Installation equipment for door plank colored tape

A technology for installing equipment and door panel color, which is applied in the field of installation equipment for door panel ribbons, and can solve problems such as uneven width, high process requirements, and increased manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

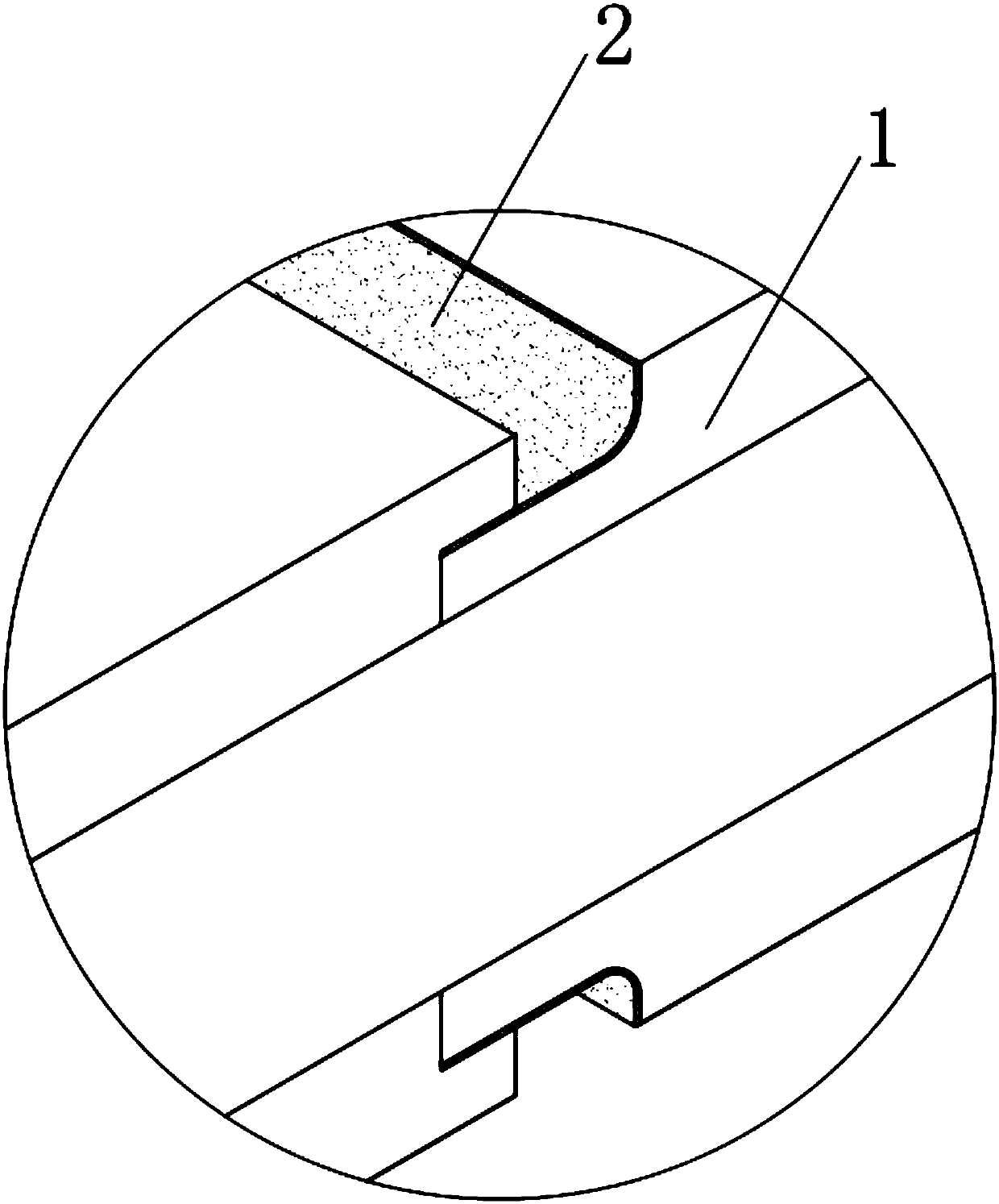

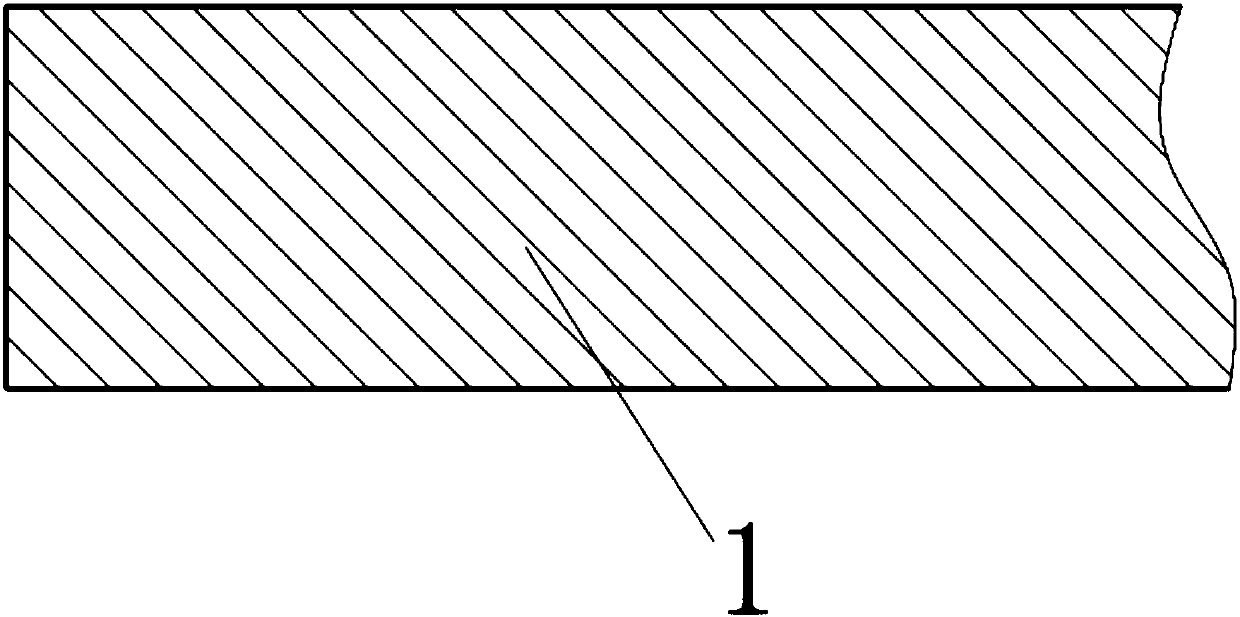

[0036] In order to achieve the purpose of the present invention, a door panel ribbon installation device includes: a feeding tray 12 for storing and transporting the ribbon 2 stacked with the base belt 3; a receiving tray 13 for collecting the base belt 3 stripped