Patents

Literature

70results about How to "Reduce the risk of missed detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

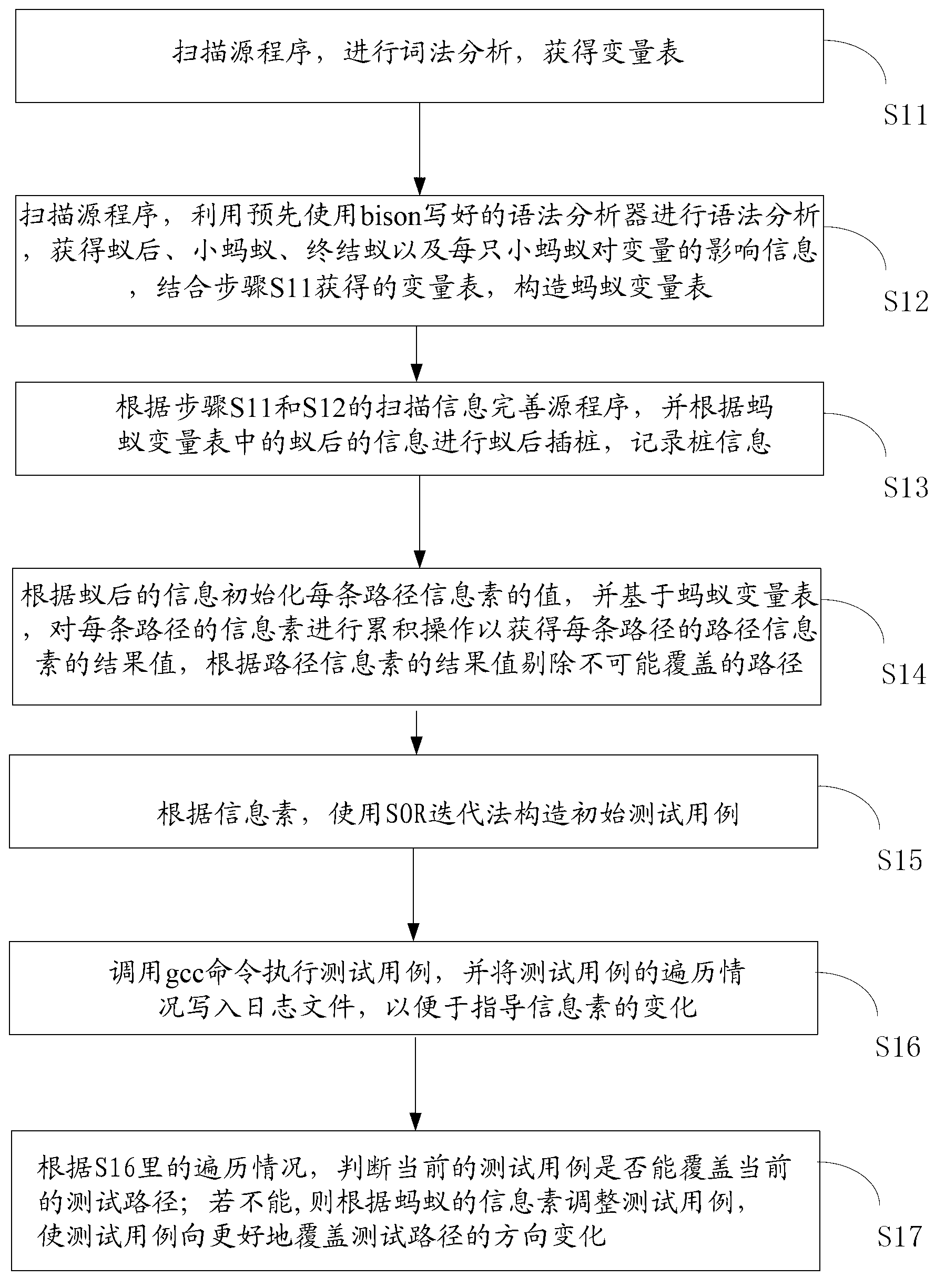

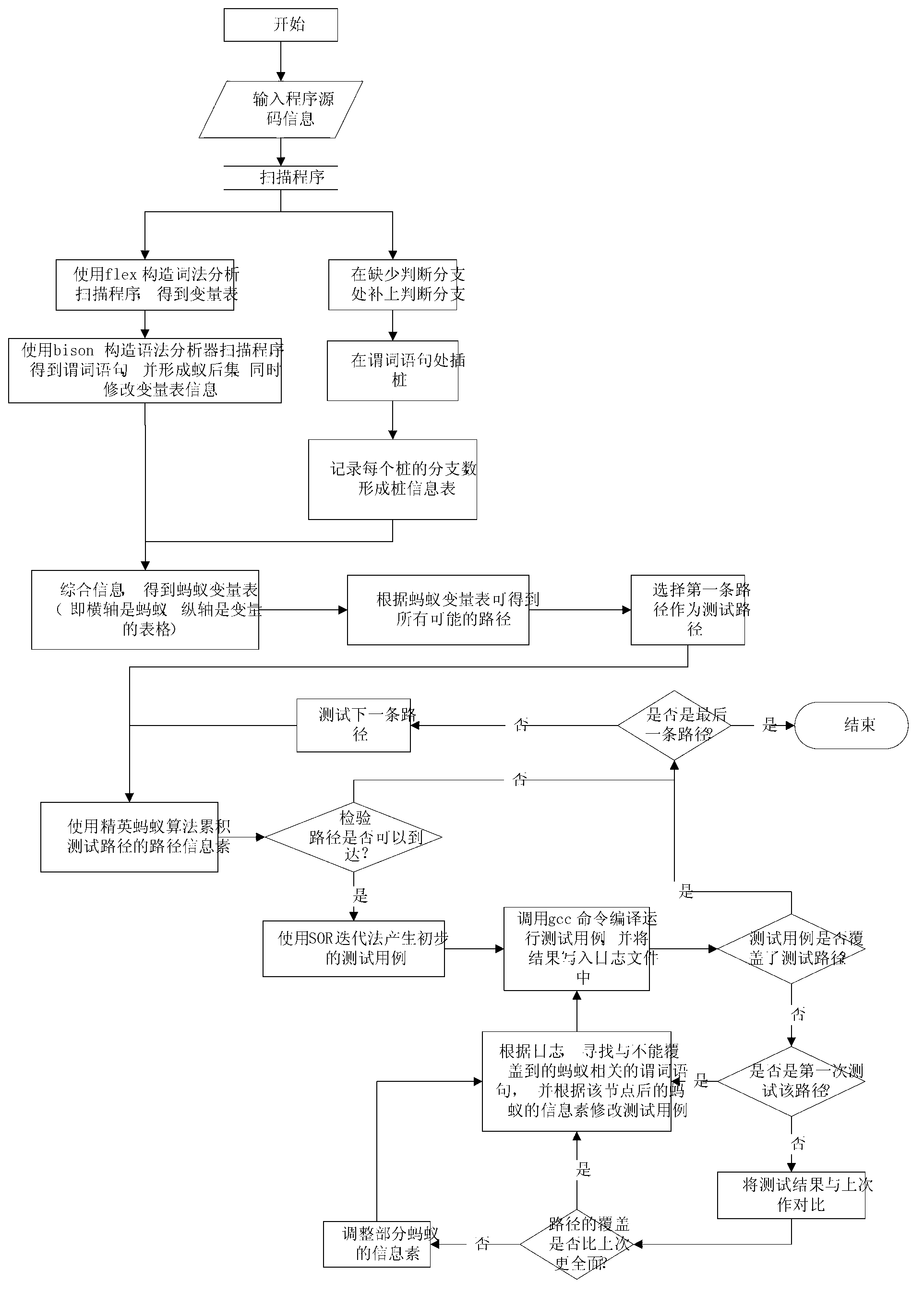

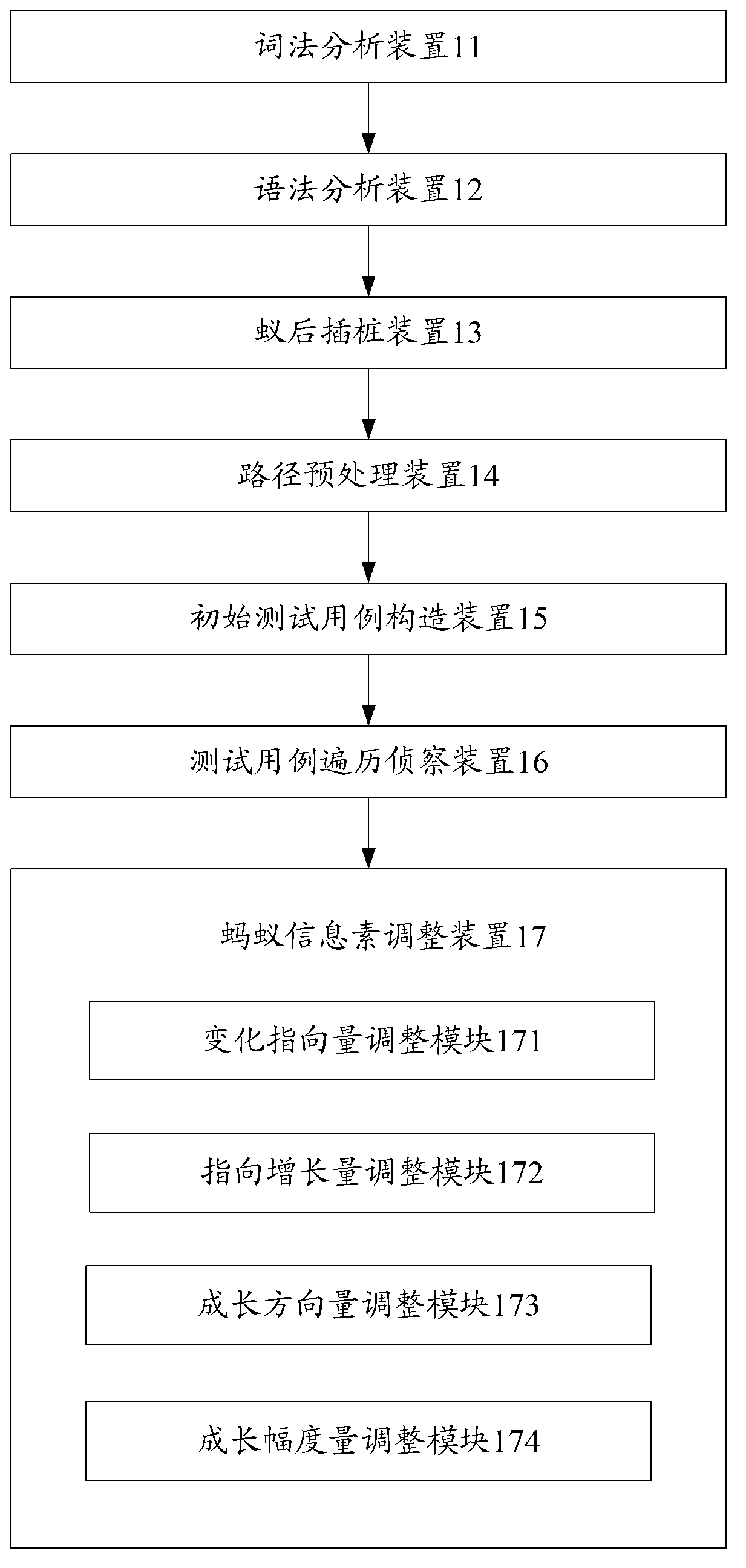

Automatic generating method and system of optimized ant colony algorithm test case

ActiveCN103218299ALow technical requirementsGuarantee the quality of software productsSoftware testing/debuggingAnt colonyInstrumentation

The invention discloses an automatic generating method and system of an optimized ant colony algorithm test case. The automatic generating method and system can be used for automatically generating and optimizing a test path and further improving an automatic generating algorithm of the test case. The technical scheme in the invention is as follows: the automatic generation and optimization of the test path and the test case can be achieved by virtue of combination of automatic generation of the test path and automatic generation of the test case by carrying out queen ant instrumentation, removal of an un-coverable path, initial case optimization, dynamic adjustment of pheromone and case optimization.

Owner:北京网宿科技有限公司

Eddy current high/low-frequency compound detection equipment for seamless steel tubes

InactiveCN103105431AEasy to detectImprove work efficiencyMaterial magnetic variablesEngineeringEddy current

The invention discloses eddy current high / low-frequency compound detection equipment for seamless steel tubes. The equipment comprises an electric control system, front and rear roller paths, a positioning pressure wheel device, a three-roller centering device, a lifting device, magnetizing devices, a flaw detection instrument, a demagnetizer, a stand and a blanking frame. The steel tubes to be detected stably enter into the pressure wheel device, the three-roller centering device and the two magnetizing devices through the transmission roller paths controlled by the electric control system for finishing full coverage detection of the steel tubes; the flaw detection instrument is used for displaying detection results; and the steel tubes enter into the demagnetizer and the stand for demagnetizing the steel tubes, finally enter into the blanking frame and are automatically separated and stored in qualified and unqualified product storage tanks. The equipment has the beneficial effects that each magnetizing device is equipped with a high-frequency probe and a low-frequency probe for on-line detection, so that the detection effect and the working efficiency are improved and the missing detection risk is lowered.

Owner:沈玉琴

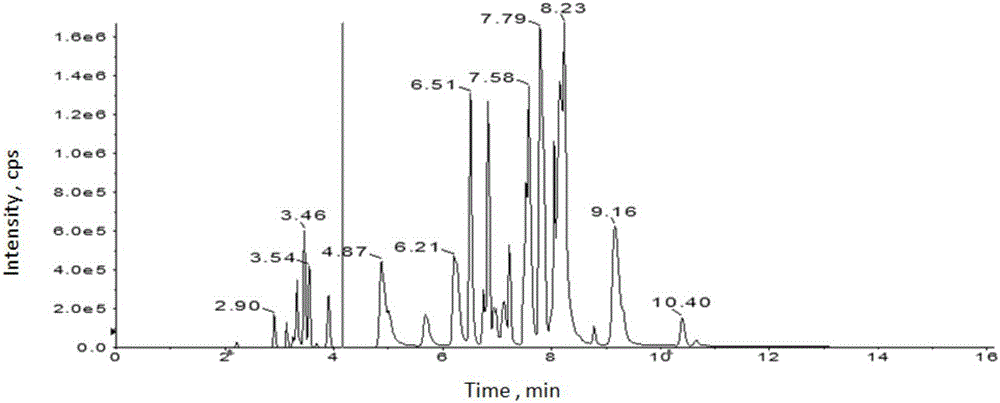

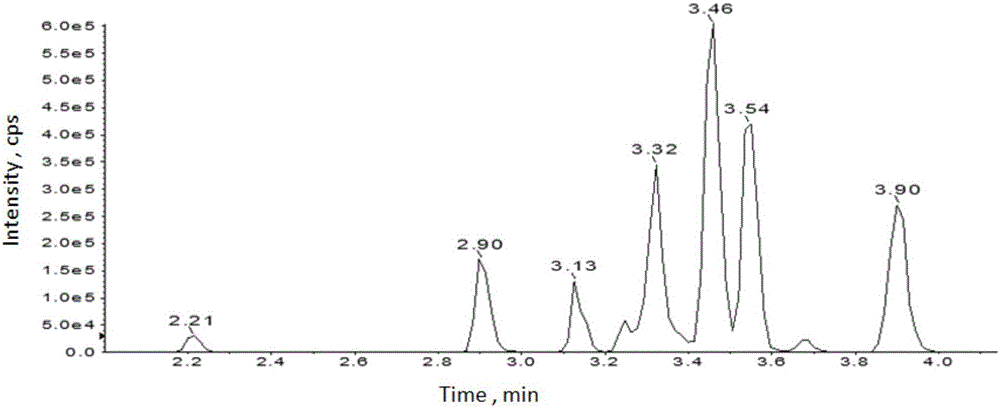

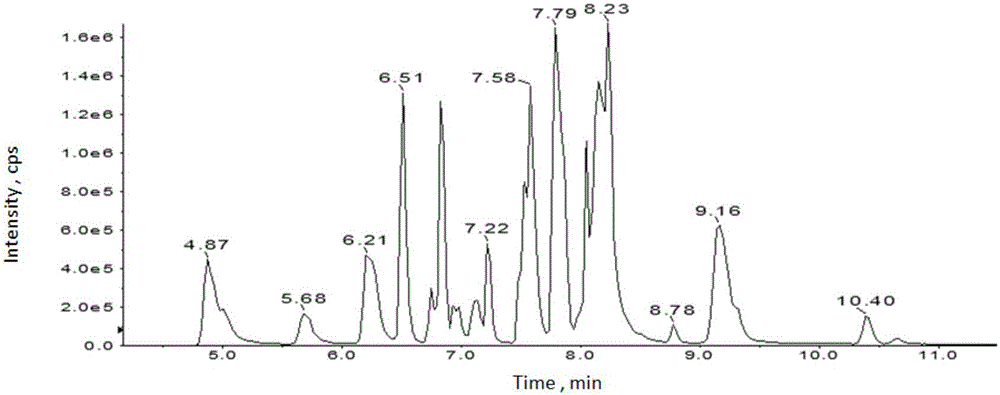

Method for detecting pigment in flavouring

The invention discloses a method for detecting pigment in flavouring. The method comprises the following steps: 1) performing pre-treatment on a sample to obtain a loading buffer; and 2) using an UPLC-MS / MS method for measuring the loading buffer, and comparing the determination result of the loading buffer with a standard solution for analysis. The detection method can perform qualitative and quantitative analysis through a positive and negative ions switching mode, can simultaneously detect the positive and negative ions of the pigment, and solves the technical problems of single detection mode of current illegal pigment and limited detection types. a QuEChERS purifying method is used for removing grease in the sample, the complex pre-treatment process in the pigment detection can be effectively improved, the method is simple and rapid, compared with the detection method in the prior art, the analysis time is short, and the sensitivity is high, detection efficiency is completely increased, and the detection period is greatly shortened.

