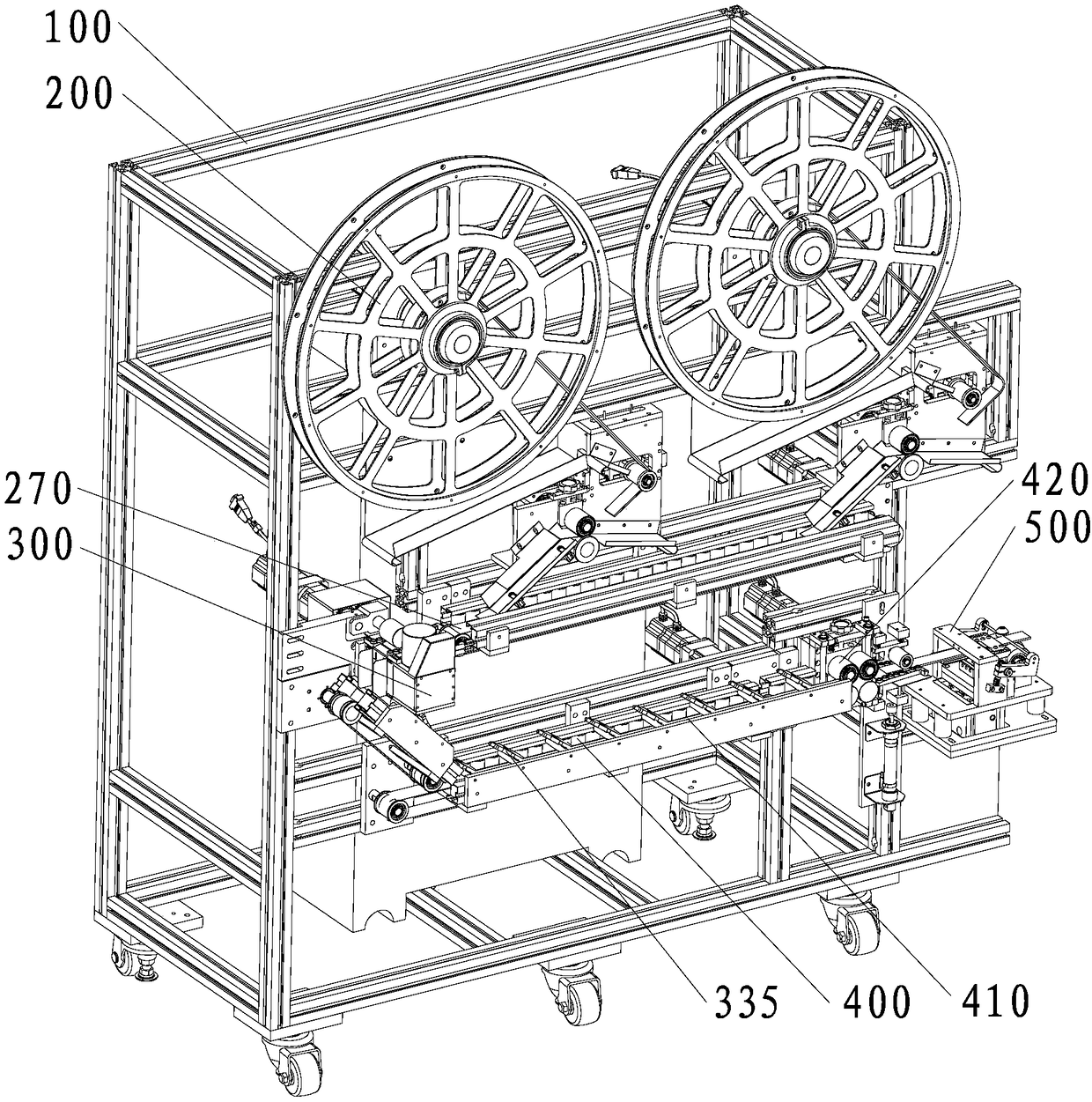

System and method for front-procedure assembly of backlights

ActiveCN107031902ACompact structureIngenious designPackagingMetal working apparatusTectorial membraneCircular disc

The invention discloses a system and a method for the front-procedure assembly of backlights. The system is provided with a feeding conveyor belt, a discharging conveyor belt, a reflector plate surface-mount working station, a light guide plate obliquely inserting surface-mount working station, a main disc, an FPC disc surface-mount press-fitting working station, a rubber framework pressing working station and a protective film covering working station and is driven by a driving device, forming one complete working cycle, so that the automatic conveying of products is realized. Each surface mount machine head consists of a material collecting platform, a chip platform, a feeding and discharging manipulator and a chip manipulator, and separately independently finishes surface mount work. The system and the method have the characteristics that the structure is compact, and the design is skillful; the machine heads simultaneously work, and the automatic production process of the middle-sized backlights is realized through a PLC control technology without excessively depending on manual work; and the production rate is high, the speed is high, and the quality is great.

Owner:深圳市小宝机器人有限公司

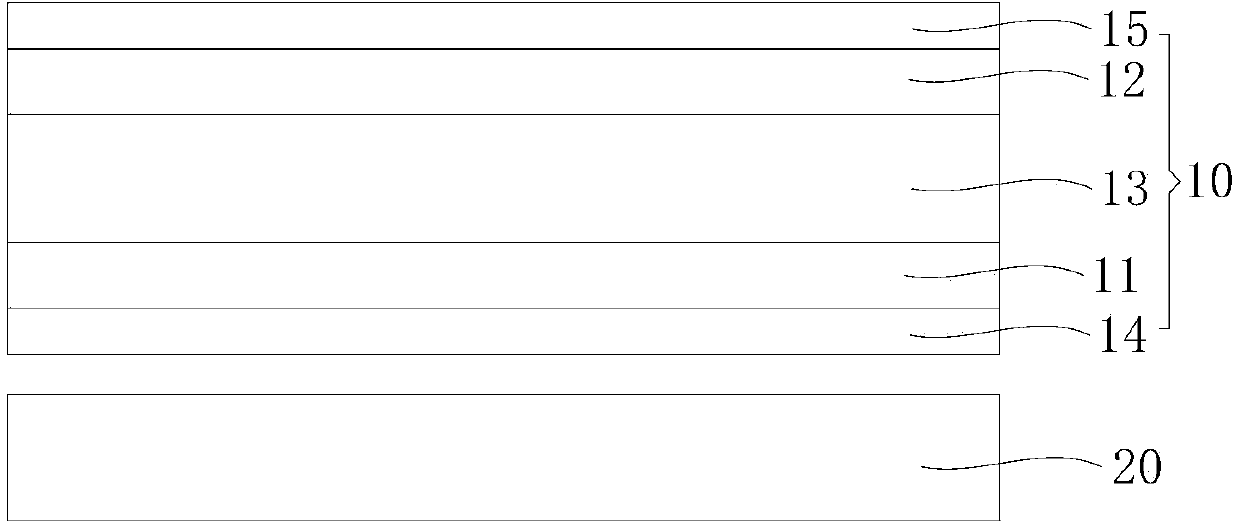

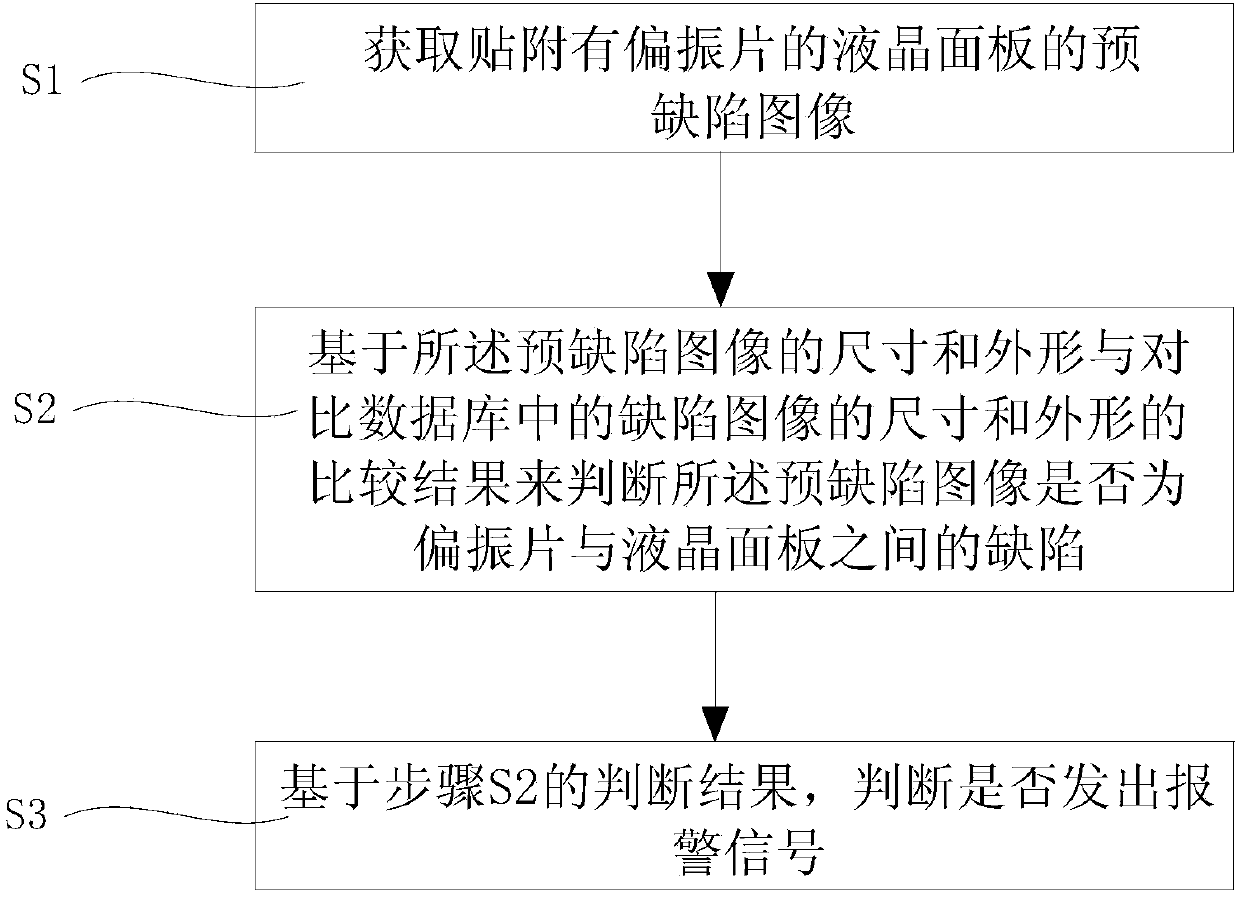

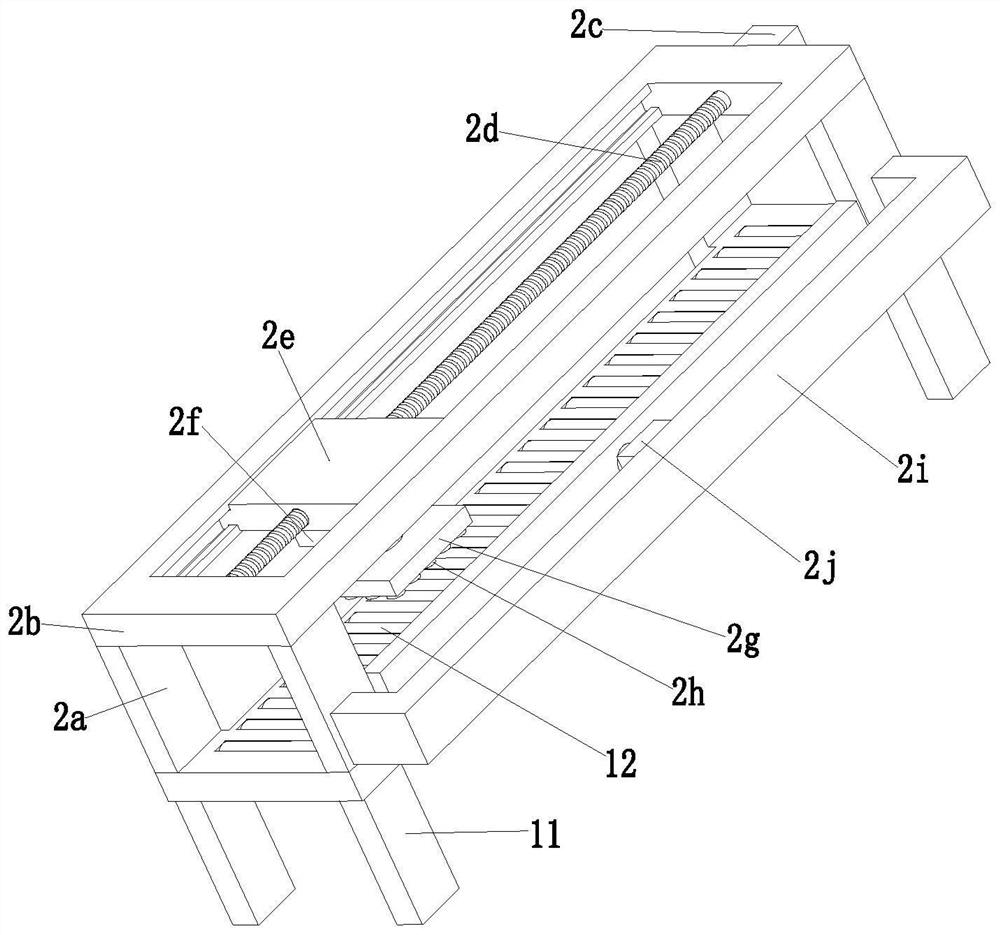

Defect detection device and method for liquid crystal display panel with polarizing film

ActiveCN103439339AReduce the risk of missed detectionImprove attachment qualityOptically investigating flaws/contaminationPolarizerLiquid-crystal display

The invention discloses a defect detection device and a defect detection method for a liquid crystal display panel with a polarizing film. The defect detection device comprises an infrared image input device (100), a signal processing device (200) and a warning device (300), wherein the infrared image input device (100) is used for acquiring and outputting an image of the liquid crystal display panel (500) with a polarizing film (600); the signal processing device (200) is used for acquiring a pre-defect image of the liquid crystal display panel (500) with the polarizing film (600) on the basis of the image of the liquid crystal display panel (500) with the polarizing film (600) and judging whether the pre-defect image is a defect according to comparison results between the size and shape of the pre-defect image and the size and shape of the defect image in a database; the warning device (300) is used for judging whether to send out a warning signal based on a judgment result of the signal processing device (200). According to the defect detection device and the detection method, foreign matters and / or bubbles on the liquid crystal display panel with the polarizing film can be detected in real time, so that the inspection missing risk of the defected liquid crystal display panel is greatly lowered, meanwhile, the production cost is lowered, and the production efficiency is increased.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

