Anisotropic conductive adhesive

An anisotropic, conductive adhesive technology, applied in the direction of conductive adhesives, adhesives, film/sheet adhesives, etc., can solve the problems of easy generation of binding bubbles, easy generation of attachment bubbles, etc., to achieve improved adhesion The effect of attaching quality or binding quality and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

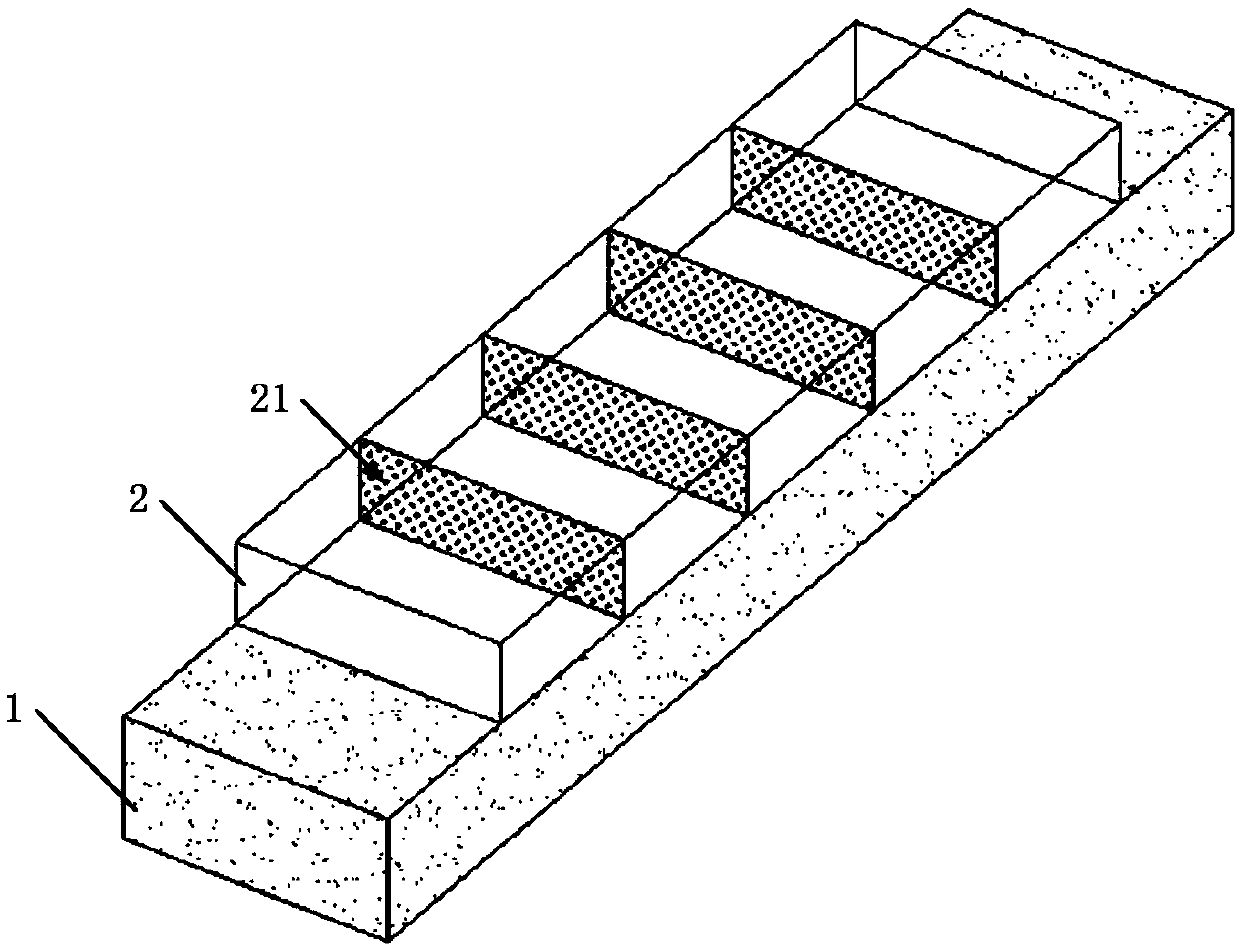

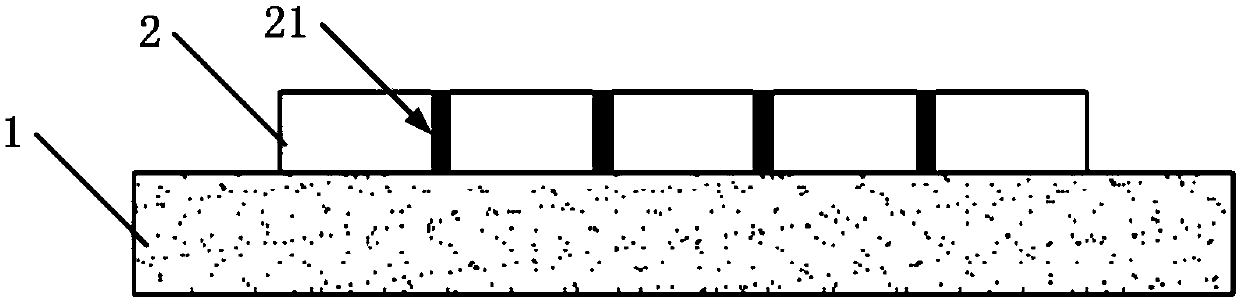

[0033] Such as figure 1 As shown, the perspective view of the anisotropic conductive adhesive in Example 1 includes a substrate 1 and an adhesive layer 2 disposed on the substrate 1 . The adhesive layer 2 is provided with a groove 21 , and the groove 21 penetrates downward through the adhesive layer 2 to the upper surface of the substrate 1 . Specifically, the through hole 21 can be provided by a die-cutting method.

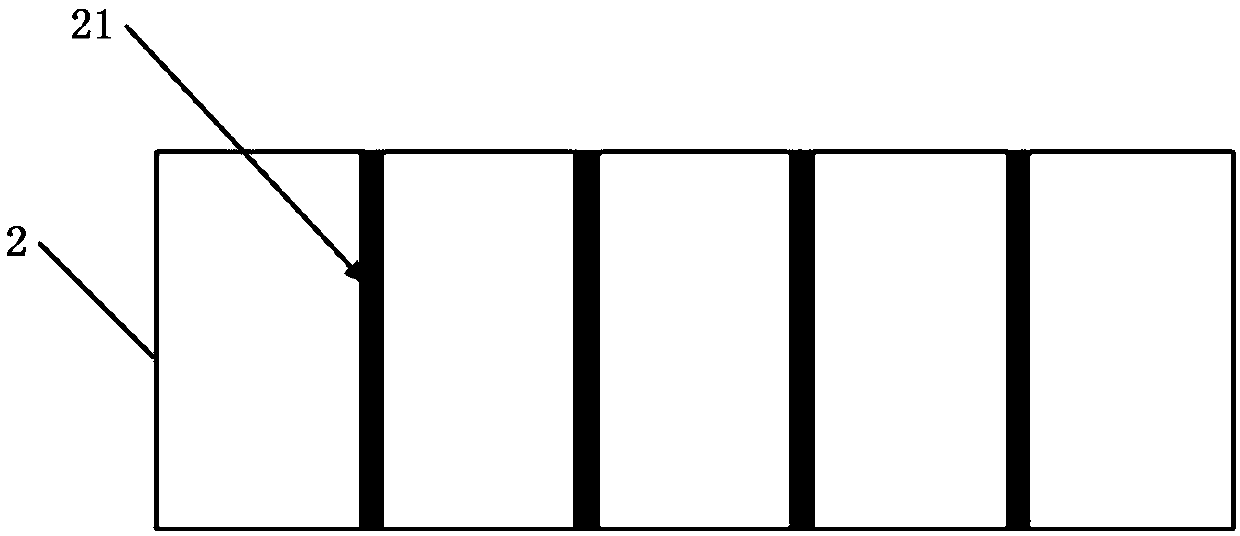

[0034] Such as figure 2 As shown in the top view of the anisotropic conductive adhesive in Example 1, the grooves 21 are parallel to each other, and the distances between the grooves 21 are the same, forming a grid array. Wherein the groove 21 is parallel to the short side direction of the adhesive layer 2 . The anisotropic conductive adhesive thus formed can well discharge the attachment air bubbles that are easily generated during attachment and the binding air bubbles that are easily generated after the pressure binding through the groove 21, thereby improv...

Embodiment 2

[0039] Such as Figure 4 As shown, the perspective view of the anisotropic conductive adhesive in Example 2 includes a substrate 1 and an adhesive layer 2 disposed on the substrate 1 . The adhesive layer 2 is provided with a groove 21 , and the groove 21 penetrates downward through the adhesive layer 2 to the upper surface of the substrate 1 . Specifically, the through hole 21 can be provided by a die-cutting method.

[0040] Such as Figure 5 As shown in the top view of the anisotropic conductive adhesive in Example 2, the grooves 21 are parallel to each other, and the distances between the grooves 21 are the same, forming a grid array. Wherein the groove 21 is arranged obliquely with respect to the short side direction of the adhesive layer 2 , preferably, the angle between the groove 21 and the short side direction of the adhesive layer 2 can be set as 45 degrees. The anisotropic conductive adhesive thus formed can well discharge the attachment air bubbles that are easily...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com