Owner:GUANGZHOU INST FOR FOOD INSPECTION(GUANGZHOU INSPECTION CENT FOR WINE & SPIRITS) +1

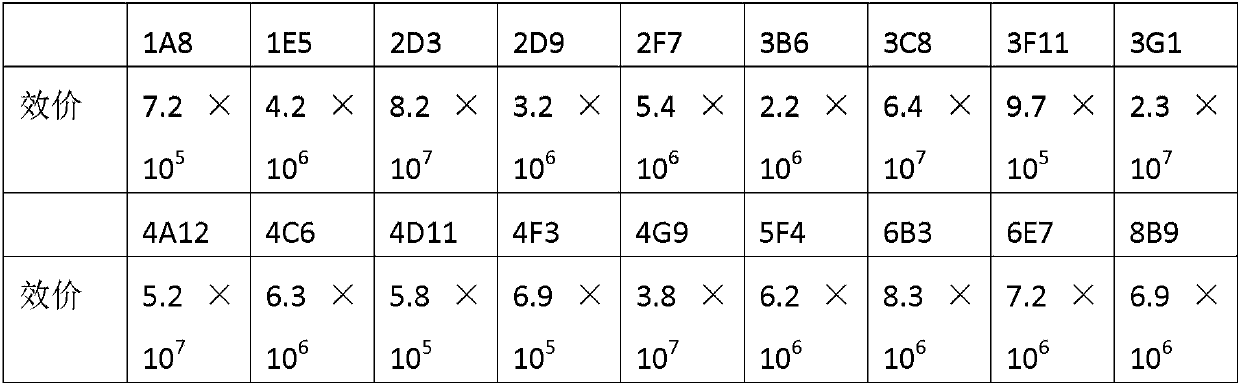

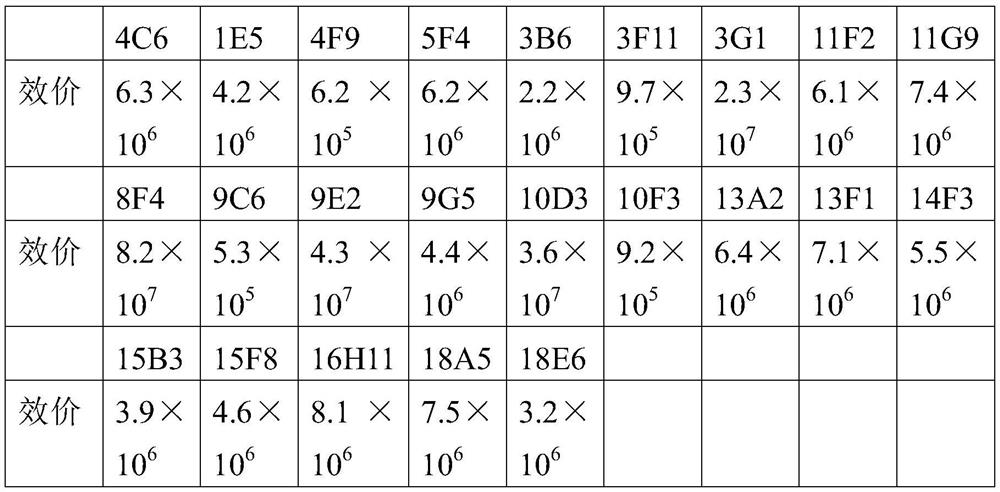

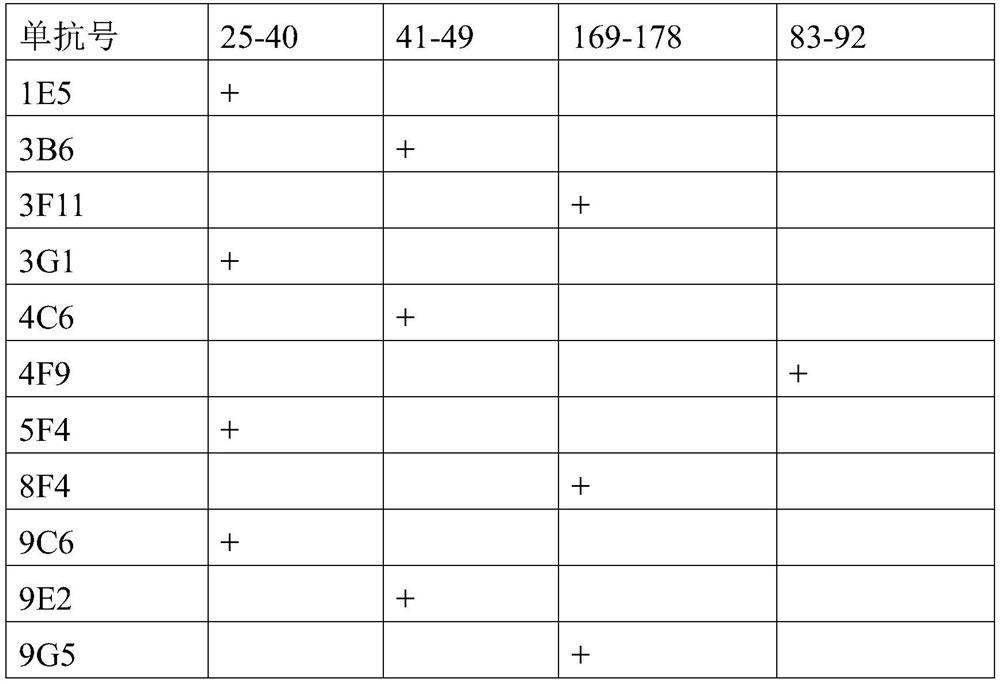

Hypersensitive cardiac troponin I detection method and kit

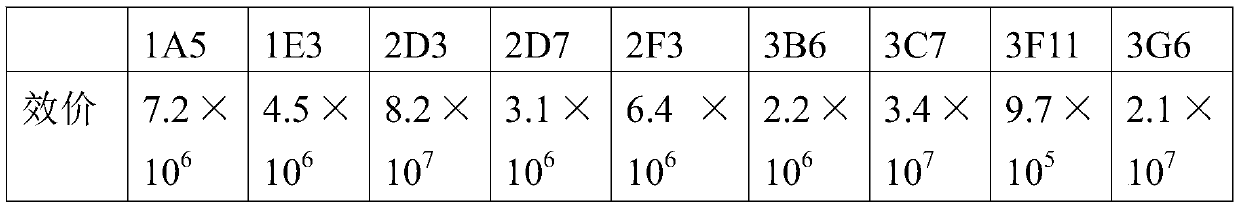

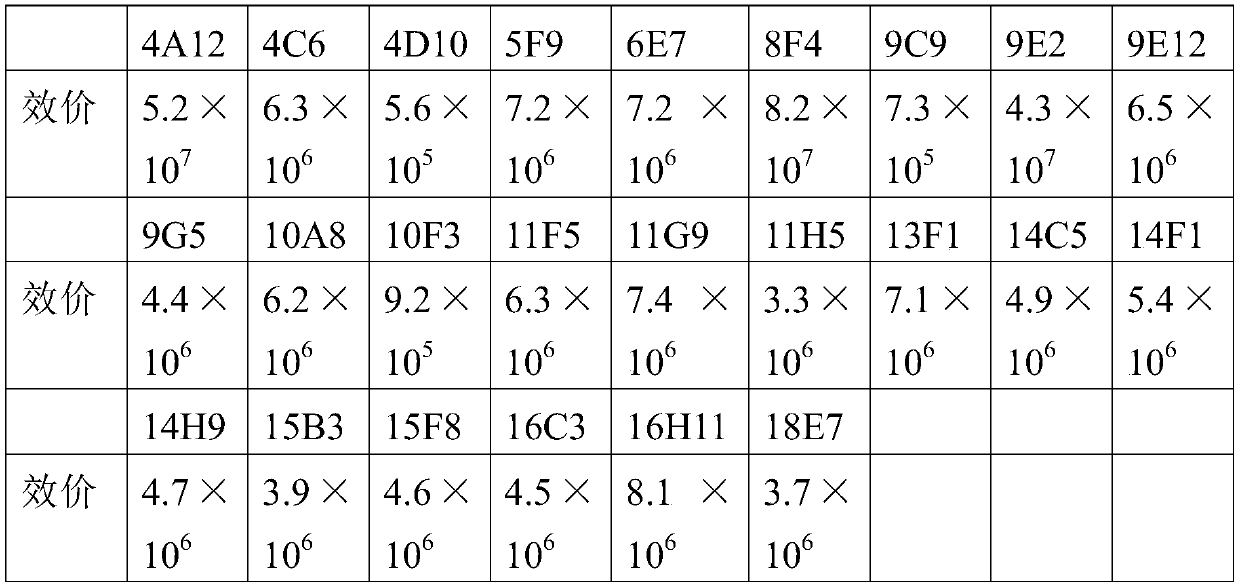

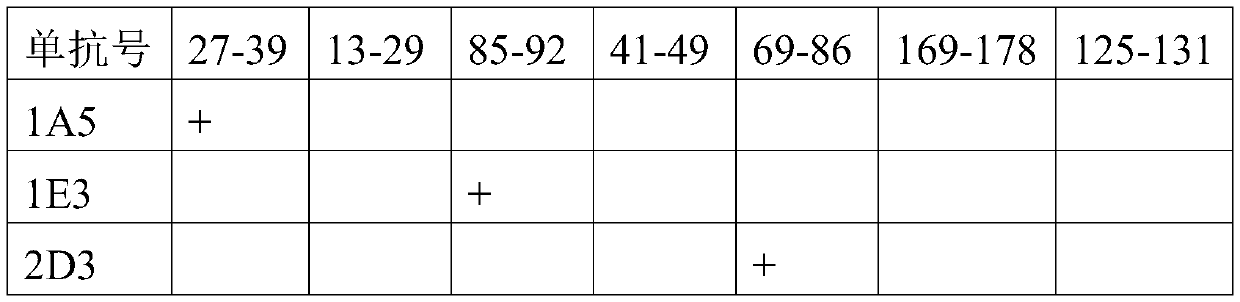

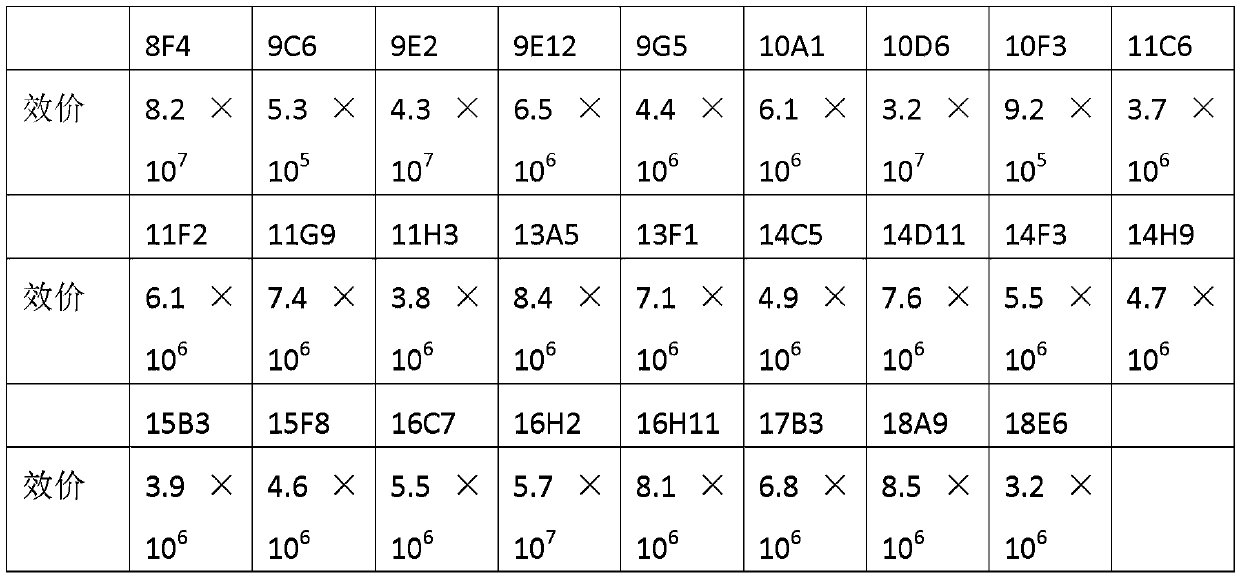

ActiveCN111308084AReduce the risk of missed detectionImprove the detection rateImmunoglobulins against animals/humansDisease diagnosisAntiendomysial antibodiesCardiac muscle

The invention relates to a hypersensitive cardiac troponin I detection method and a kit. The kit comprises a first group of antibodies and a second group of antibodies for detecting cardiac troponin Iin a sample from a subject, wherein the antibodies are selected from antibodies specifically binding to the following amino acid fragments: antibody 1: 13th to 29th sites; antibody 2: 27th to 39th sites; antibody 3: the 41st to 49th sites; and an antibody 4: the 85th to 92nd sites. The method and the kit disclosed by the invention are high in sensitivity and simple to operate, and can be used fordynamically monitoring the cardiac troponin I.

Owner:GUANGDONG WESAIL BIOTECH CO LTD

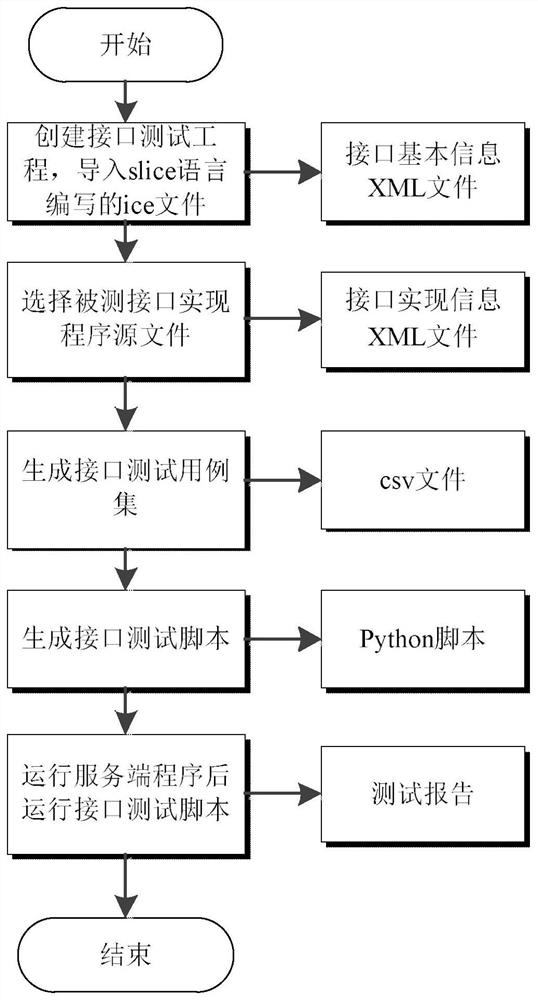

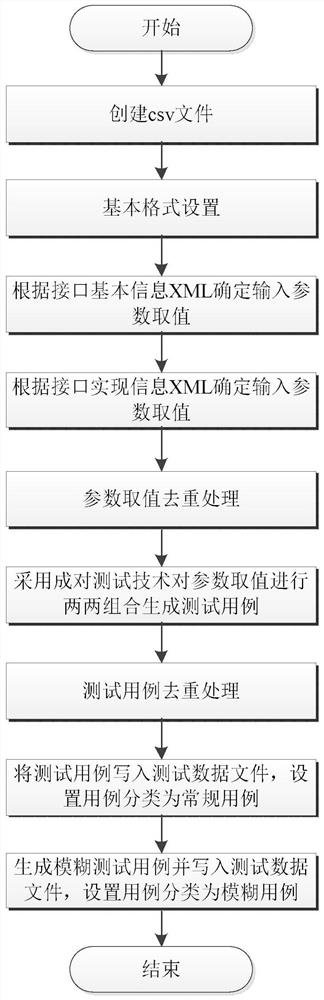

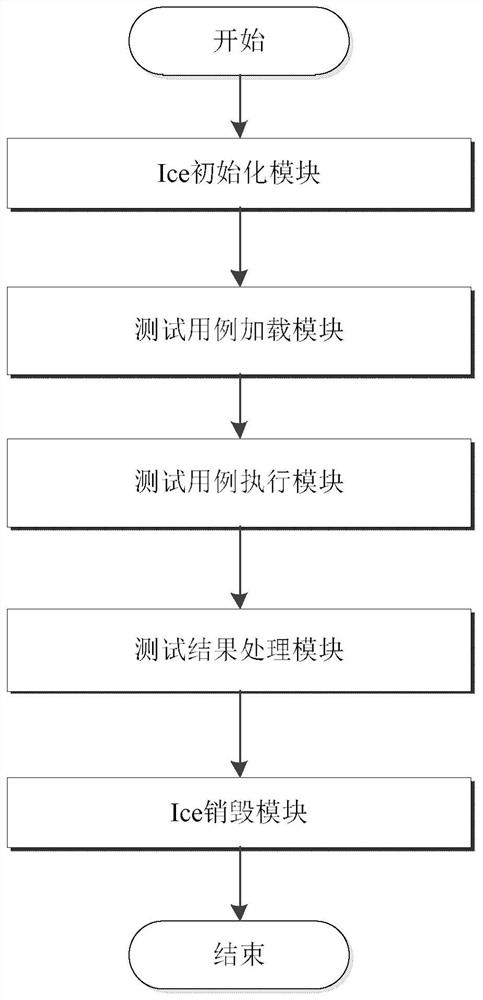

Method for automatically generating Ice interface test case and test script

ActiveCN113419946AImprove execution efficiencyImprove integritySoftware testing/debuggingEnergy efficient computingTest scriptTest quality

The invention discloses a method for automatically generating Ice interface test case and test script. The coverage degree of a test case and the test quality of an ICE interface can be improved. The method is realized through the following technical scheme: establishing an ICE interface test project based on network communication engine ICE communication middleware, importing a slice file to extract interface description information, storing the interface description information in interface basic information XML, creating adapter information and interface implementation information, storing the adapter information and the interface implementation information in the interface implementation information XML, and calling a command to generate a skeleton code; determining an input parameter value through interface basic information and interface implementation information XML, and automatically generating an interface test case set file by adopting equivalence class division, boundary value analysis, logic coverage analysis and pairwise test and fuzzy test technologies; and automatically generating an ICE interface test script according to the ICE interface implementation information XML, running the interface test script after running the server program, automatically completing interface test case execution and generating a test report.