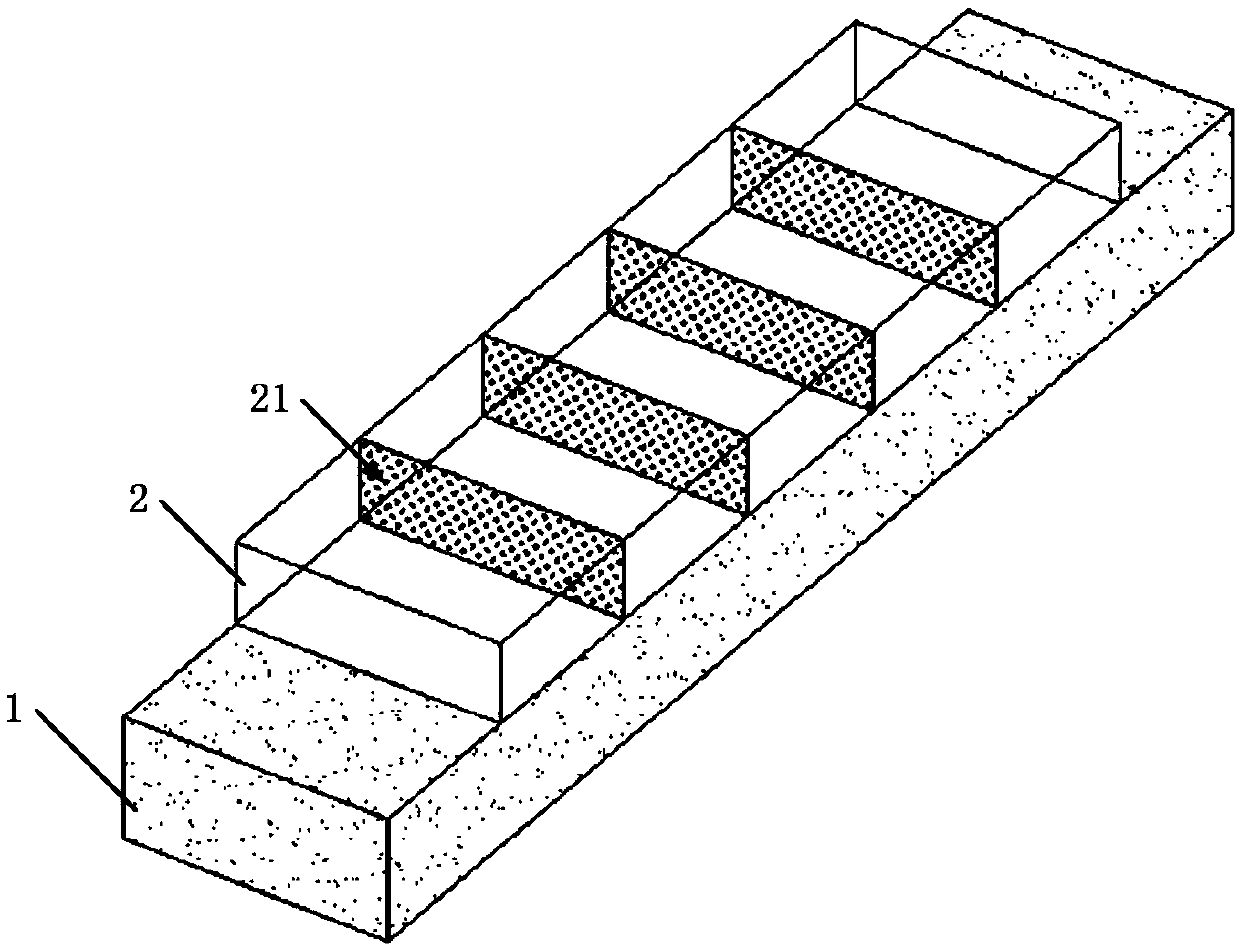

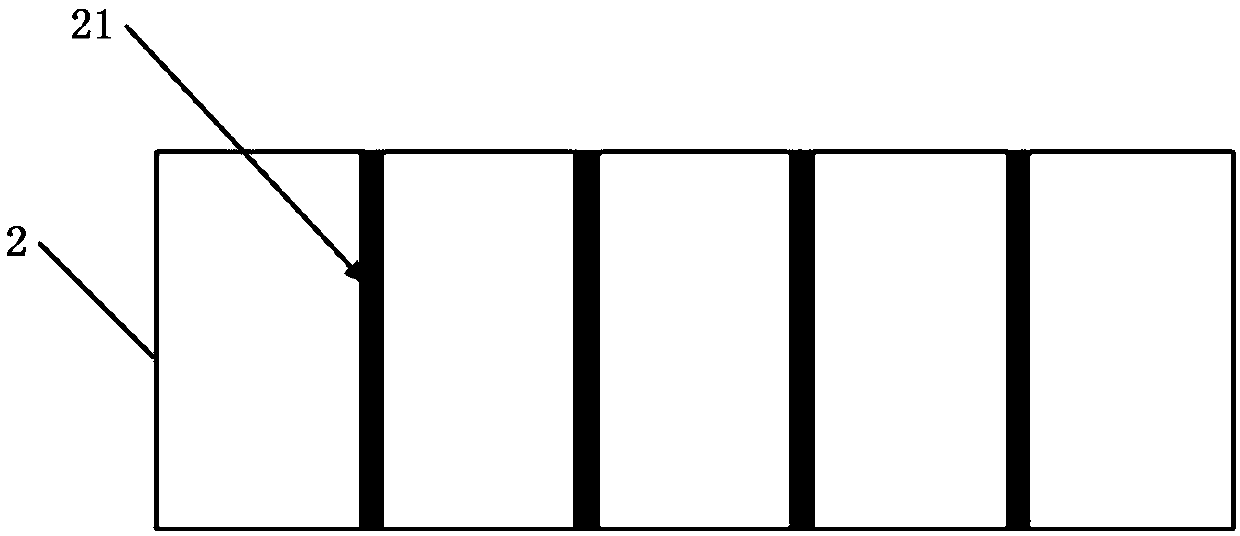

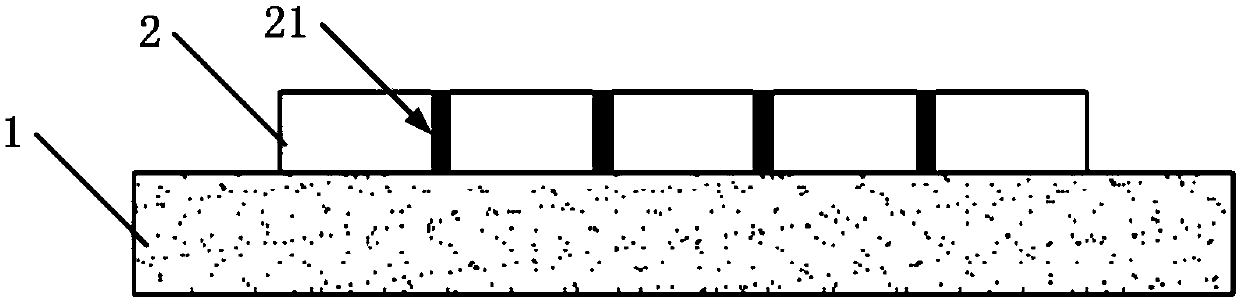

Turnover device

A turnover device is used for performing surface mounting on products. The turnover device comprises a frame and at least two turnover portions; the turnover portions are arranged on the frame in turn; every turnover portion comprises at least one composite surface; the composite surfaces of the adjacent turnover portions are attached to each other in a turnover mode. According to the turnover device which is used for performing the surface mounting on the products, one layer or multi-layer attachment can be rapidly achieved through turnover match of the turnover portions and accordingly the attachment quality is improved and the working efficiency is increased.

Owner:YIHE PRECISION IND SUZHOU

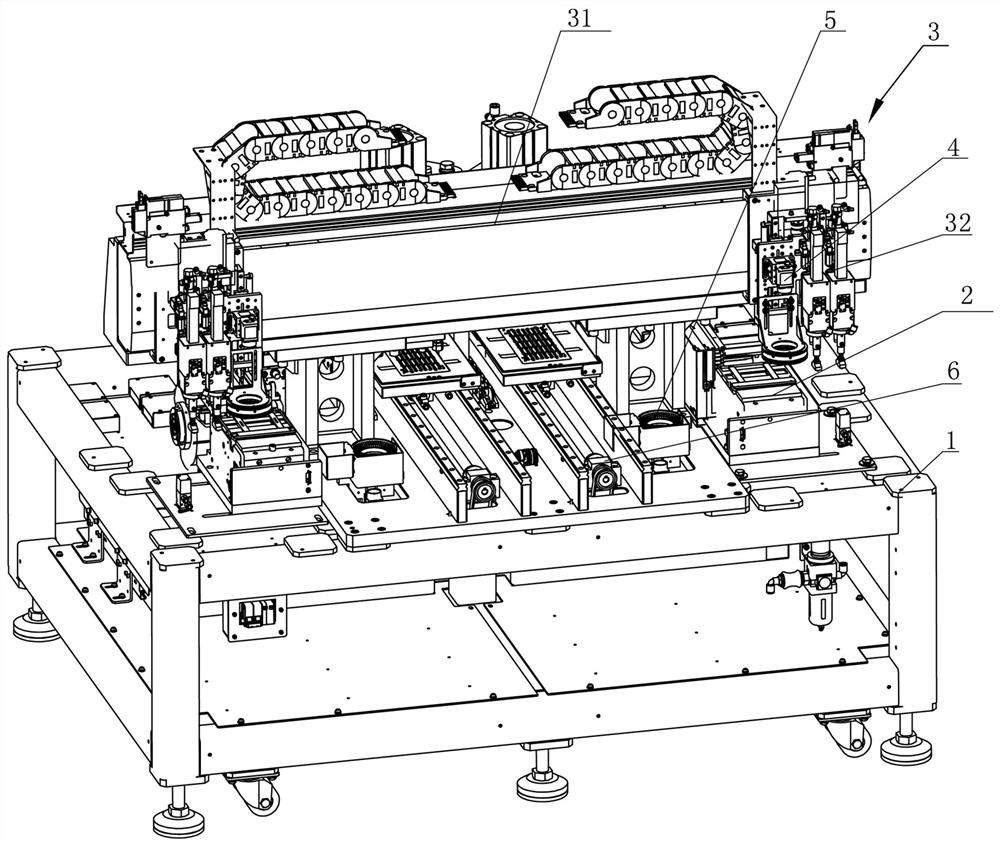

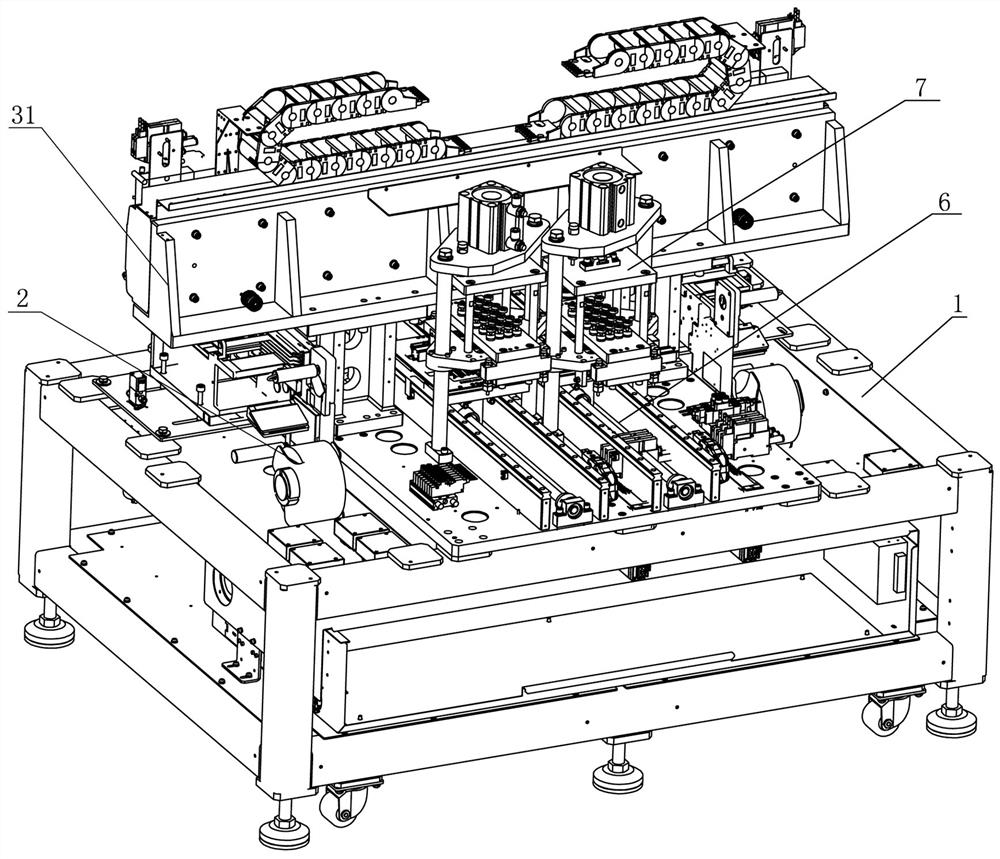

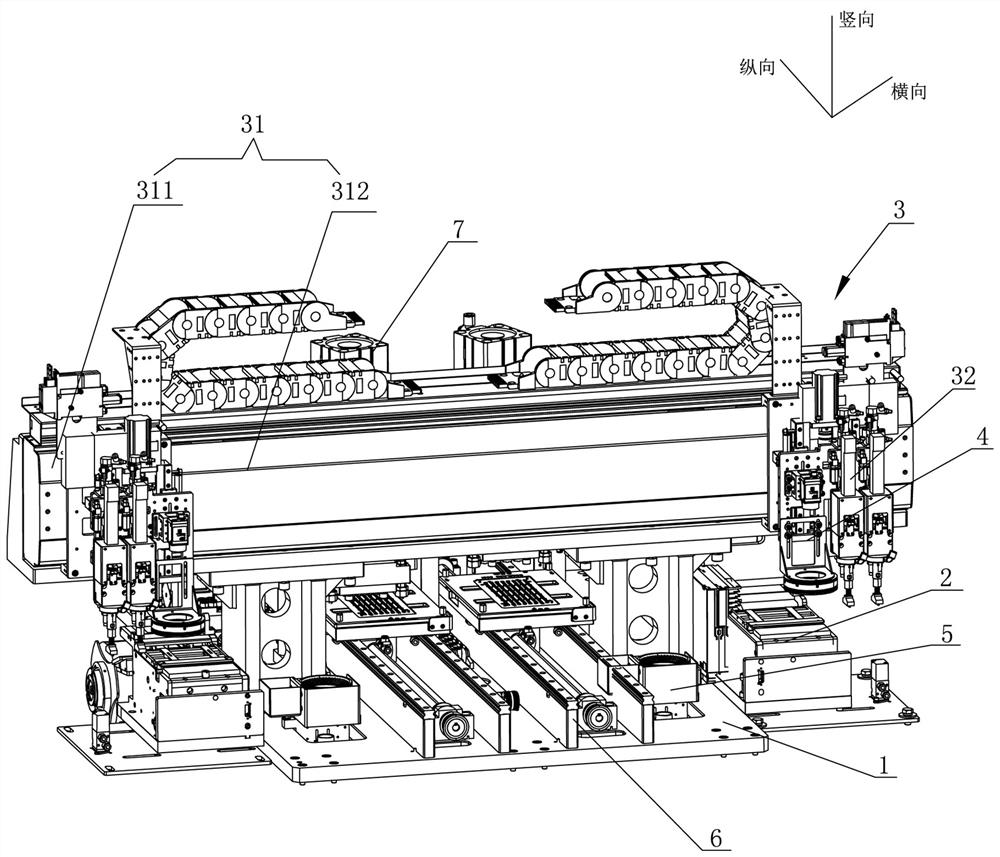

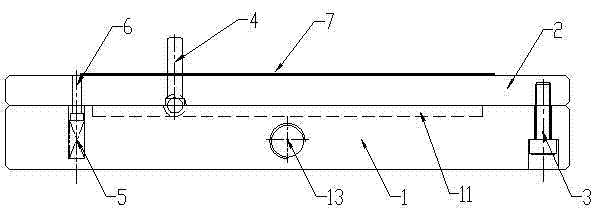

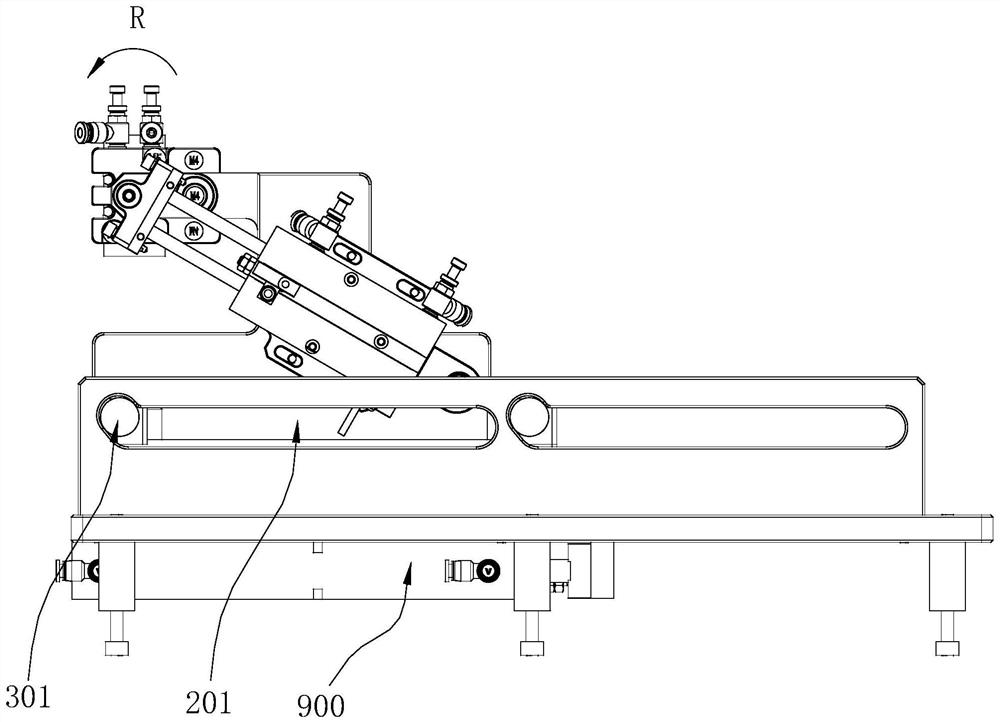

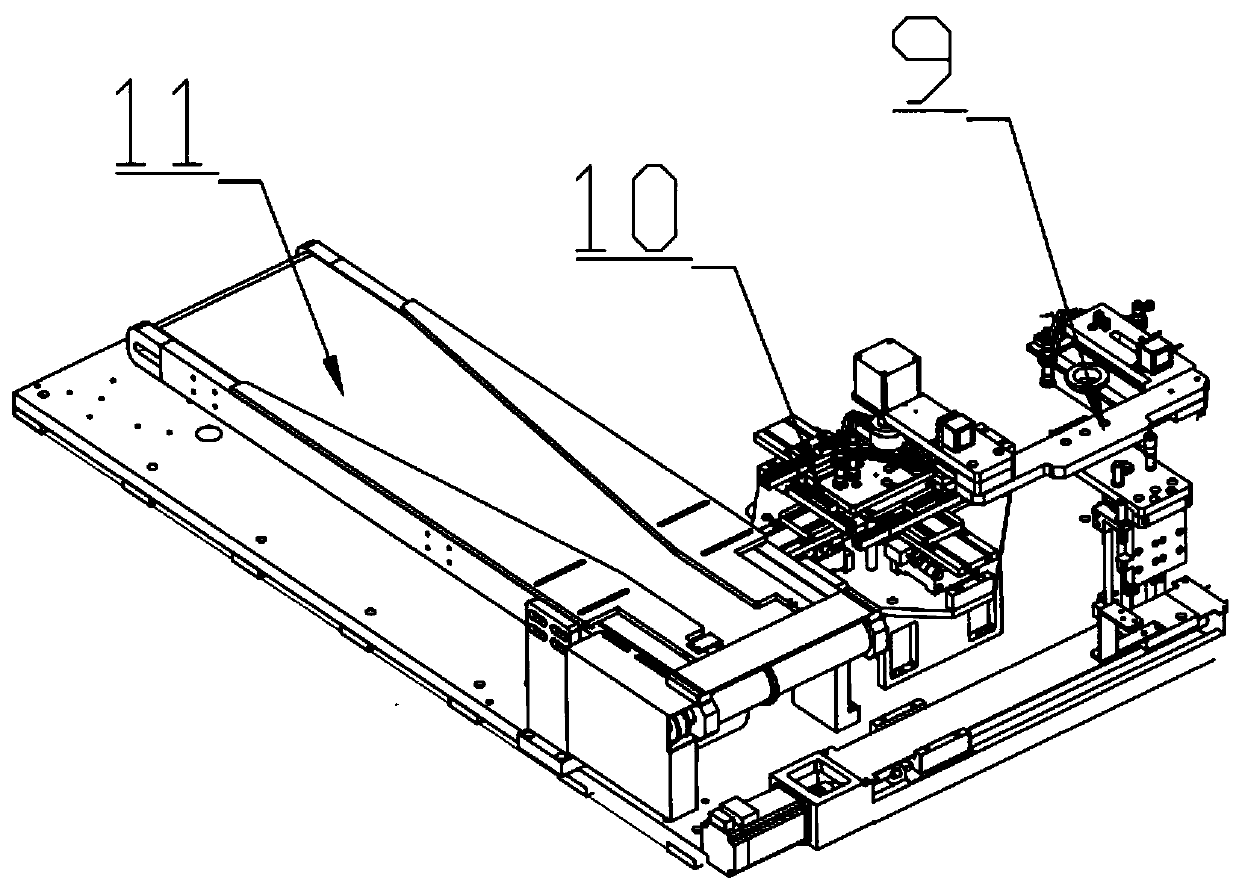

Product surface attaching equipment

ActiveCN111935971AImprove attachment qualityHigh degree of automationElectrical componentsConveyor partsVision basedProcess engineering