from the ribbon 2; The door panel 1 is conveyed horizontally, the pressure roller 10 is set on one side of the door panel 1, and contacts the back of the base belt 3, and the ribbon 2 is rolled and adhered to the groove 1a of the door panel 1; the pressure roller 10 is connected with a first telescopic mechanism 11. The first telescopic mechanism 11 provides translational freedom for the pressure roller 10 to approach or move away from the door panel 1 .

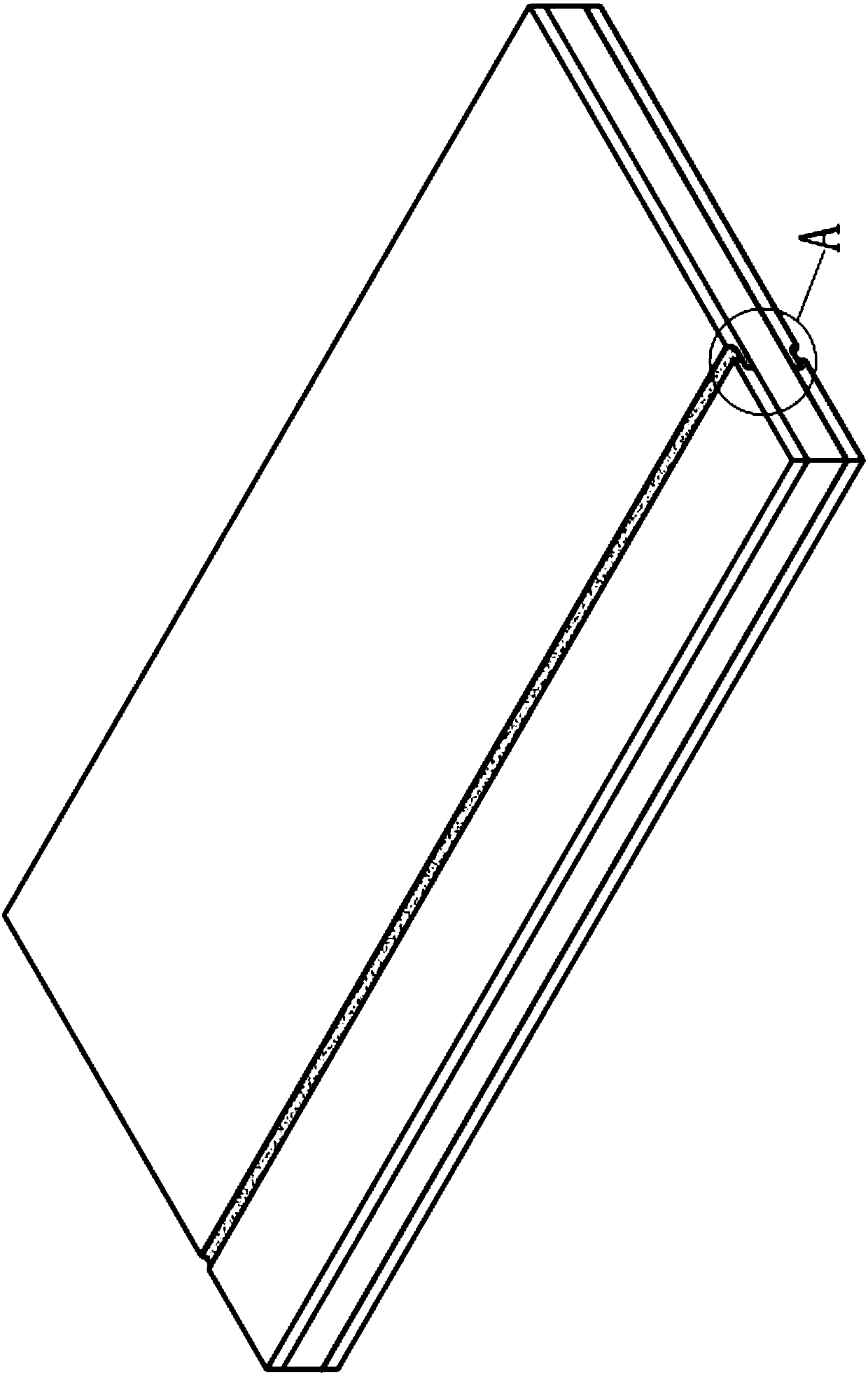

[0037] figure 1 It is a schematic diagram of the application of the door panel 1 attached with the ribbon 2 . figure 2 , image 3 , Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com