Owner:10TH RES INST OF CETC

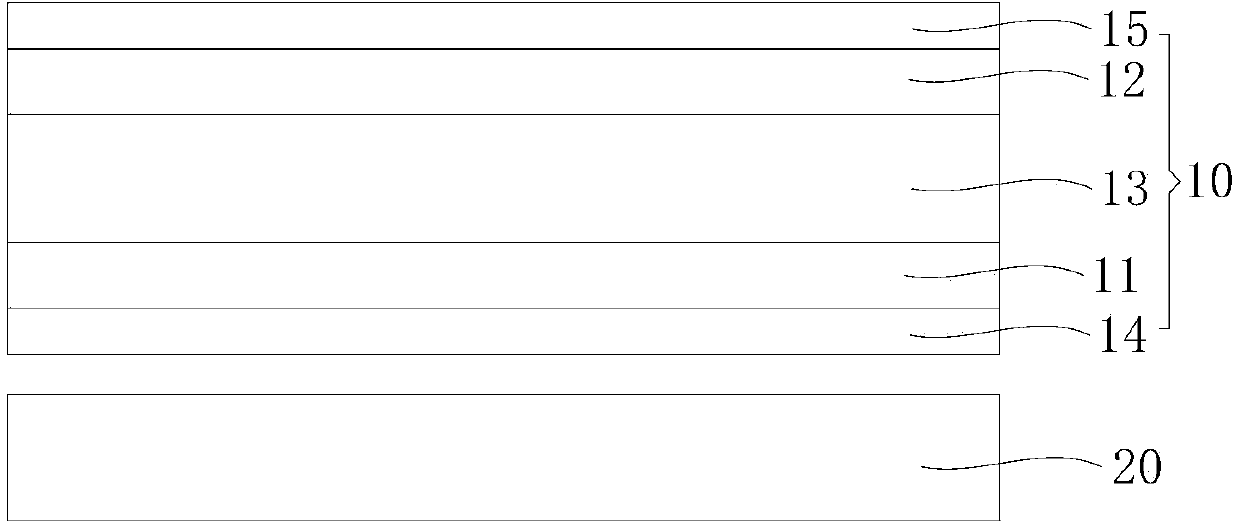

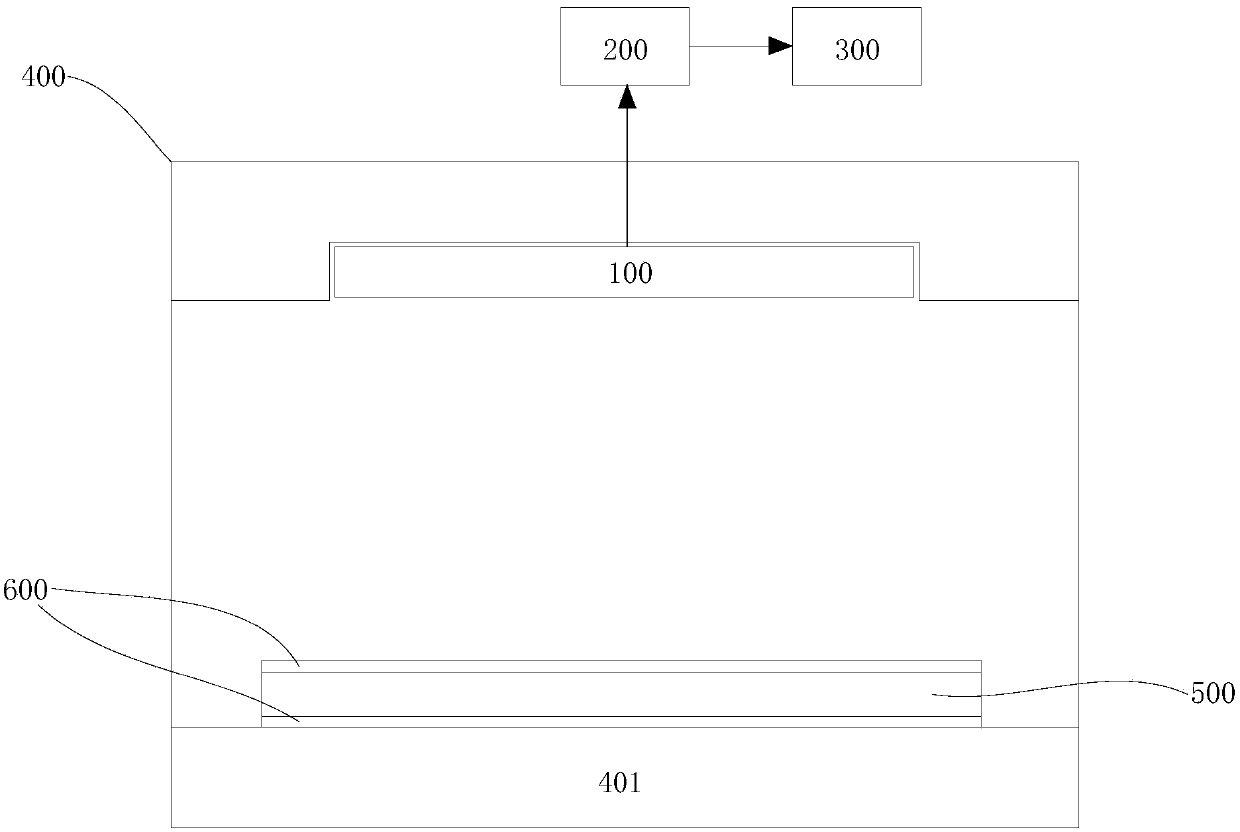

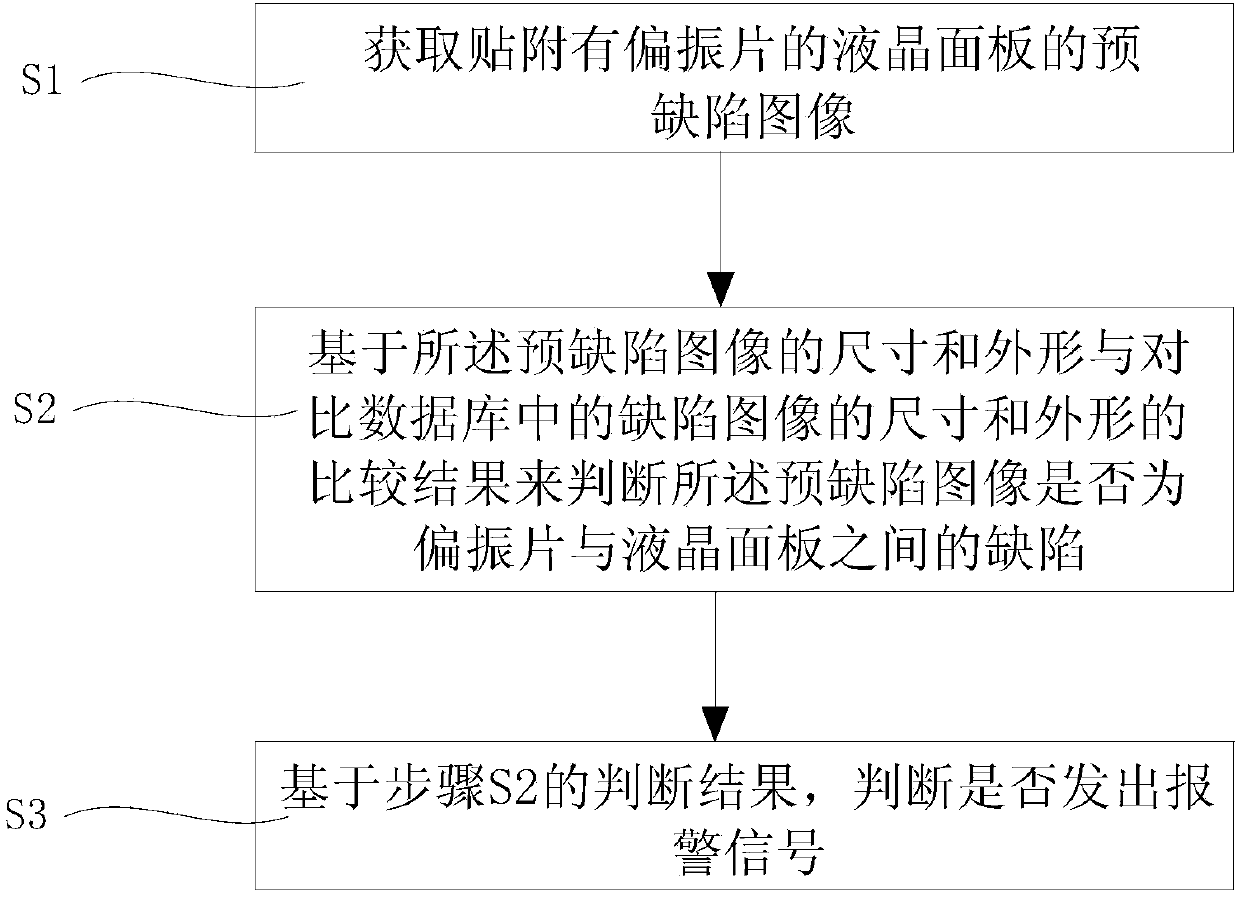

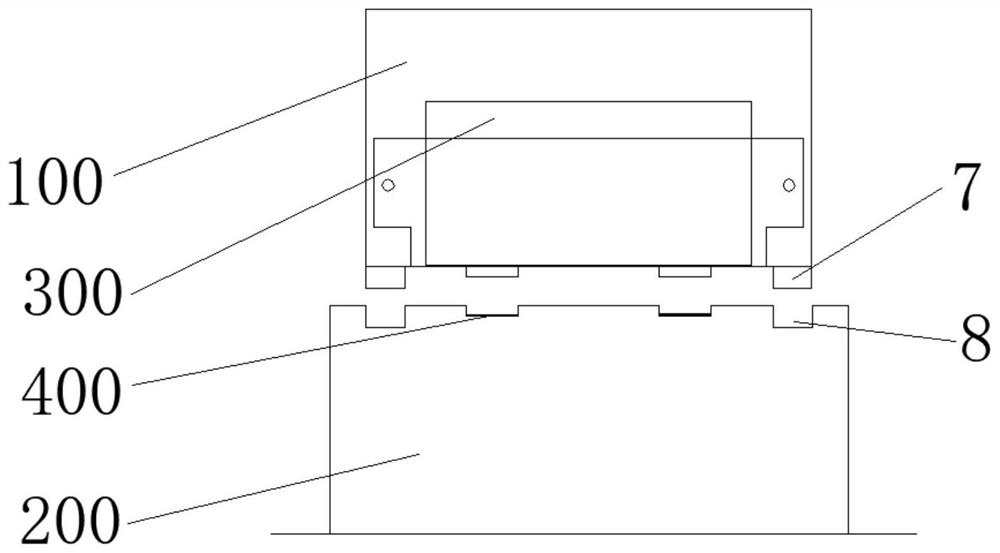

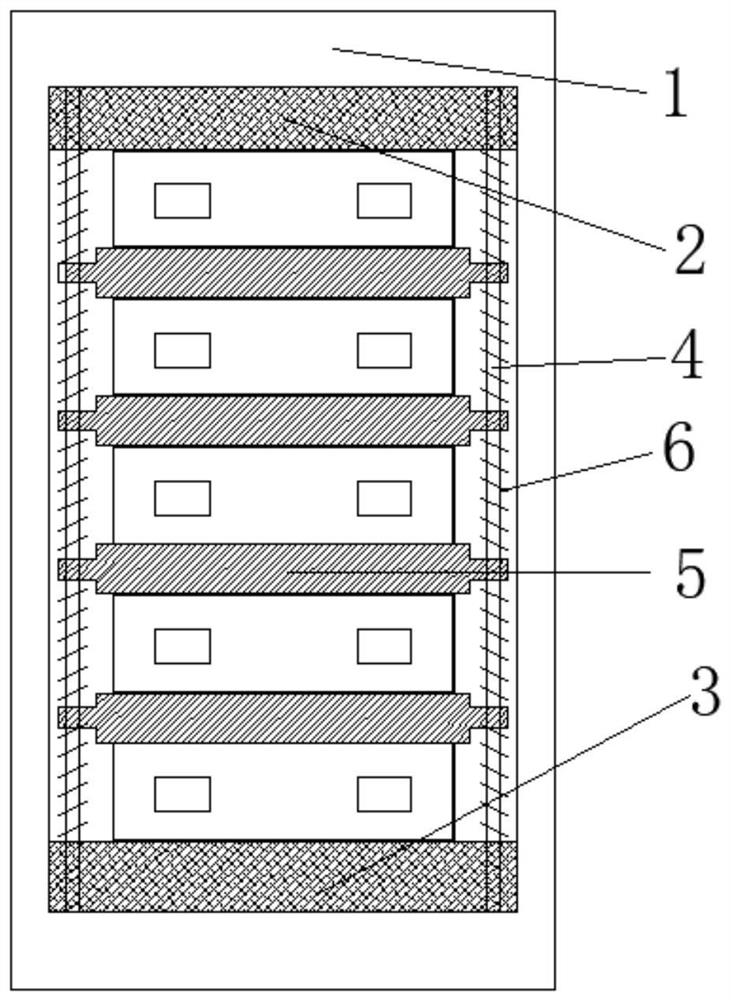

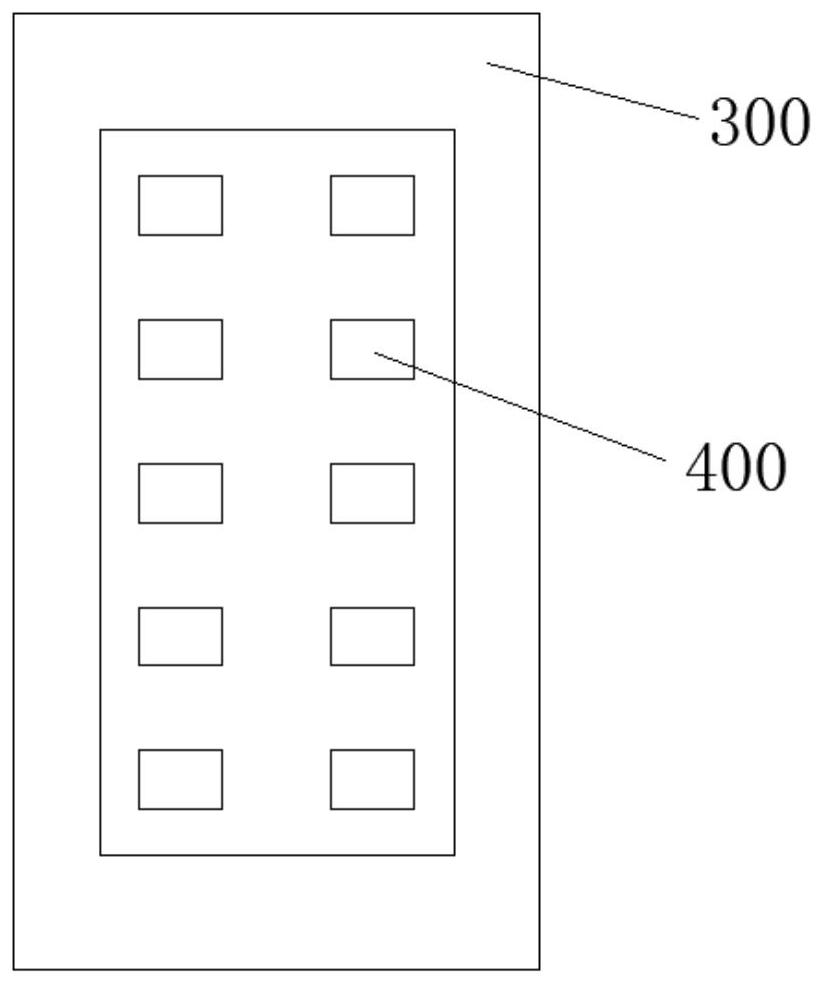

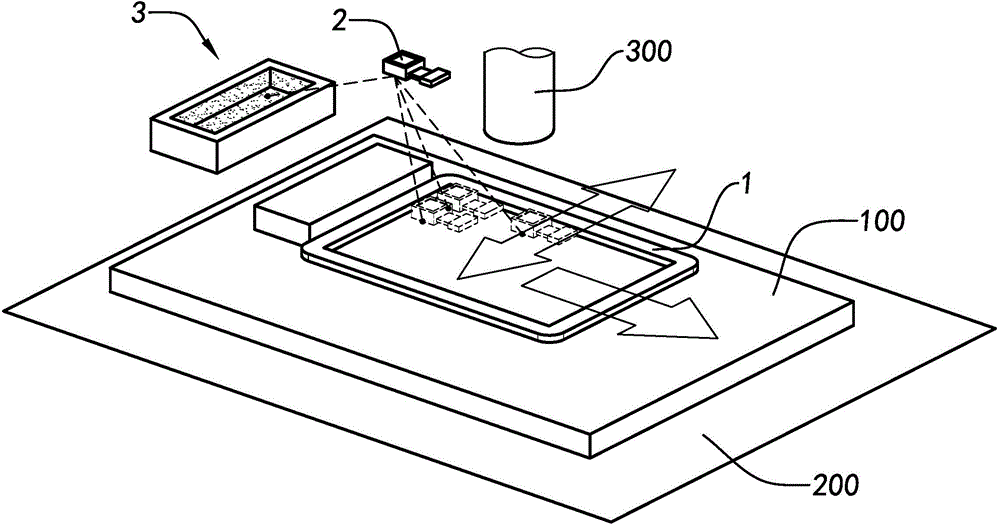

Defect detection device and method for liquid crystal display panel with polarizing film

ActiveCN103439339AReduce the risk of missed detectionImprove attachment qualityOptically investigating flaws/contaminationPolarizerLiquid-crystal display

The invention discloses a defect detection device and a defect detection method for a liquid crystal display panel with a polarizing film. The defect detection device comprises an infrared image input device (100), a signal processing device (200) and a warning device (300), wherein the infrared image input device (100) is used for acquiring and outputting an image of the liquid crystal display panel (500) with a polarizing film (600); the signal processing device (200) is used for acquiring a pre-defect image of the liquid crystal display panel (500) with the polarizing film (600) on the basis of the image of the liquid crystal display panel (500) with the polarizing film (600) and judging whether the pre-defect image is a defect according to comparison results between the size and shape of the pre-defect image and the size and shape of the defect image in a database; the warning device (300) is used for judging whether to send out a warning signal based on a judgment result of the signal processing device (200). According to the defect detection device and the detection method, foreign matters and / or bubbles on the liquid crystal display panel with the polarizing film can be detected in real time, so that the inspection missing risk of the defected liquid crystal display panel is greatly lowered, meanwhile, the production cost is lowered, and the production efficiency is increased.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

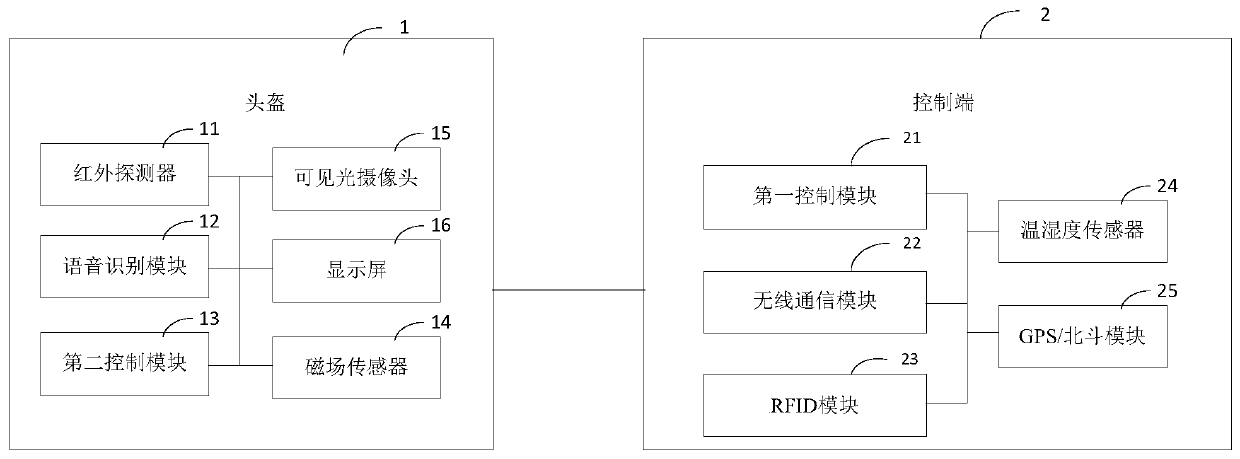

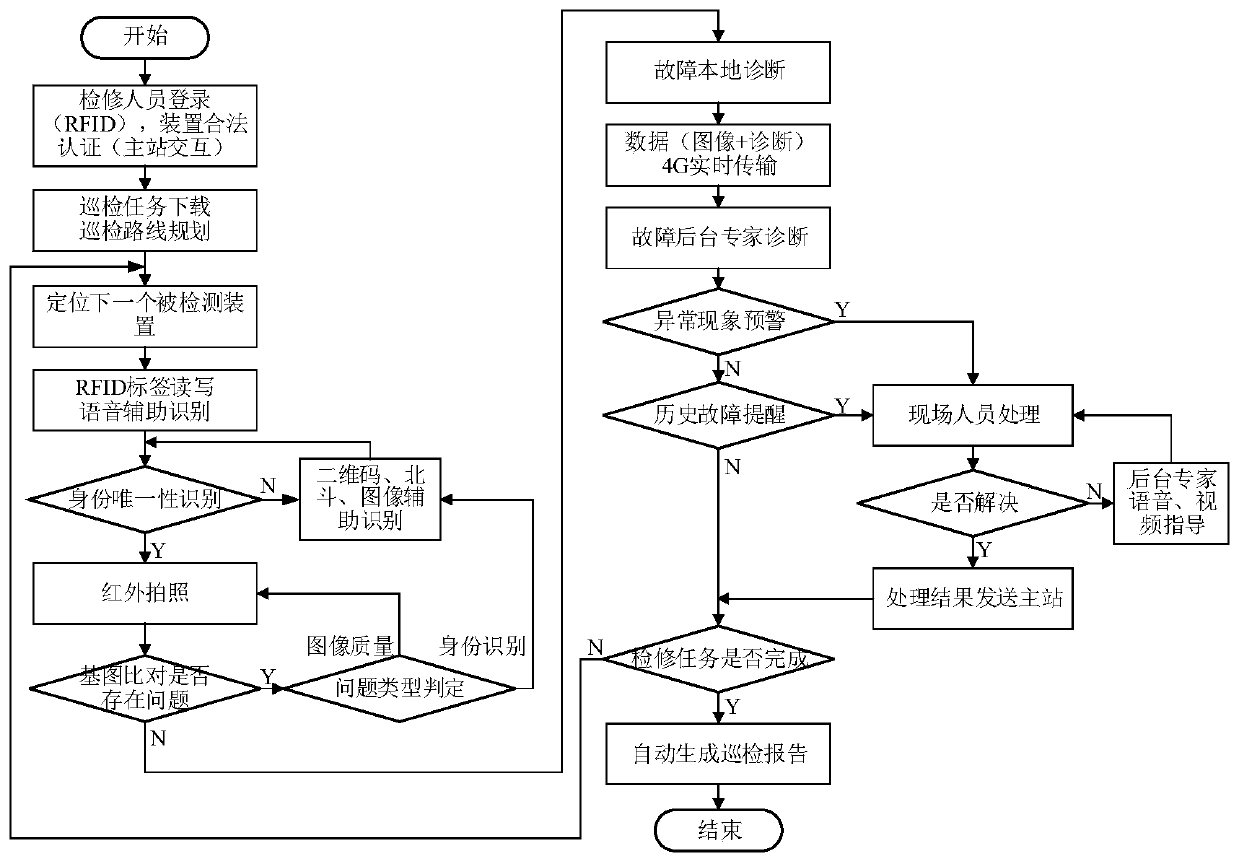

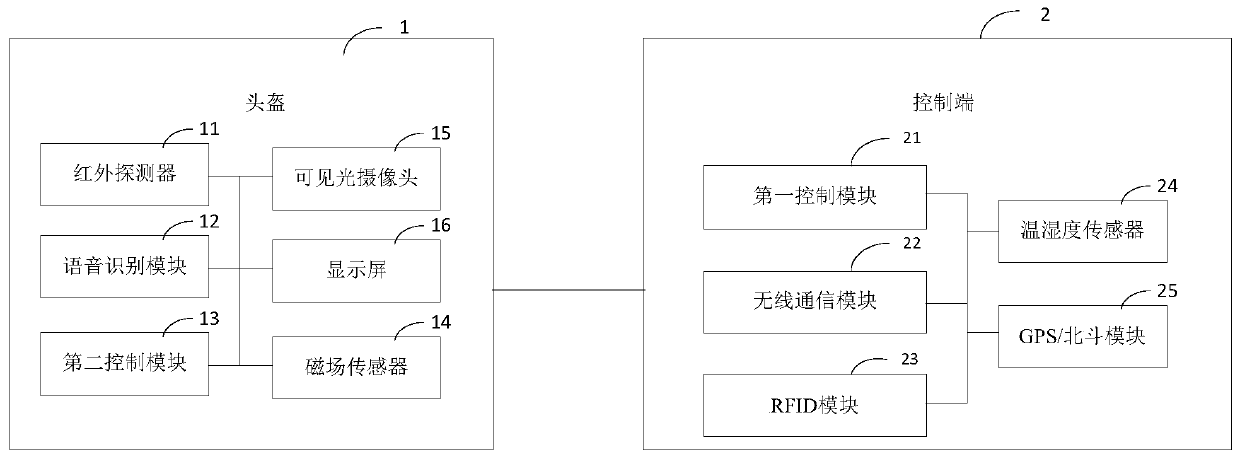

Intelligent inspection device

InactiveCN109982037AImprove accuracyIncrease diversityClosed circuit television systemsAlarmsComputer moduleData acquisition

The invention discloses an intelligent inspection device which comprises a helmet and a control end which are in communication connection. The control end comprises a first control module, a wirelesscommunication module and a radio frequency identification module; the helmet comprises an infrared detector, a voice identification module and a second control module; and after the first control module successfully authenticates the intelligent inspection device and a detector, the wireless communication module receives inspection information sent by a master station; the first control module sends a data acquisition instruction to the helmet after the radio frequency identification module successfully authenticates the detection equipment; the second control module sends an instruction according to the voice data converted by the voice recognition module, and receives and processes the infrared image data transmitted by the infrared detector; and the first control module carries out diagnosis on the processed infrared image data, and sends the diagnosis result and the processed infrared image data. The intelligent inspection device provided by the invention can completely cover an inspection area, and the accuracy and comprehensiveness of data are improved.

Owner:BEIJING SMARTCHIP MICROELECTRONICS TECH COMPANY +3

Driving circuit, display device and detection method by using time schedule controller

ActiveCN111816124AAccurate detectionReduce the risk of missed detectionStatic indicating devicesTime scheduleDisplay device

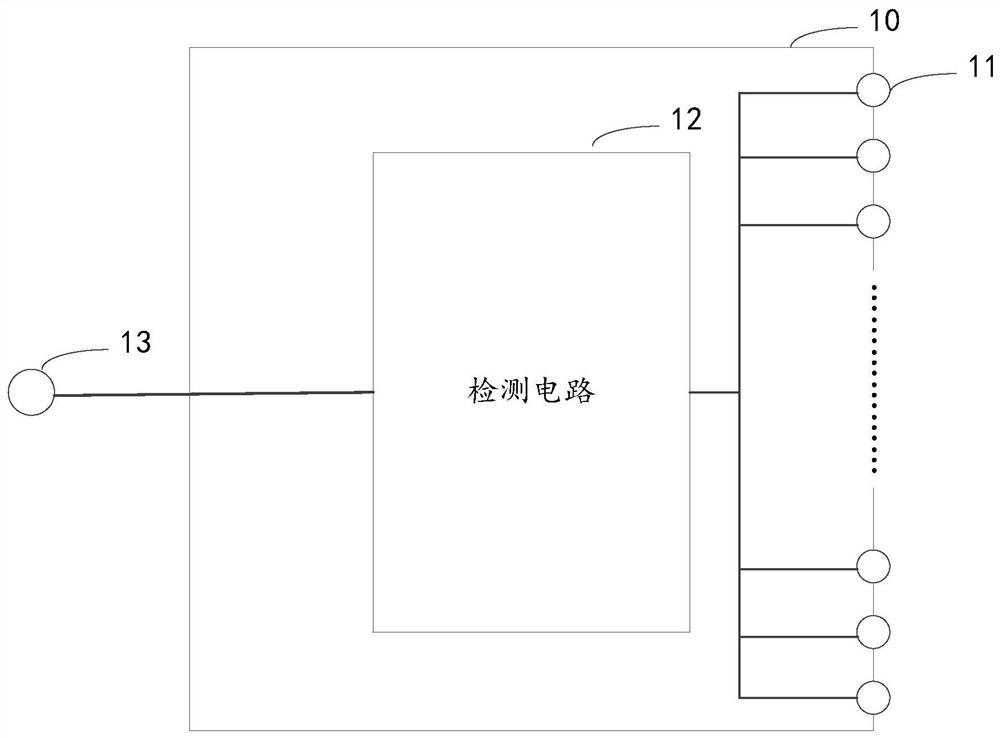

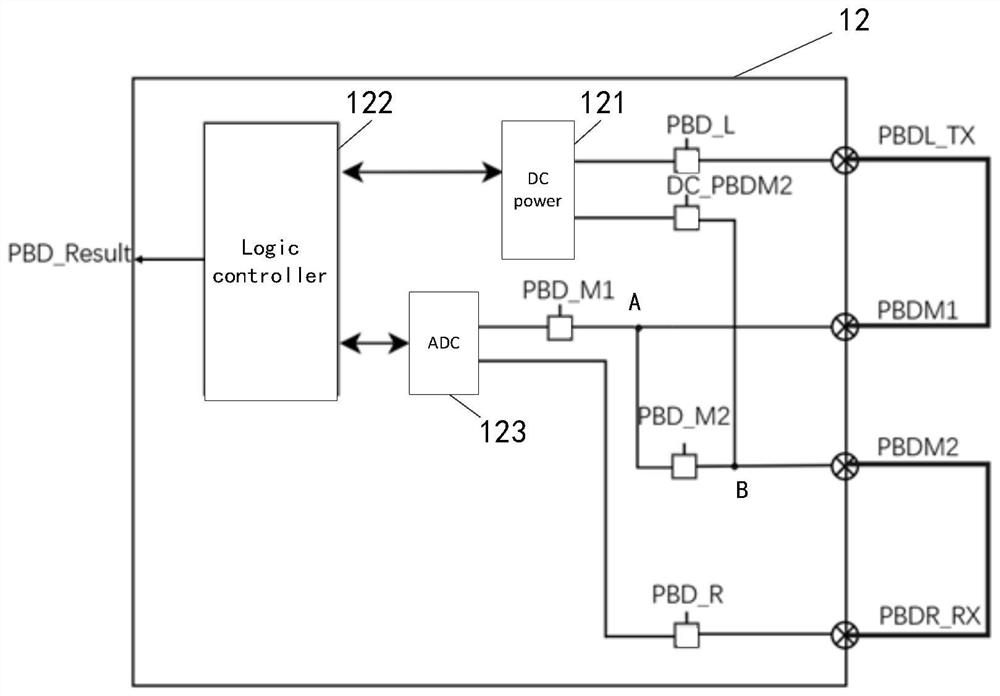

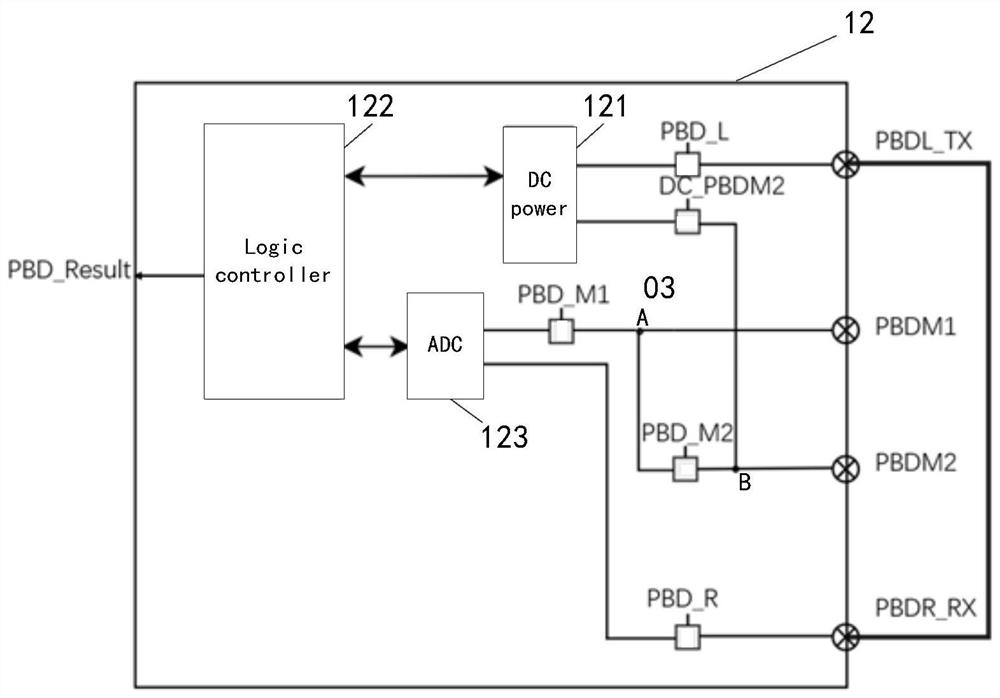

The invention provides a driving circuit, a display device and a detection method by using a time schedule controller. The driving circuit comprises: N pairs of chip pins, wherein each pair of chip pins comprises an input pin and an output pin, after the driving circuit is bound with a display panel through a COF, each pair of chip pins form a path through a pair of connected panel pins on the display panel, and N is a positive integer larger than or equal to 1; a detection circuit which comprises a detection signal generator which is connected with an input pin of at least one pair of chip pins in the N pairs of chip pins and is used for loading a detection signal to the input pin connected with the detection signal generator; and an output node which is directly connected with the outputpin of at least one pair of chip pins in the N pairs of chip pins or indirectly connected with the output pin of at least one pair of chip pins through the detection circuit. The binding condition ofthe display panel can be rapidly and accurately detected.