The invention discloses product surface attaching equipment. The product surface attaching equipment comprises an attaching piece stripping and supplying device, a product carrying device and a visualguidance attaching piece taking and placing device. The attaching piece stripping and supplying device is used for stripping a to-be-used attaching piece from a material supply belt and conveying theto-be-used attaching piece to a material taking position; the product carrying device carries the product to the attaching position; the visual guidance attaching piece taking and placing device comprises a first visual unit and an attaching piece taking and placing carrying unit. The first visual unit obtains visual information of the to-be-used attaching piece on the material taking position and the product on the attaching position. Based on the visual information, the attaching piece taking and placing carrying unit moves to the material taking position to suck the to-be-used attaching piece and moves to the attaching position to attach the to-be-used attaching piece to the product. The product surface attaching equipment integrates the functions of attaching piece stripping and supplying, attaching piece taking and placing under visual guidance, product carrying and the like, the automation degree is high, and the production efficiency and attaching quality are improved.

Owner:GEER TECH CO LTD

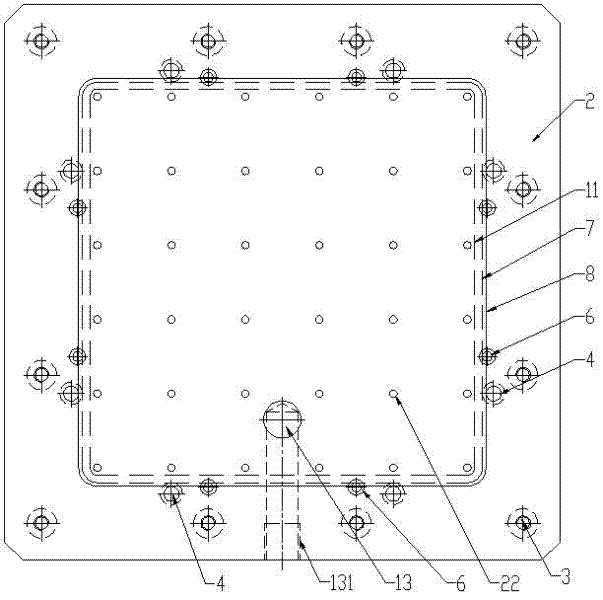

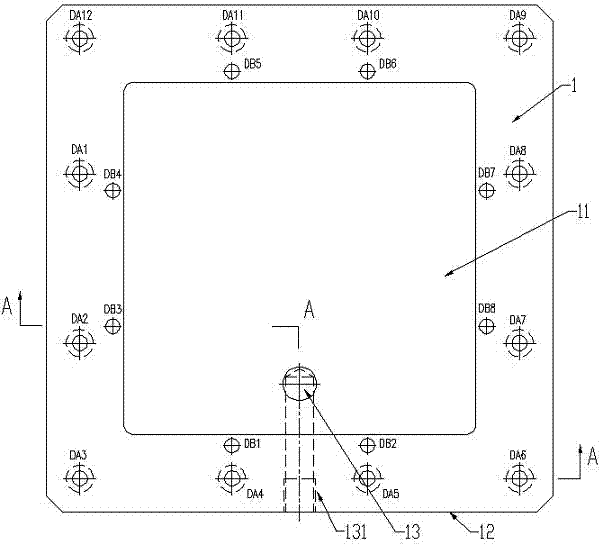

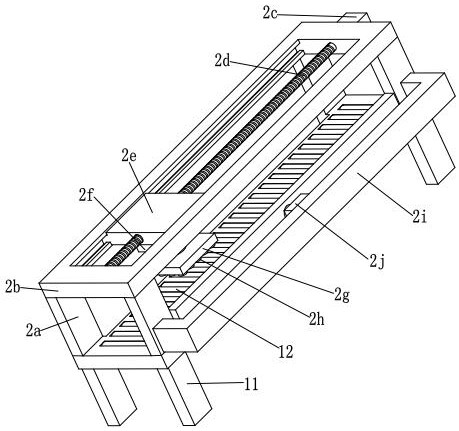

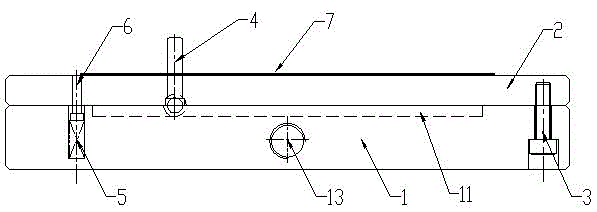

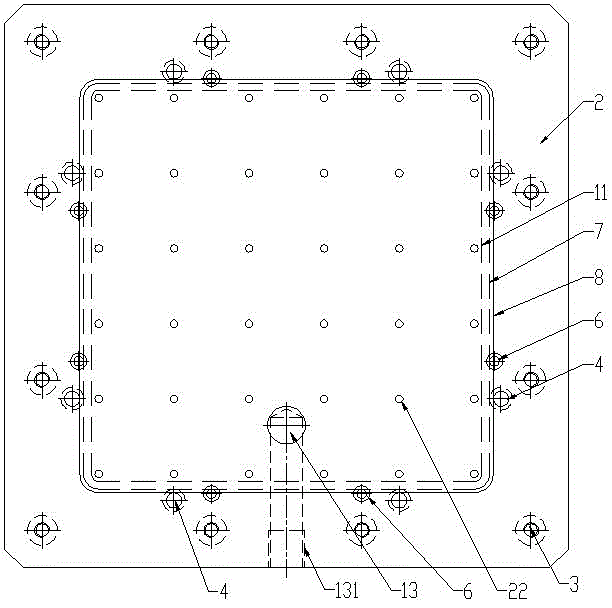

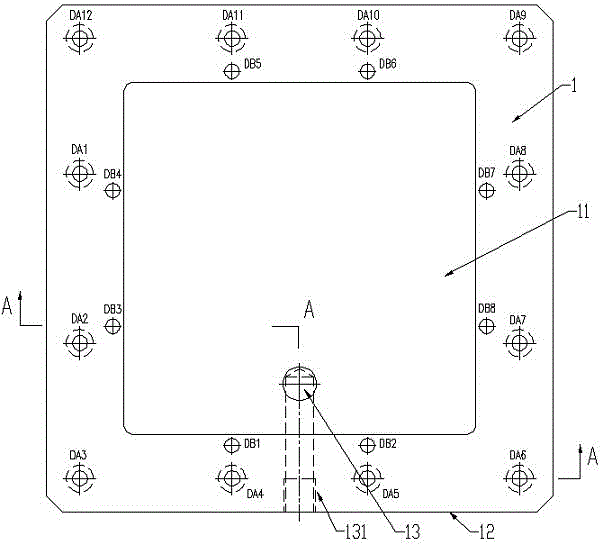

Suction jig

ActiveCN102642379AImprove attachment qualityReduce surface blemishesLamination ancillary operationsLaminationPulp and paper industryAir compressor

The invention discloses a suction jig for attaching attached products to a large-area product, wherein the attached products are smaller than the outer frame of the large-area product. The suction jig comprises a lower mold, wherein a groove is arranged on the upper surface of the lower mold, the frame shape of the groove is the same as that of the product but is smaller than the outer frame of the product, and a passage is arranged in the lower mold and through connected to a vacuum machine out of the lower mold from the groove; and an upper mold above the lower mold, wherein air holes are uniformly arranged on the upper mold and are perpendicularly connected with the groove. According to the invention, when films or gummed paper in a large area is attached to the product, the films or gummed paper is placed on the suction jig provided by the invention; vacuum is generated in the jig through an air compressor so that the films or the gummed paper is flattened; then, the product is laminated on the flat films or gummed paper; the attaching quality can be greatly improved; and the surface defects are reduced.

Owner:CHENGYEDE KUNSHAN COMM TECH

Material identification equipment and control method of material identification equipment

InactiveCN105416738AImprove storage efficiencyReduce labor intensityLabelling machinesEngineeringSupport plane

Owner:CELESTICA DONGGUAN SSL TECH LTD

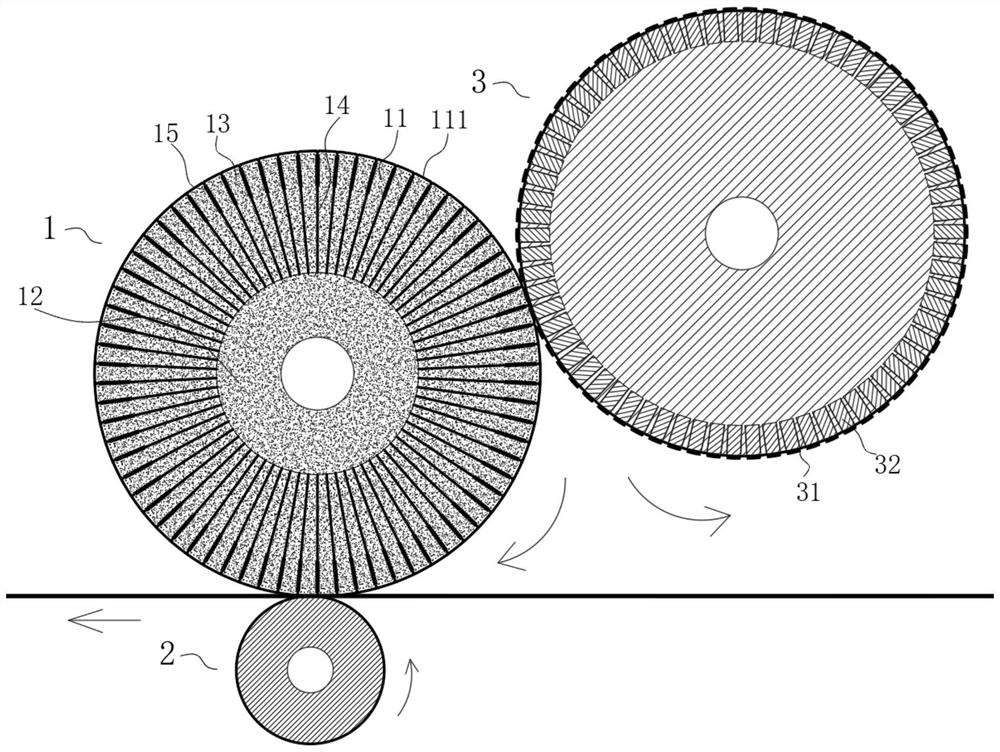

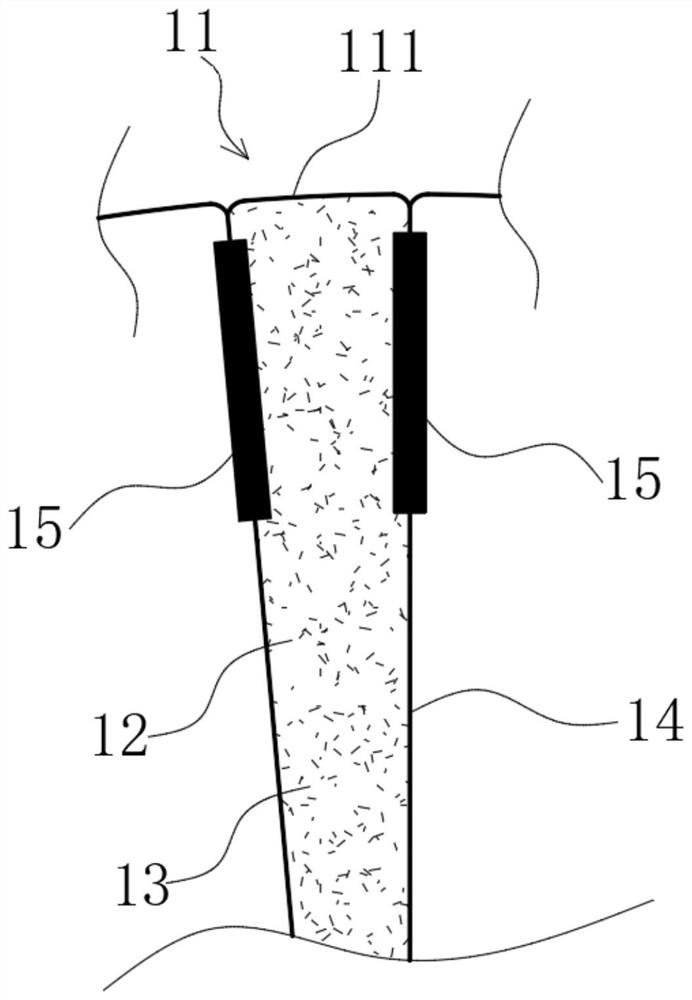

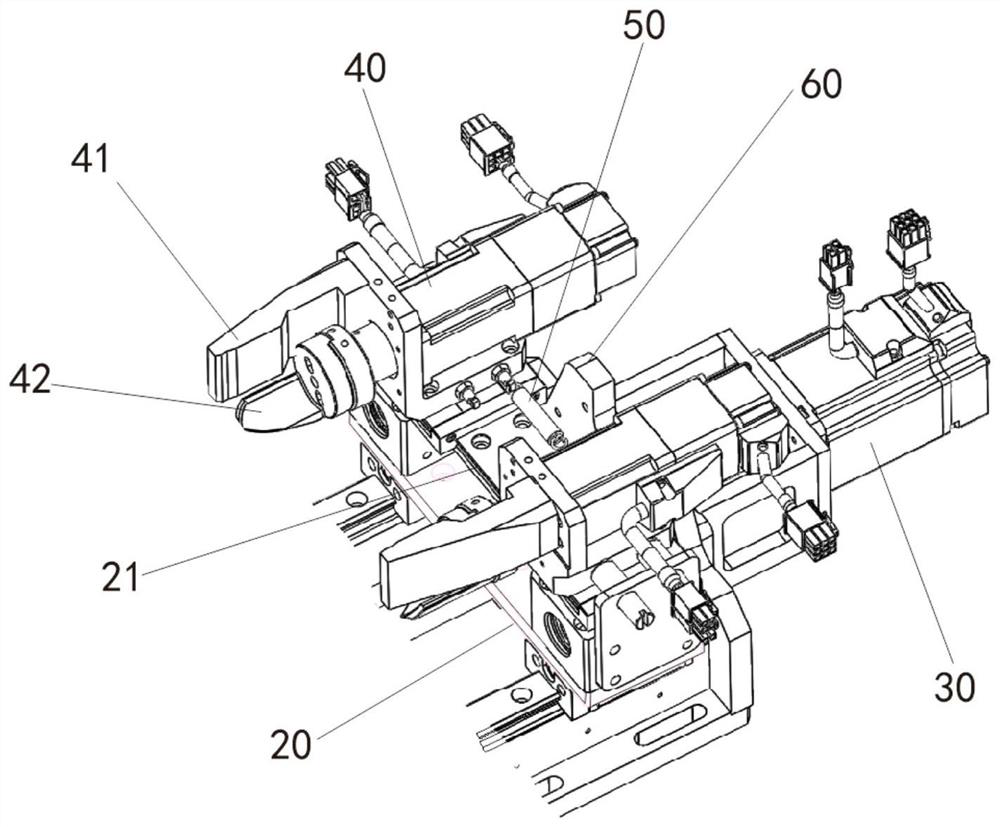

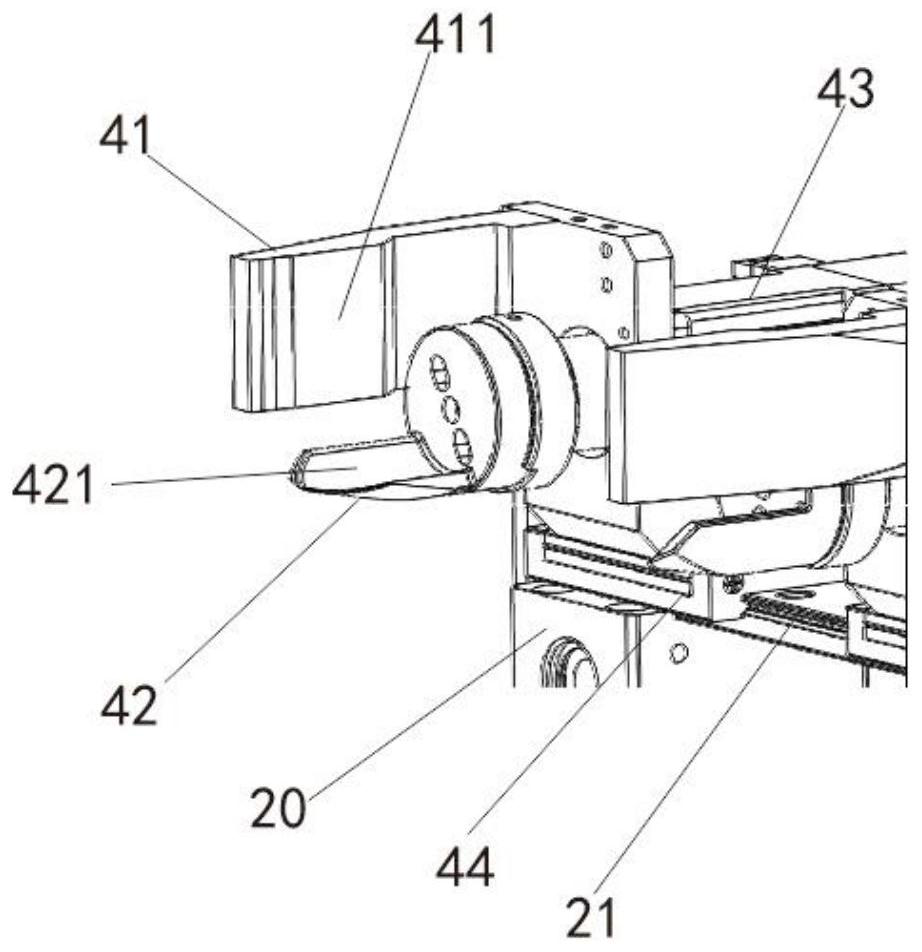

Motor rotor permanent magnet attachment system

ActiveCN110350733AReduce labor costsImprove pasting effectManufacturing stator/rotor bodiesEngineeringPower equipment

The invention relates to the technical field of power equipment, in particular to a motor rotor permanent magnet attachment system. The process of attaching a permanent magnet onto a rotor can be completely and automatically completed by equipment, the labor cost is reduced, and the pasting effect is improved. The motor rotor attachment permanent magnet equipment comprises the motor rotor permanent magnet attachment system. The motor rotor permanent magnet attachment system comprise a gluing station, a pasting station, a permanent magnet push device, a gluing device and a rotor installation device, wherein the gluing device comprises a gluing machine, a gluing nozzle of the gluing machine is opposite to the gluing station and can be used for gluing a permanent magnet arranged at the gluingstation, the rotor installation device is used for installing the rotor to which the permanent magnet is needed to be pasted, and the device can drive the rotor to circumferentially rotate by a setting angle so that a plurality of permanent magnets are attached onto a surface of the rotor. In the motor rotor permanent magnet attachment system disclosed by the technical scheme of the invention, artificial permanent magnet attachment is not needed by the motor rotor permanent magnet attachment system, the motor rotor permanent magnet attachment operation can be completely and automatically completed, so that the labor cost is reduced, and the production efficiency is improved.

Owner:YASKAWA DENKI KK

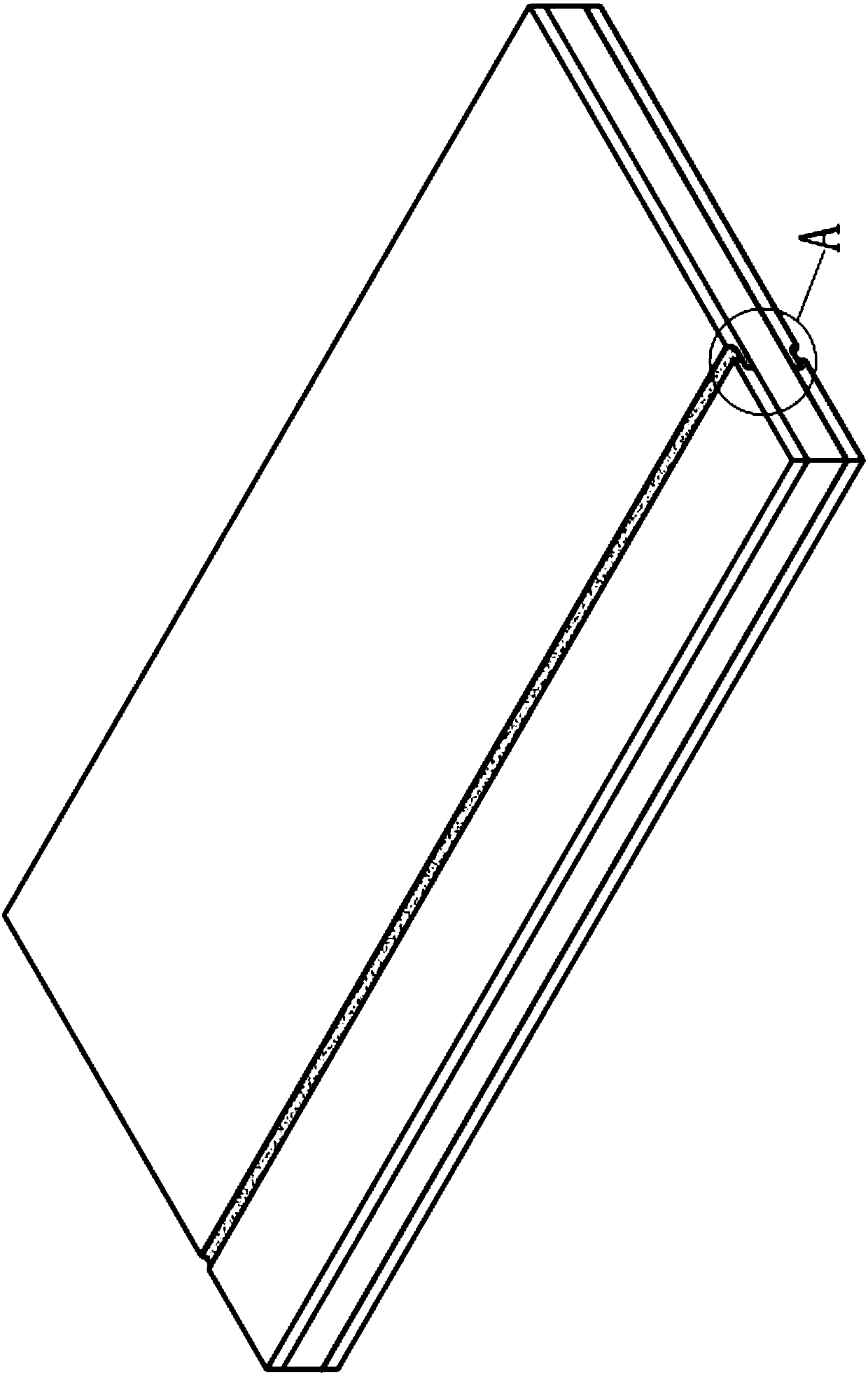

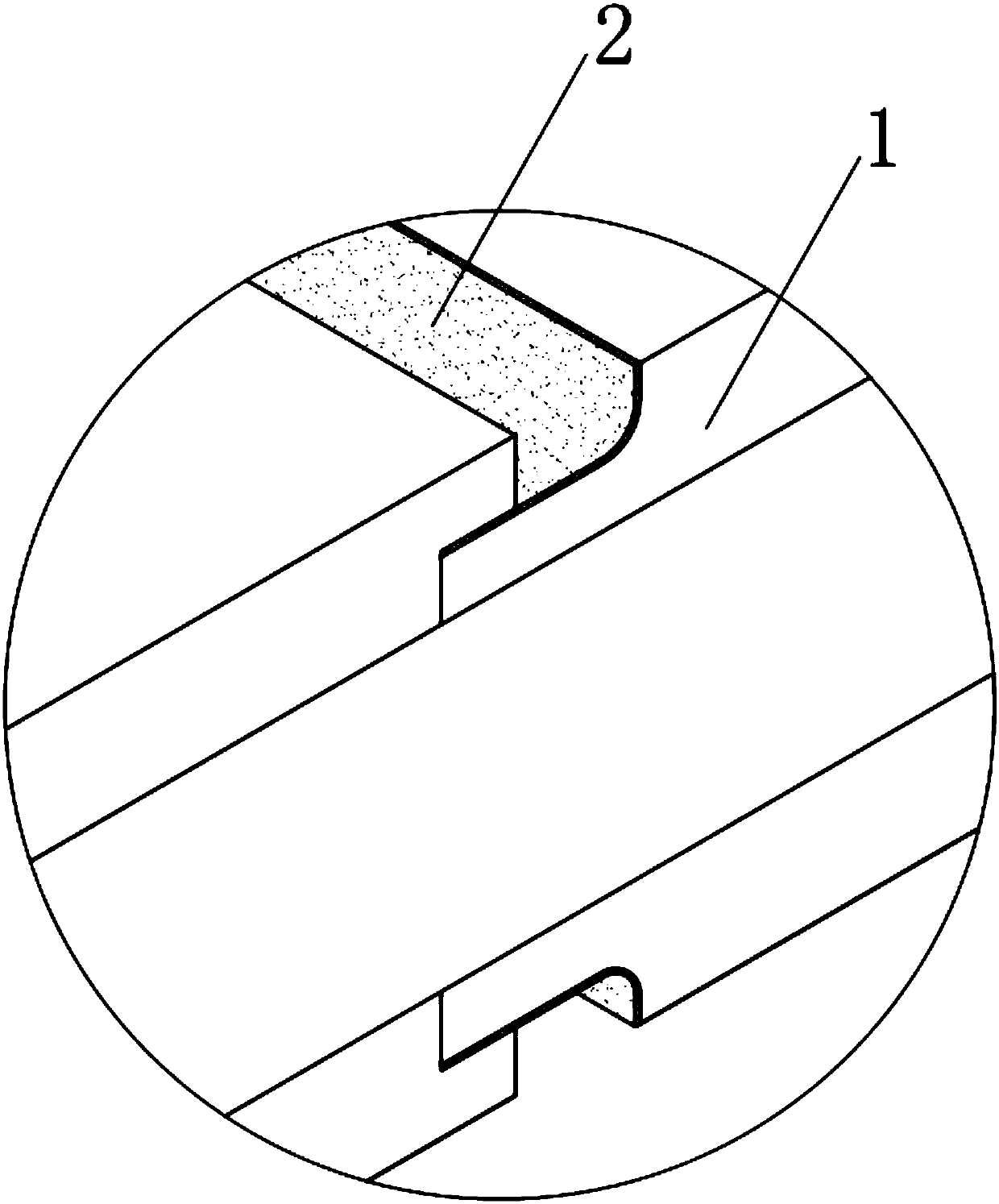

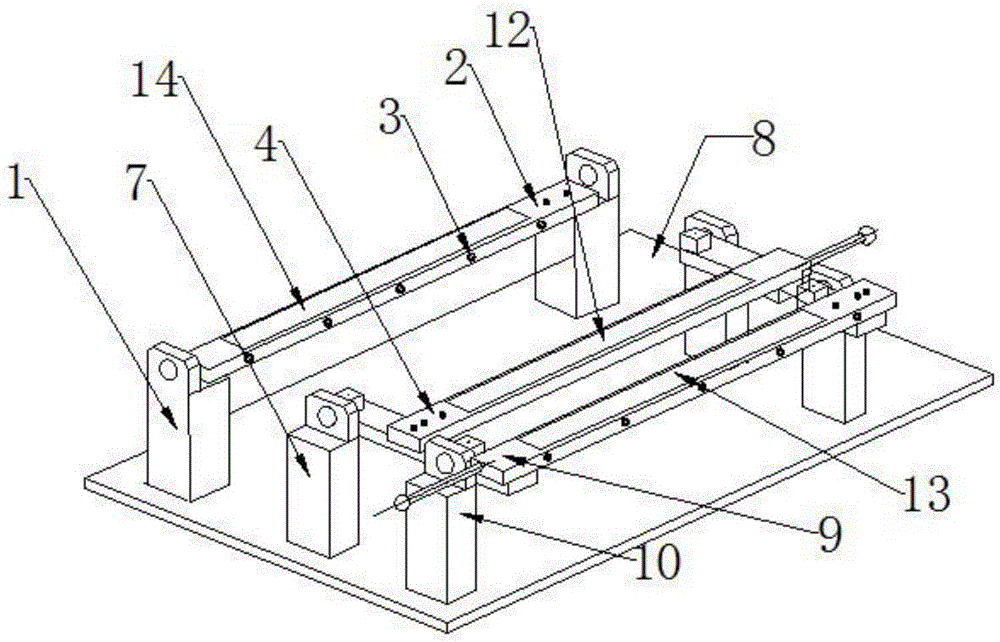

Installation equipment for door plank colored tape

ActiveCN107932681AAdhesion without hysteresisCoherent adhesionWood working apparatusDrive wheelEngineering

The invention discloses installation equipment for a door plank colored tape. The installation equipment for the door plank colored tape comprises a feeding disk for storing and conveying the coloredtape stacked with a base belt, a material collection disk for collecting the base belt stripped from the colored tape and pressing wheels, wherein a door plank is horizontally conveyed, the pressing wheels are arranged on one side of the door plank, make contact with the back face of the base belt and roll the colored tape to adhere to a groove of the door plank, the pressing wheels are connectedwith first telescopic mechanisms, and the first telescopic mechanisms provide the translational degrees of freedom, getting close to the door plank or keeping away from the door plank, of the pressingwheel, and while the door plank is rolled by the pressing wheels, an upper conveyor belt makes contact with the upper surface of the door plank, and a lower conveyor belt makes contact with the lowersurface of the door plank. The lower conveyor belt is provided with a plurality of driven wheels on the same horizontal plane, the driven wheels are provided with second telescopic mechanisms, and the second telescopic mechanisms provide the translational degree of freedom perpendicular to the conveying direction of the lower conveyor belt for the driven wheels. By means of the installation equipment for the door plank colored tape, the colored tape is attached to the groove in the door plank, high efficiency is achieved, the surface quality is good, and the colored tape is attached firmly.