Owner:HEFEI ESWIN IC TECH CO LTD

Capsule automatic navigation system and navigation method

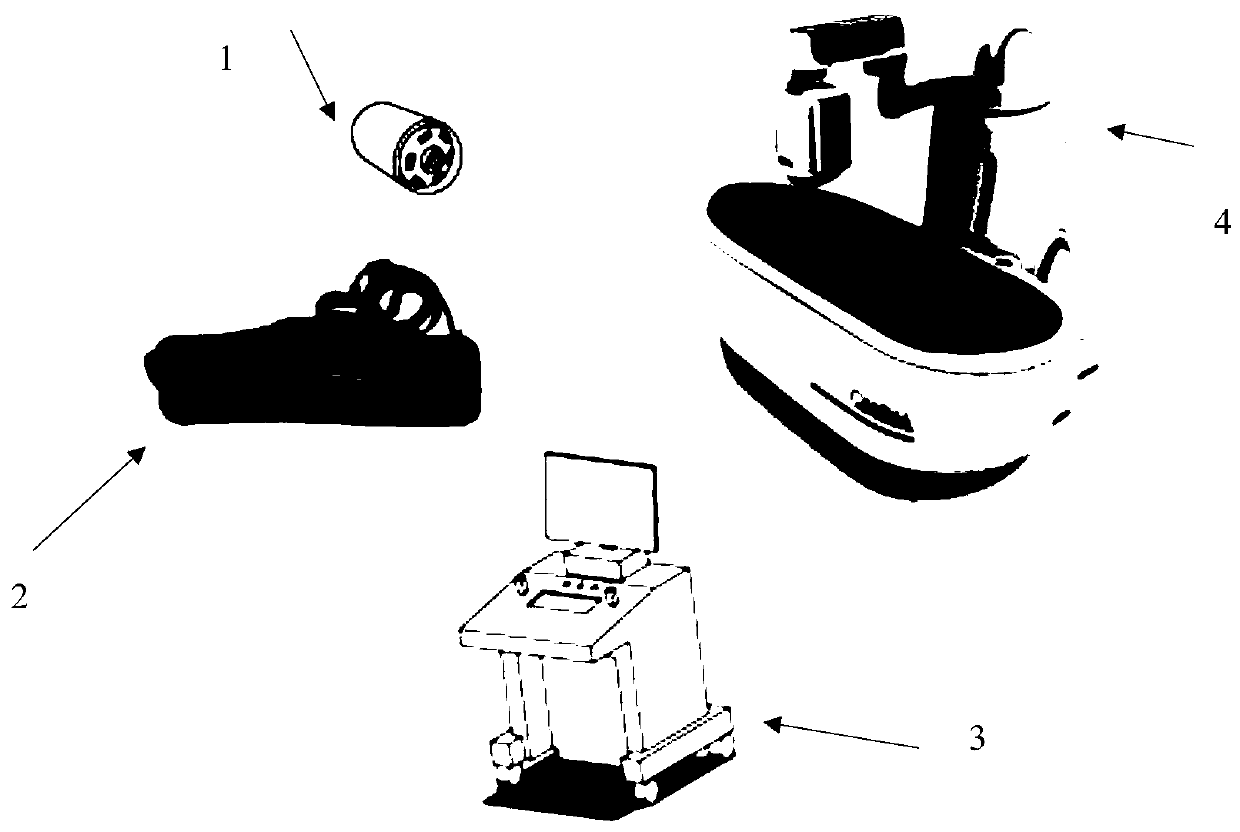

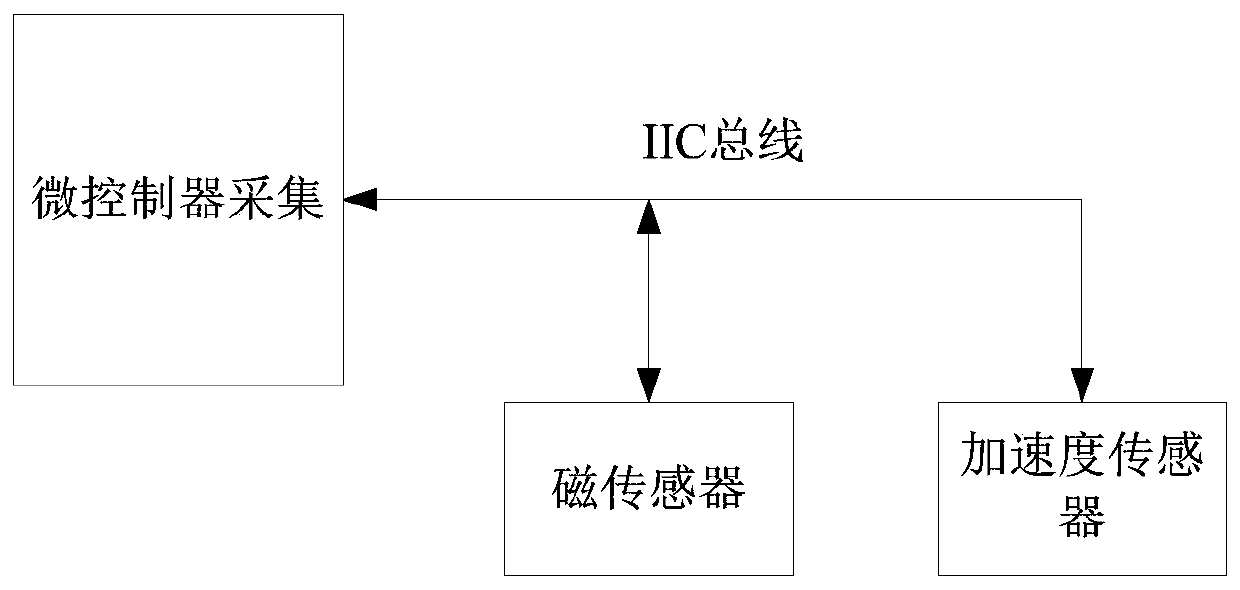

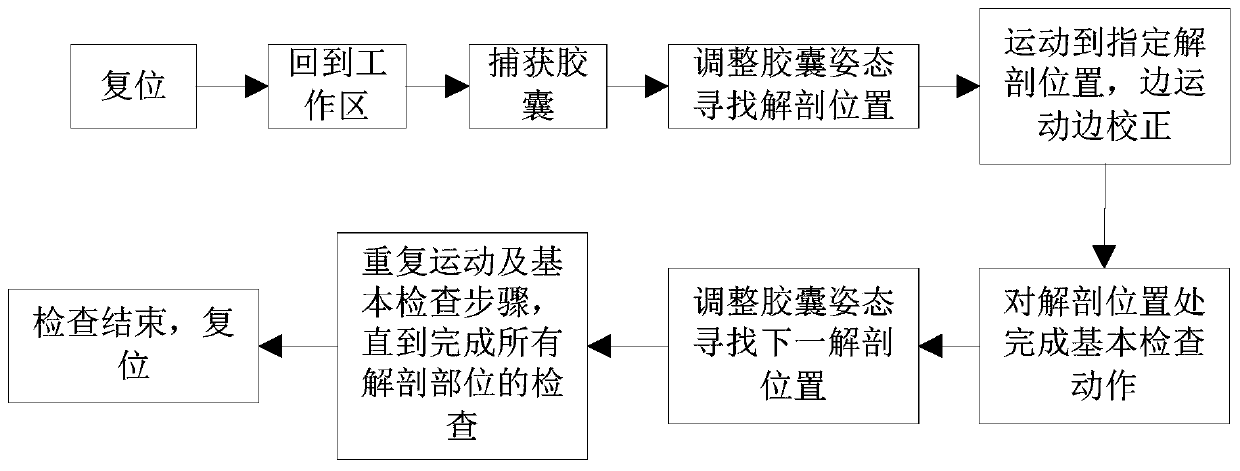

InactiveCN109846444AAutomated auto-navigation checksReduce operational burdenGastroscopesOesophagoscopesMotor driveRobotic arm

The invention discloses a capsule automatic navigation system and a navigation method. The system comprises a capsule endoscope controller, wherein the capsule endoscope controller comprises an automatic inspection control device; the system also comprises a magnetic control device; the automatic inspection control device comprises a capsule capturing module, a capsule posture acquisition module,a capsule image position recognition module and a capsule basic action inspection module; and the magnetic control device comprises a mechanical arm with multiple degrees of freedom, a motor driving the mechanical arm to move and a permanent magnet. The automatic inspection control device captures the capsule position, adjusts the capsule posture, and performs navigation with the capsule image position recognition module. The automatic inspection control device controls the mechanical arm to pull the capsule to move to the designated anatomical position, and completes the inspection at anatomical positions until the automatic inspection of all anatomical positions is completed. The system can automatically realize automatic navigation inspection of the capsule, and greatly reduce the operation burden of a doctor. Meanwhile, the capsule image position recognition module ensures that all anatomical positions are inspected so as to reduce the risk of inspection missing.

Owner:重庆金山医疗技术研究院有限公司

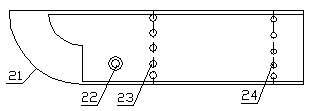

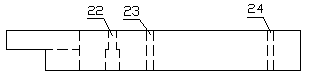

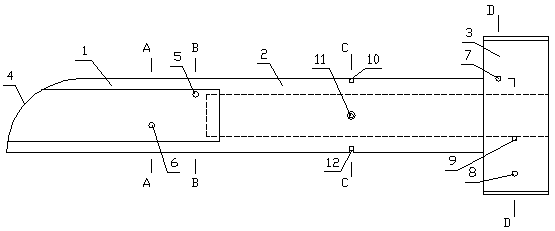

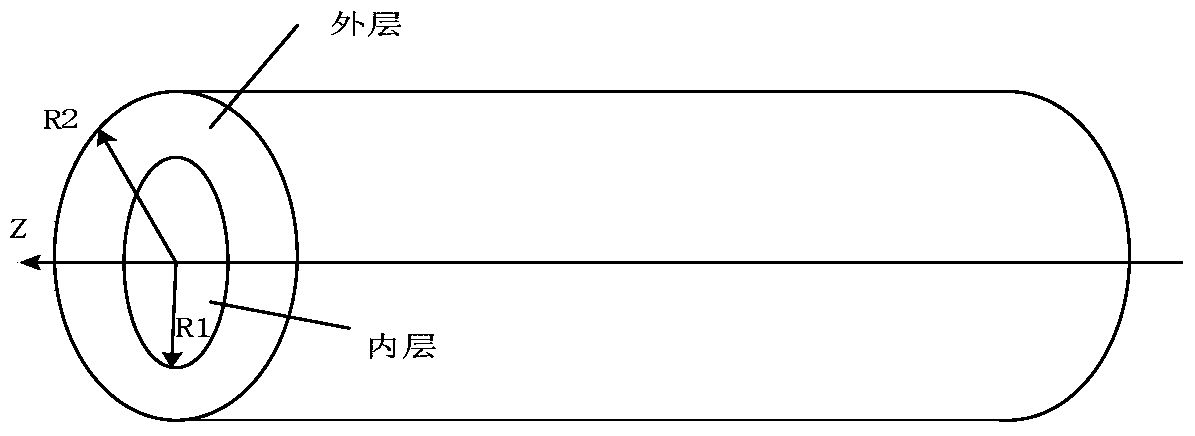

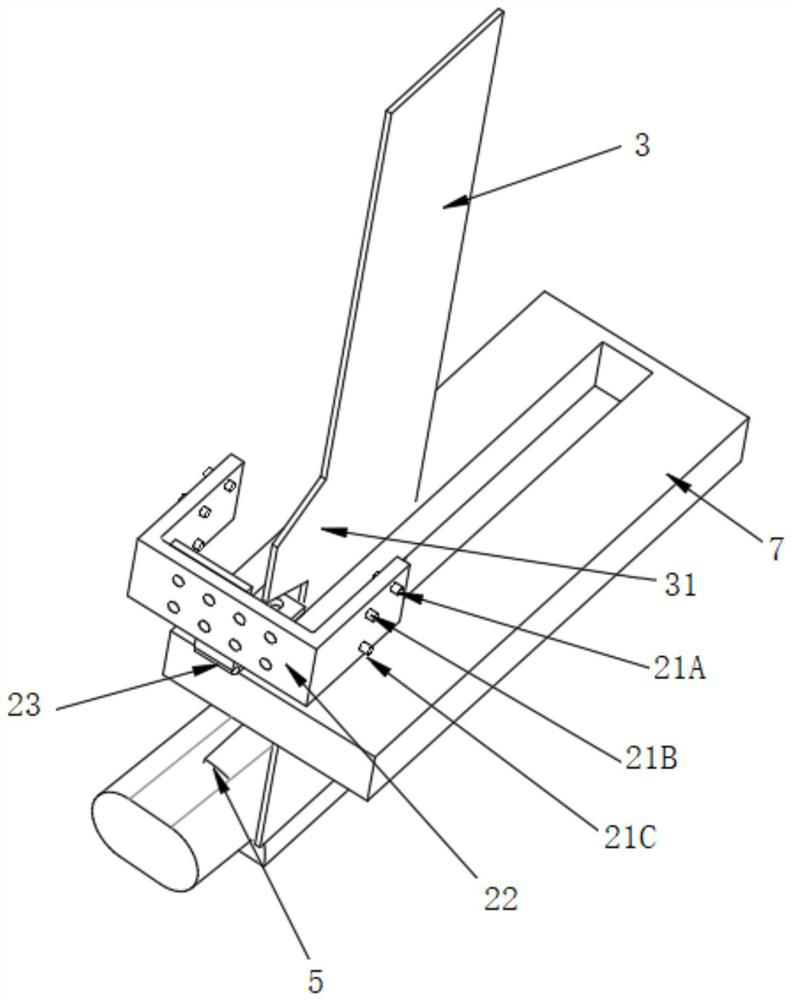

Small-diameter pipe phased array ultrasonic detection comparison test block and detection calibration method using same

PendingCN109946387AImprove accuracyImprove reliabilityAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis using acoustic emission techniquesReflected wavesMechanics

The invention discloses a small-diameter pipe phased array ultrasonic detection comparison test block. The small-diameter pipe phased array ultrasonic detection comparison test block comprises a middle pipe section (2) and calibration sections (1) and (3) at two ends, wherein an arc surface (4) is arranged at an end of each calibration section (1), and a through hole (5) is formed in the end of each calibration section (1); the axis of each through hole (5) is positioned on an extension surface of an inner hole of the middle pipe section (2); two long through holes (7) and (8) and a section ofarc-shaped groove (9) are formed in each calibration section (3); the axis of each long through hole (7) is positioned on an extension surface of an outer circle of the middle pipe section (2); and blind holes (10) and (11) are respectively formed in the outer circle and the inner hole of the middle pipe section (2); and the outer circle of the middle pipe section (2) is also provided with a section of arc-shaped groove (12). The invention also discloses a small-diameter pipe phased array ultrasonic detection calibration method. According to the invention, the influence of the inner wall andthe outer wall of a small-diameter pipe on reflection of an ultrasonic sound beam can be reflected, the consistency of the detection sensitivity of reflected wave at different times is ensured, the accuracy and the reliability of defect quantification are improved, and the risk of missing detection of point defects is reduced.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

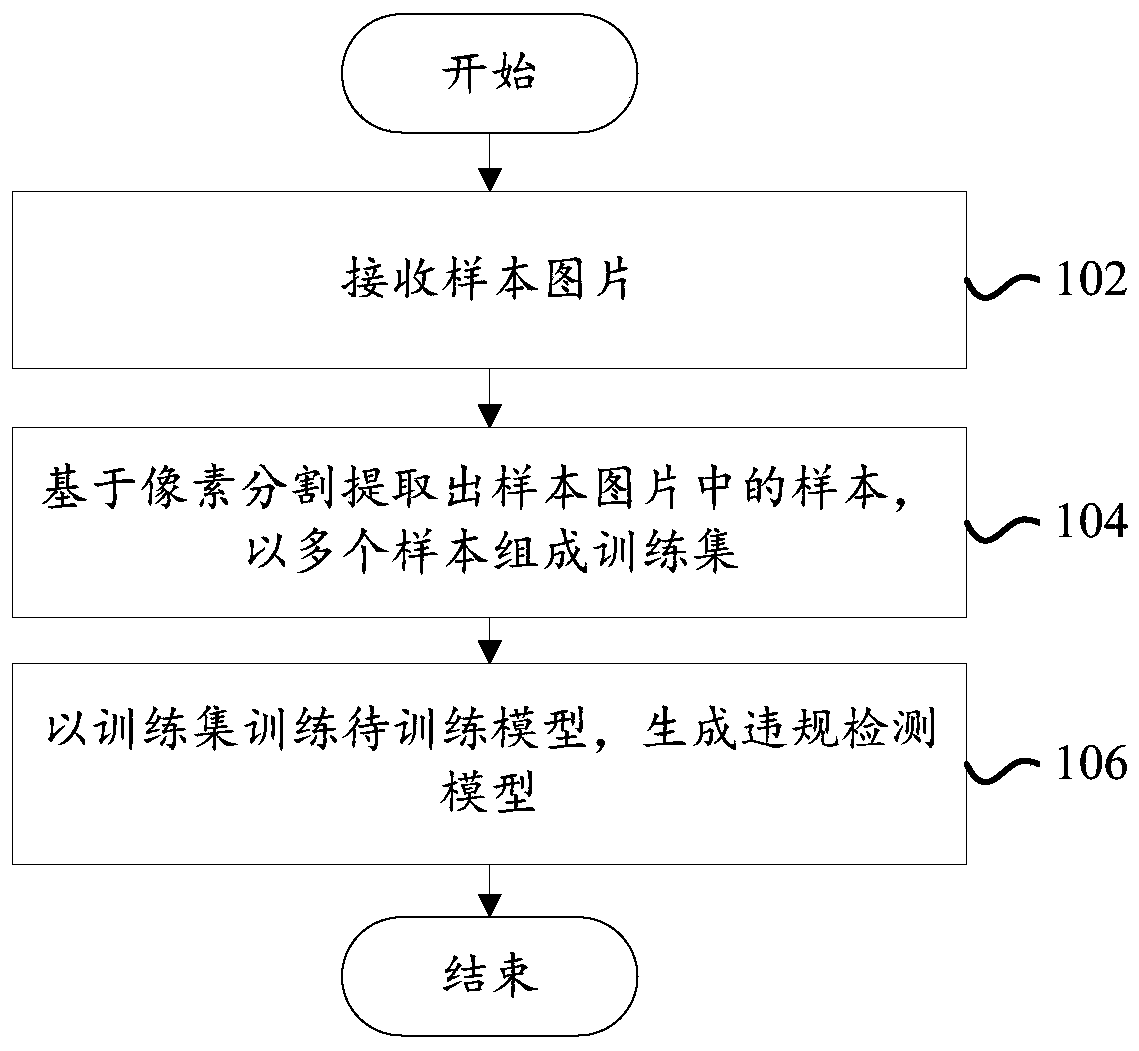

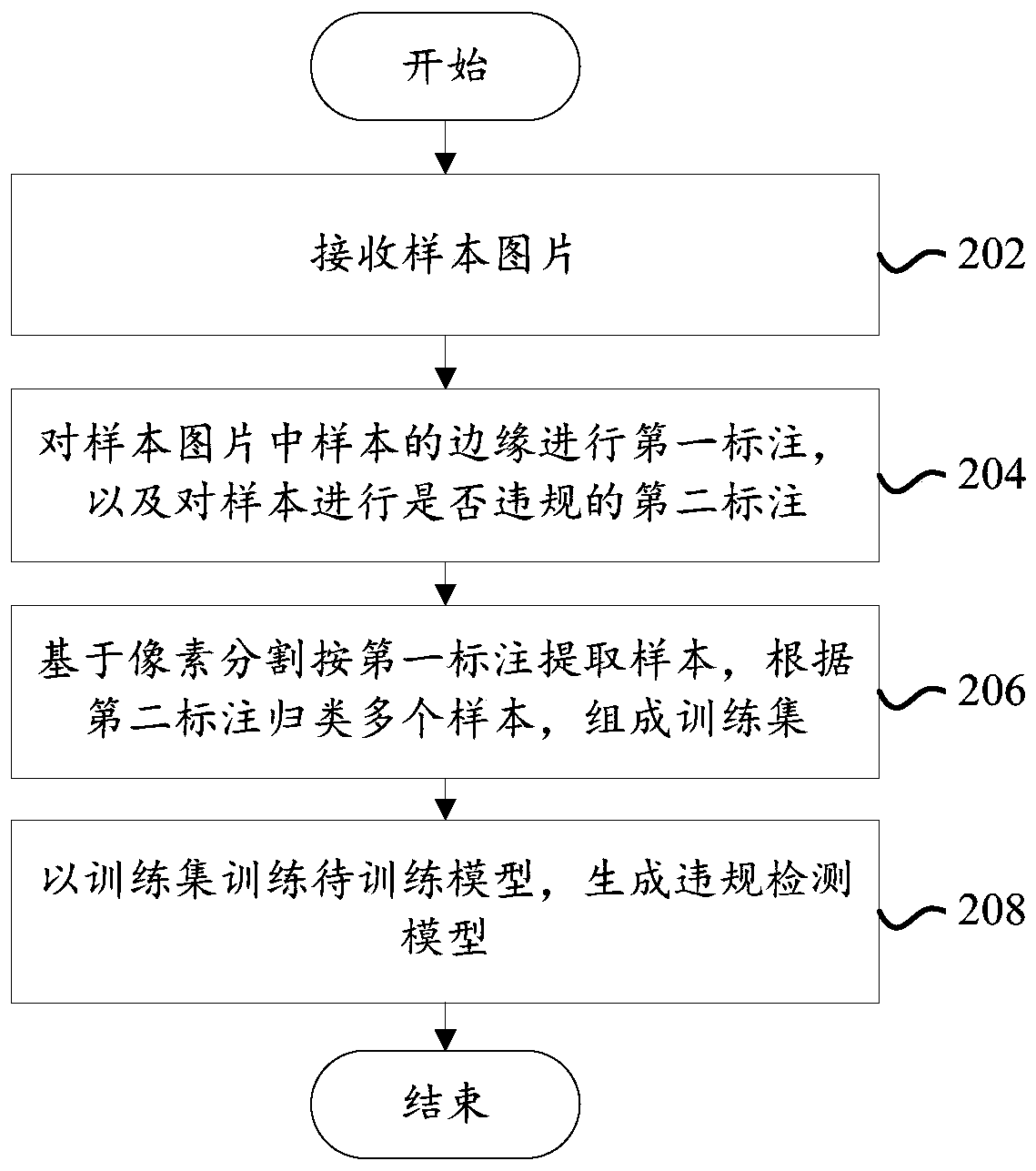

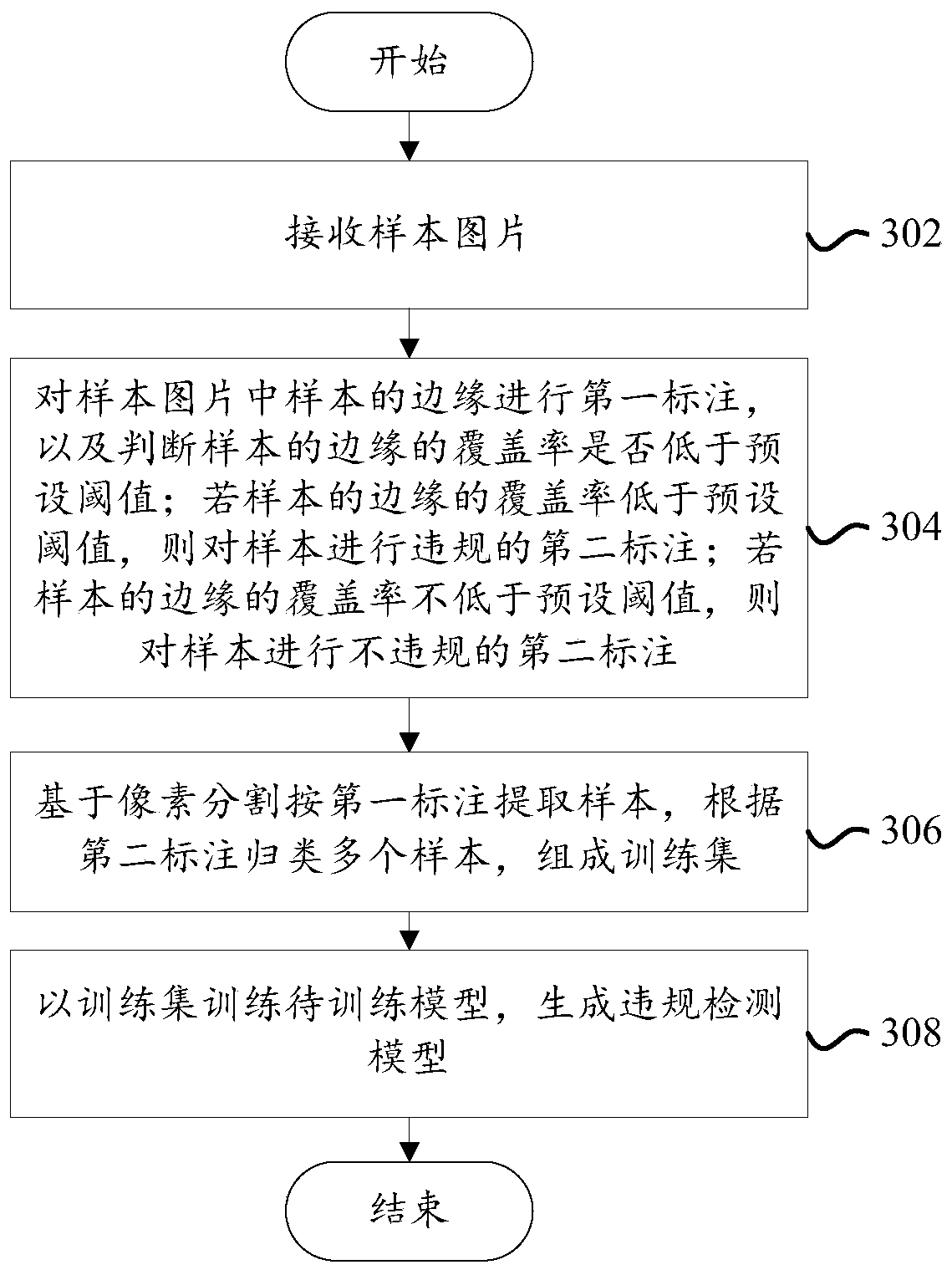

Violation detection model generation method, computer equipment and readable storage medium

PendingCN110321927AAvoid overlapping extractionsPrevent extractionImage enhancementImage analysisBackground informationSample image

According to a first aspect embodiment of the invention, the invention provides a violation detection model generation method, which comprises the steps of receiving a sample picture; extracting samples in the sample pictures based on pixel segmentation, and forming a training set by a plurality of samples; and training the to-be-trained model by using the training set to generate a violation detection model. According to the violation detection model generation method provided by the invention, after the sample pictures are received, the samples in the sample pictures are extracted based on the pixel segmentation technology, so that the samples are extracted according to the contours of the samples, and a training set is formed by a plurality of samples; the to-be-trained model is trainedthrough the training set, the violation detection model is generated, for articles needing to be transported or stored in a covering mode such as coal piles and sand piles, recognition is conducted according to the contours, background information can be prevented from being extracted, overlapping extraction of multiple samples is avoided, the risk of false detection or missing detection is reduced or even avoided, and the accuracy of the detection result is improved.