Owner:昆山日门建筑装饰有限公司

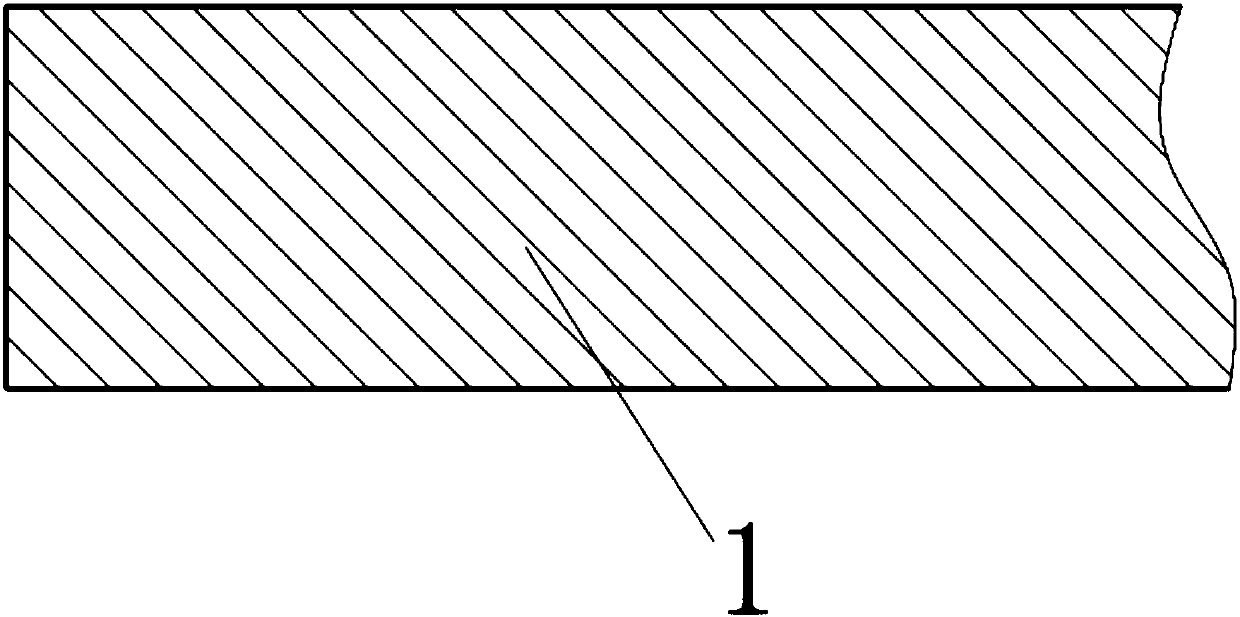

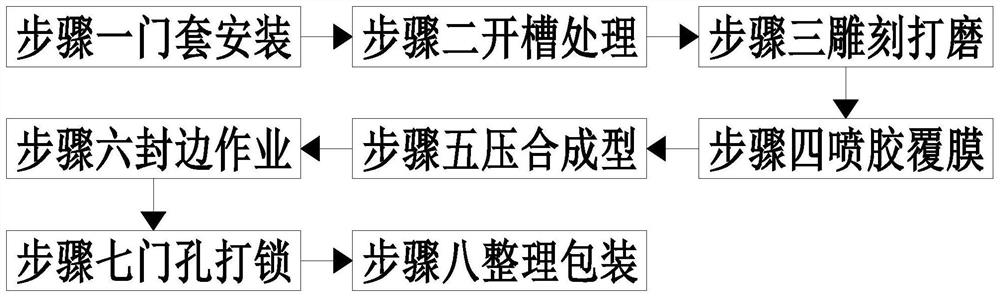

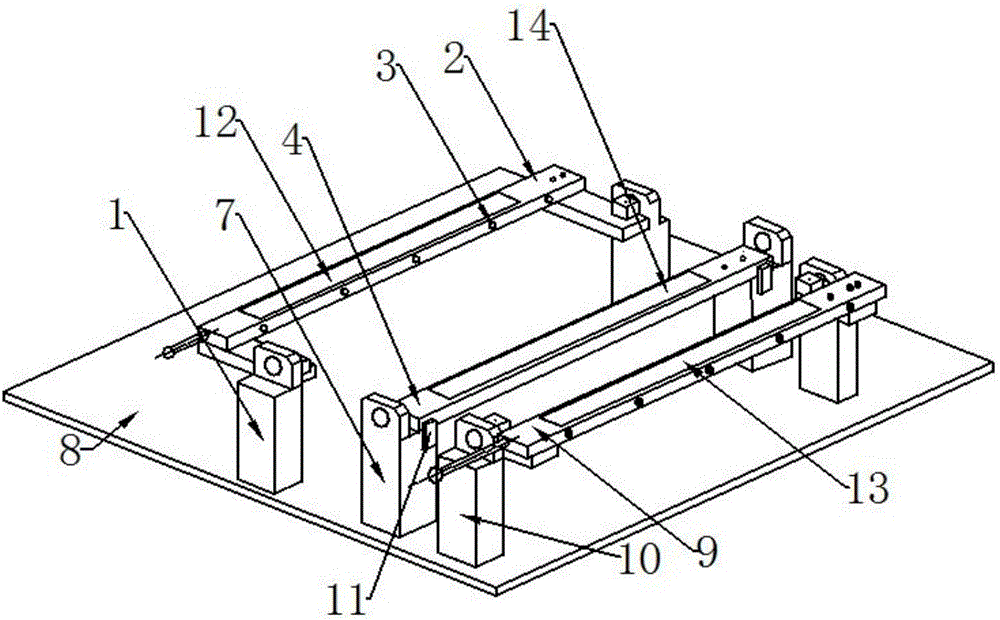

Production method of environment-friendly paint-free door

ActiveCN111761679AQuality improvementImprove efficiencyOther plywood/veneer working apparatusWood mortising machinesAdhesiveIndustrial engineering

The invention relates to a production method of an environment-friendly paint-free door. The production method mainly comprises the following steps of plate cutting, slotting treatment, carving and grinding, adhesive spraying and film laminating, pressing molding, edge banding operation, door lock perforating, finishing and packaging, etc. The used paint-free door plate edge banding equipment comprises a bottom plate, a moving device, an adhesive spraying device and an edge banding device. The production method can solve the difficult problems existing in the existing door plate edge banding process, as follows: a, during traditional door plate edge banding, a worker needs uses an adhesive spraying machine to spray adhesive on a door plate, and then the adhering operation of edge bands iscarried out; when the edge bands are manually adhered, a board is easy to skew, and the force on the edge banding position is not uniform so that the edge banding quality is affected; the effective ofmanually door plate edge banding is low, and the labor intensity is high; and b, in the operation process of the existing door plate edge banding equipment, the air between the edge bands and a doorend face is not easily drained, and the edge bands bubble easily. The quality and efficiency of door plate edge banding are improved.

Owner:宿迁普奈家居科技有限公司

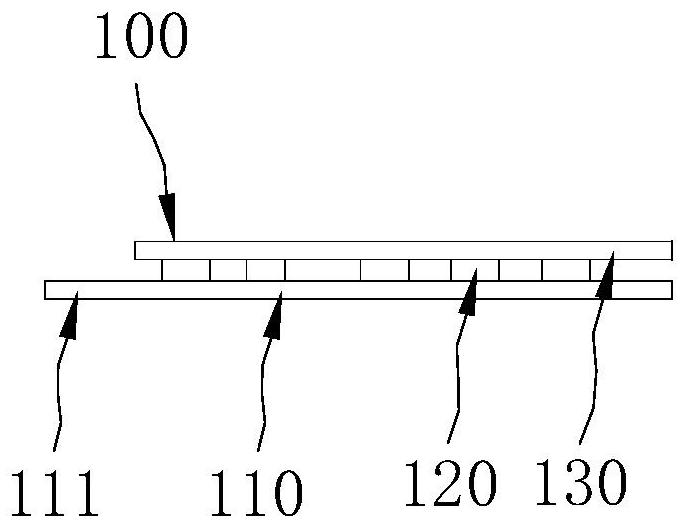

Stripping device for LOGO label, stripping method and automatic labeling machine

ActiveCN113682595ASmooth peelingThe peeling device peels off smoothlyPlastic recyclingLabelling machinesReciprocating motionEngineering

The invention provides a stripping device for a LOGO label, a stripping method and an automatic labeling machine. The stripping device comprises a base, a moving assembly, a first mounting seat, a rotating part and a clamping assembly; and the moving assembly is arranged on the base in a reciprocating motion manner in the first direction, the first mounting seat is arranged on the moving assembly and synchronously moves along with the moving assembly, the rotating part is hinged to the first mounting seat and rotates in the second direction, the clamping assembly is arranged on the rotating part and used for clamping a bottom release film of the LOGO label, after the clamping assembly is clamped on the bottom release film, the rotating part rotates by a set angle, the bottom release film is partially separated from a protective film of the LOGO label, then the moving assembly is moved, and the bottom release film is completely separated from the protective film of the LOGO label. By adopting the stripping device to strip the bottom release film of the LOGO label, not only is the working intensity of workers reduced, but also the working efficiency is improved, and the production cost is saved; and by adopting the stripping method, the bottom release film can be smoothly stripped.

Owner:INVENTEC CHONGQING

High-efficiency vertical indoor top wall tiling equipment for building construction

InactiveCN112459431APlay a compacting roleImprove work efficiencyBuilding constructionsBrickGear wheel

The invention discloses high-efficiency vertical indoor top wall tiling equipment for building construction, and belongs to the technical field of tiling equipment. The high-efficiency vertical indoortop wall tiling equipment comprises a mounting top plate, an adjusting assembly and a part pasting mechanism, wherein the adjusting assembly comprises a first servo motor fixed to the right side of the mounting top plate through a support, a driving gear is arranged at the output end of the first servo motor, a bearing disc is arranged on the mounting top plate, and a plurality of sets of teeth meshing with the driving gear are arranged on the outer wall of the bearing disc in an annular array mode; and the part pasting mechanism is arranged at the top of a mounting seat and located between acoating mechanism and a brick feeding device, and the part pasting mechanism comprises four sets of supporting telescopic rods arranged in a rectangular array. According to the high-efficiency vertical indoor top wall tiling equipment for the building construction, the part pasting mechanism is arranged to be matched with auxiliary assemblies, a user can attach another group of wall bricks without waiting for another group of wall bricks to be solidified after tiling, and the working efficiency is greatly improved.

Owner:安徽云企装饰工程有限公司

Flexible display panel attaching device and attaching method thereof

ActiveCN107039604BImprove attachment qualitySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringFlexible display

The present invention provides a flexible display panel attaching device, which includes a profiling fixture, a first adsorption platform, a second adsorption platform, a first pressure jaw assembly, a second pressure jaw assembly, a roller shaft, a first air gun and a second air gun. Air gun; the present invention attaches part of the flexible display layer to the main body of the cover glass by first rolling with the roller, and then uses the air gun to remove the flexible display layer that cannot be touched by the roller The region is stroked so that the region of the flexible display layer is bonded to the curved portion of the cover glass, so that the flexible OLED display layer is attached to the surface of the cover glass with a larger radian and a smaller rounded edge, Moreover, the attachment quality of the flexible OLED display layer is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

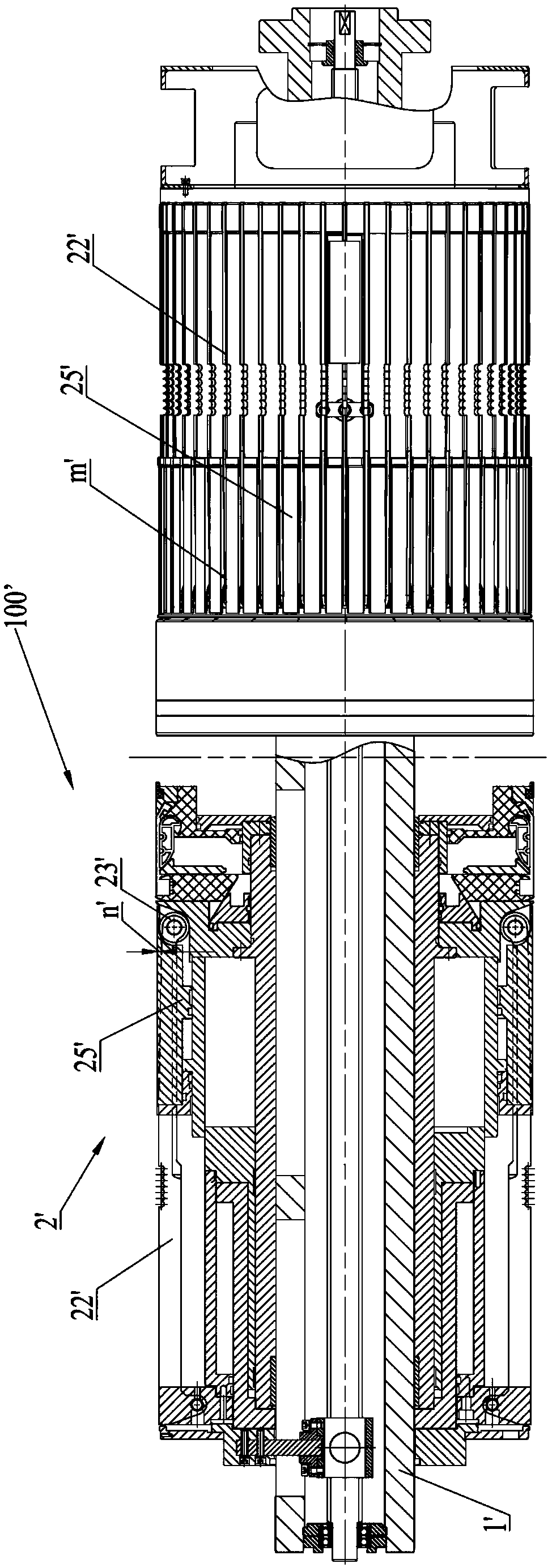

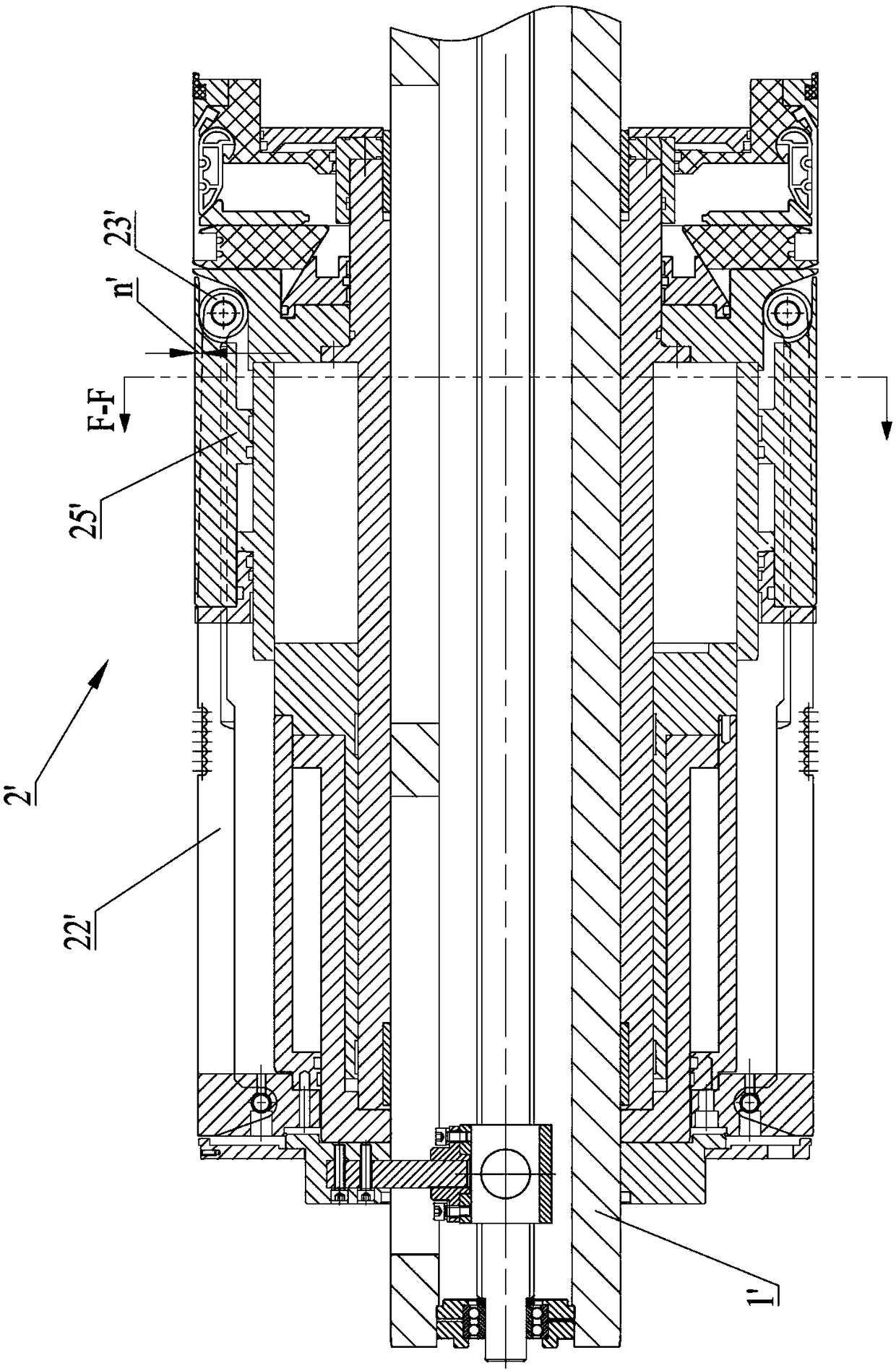

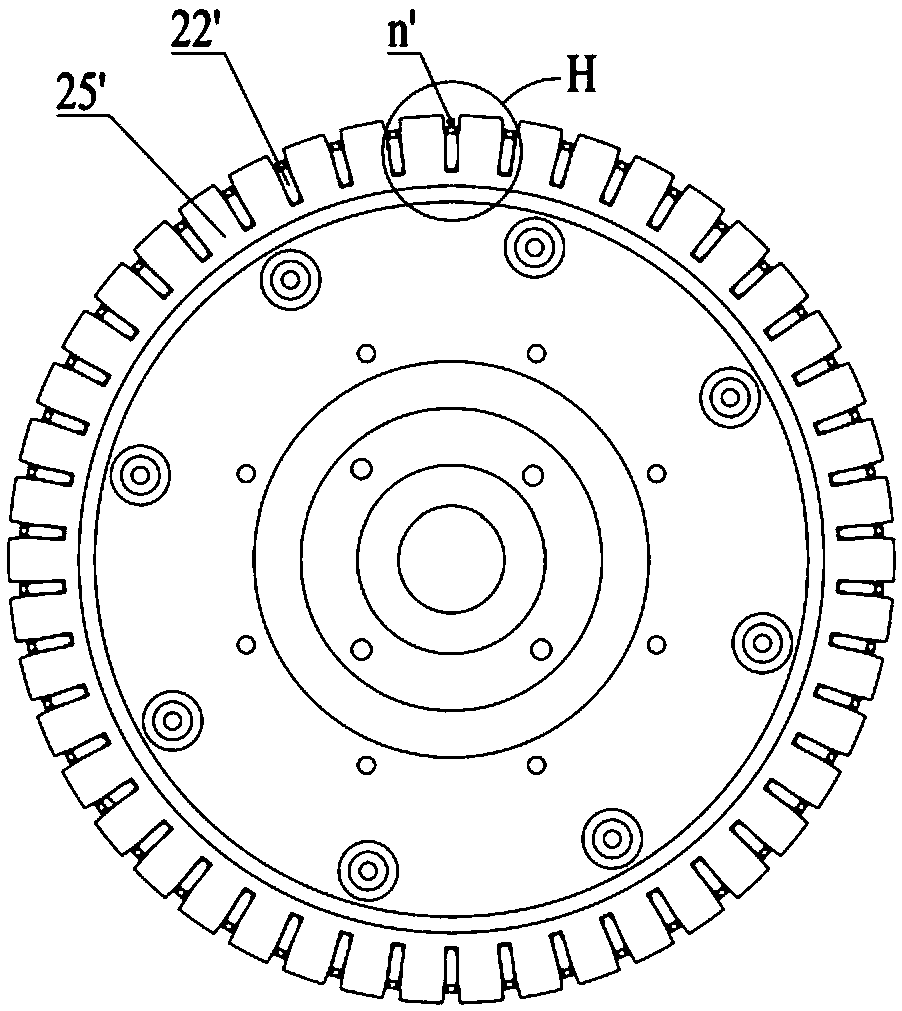

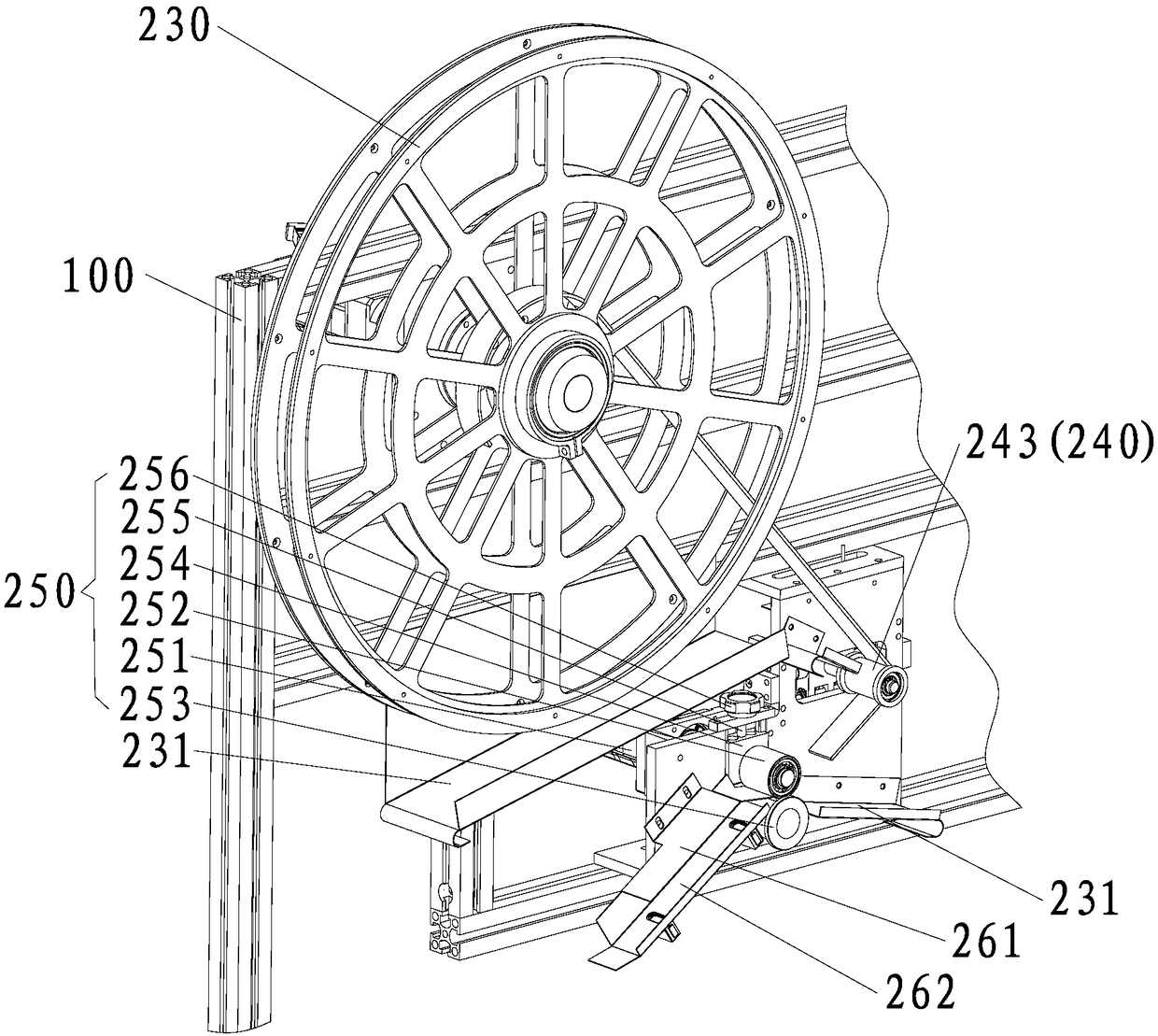

Tyre moulding drum

The invention provides a tyre moulding drum. The tyre moulding drum comprises two semi-drum devices used for sleeving a main shaft; each semi-drum device comprises a reverse coating unit, a guiding body, and a guiding disk; each reverse coating unit comprises a plurality of reverse coating rods and a rolling unit connected with the reverse coating rods through pivotal connection; each guiding bodyis used for guiding and accommodating the reverse coating rods; each rolling unit is designed to be cooperative with the external peripheral arc-shaped surface of the corresponding guiding disk; whenthe plurality of reverse coating rods are at initial positions, a corresponding rolling unit is driven to swing inward, and is stored at the radial inner side of a corresponding guiding body; the radial height of a first periphery surface formed at the outermost radial side of the rolling units is lower than that of a second periphery surface formed by the external surface of the guiding body, and that of a third periphery surface formed by the supporting surfaces of the reverse coating rods; the height of the second periphery surface is equal to the height of the third periphery surface; thereverse coating rods and the guiding bodies are combined so as to form basically sealed flat cylindrical surfaces used for receiving tyres; and at the same time, in reverse coating, the rolling unitsare driven to swing outward, and are higher than the reverse coating rods, so that tyre parts are jacked along the radial direction, and the friction between tyre parts and the reverse coating rods and the guiding body is reduced.

Owner:SAFE RUN & HISCENT MACHINERY SUZHOU

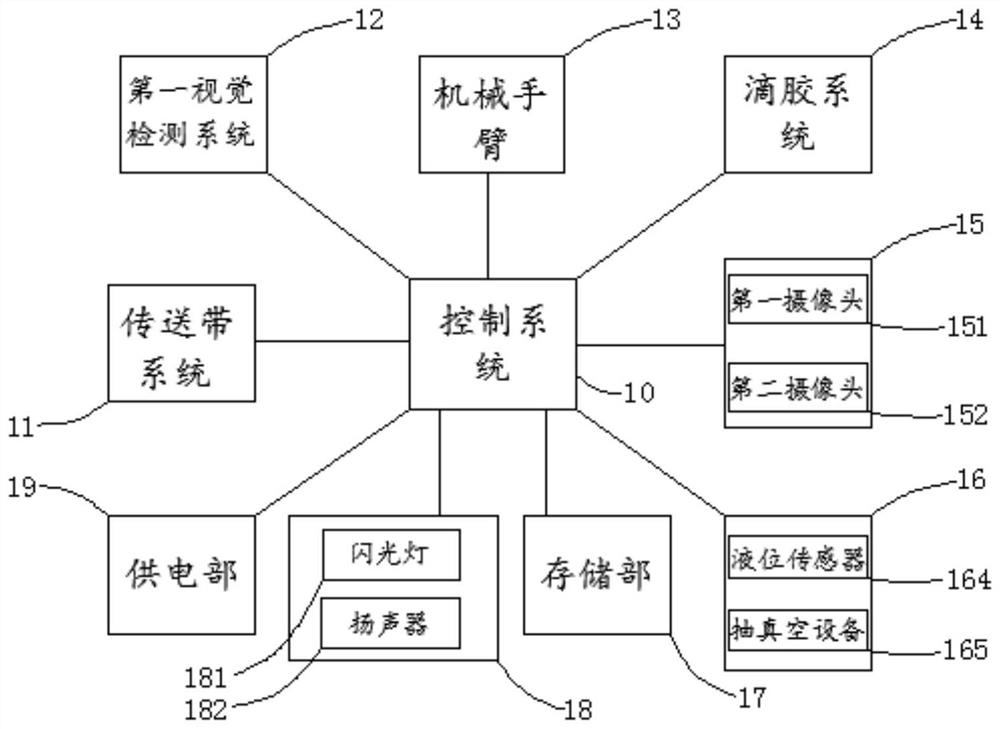

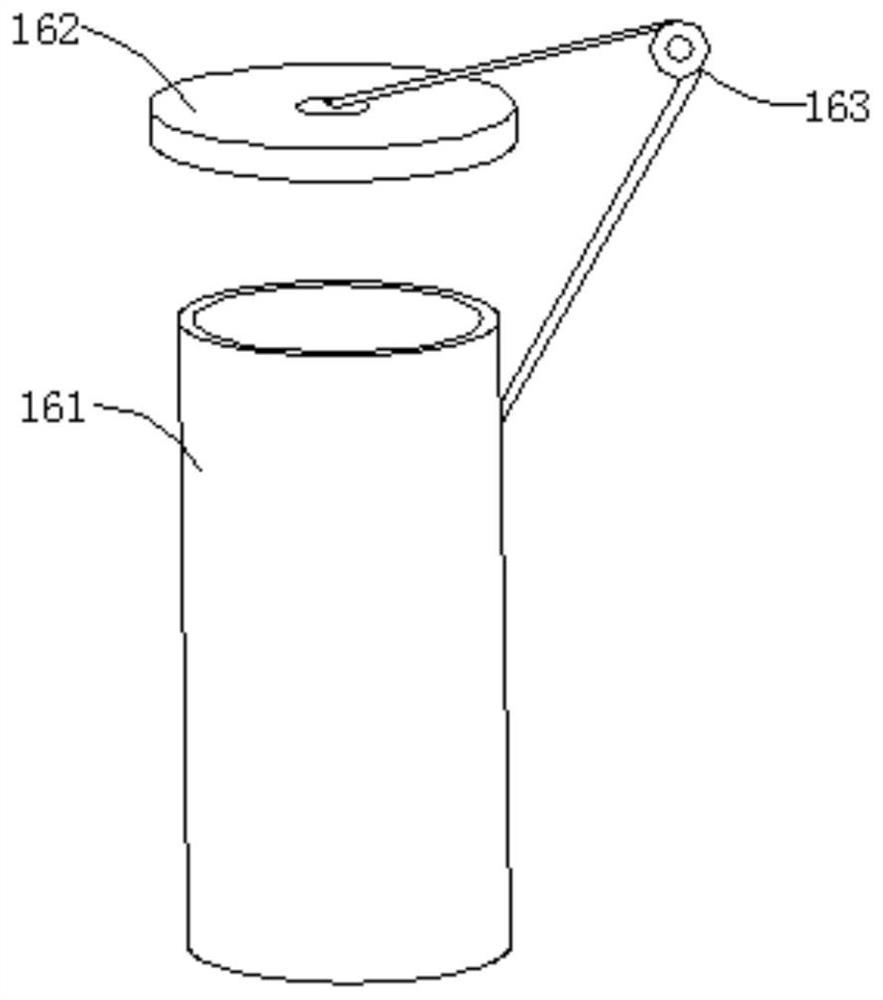

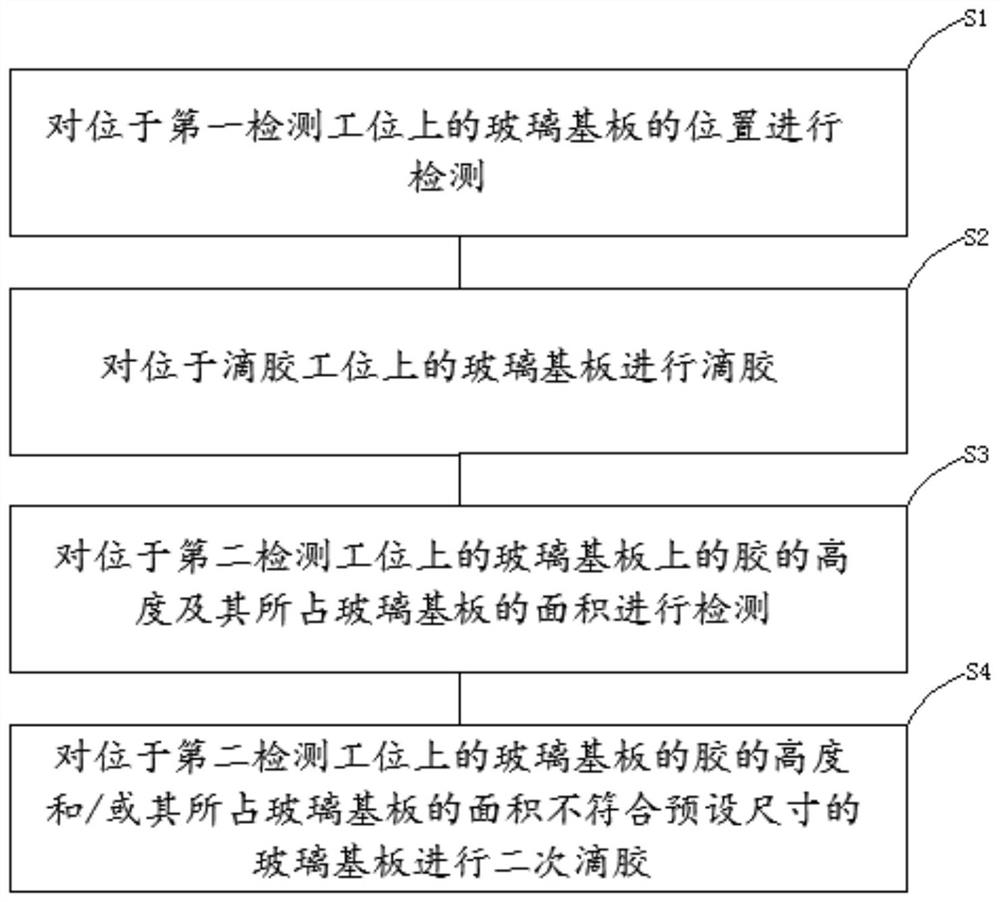

Industrial automatic control device and method

PendingCN112894807AImprove attachment qualityIncrease productivityProgramme-controlled manipulatorAutomatic controlControl system

The invention relates to the technical field of automatic control, in particular to an industrial automatic control device. The industrial automatic control device comprises a control system, a conveying belt system, a first visual detection system, a mechanical arm, a glue dripping system and a second visual detection system. The conveying belt system comprises a first detection station, a glue dripping station and a second detection station, the first visual detection system is located at the first detection station, the glue dripping system is located at the glue dripping station, the second visual detection system is located at the second detection station, and the conveying belt system, the first visual detection system, the mechanical arm, the glue dripping system and the second visual detection system are electrically connected with the control system. The; and the mechanical arm is mechanically connected with the glue dripping system and can drive the glue dripping system to move under the control of the control system, and the conveying belt is used for conveying a glass substrate. The invention further relates to an industrial automatic control method which adopts the industrial automatic control device.

Owner:深圳市玄羽科技有限公司

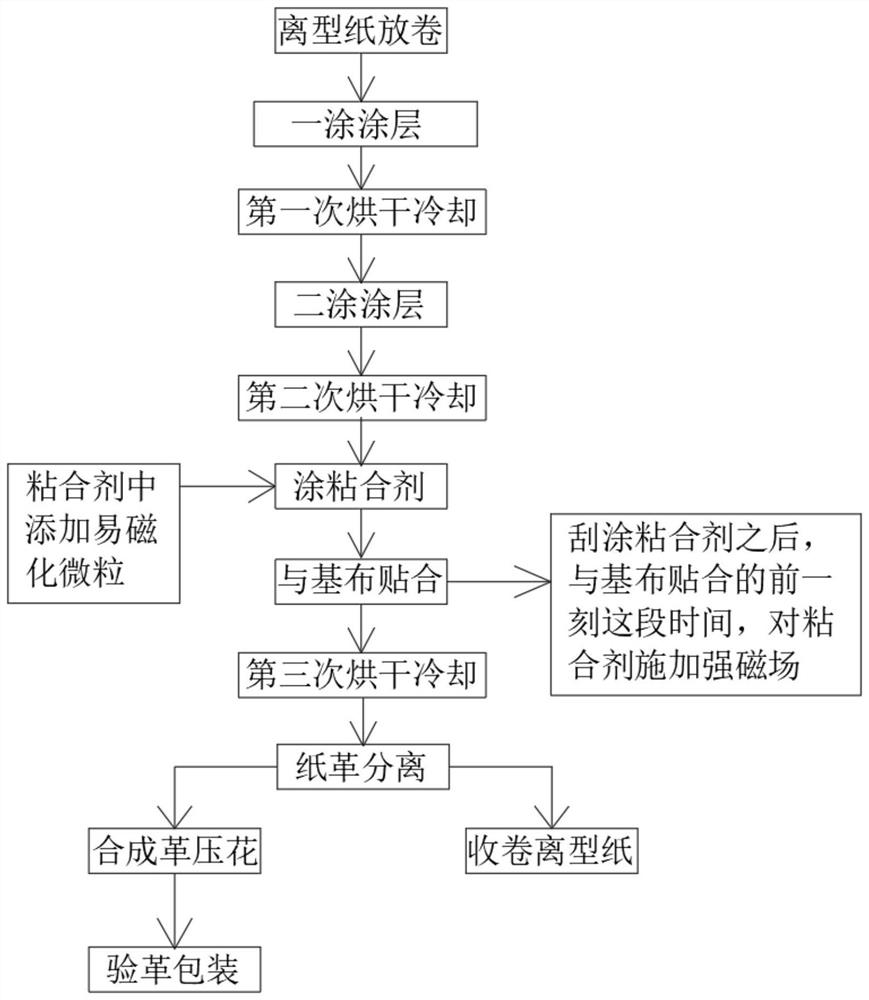

Preparation process of attached environment-friendly synthetic leather

ActiveCN112111975AVariable and Controllable LiquidityModerate fluidityPattern makingPolymer scienceAdhesive

The invention discloses a preparation process of attached environment-friendly synthetic leather. The preparation process includes the steps of smooth release paper unwinding, primary coating, primarydrying and cooling, secondary coating, secondary drying and cooling, adhesive coating, bonding with base cloth, tertiary drying and cooling, paper-leather separation, release paper winding, syntheticleather embossing, and leather inspection and packaging. Tiny soft magnetic particles with high magnetic conductivity and low hysteresis are added into an adhesive and dispersed in the adhesive; anda strong magnetic field is applied to the adhesive in the moment after the adhesive is coated and before the adhesive is attached to the base cloth, so that the viscosity of the adhesive is increased,and the flowability of the adhesive is reduced. According to the preparation process of the attached environment-friendly synthetic leather, a bonding layer between a synthetic leather semi-finishedproduct and the base cloth has variable and controllable fluidity, so that the bonding layer has the most suitable fluidity in the two processes of adhesive coating and bonding with base cloth.