Owner:ZICT TECH CO LTD

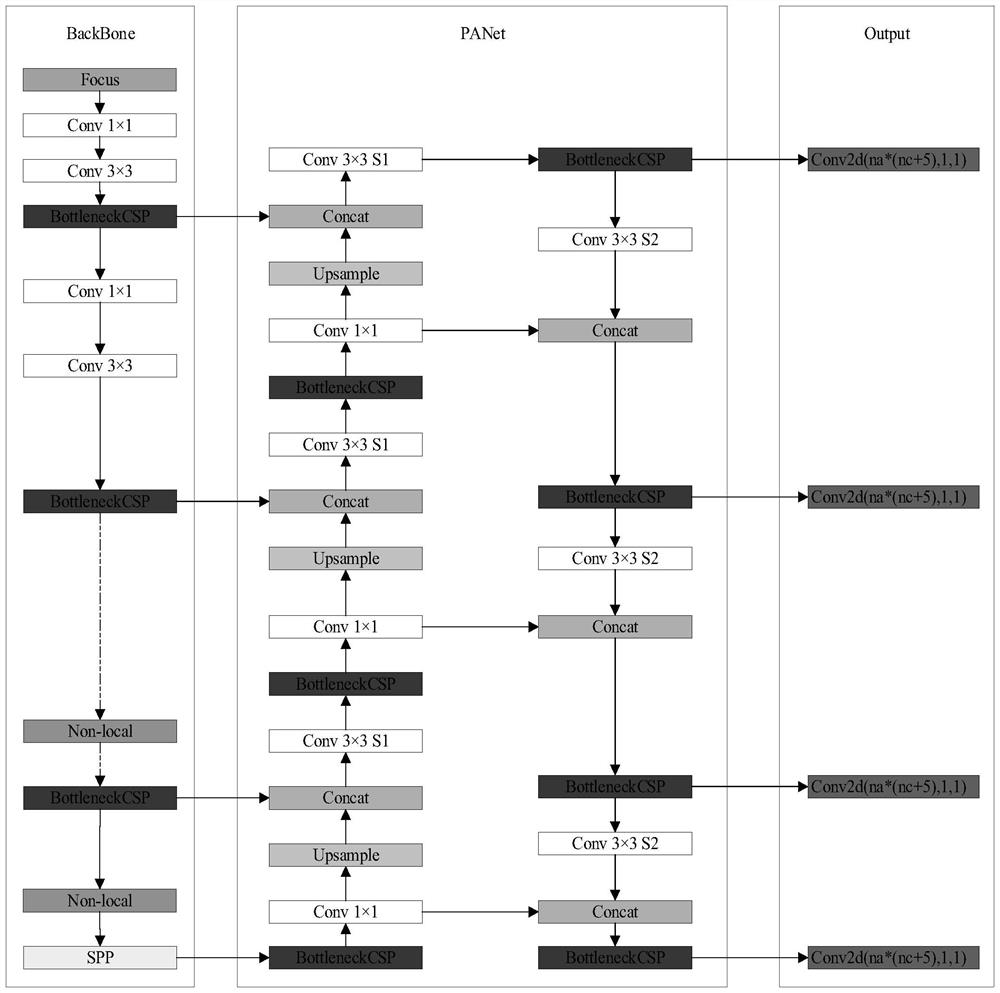

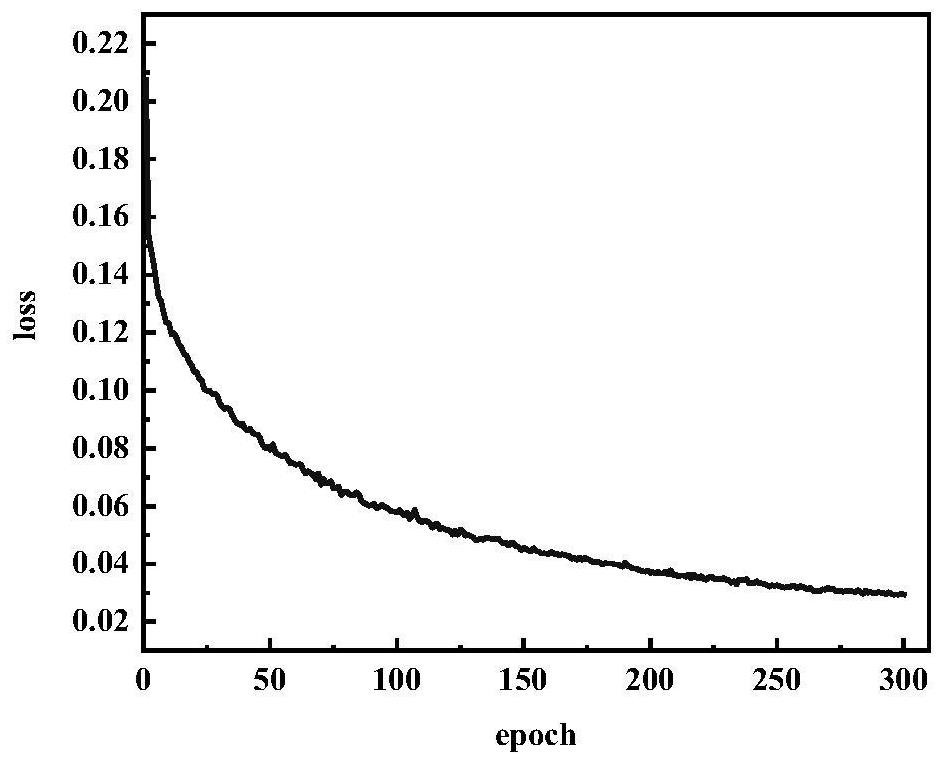

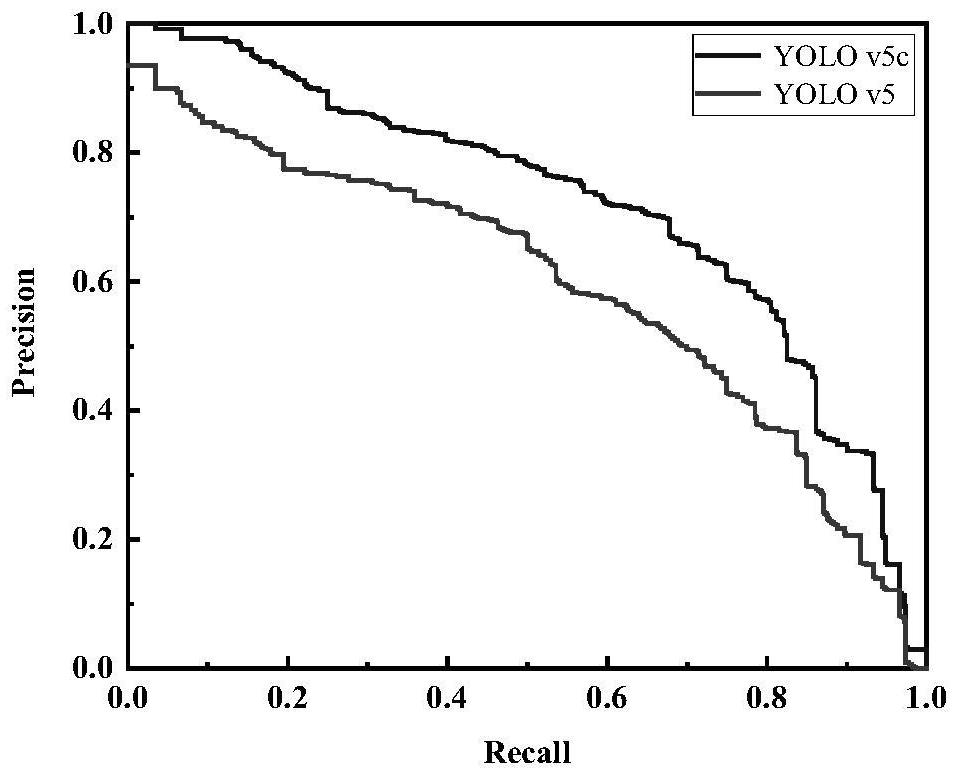

YOLO v5-based attached marine organism type identification method

PendingCN113688948AImprove recognition accuracyEasy to detectCharacter and pattern recognitionNeural architecturesData setAlgorithm

The invention discloses a YOLO v5-based attached marine organism type identification method, which specifically comprises the steps of collecting marine organism attachment pictures to construct a data set, and dividing the constructed data set into a training set, a test set and a verification set; adding 1*1 convolution kernels in front of the first 3*3 convolution layer and the second 3*3 convolution layer of the Backbone of the YOLO v5 algorithm; adding a Non-local attention mechanism module respectively in front of the third BottleneckCSP of the Backbone and in front of the fourth BottleneckCSP of the Backbone; using a CSPNet structure composed of a Bottleneck and a standard convolution layer in the Backbone, and adding a detection layer of Output; introducing a PANet structure in the Neck; and generating an improved YOLO v5 algorithm, and finally, performing training by utilizing a data set, so that the accuracy of identifying the types of the attached marine organisms is higher, a good detection effect on small targets is achieved, the missing detection risk is reduced, and the detection performance of the traditional YOLO v5 algorithm is improved.

Owner:CHINA NUCLEAR IND MAINTENANCE

Hepatitis C virus recombination protein and gene sequence

ActiveCN102321179AReduce the risk of missed detectionAvoid the risk of false positivesHybrid peptidesVector-based foreign material introductionEscherichia coliSingle-Chain Antibodies

The invention discloses hepatitis C virus recombination protein, characterized in that: the hepatitis C virus recombination protein is fusion protein formed by fusing hepatitis C virus main antigenic determinant and hepatitis C virus core protein single chain antibody, and the amino acid sequence is represented as SEQ ID No.1. According to the invention, gene engineering recombination technology is utilized, the hepatitis C virus main antigenic determinant-core protein single chain antibody fusion protein is expressed in escherichia coli system, and the advantages of short production period, high yield and low cost are achieved. The recombination protein can be used as a part of an immunodiagnostic kit for hepatitis C virus.

Owner:杭州博林生物技术有限公司

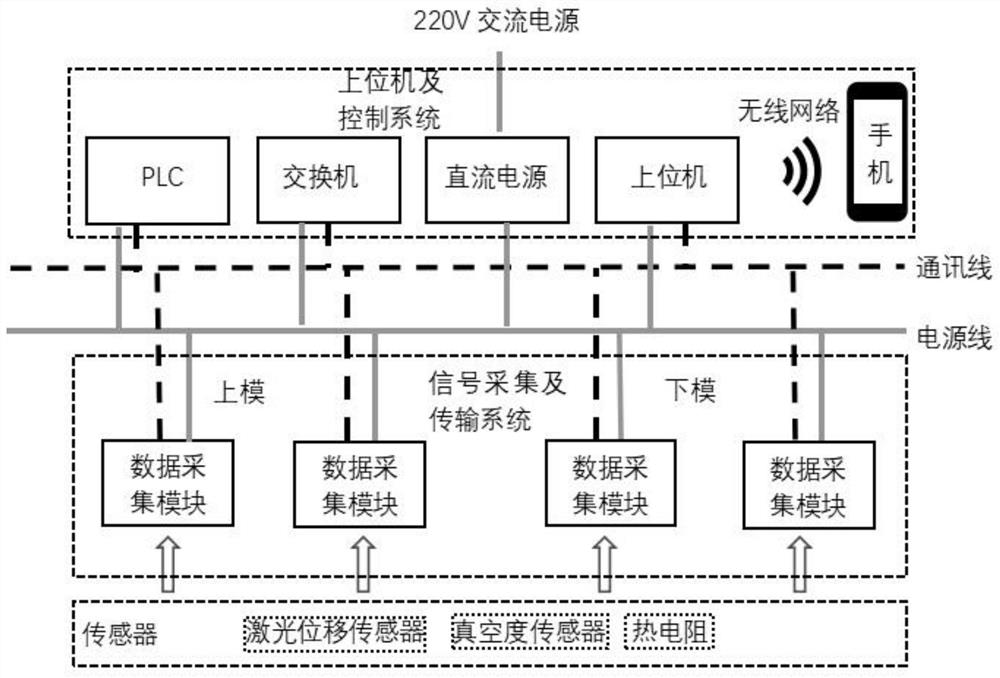

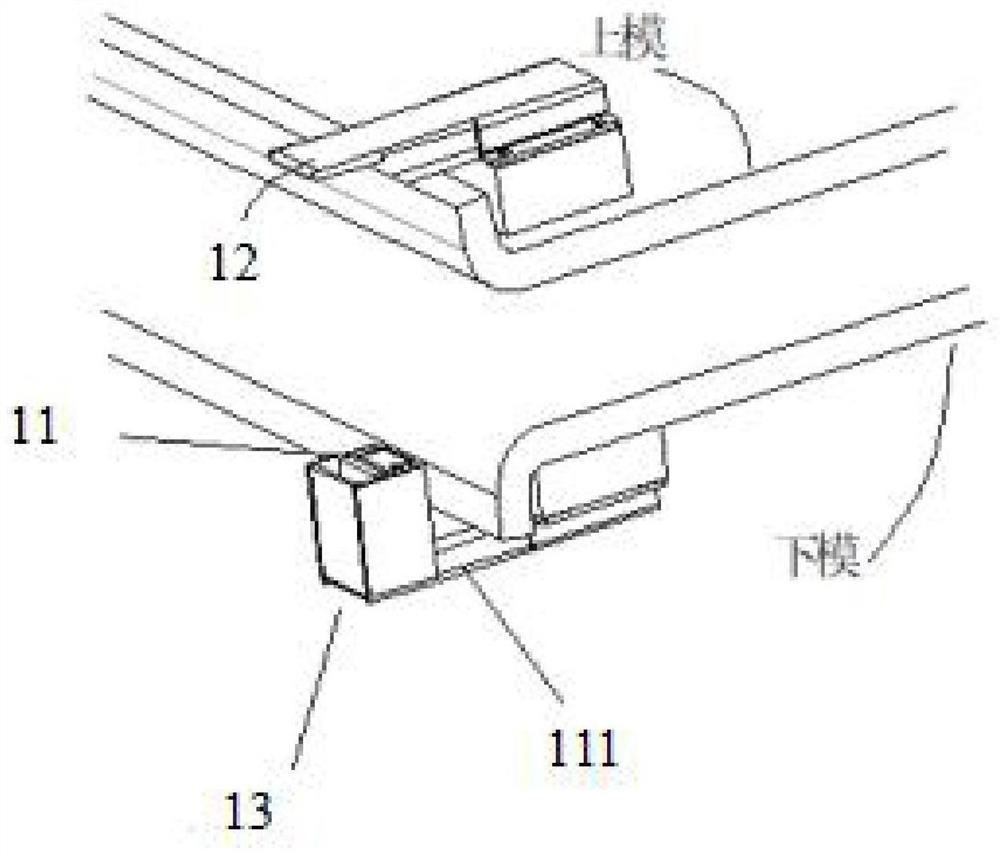

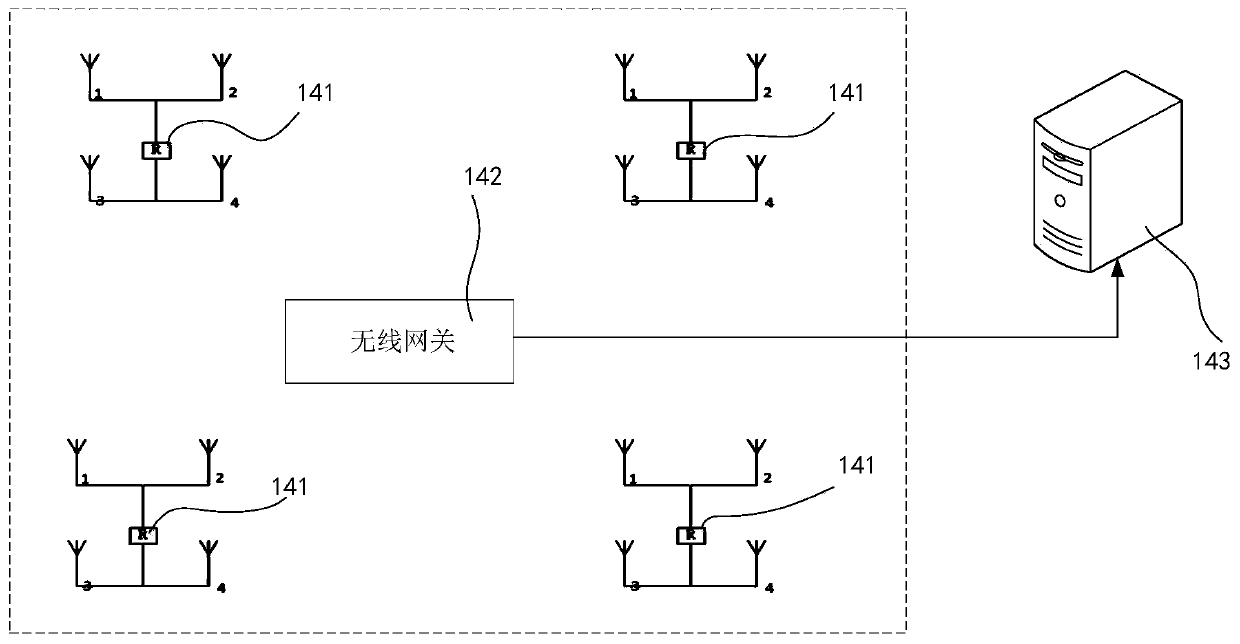

Intelligent monitoring system for wind power blade assembly mold

PendingCN112477195AReduce labor intensityReduce labor costsDomestic articlesControl systemWind power

The invention relates to an intelligent monitoring system for a wind power blade assembly mold. The intelligent monitoring system comprises a sensor, a signal acquisition and transmission system and acontrol system; the sensor comprise a plurality of vacuum degree sensors, a temperature sensor and a plurality of laser displacement sensors, and the laser displacement sensors are used for detectingthe width of a mold closing joint and the axial and chordwise dislocation degree of the mold closing joint; the multiple vacuum degree sensors are respectively installed on vacuumizing pipelines at the rear edge of an upper mold and the rear edge of a lower mold; the temperature sensor comprises a plurality of thermal resistors pre-buried in the surfaces of the upper mold and the lower mold, andthe thermal resistors are uniformly distributed on the whole surfaces of the upper mold and the lower mold; and the upper mold and the lower mold are divided into a plurality of areas, each area is provided with a data acquisition module, each data acquisition module is used for acquiring sensor data of the area nearby and sending the sensor data to an upper computer of the control system, and theupper computer monitors and displays the sensor data in real time. Parameters of the molds are fed back comprehensively, centrally and online, and the production efficiency and the product quality are improved.

Owner:中材科技(邯郸)风电叶片有限公司

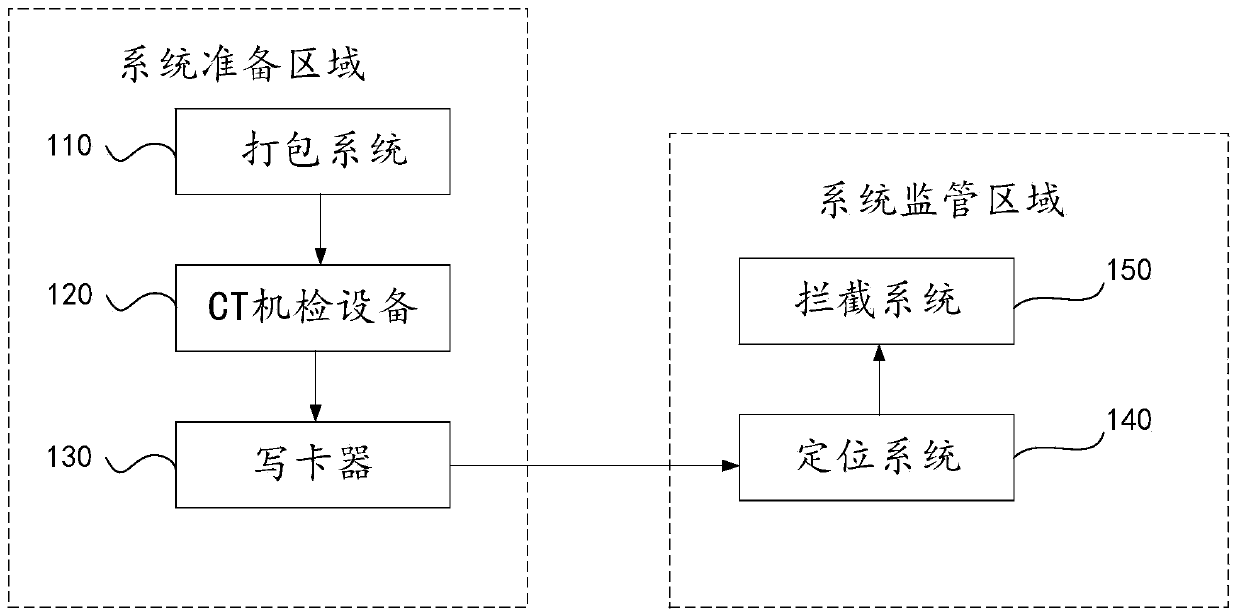

A customs supervision method and system

InactiveCN109785209AImprove inspection efficiencyReduce the risk of missed detectionData processing applicationsCo-operative working arrangementsEngineeringPositioning system

The invention provides a customs supervision method and system, and the system comprises: a packaging system which is used for packaging luggage and is integrated with an RFID tag; The CT machine inspection equipment which is used for scanning each piece of luggage in sequence; The card writer which is used for writing corresponding information into the RFID tag of the corresponding luggage according to the scanning result of the CT machine inspection equipment; The positioning system which is used for positioning the luggage according to the RFID tag on the luggage; And the interception system which is used for intercepting the corresponding baggage according to the information in the RFID tag on the baggage at the exit of the customs. By adopting the technical scheme provided by the embodiment of the invention, missed inspection of articles can be effectively avoided, and the inspection efficiency is improved.

Owner:曾维

Leakage detection device and leakage detection method for lithium ion battery

PendingCN113218589ASimple structureEasy to useDetection of fluid at leakage pointEngineeringWeld seam

The invention provides a leakage detection device for a lithium ion battery, which comprises a loading disc structure, a battery is loaded on the loading disc structure, the loading disc structure is detachably mounted on a test platform, a test hole corresponding to the battery is formed in the test platform, and test paper is arranged in the test hole. The loading disc structure loaded with the battery is mounted on the test platform after being positively mounted or turned over, so that the battery is in contact with and clings to the test paper after being inverted, and the test paper is used for detecting whether a leak hole exists in a welding seam of the battery to cause electrolyte leakage or not. The leakage detection device is used for conveniently, quickly and efficiently screening the lithium ion batteries subjected to laser welding and screening the unqualified lithium ion batteries with leakage holes in welding seams, so that the risk of combustion or explosion caused by electrolyte leakage is avoided.