Owner:福建锐信新材料科技有限公司

Anisotropic conductive adhesive

InactiveCN109628000AImprove attachment quality or binding qualityImprove reliabilityFilm/foil adhesivesElectrically-conducting adhesivesAnisotropic conductive adhesiveEngineering

The invention relates to an anisotropic conductive adhesive. The conductive adhesive comprises a substrate and an adhesive layer arranged on the substrate. The surface of the adhesive layer is sunkendownwards to penetrate through the adhesive layer till a groove is formed in the upper surface of the substrate, wherein one end of the groove extends out of the edge of the adhesive layer. Accordingto the anisotropic conductive adhesive, due to the groove and a channel formed by the port, extending out of the edge of the adhesive layer, of the groove and the external world, attaching bubbles aregenerated during attaching, and binding bubbles generated by binding can be exhausted out of the adhesive layer through the channel, so that the attaching quality or the binding quality is improved,and then, the product reliability is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

An automatic sticker forming device for curved corner packaging boxes and its application method

ActiveCN109878143BSimple structureEasy to operateBox making operationsPaper-makingBonding processStructural engineering

The invention relates to packing box processing equipment, in particular to an automatic paper pasting formation device for an arc-shaped corner packing box and a using method thereof. The automatic paper pasting formation device for the arc-shaped corner packing box comprises a pedestal, a transverse sliding block arranged on the pedestal, a first driving mechanism used for driving the transversesliding block to move and two arc-shaped corner forming assemblies which are symmetrically arranged on the transverse sliding block. The arc-shaped corner forming assemblies comprise positioning claws, cambered surface forming cutters and second driving mechanisms used for driving the cambered surface forming cutters to rotate. According to the automatic paper pasting formation device for the arc-shaped corner packing box in the invention, the lug folding portion of facial paper of the packing box can be attached to a corresponding area of an inner box body while the packing box is positionedand clamped due to arrangement of the two positioning claws; and due to arrangement of the rotatable cambered surface forming cutters with inner arc-shaped cutter faces, the facial paper at the connecting position of the arc-shaped corner and end face of the packing box and the inner box body can be attached more tightly, and folded corner rebounding formed in the formation bonding process of thefacial paper can be effectively reduced.

Owner:XUCHANG YUTO PRINTING & PACKING

Thin film absorption device

InactiveCN108172537ASimple structureReasonable designSemiconductor/solid-state device manufacturingDrive motorEngineering

The invention relates to the technical field of automatic attachment, in particular to a thin film absorption device. The thin film absorption device comprises an absorption disc, wherein the absorption disc is arranged on a rotation seat and is in a conical shape, an air exhaust pipeline is arranged in the absorption disc, a cavity is formed in the rotation seat, the air exhaust pipeline penetrates through the cavity and is connected with a negative pressure device, and the rotation seat is driven by a driving motor. The thin film absorption device is simple in structure and reasonable in design, a plurality of small holes are formed in the absorption disc, a flexible dielectric layer is connected with the absorption disc, and wear of the absorption disc to a surface of a thin film can beprevented by the flexible dielectric layer so as to improve the attachment quality; the hole diameters of the small holes are 2-3 millimeters, and the distance between adjacent small holes is 2-4 centimeters; and with the adoption of the structure, the absorption effect is better.

Owner:NANJING LIANXIN AUTOMATION TECH CO LTD

a turning device

A turnover device is used for performing surface mounting on products. The turnover device comprises a frame and at least two turnover portions; the turnover portions are arranged on the frame in turn; every turnover portion comprises at least one composite surface; the composite surfaces of the adjacent turnover portions are attached to each other in a turnover mode. According to the turnover device which is used for performing the surface mounting on the products, one layer or multi-layer attachment can be rapidly achieved through turnover match of the turnover portions and accordingly the attachment quality is improved and the working efficiency is increased.

Owner:YIHE PRECISION IND SUZHOU

A kind of production method of environment-friendly paint-free door

ActiveCN111761679BQuality improvementImprove efficiencyOther plywood/veneer working apparatusWood mortising machinesEngravingMobile device

The invention relates to an environment-friendly production method for paint-free doors, which mainly includes the following steps: plate cutting, slotting treatment, engraving and polishing, glue spraying and coating, pressing and molding, edge sealing, door lock drilling, finishing and packaging, etc. A variety of processes, the paint-free door panel edge banding equipment used includes a bottom plate, a mobile device, a glue spraying device and an edge banding device. The present invention can solve the following problems in the existing door panel edge banding, a, traditional door panel edge banding At this time, it is necessary to manually use a glue spraying machine to spray glue on the door panel, and then attach the edge banding strip. Manually attaching the edge banding strip will easily cause the board to be skewed, and the force on the edge banding will be uneven, which will affect the quality of the edge banding , and the efficiency of manual door panel edge sealing is low, and the labor intensity is relatively high; b. During the operation of the existing door panel edge sealing equipment, the air between the edge sealing strip and the door end surface is not easy to be discharged, and it is easy to foam, which improves the door panel edge sealing. quality and efficiency.

Owner:宿迁普奈家居科技有限公司

Suction jig

ActiveCN102642379BImprove attachment qualityReduce surface blemishesLamination ancillary operationsLaminationPulp and paper industryAir compressor

The invention discloses a suction jig for attaching attached products to a large-area product, wherein the attached products are smaller than the outer frame of the large-area product. The suction jig comprises a lower mold, wherein a groove is arranged on the upper surface of the lower mold, the frame shape of the groove is the same as that of the product but is smaller than the outer frame of the product, and a passage is arranged in the lower mold and through connected to a vacuum machine out of the lower mold from the groove; and an upper mold above the lower mold, wherein air holes are uniformly arranged on the upper mold and are perpendicularly connected with the groove. According to the invention, when films or gummed paper in a large area is attached to the product, the films or gummed paper is placed on the suction jig provided by the invention; vacuum is generated in the jig through an air compressor so that the films or the gummed paper is flattened; then, the product is laminated on the flat films or gummed paper; the attaching quality can be greatly improved; and the surface defects are reduced.

Owner:CHENGYEDE KUNSHAN COMM TECH

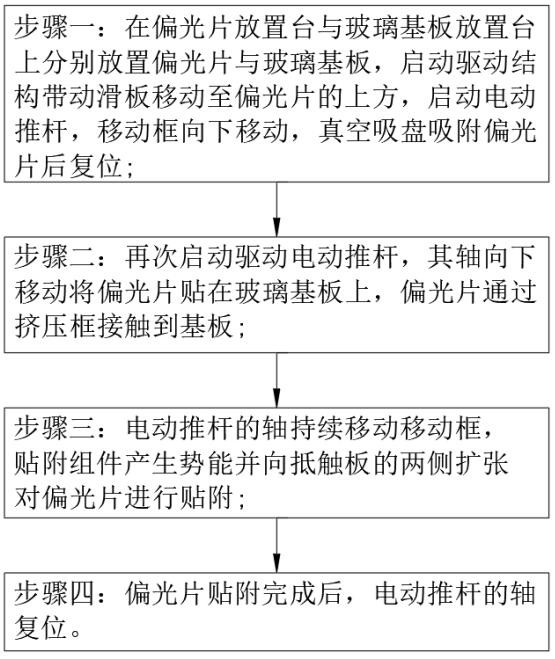

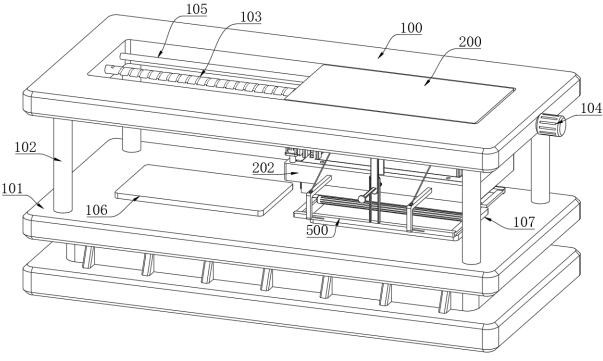

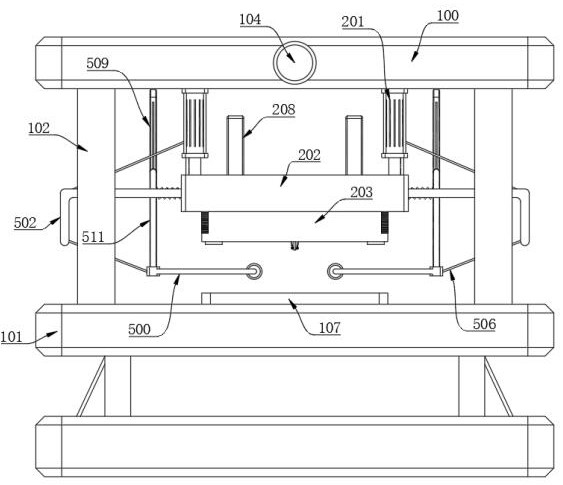

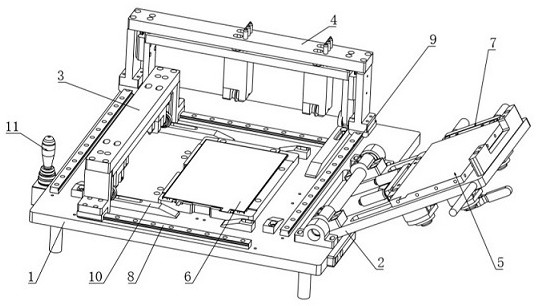

An intelligent polarizer attaching device and method

ActiveCN114488590BReduce attachment timeImprove attachment efficiencyNon-linear opticsLiquid-crystal displayDisplay device

Owner:深圳前海锦泽实业有限公司

A semi-automatic gluing machine for backlight panels

ActiveCN111115343BHigh degree of automationImprove work efficiencyArticle deliveryAdhesive beltSemi automatic

A semi-automatic gluing machine for backlight panels, including: a substrate, a rotary pre-pressing mechanism, a tape pressing mechanism A, a tape pressing mechanism B, a vacuum adsorption unit, a jig, a tape position adjustment and limiting mechanism, a guide rail A, a guide rail B, Laminating walking track mechanism and control mechanism; open by rotating the pre-pressing mechanism, put the adhesive tape to be attached into the vacuum adsorption unit and adjust the positioning through the tape position adjustment limit mechanism, close the rotating pre-pressing mechanism, and the pre-pressing position adjustment mechanism is in place The rear preloading mechanism moves down through the preloading guide column to pre-stick the tape on the backlight plate in the fixture, the rotating preloading mechanism opens, and the tape pressing mechanism A and tape pressing mechanism B move along the guide rail A and guide rail B , through the glue walking track mechanism, each glue up and down floating mechanism and the pressure adjustment mechanism to compress the tape and the product, thereby improving the work efficiency and attachment quality.