Owner:湖南领湃科技股份有限公司 +4

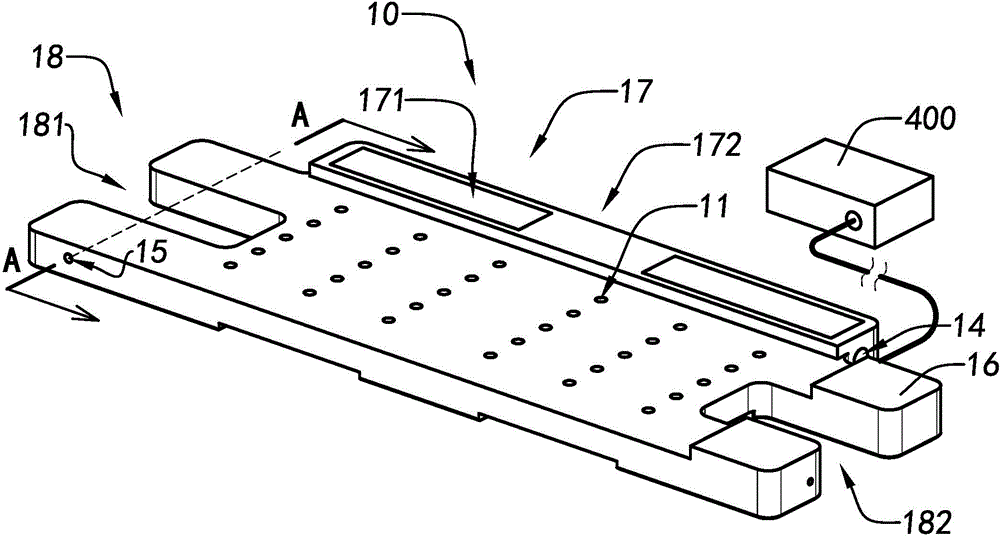

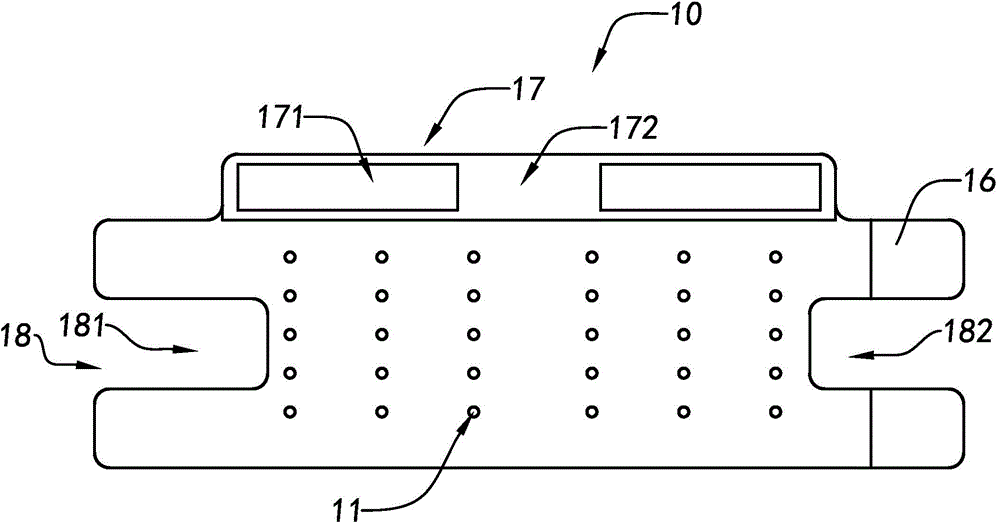

Vacuum auxiliary examination tool and manufacture method for the same

ActiveCN106034198AReduce detection adjustment processCheck levelTelevision system detailsColor television detailsEngineeringMobile phone

The invention discloses a vacuum auxiliary examination tool and a manufacture method for the same. The vacuum auxiliary examination tool comprises a tool main body; the tool main body has at least one vacuum suction hole; the vacuum suction hole is communicated with a vacuum generator in order to absorb and fix a workpiece to the tool main body; the vacuum auxiliary examination tool is further provided with a limitation groove for positioning, and operation grooves and a broken hole for convenient usage. The vacuum auxiliary examination tool can stably fix a detection workpiece in a mobile phone shooting module and guarantees the flatness of the workpiece.

Owner:NINGBO SUNNY OPOTECH CO LTD

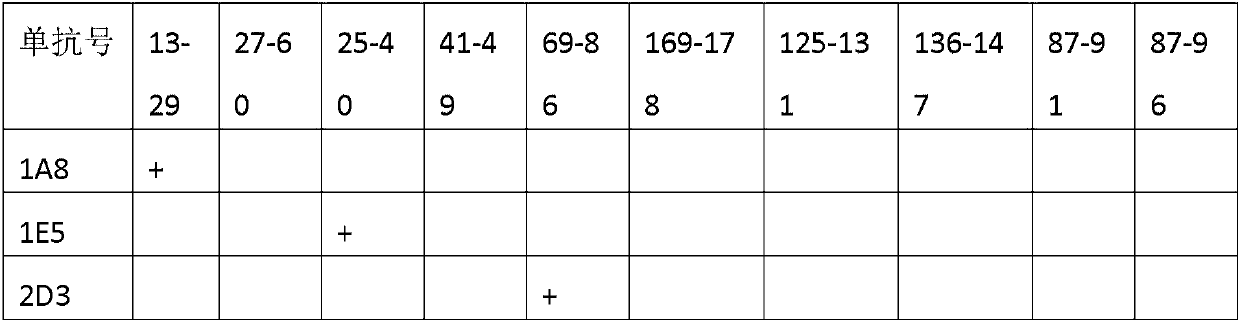

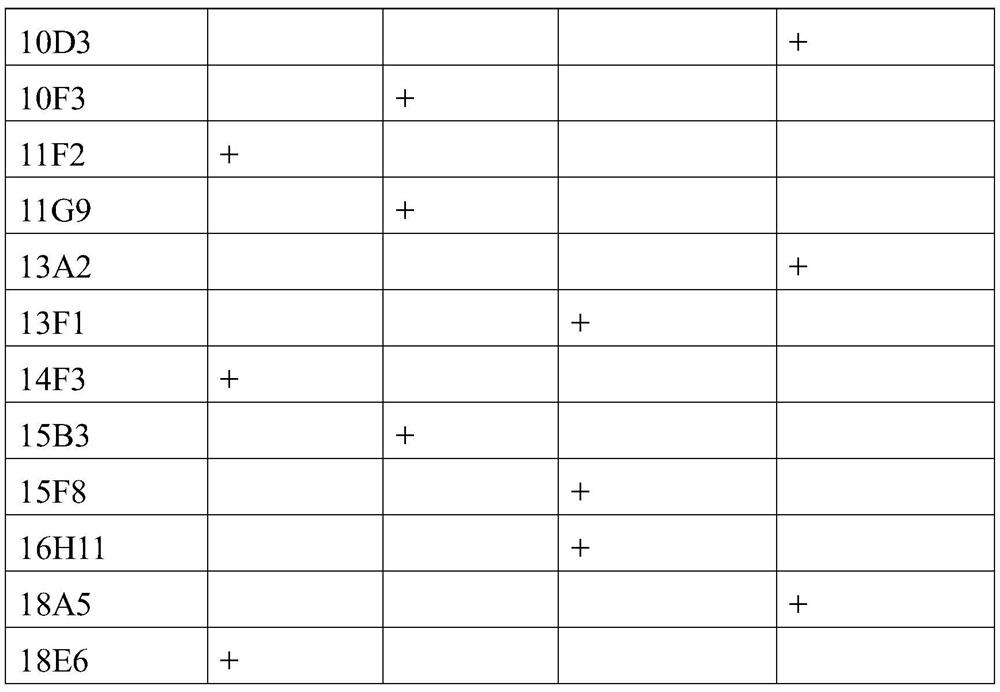

Hypersensitive cardiac troponin I detection method and kit

ActiveCN111308085AReduce the risk of missed detectionImprove the detection rateImmunoglobulins against animals/humansDisease diagnosisAntiendomysial antibodiesCardiac muscle

The invention relates to a hypersensitive cardiac troponin I detection method and a kit. The provided hypersensitive cardiac troponin I detection kit comprises a first group of antibodies and a secondgroup of antibodies for detecting cardiac troponin I from a subject sample, and the antibodies are selected from 1-6 antibodies specifically binding to the following cTnI fragment: antibody 1: 27-60aa; an antibody 2: 69 to 86 aa; an antibody 3: 13 to 29 aa; an antibody 4: 25 to 40 aa; an antibody 5: 41 to 49 aa; and an antibody 6: 169 to 178 aa. The method and the kit disclosed by the inventionare high in sensitivity and simple to operate, and can be used for dynamically monitoring the cardiac troponin I.

Owner:GUANGDONG WESAIL BIOTECH CO LTD

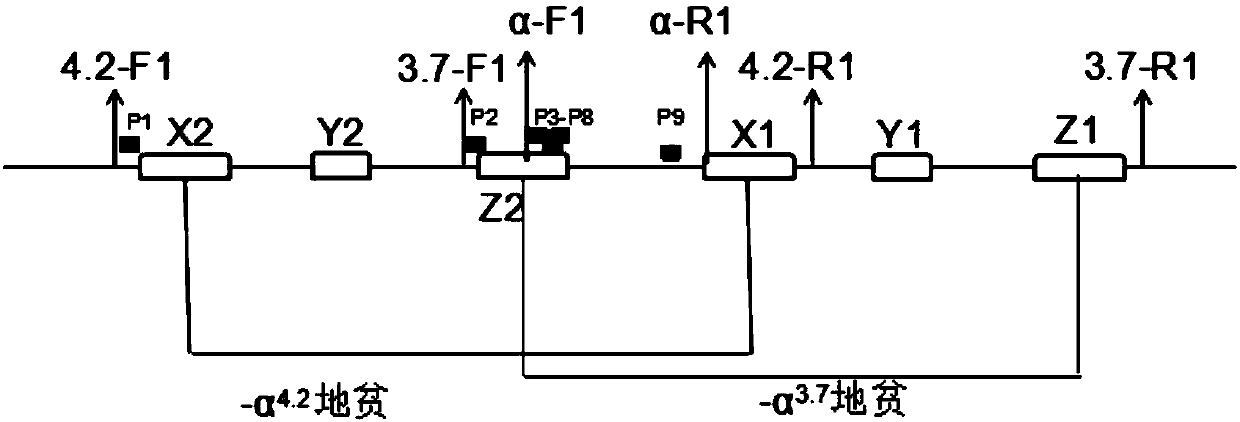

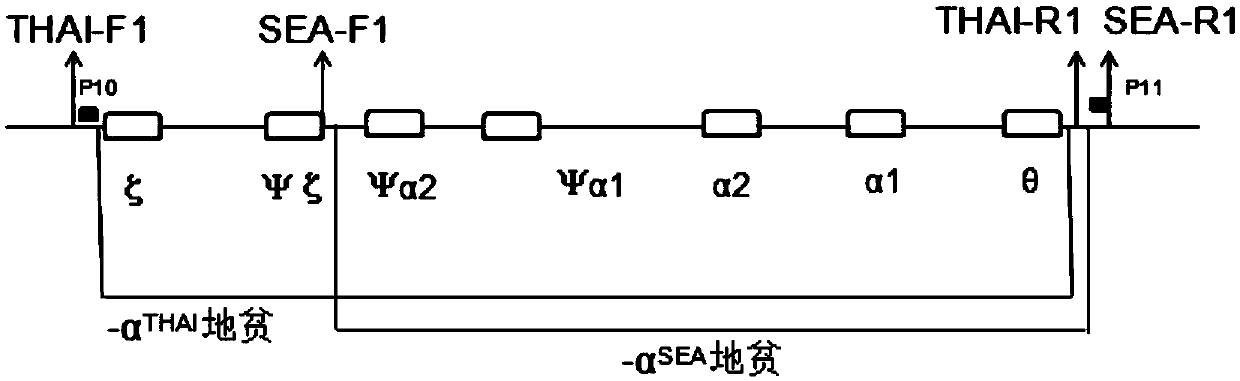

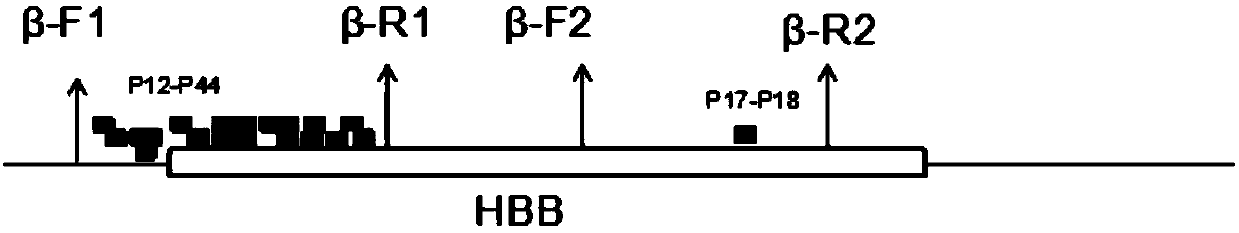

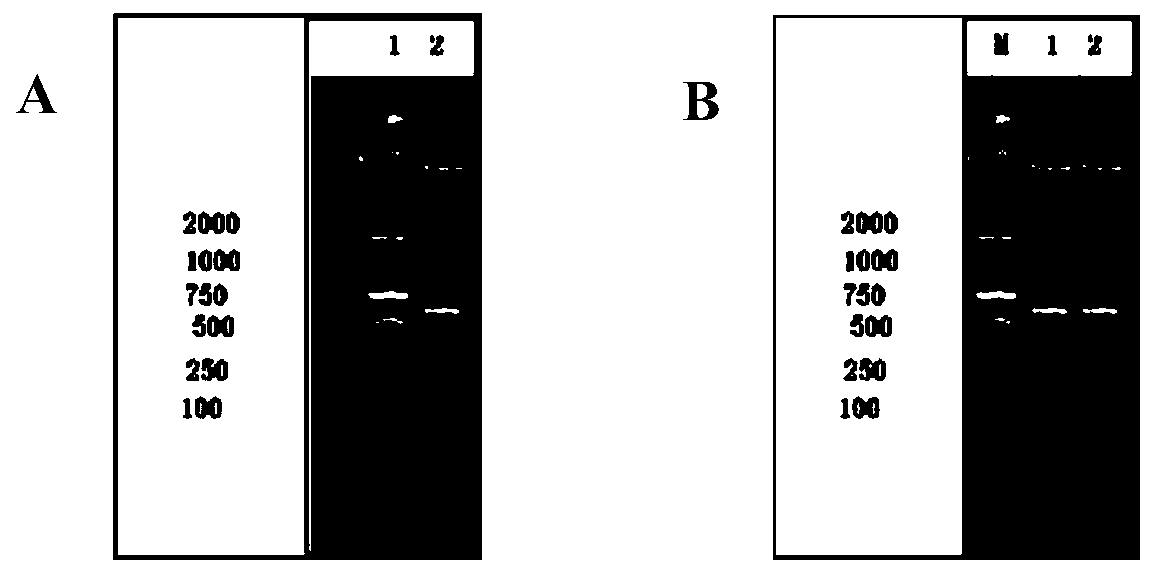

Nucleic acid composition and detection kit for detecting genetic anemia as well as use method

ActiveCN108796042AAffect the effect of amplificationImprove accuracyMicrobiological testing/measurementDNA/RNA fragmentationBeta thalassemiaMutation detection

The invention relates to a nucleic acid composition and a detection kit for detecting genetic anemia as well as a use method. The nucleic acid composition and the detection kit for detecting the genetic anemia can be used for simultaneously detecting four deletion type alpha thalassemia genes, three non-deletion type alpha thalassemia genes, nineteenth mutation type beta thalassemia genes, geneticanemia types such as sickle-shaped thalassemia gene as well as specific gene mutation types. Compared with the prior similar technologies, the detection kit for the genetic anemia has the characteristics that several mutation detection types for the genetic anemia are increased, such as alphaTHAI deleted thalassemia, sickle-shaped thalassemia and 71 / 72(+T) mutation and -28M(A-C) mutation which are relatively-rare thalassemia types. The detection for the genetic anemia types can provide visual reference and prompt for clinically detecting the genetic anemia, so that the leak detection risk ofclinical genetic anemia can be greatly reduced and the birth rate of severe anemia children is reduced.

Owner:BEIHAO STEM CELL & REGENERATIVE MEDICINE RES INST CO LTD

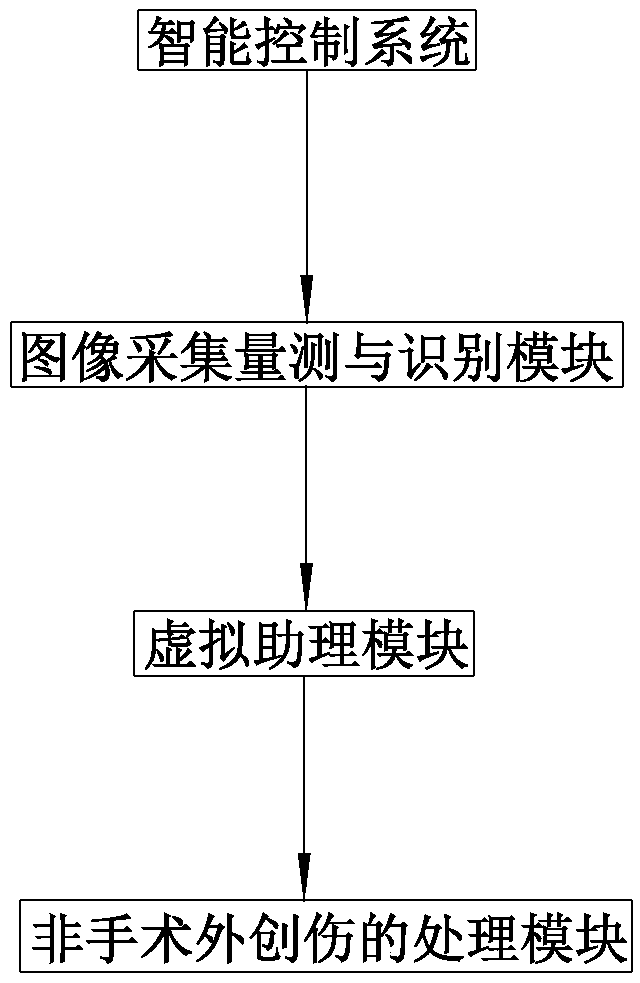

Debridement robot for surgical trauma detection

PendingCN109087285AReduce the risk of missed detectionIncreased sensitivityImage enhancementImage analysisDrug dispensingEngineering

The invention relates to the technical field of medical devices, particularly relates to a surgical wound detection and debridement robot, comprising an intelligent control system for realizing human-computer interaction, image recognition and processing, an image acquisition and measurement and identification module based on machine vision, a virtual assistant module, and a non-surgical externalwound processing module, wherein, the robot comprises a robot arm, an intelligent drug dispensing system and a negative ion wind output control system. The robot can accurately evaluate the depth, size and severity of the lesion.

Owner:NAVAL UNIV OF ENG PLA

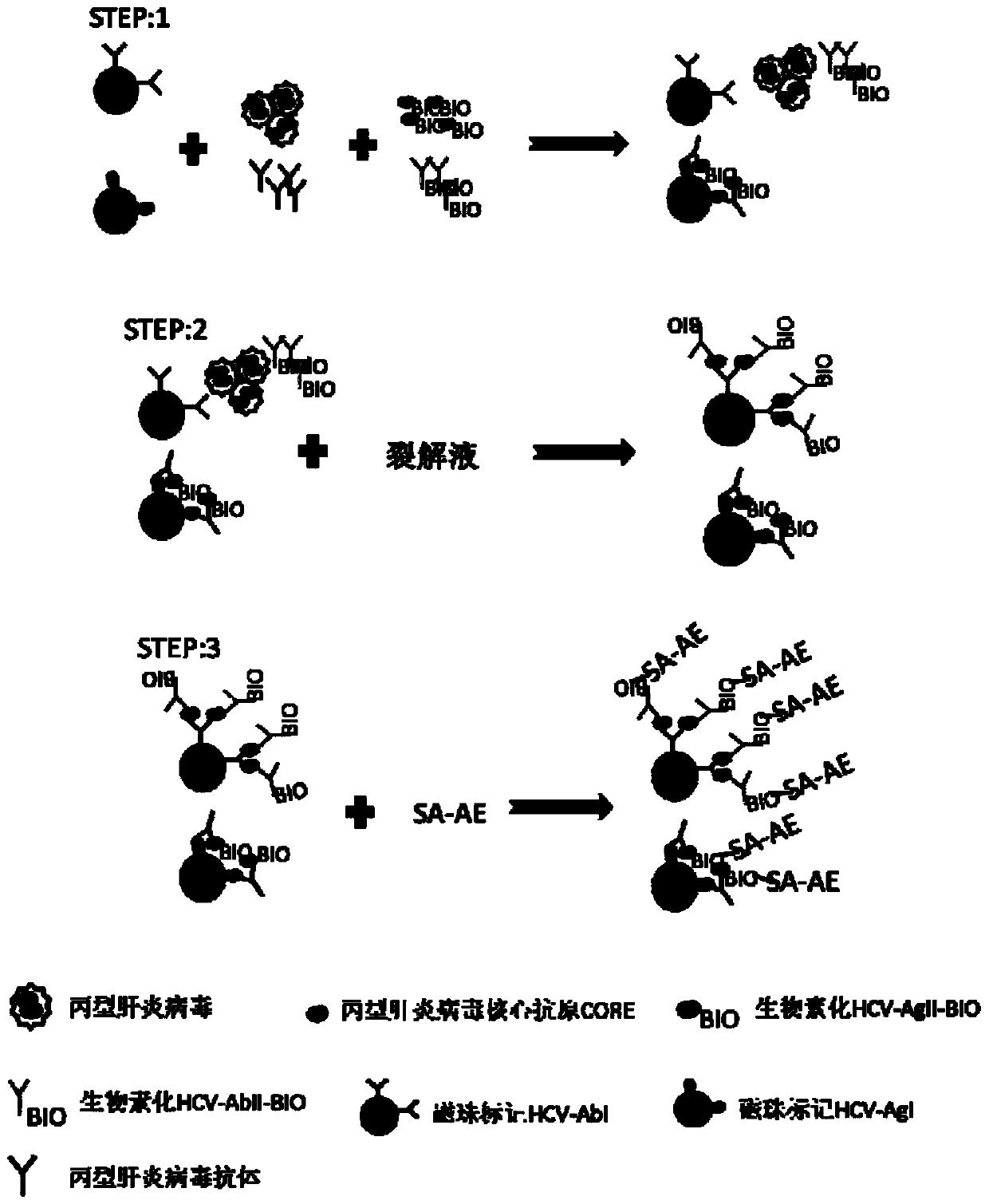

Hepatitis c virus detection kit

ActiveCN110261616AAvoid cross-reactionLow costBiological testingImmunoassaysRapid detectionHepacivirus

The invention relates to a hepatitis c virus detection kit. The hepatitis c virus detection kit comprises a first antibody and a second antibody for detecting a hepatitis c virus core antigen. The first antibody combines 95th-117th amino acid sequence of the hepatitis c virus core antigen aiming at an epitope or specificity in the 95th-117th amino acid sequence of the hepatitis c virus core antigen. The second antibody combines 55th-72th amino acid sequence of the hepatitis c virus core antigen aiming at the epitope or the specificity in the 55th-72th amino acid sequence of the hepatitis c virus core antigen. The kit has high sensitivity, good stability and simple operation, and can be used for rapid detection of early acute hepatitis c.

Owner:GUANGDONG FAPON BIOTECH CO LTD

Mental therapy non-surgical wound management system

PendingCN109065151AReduce the risk of missed detectionIncreased sensitivityEnemata/irrigatorsMedical automated diagnosisAnaerobic bacteriaChlorhexidine

The invention relates to the technical field of a medical system and particularly relates to a mental therapy non-surgical wound management system. The system is characterized by comprising steps that(1), an image identification system is utilized to measure, identify and record image data of images, and the wound is classified; (2), a near-infrared blood vessel display system is utilized to determine whether a blood vessel is broken due to trauma to obtain the injury degree, and severity of the wound is determined; (3), the dosage and the treatment method are determined according to obtainedcharacteristics of the wound; (4), the wound is disinfected with 0.1% chlorhexidine or hydrogen peroxide rinse; and (5), the negative ion wind is outputted to the wound, shrinkage of local capillaries in the wound and reproduction of anaerobic bacteria are avoided, local blood circulation is promoted, the comfort of a patient is improved, and the detection missing risk can be reduced.

Owner:NAVAL UNIV OF ENG PLA

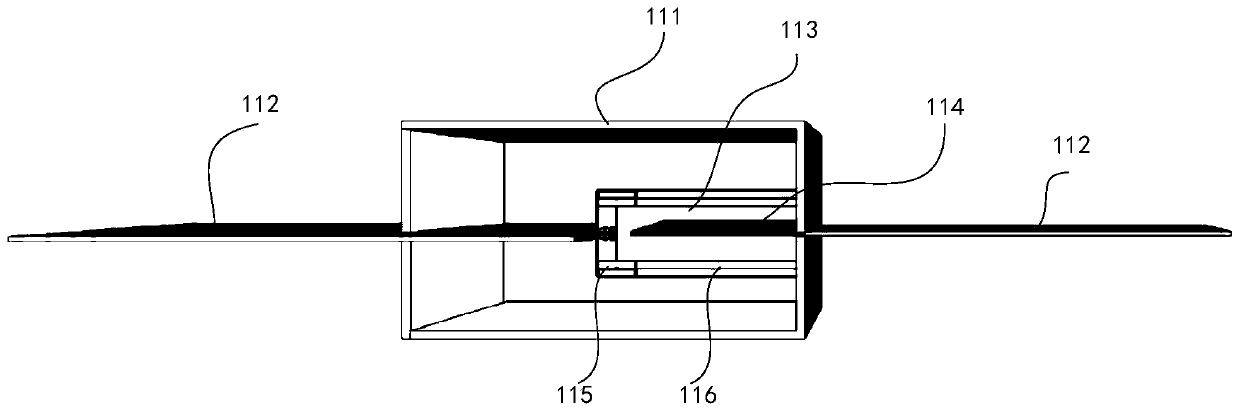

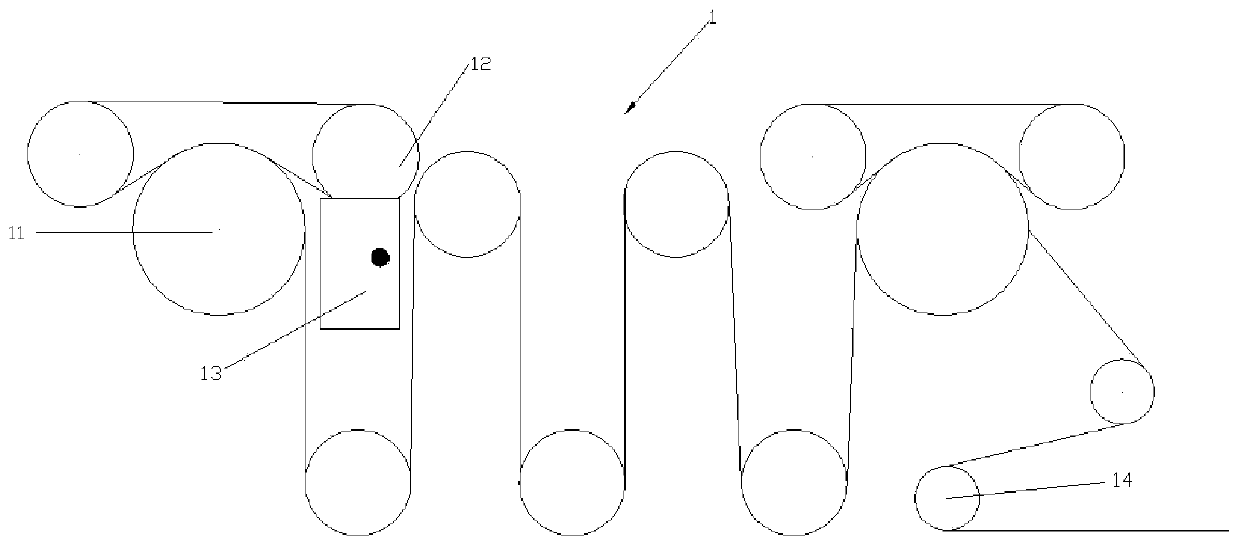

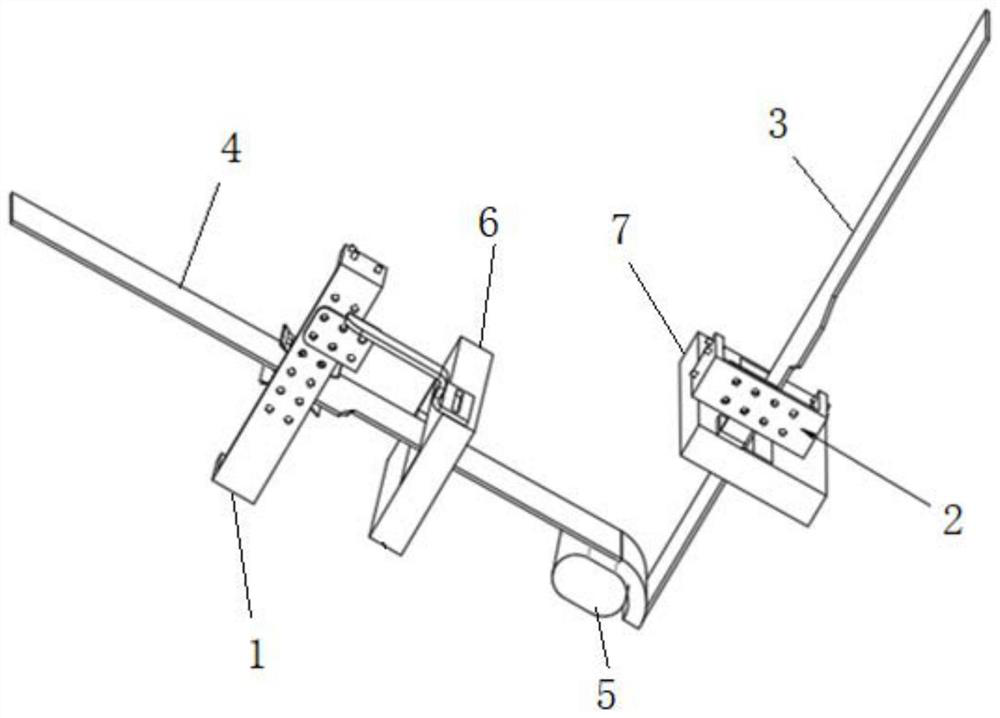

Protective device used for preventing whipping in optical fiber screening process

ActiveCN109911704ASimplify your workflowReduce the risk of missed detectionFilament handlingFiberMechanical engineering

The invention provides a protective device used for preventing whipping in an optical fiber screening process. The protective device is characterized by comprising a screening device, a winding displacement guide wheel, a winding displacement disc, a limiting slot, a protective cover, a barrier plate and a motor, wherein two screening large guide wheels are arranged in the screening device; a broken fiber collecting box and a plurality of screening small guide wheels are arranged between the screening large guide wheels; the winding displacement guide wheels are used for guiding optical fibersto enter the winding displacement disc from the screening device; the winding displacement guide wheels are arranged between openings of the protective cover; the openings of the protective cover arestrip-shaped, and upper and lower surfaces of the openings are alternated; bulges are arranged on lower plate surfaces of the openings of the protective cover; a limiting slot is formed in the tail ends of the lower plate surfaces; and an electrostatic elimination rod is embedded into the upper plate surfaces of the opening of the protective cover. In the technical field of optical fiber production, in order to solve the problem that normal optical fibers are damaged as broken fiber heads in an optical fiber screening process easily whip small disc surfaces of qualified optical fibers in front, the invention provides the protective device which is simple in structure and is easy in operation.

Owner:JIANGSU STERLITE TONGGUANG FIBER

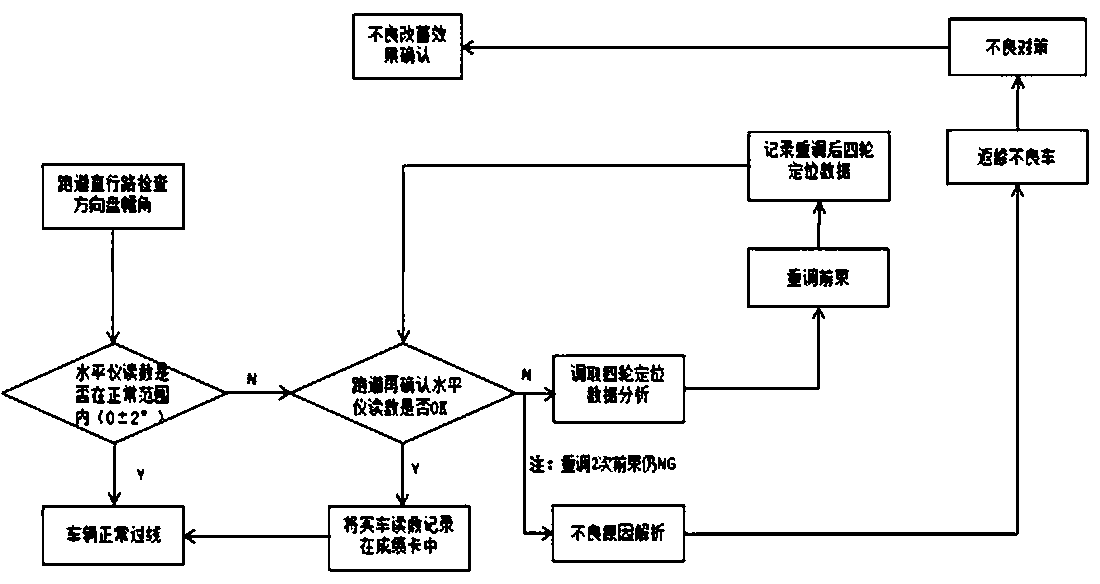

Detection method based on improving vehicle steering wheel amplitude angle level

InactiveCN109506623AHigh measurement accuracyReduce the risk of missed detectionIncline measurementMeasurement deviceSteering wheel

The invention relates to the technical field of steering wheel level detection, and in particular provides a detection method based on improving a vehicle steering wheel amplitude angle level. When avehicle is subjected to track testing, measurement equipment is introduced, a steering wheel level measurement device is arranged on a steering wheel, and whether the steering wheel has an amplitude angle tolerance or not can be detected through observing the measurement numerical value of the steering wheel level measurement device. The measurement equipment is introduced to quantize a checking standard, and inspection leakage risks and bad vehicle outflowing risks caused by personal subjective factors can be lowered.

Owner:GUANGZHOU AUTOMIBILE GRP MOTOR

Hypersensitive cardiac troponin I detection method and kit

ActiveCN113125742ASolve technical problems such as low detection rate, long reaction time, cumbersome operation, etc.Reduce the risk of missed detectionImmunoglobulins against animals/humansDisease diagnosisAntiendomysial antibodiesCardiac muscle

The invention relates to a hypersensitive cardiac troponin I detection method and a kit. The kit comprises a first group of antibodies and a second group of antibodies which are used for detecting cardiac troponin I in a sample of a subject, wherein the antibodies are selected from the following antibodies: an antibody 1: 41st-49th amino acid fragments specifically binding to cardiac troponin I, an antibody 2: 83rd to 92nd amino acid fragments specifically binding to cardiac troponin I, an antibody 3: 169th to 178th amino acid fragments specifically binding to cardiac troponin I, and an antibody 4: an antibody specifically binding to a cardiac troponin compound cTnC-T-I. The method and the kit disclosed by the invention are high in sensitivity and simple to operate, and can be used for dynamically monitoring cardiac troponin I.

Owner:GUANGDONG WESAIL BIOTECH CO LTD

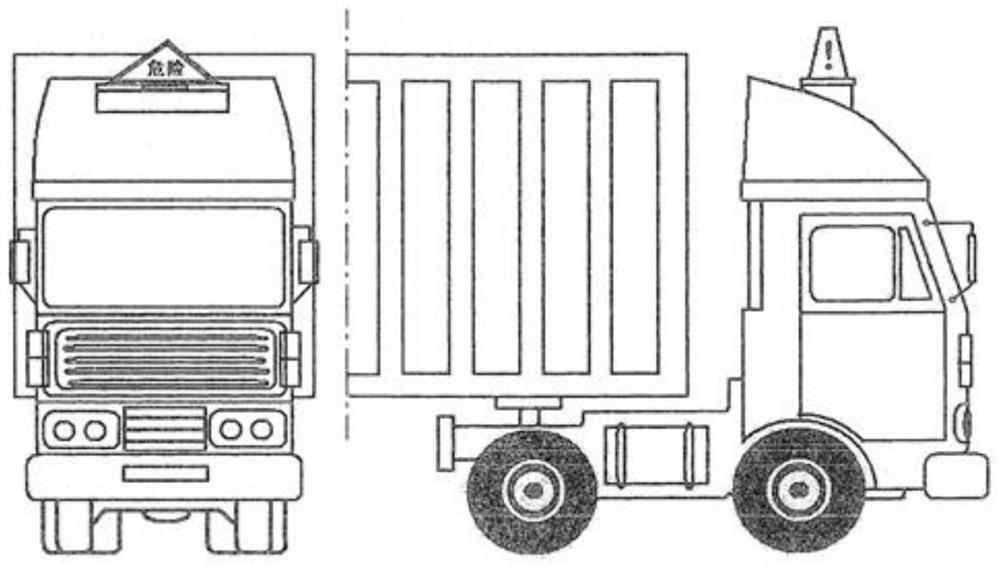

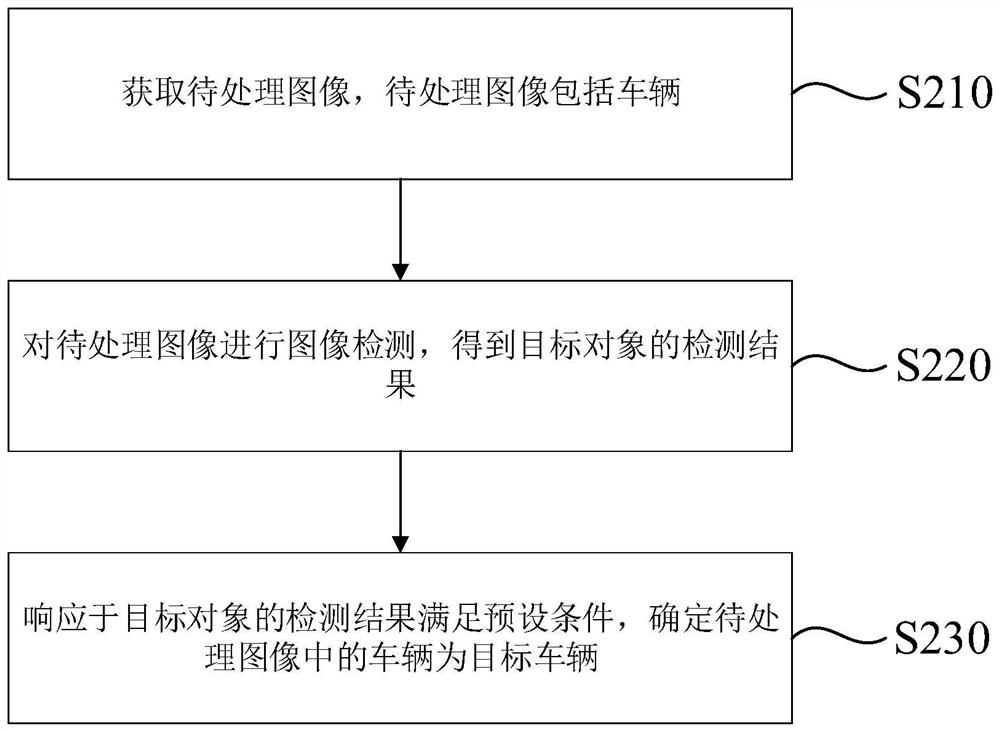

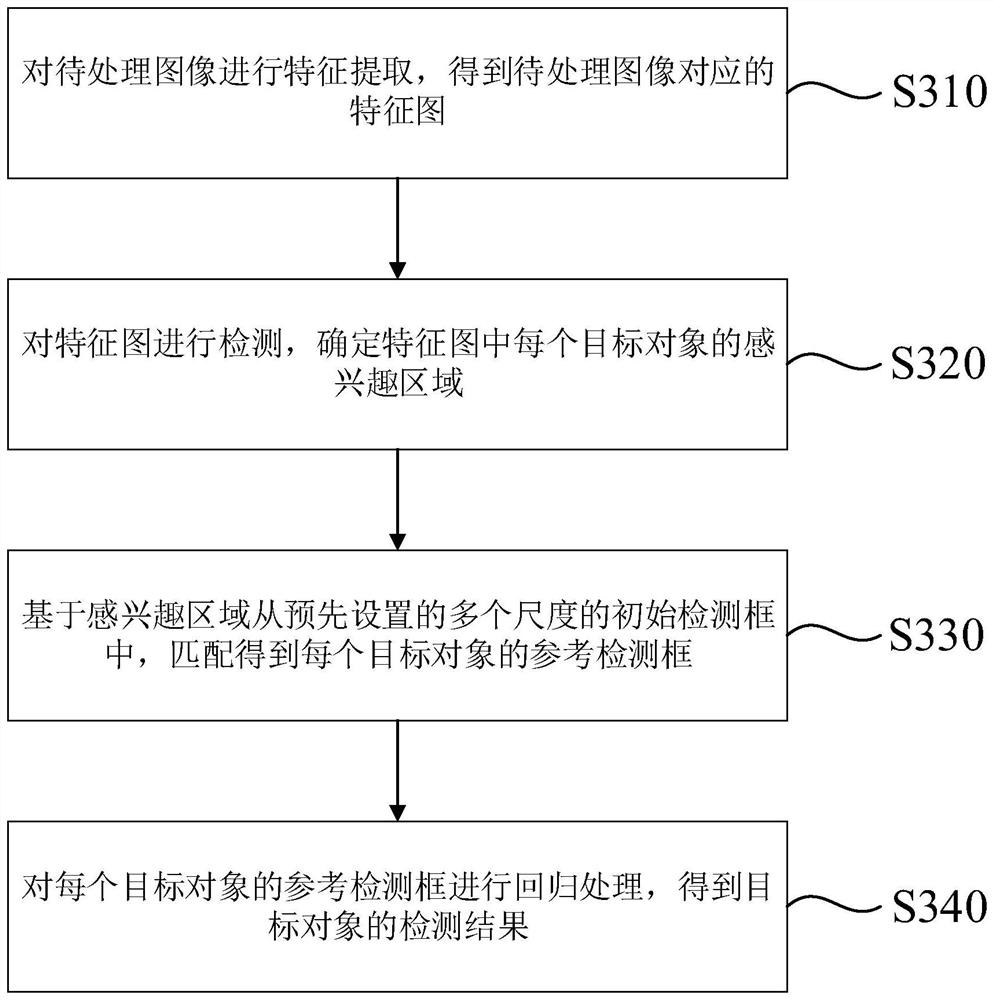

Target vehicle detection method and device

PendingCN114429619AReduce the risk of false detection and missed detectionImprove detection and recognition accuracyScene recognitionNeural architecturesFalse detectionEngineering

The invention relates to the technical field of computer vision, and particularly provides a target vehicle detection method and device. The target vehicle detection method comprises the steps that a to-be-processed image is acquired, and the to-be-processed image comprises a vehicle; performing image detection on the to-be-processed image to obtain a detection result of the target object; the target object is at least one type of vehicle component belonging to the vehicle; and determining that the vehicle in the to-be-processed image is a target vehicle in response to the condition that the detection result of the target object meets a preset condition. According to the embodiment of the invention, the false detection and missing detection risks of the target vehicle are reduced, and the detection and recognition precision is improved.

Owner:ZHEJIANG SENSETIME TECH DEV CO LTD

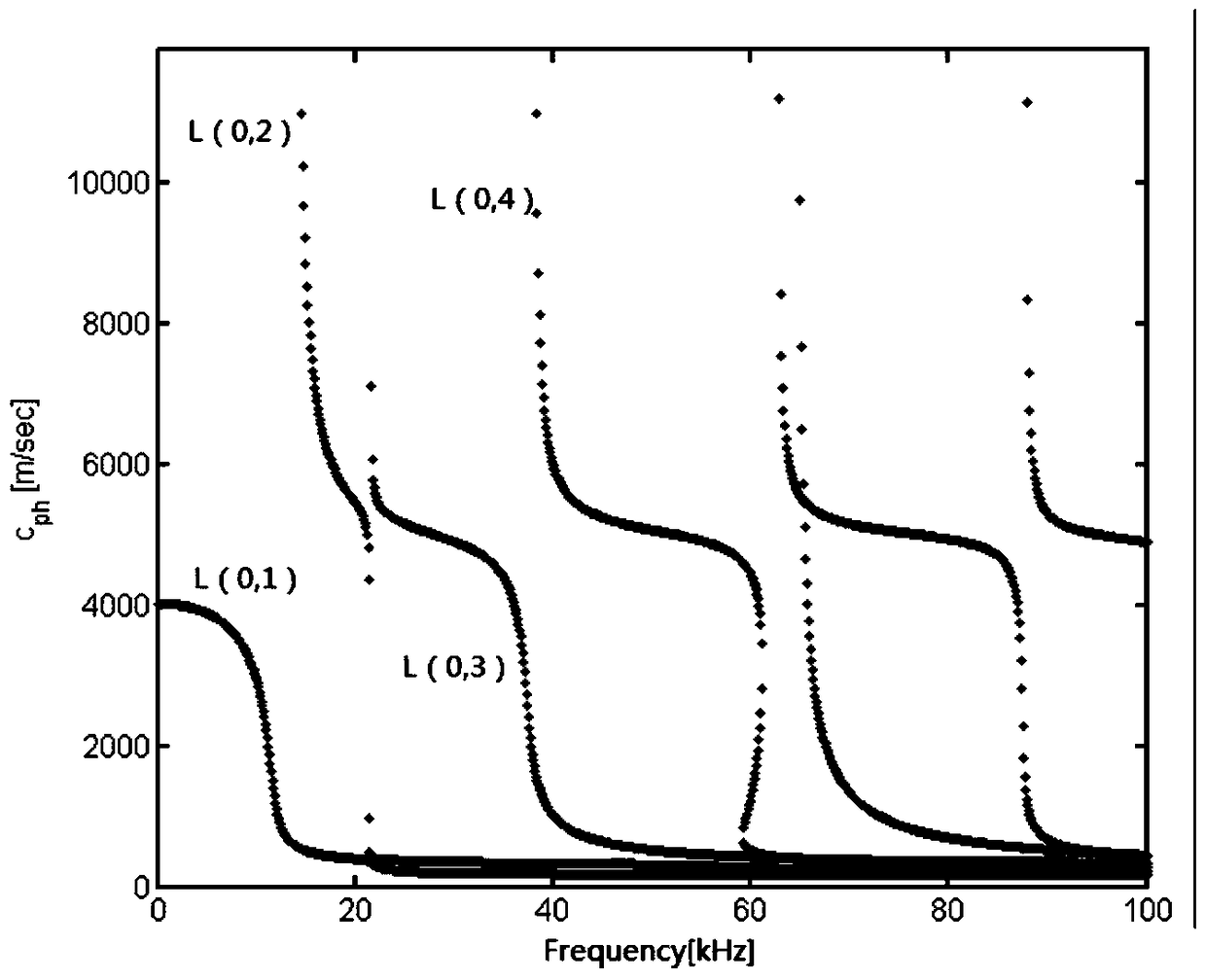

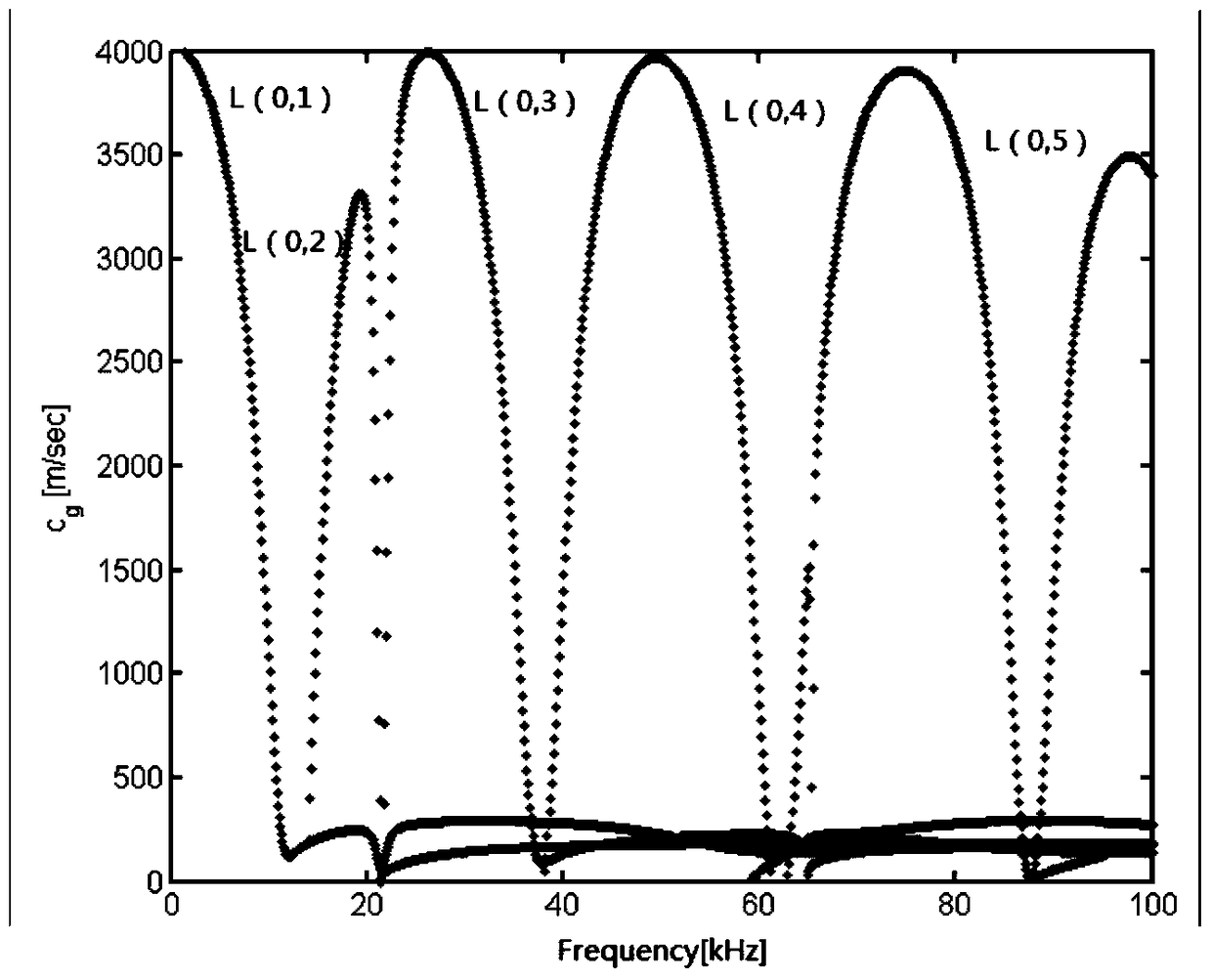

An ultrasonic guided wave detection system and detection method for composite insulator defects