Owner:深圳市雷普科技有限公司

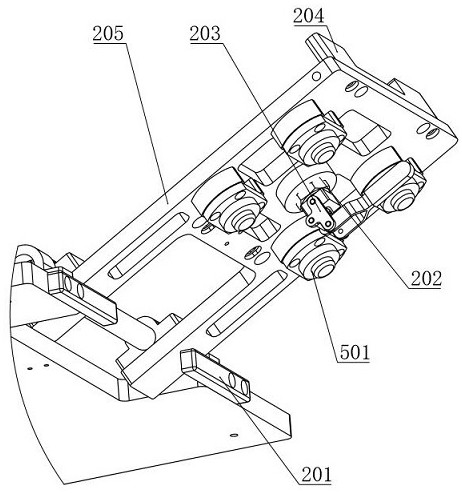

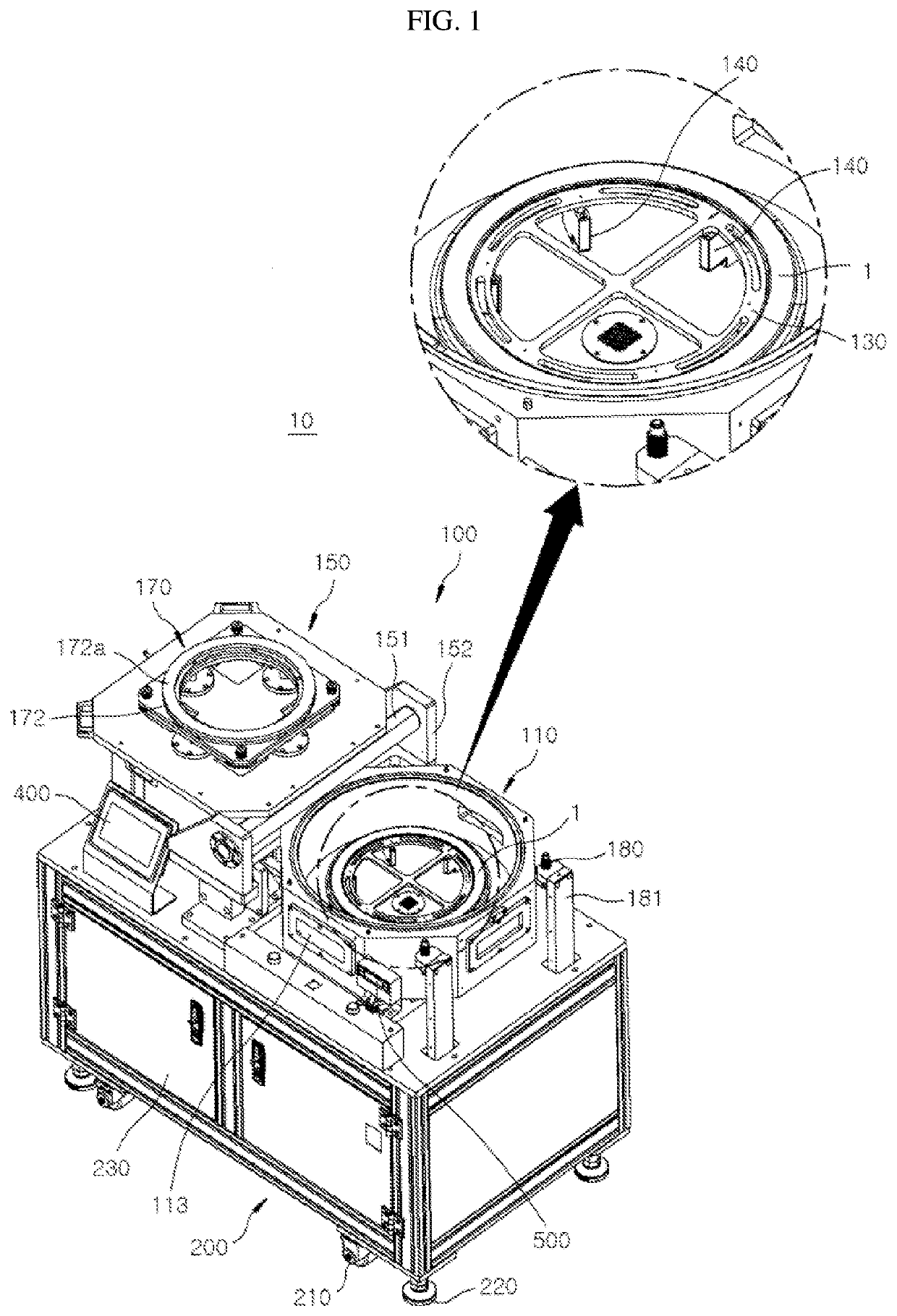

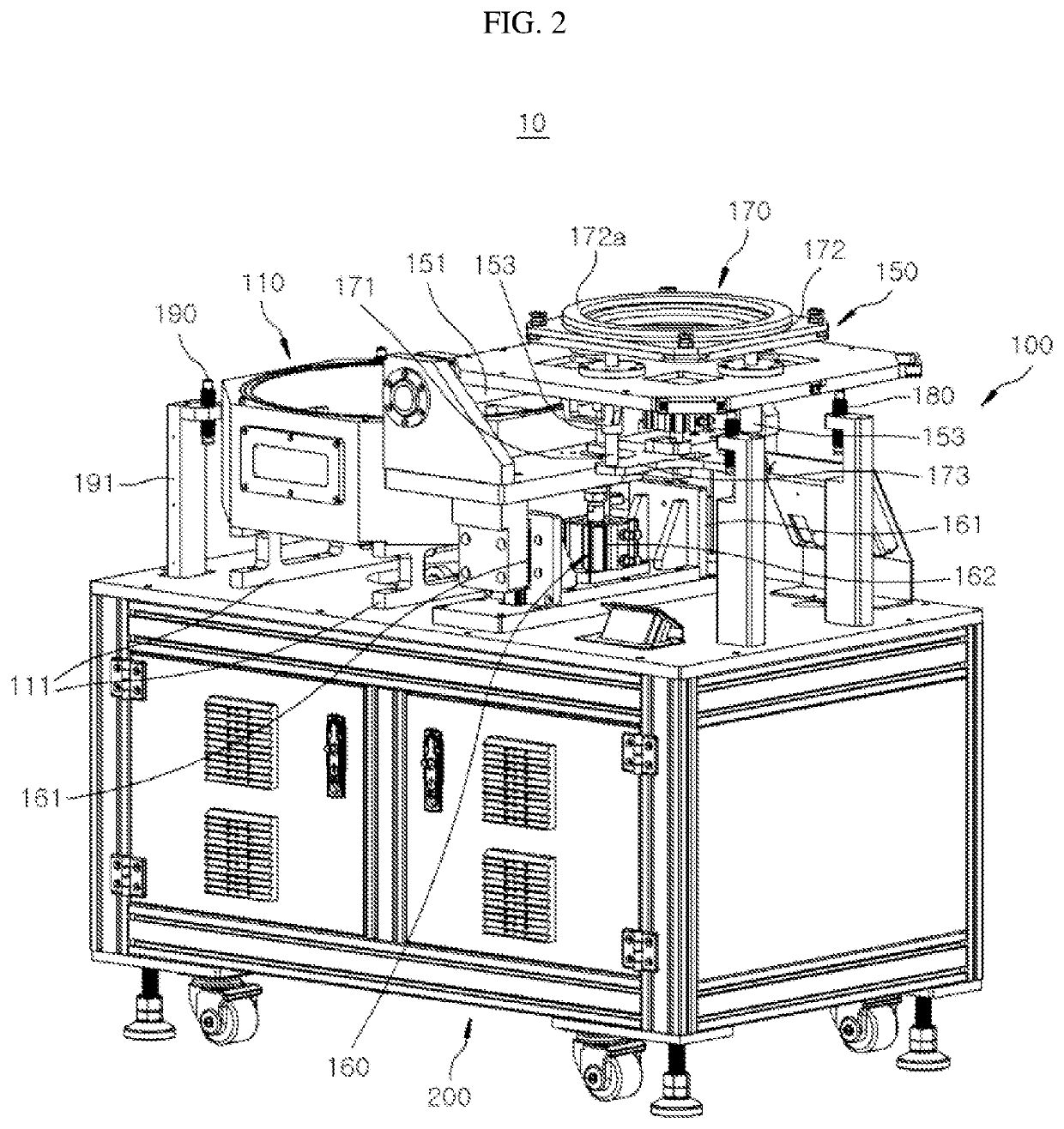

Cooling sheet attachment apparatus to focusing ring for semiconductor manufacturing apparatus

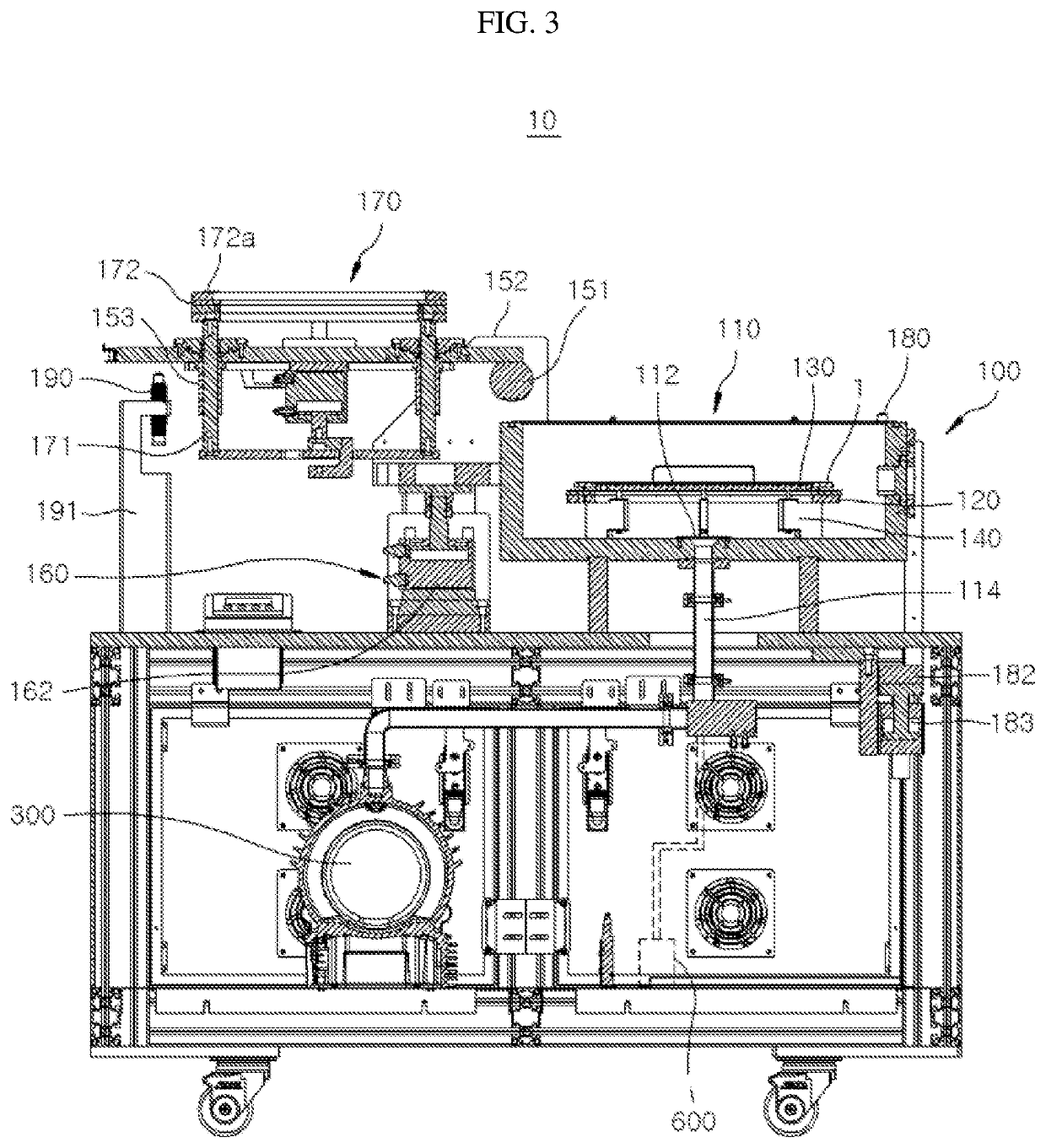

PendingUS20220181175A1Low costMinimize timeSemiconductor/solid-state device manufacturingLapping machinesManufactured apparatusEngineering

Provided is a cooling sheet attachment apparatus to a focusing ring for a semiconductor manufacturing apparatus, including: a vacuum chamber equipped with a sheet support ring fixed to seat a cooling sheet in a chamber body with an adhesion surface exposed in an upward direction, a centering jig installed on an inner or outer circumferential surface of the sheet support ring liftably to be moved back in the upward direction by an elastic support, a cover for opening / closing installed above the chamber body and lifted by a lift unit, a press unit provided on the cover to press down the focusing ring, and a vacuum suction tube connected to the chamber body for vacuum suction; and a vacuum suction unit to create a vacuum in the vacuum chamber by the suction through the vacuum suction tube.

Owner:CM TECH CO LTD

A backlight front assembly system and method

ActiveCN107031902BCompact structureIngenious designLamination ancillary operationsLaminationProduction rateTectorial membrane

Owner:深圳市小宝机器人有限公司

Automatic paper pasting formation device for arc-shaped corner packing box and using method thereof

ActiveCN109878143ASimple structureEasy to operatePaper-makingBox making operationsBonding processMechanical engineering

The invention relates to packing box processing equipment, in particular to an automatic paper pasting formation device for an arc-shaped corner packing box and a using method thereof. The automatic paper pasting formation device for the arc-shaped corner packing box comprises a pedestal, a transverse sliding block arranged on the pedestal, a first driving mechanism used for driving the transversesliding block to move and two arc-shaped corner forming assemblies which are symmetrically arranged on the transverse sliding block. The arc-shaped corner forming assemblies comprise positioning claws, cambered surface forming cutters and second driving mechanisms used for driving the cambered surface forming cutters to rotate. According to the automatic paper pasting formation device for the arc-shaped corner packing box in the invention, the lug folding portion of facial paper of the packing box can be attached to a corresponding area of an inner box body while the packing box is positionedand clamped due to arrangement of the two positioning claws; and due to arrangement of the rotatable cambered surface forming cutters with inner arc-shaped cutter faces, the facial paper at the connecting position of the arc-shaped corner and end face of the packing box and the inner box body can be attached more tightly, and folded corner rebounding formed in the formation bonding process of thefacial paper can be effectively reduced.

Owner:XUCHANG YUTO PRINTING & PACKING

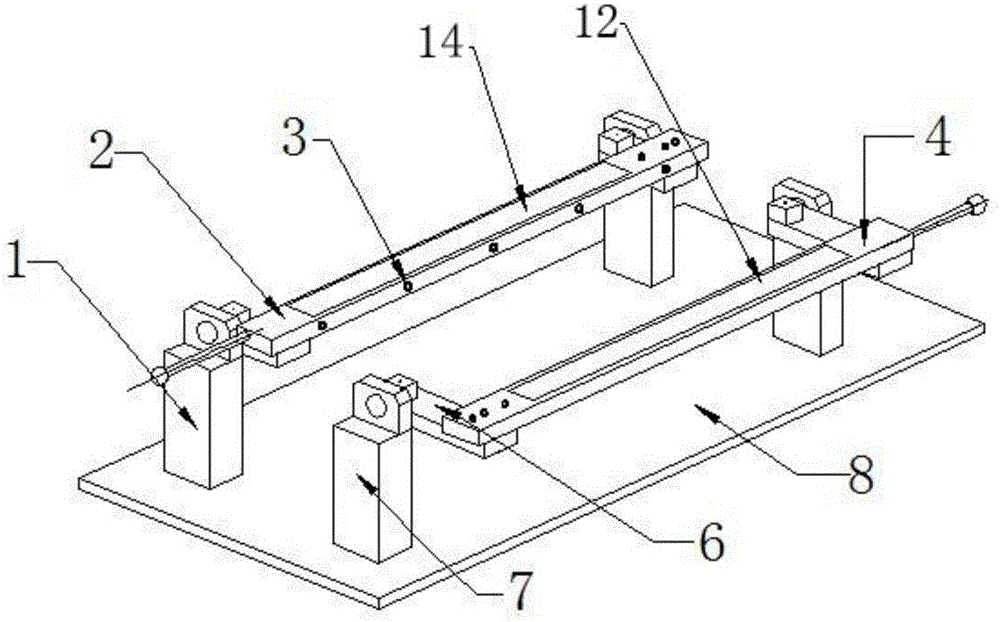

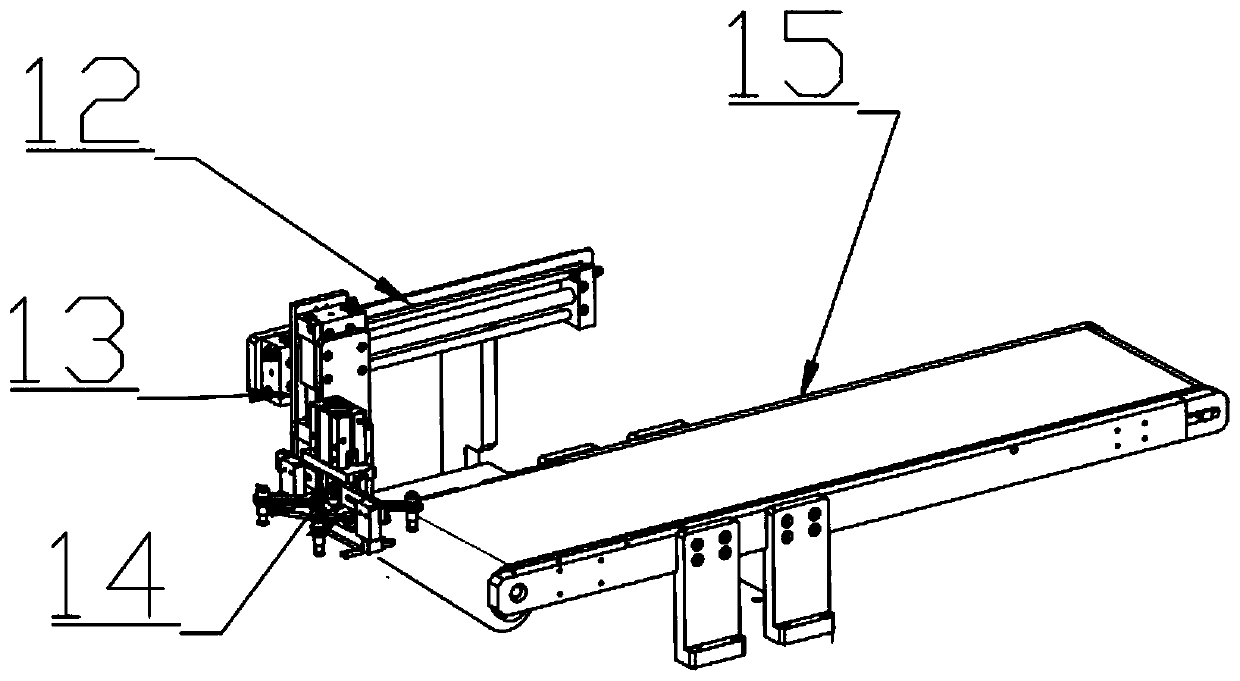

Strip-type workpiece film-sticking mechanism

The invention discloses a strip-type workpiece film-sticking mechanism which comprises a displacement device and a sticking device. The displacement device is at least arranged on one side of a workpiece, and the sticking device can move along with the displacement device and carry out film sticking in the workpiece length direction. The sticking device comprises a paying-off device, a taking-up device and a stripping device and further comprises a sticking part, wherein the paying-off device pays off material belts coiled into barrel shapes, the taking-up device is matched with the paying-off device and takes up a bottom film, the stripping device is arranged in the material belt advancing direction and used for stripping a part to be stuck from the bottom film, and the sticking part is used for sticking the to-be-stuck part stripped from the bottom film to the surface of the workpiece. According to the strip-type workpiece film-sticking mechanism, the displacement device and the sticking device are arranged to be matched, and film sticking can be accurately and rapidly achieved in the length direction of the workpiece; particularly, due to the cooperation of the paying-off, taking-up and stripping devices in the sticking device, the structure is simple, stable film stripping is ensured, and the sticking quality can be improved.

Owner:APS SUZHOU AUTOMATION TECH

A product surface mount device

ActiveCN111935971BImprove attachment qualityHigh degree of automationConveyor partsElectrical componentsVision basedProcess engineering

The invention discloses product surface attaching equipment. The product surface attaching equipment comprises an attaching piece stripping and supplying device, a product carrying device and a visualguidance attaching piece taking and placing device. The attaching piece stripping and supplying device is used for stripping a to-be-used attaching piece from a material supply belt and conveying theto-be-used attaching piece to a material taking position; the product carrying device carries the product to the attaching position; the visual guidance attaching piece taking and placing device comprises a first visual unit and an attaching piece taking and placing carrying unit. The first visual unit obtains visual information of the to-be-used attaching piece on the material taking position and the product on the attaching position. Based on the visual information, the attaching piece taking and placing carrying unit moves to the material taking position to suck the to-be-used attaching piece and moves to the attaching position to attach the to-be-used attaching piece to the product. The product surface attaching equipment integrates the functions of attaching piece stripping and supplying, attaching piece taking and placing under visual guidance, product carrying and the like, the automation degree is high, and the production efficiency and attaching quality are improved.

Owner:GEER TECH CO LTD

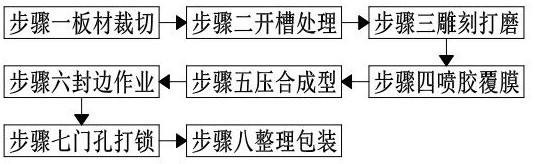

Surrounding strip press-fit feeding machine

PendingCN108439026ALittle change in extrusion forceAvoid deformationArticle deliveryShoe gluingEngineeringMechanical engineering

The invention provides a surrounding strip press-fit feeding machine. The surrounding strip press-fit feeding machine comprises a rack, and the rack is provided with an unreeling device, a gluing device, a drying device and a press-fit device. The press-fit device comprises a tensioning assembly and an attaching assembly which are sequentially arranged. The attaching assembly comprises a supporting plate, a movable base, a supporting spring, a supporting shaft, a carrier roller, a guide rod, a needle-shaped air cylinder, a limiting wheel, a swinging rod, a pressing rod, a reset spring and an elevating air cylinder. The reset spring and the elevating air cylinder are located at the positions corresponding to the two ends of the swinging rod correspondingly. One end of the reset spring abutsagainst the movable base, and the other end of the reset spring abuts against the swinging rod. The side, towards the tensioning assembly, of the carrier roller is provided with a shearing mechanism.The supporting spring is utilized for compensating for the contraction amount existing in the scanning track, in the surrounding strip attaching process, the changes of extrusion force exerted on thesurrounding strip are relatively weak, the surrounding strip is not prone to deformation, the attaching error is small, the production efficiency is relatively high, and the attaching quality is relatively good.

Owner:QUANZHOU HUAZHONG UNIV OF SCI & TECH INST OF MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com