InactiveCN105424802BLow costReduce sensitivityAnalysing solids using sonic/ultrasonic/infrasonic wavesComposite insulatorsSonification

The invention discloses an ultrasonic guided-wave detecting system for the defect of a composite insulator. The ultrasonic guided-wave detecting system comprises a system master control computer, a signal generator, a power amplifier, a piezoelectric paster and a digital oscilloscope. The invention further discloses a detecting method applied to the ultrasonic guided-wave detecting system for the defect of the composite insulator. The detecting method comprises the following steps that 1, the frequency dispersion equation of propagation of guided waves in a composite insulator model is determined; 2, a corresponding frequency dispersion curve is obtained through insulator test piece related parameters tested through experiments; 3, stimulation guided wave frequency, periods and modal are determined according to a frequency dispersion curve conclusion; 4, stimulation and receiving points are selected, and defect detection of guided waves is achieved; 5, a guided wave detecting waveform is placed in a computer for data analysis processing, whether the defect exits or not it judged, and the size and type of the defect are judged. The detecting advantages of being accurate, fast, long in distance, large in range, low in cost and the like are achieved.

Owner:SOUTH CHINA UNIV OF TECH

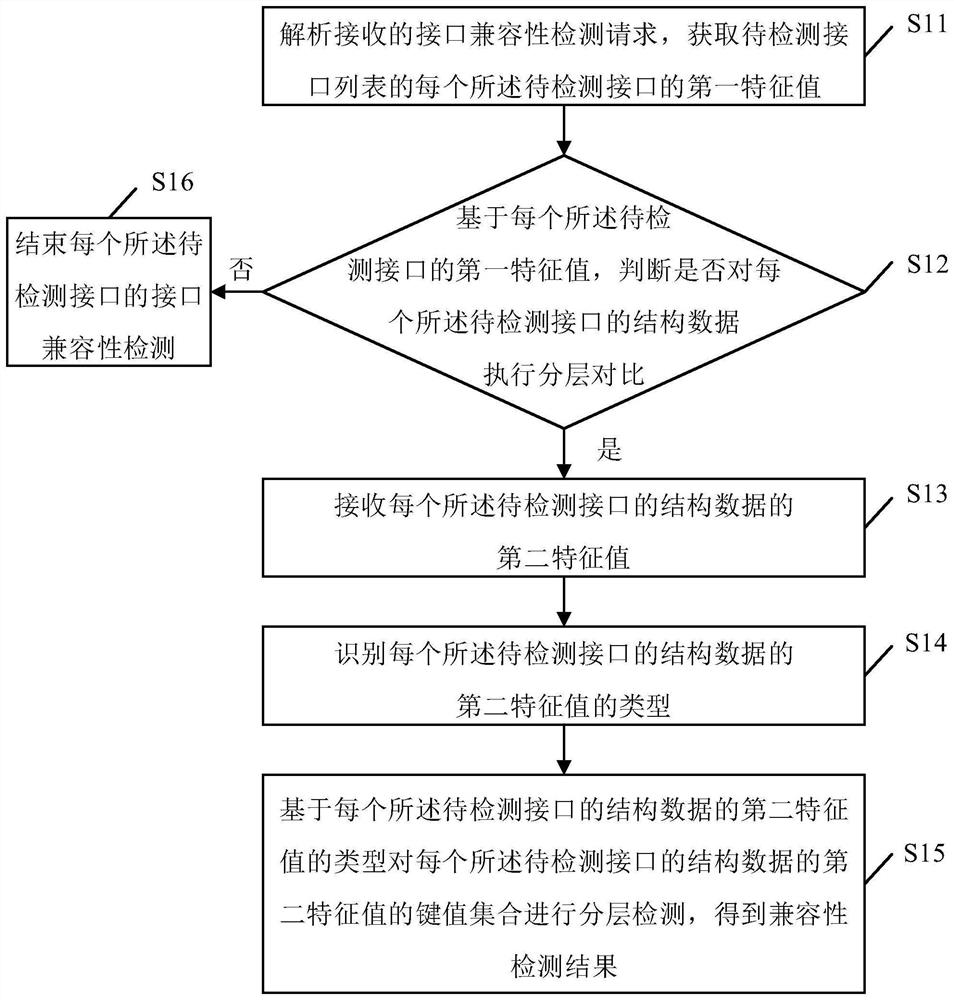

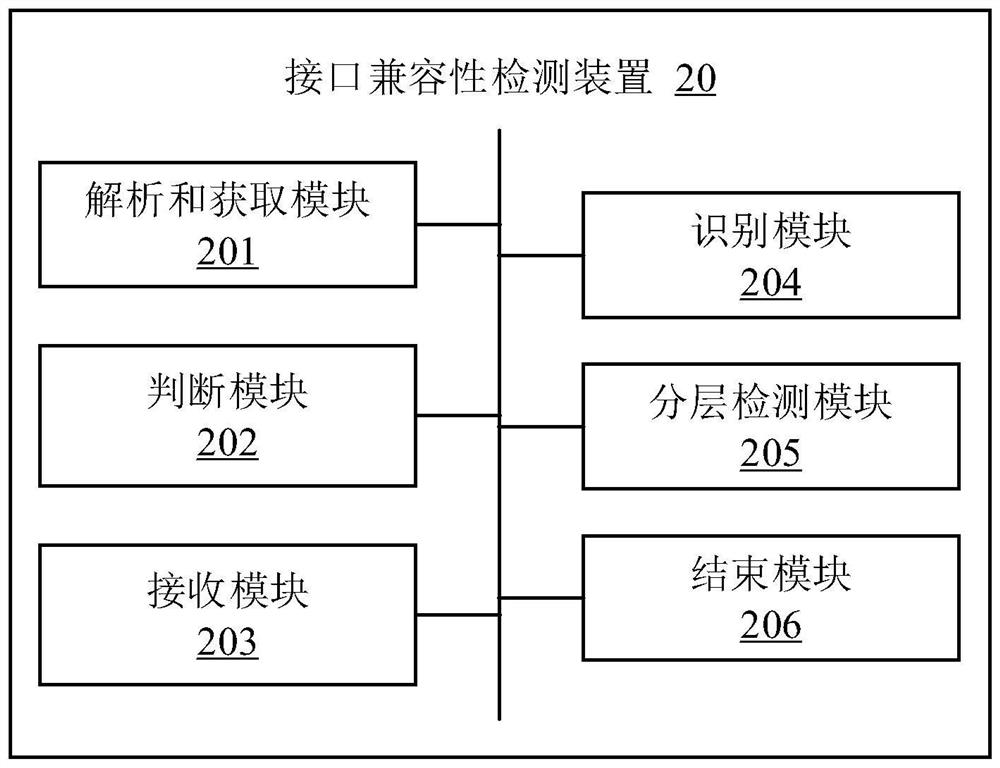

Interface compatibility detection method and device, electronic equipment and storage medium

PendingCN114741260AImprove the efficiency of compatibility testingImprove accuracyHardware monitoringSoftware testing/debuggingValue setComputer compatibility

The invention relates to the technical field of data testing, and provides an interface compatibility detection method and device, electronic equipment and a storage medium, and the method comprises the steps: obtaining a first feature value of each to-be-detected interface of a to-be-detected interface list; based on the first feature value of each to-be-detected interface, when it is determined that hierarchical comparison is executed on the structure data of each to-be-detected interface, receiving a second feature value of the structure data of each to-be-detected interface; identifying the type of the second characteristic value of the structural data of each to-be-detected interface; and performing hierarchical detection on the key value set of the second characteristic value of the structure data of each to-be-detected interface based on the type of the second characteristic value of the structure data of each to-be-detected interface to obtain a compatibility detection result. Layered detection is performed through the key value set of the second feature value of the structure data of each to-be-detected interface, so that the risk of missing detection is reduced, and the compatibility detection accuracy and efficiency of the interface are improved.

Owner:PINGAN INT SMART CITY TECH CO LTD

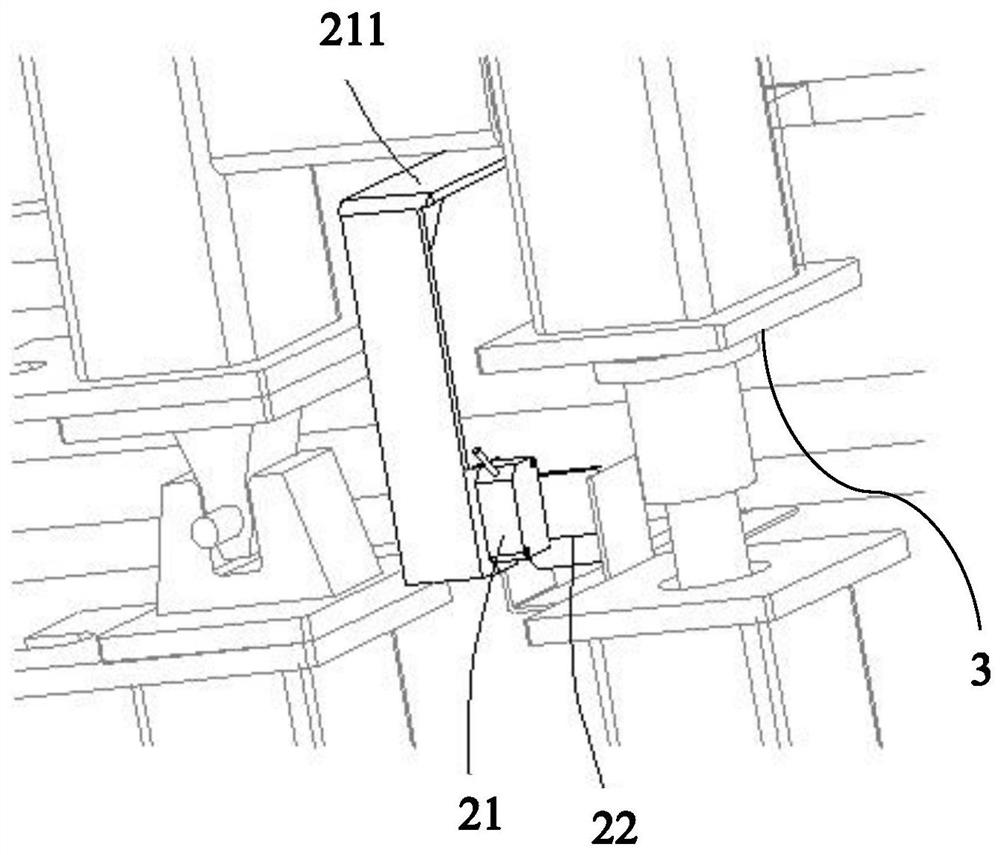

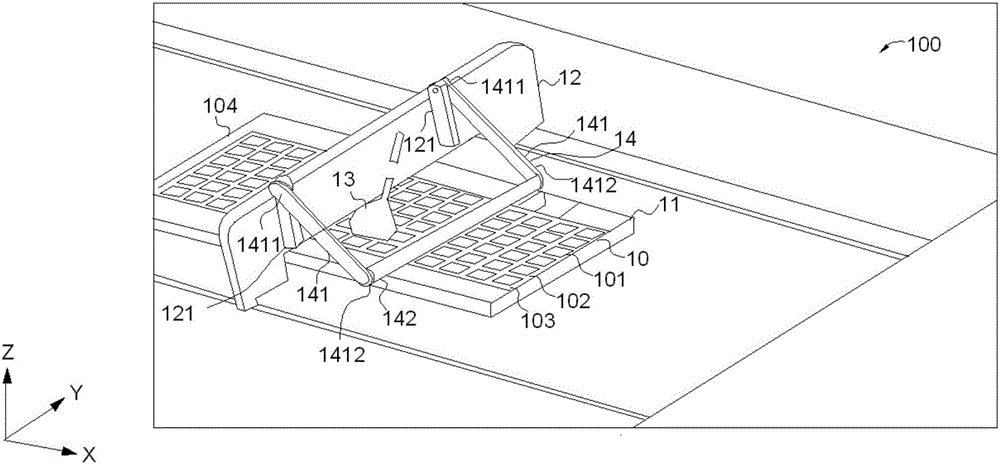

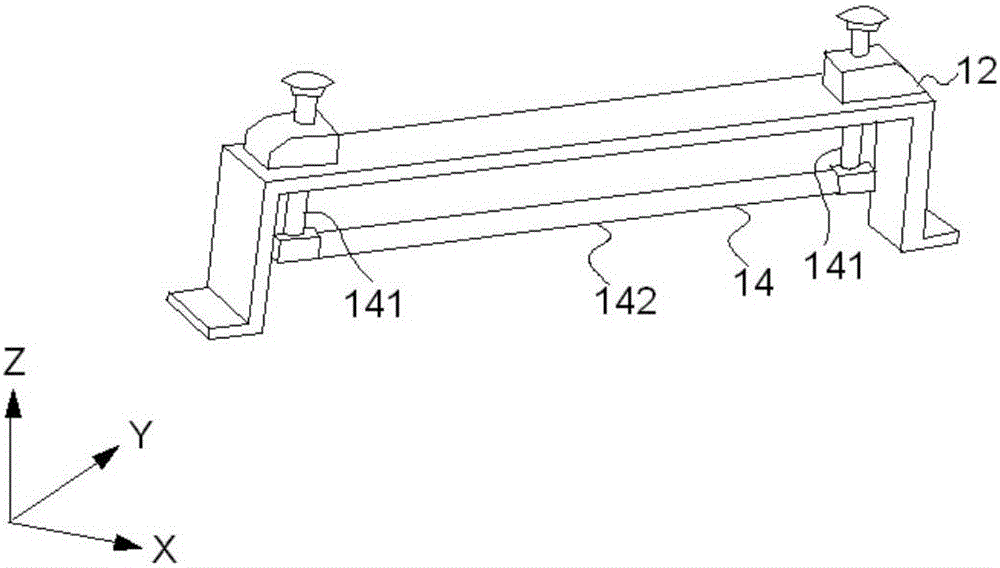

Fall-off detector

InactiveCN106018272ALower detection rateReduce the risk of missed detectionMachine part testingUsing mechanical meansEngineeringTest fixture

The invention discloses a fall-off detector which is used for detecting keycaps of a keyboard. The fall-off detector comprises a base, a moving bracket as well as a testing structure and a limiting structure which are arranged on the moving bracket; when the moving bracket moves from a first end of the keyboard to a second end of the keyboard relative to a to-be-tested device, the testing structure and the limiting structure are enabled to move from the first end to the second end relative to the to-be-tested device, in the moving process, the testing structure applies force in a first direction to a to-be-tested component, the limiting structure limits movement of the to-be-tested device in the first direction under the force in the first direction, and the testing structure and the limiting structure act on the same to-be-tested component at different moments, that is, the condition of reduction of the detection rate due to bringing up of the stressed keyboard during testing can be avoided, and the detection missing risk is reduced.

Owner:HUAIAN DARFON ELECTRONICS

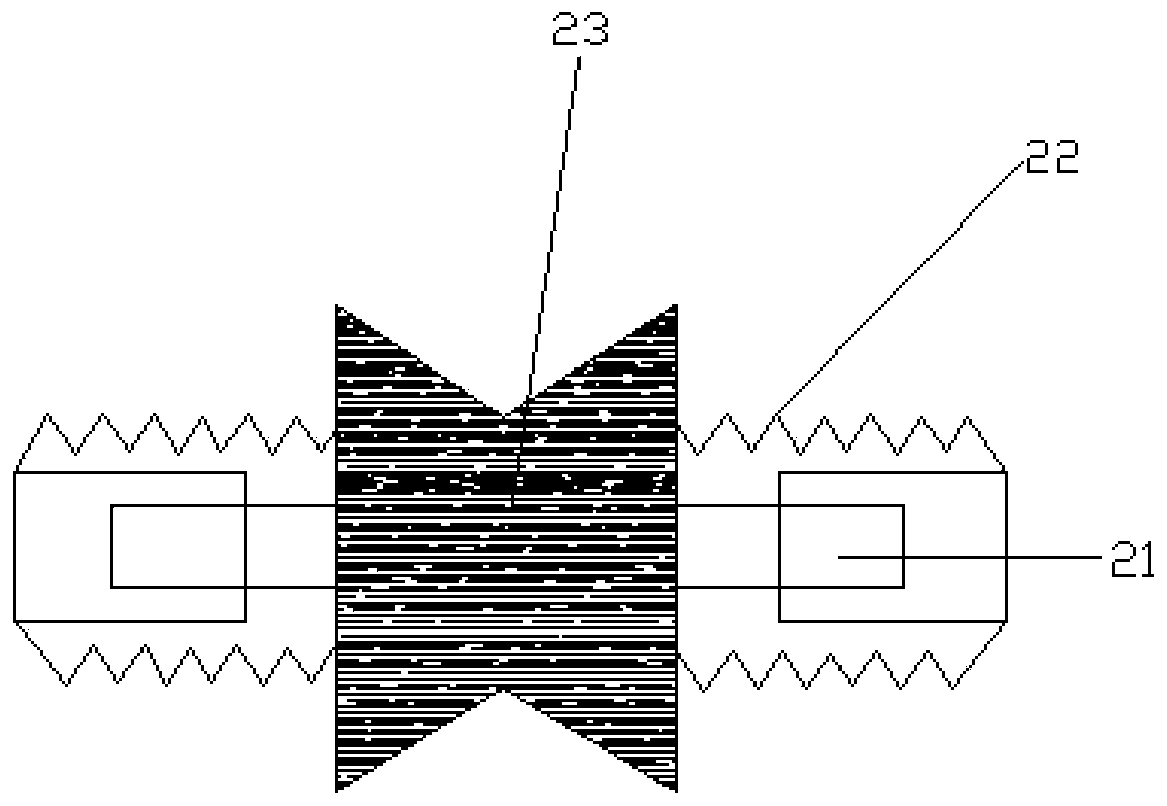

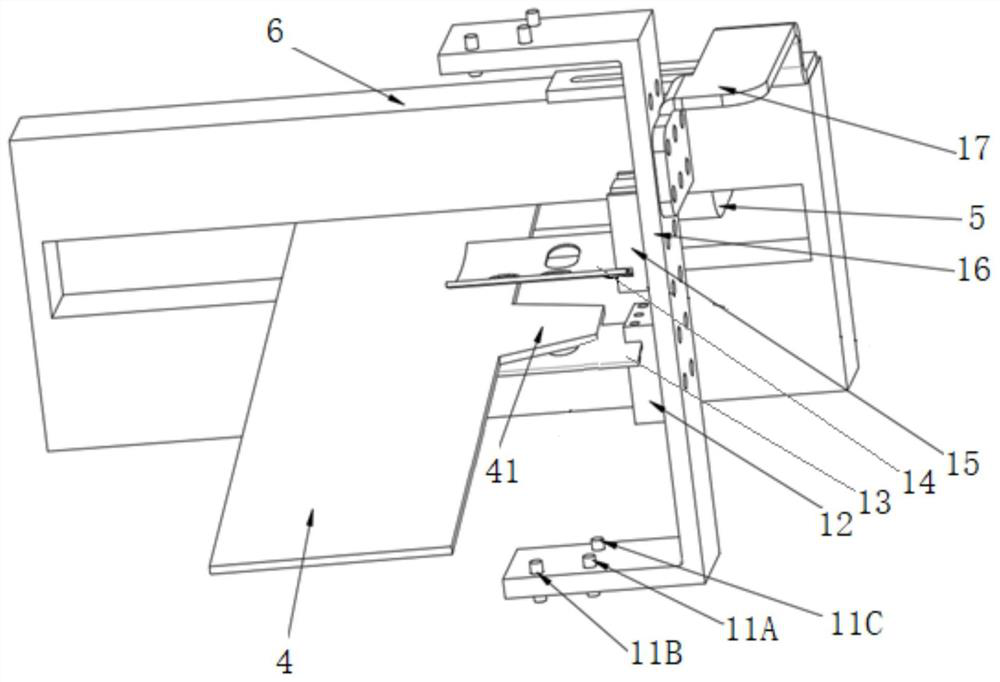

Battery winding mechanism for tab detection

ActiveCN112635848AReduce the risk of missed detectionAccurate judgmentAssembling battery machinesFinal product manufactureElectrical batteryMechanical engineering

The invention provides a battery winding mechanism for tab detection, which comprises a winding needle for winding a positive plate and a negative plate into a wound battery, and a positive cutter and a negative cutter used for cutting the positive plate and the negative plate, wherein the front end of the positive cutter is connected with a positive detection mechanism for detecting the turnover of a positive tab of the positive plate; the positive electrode detection mechanism comprises a positive electrode frame and a second correlation sensor; and the front end of the negative electrode cutter is connected with a negative electrode detection mechanism for detecting the turnover of a negative electrode lug of the negative electrode piece; and the negative electrode detection mechanism comprises a negative electrode frame and a first correlation sensor. The turnover condition of the tab is detected, and the missing detection risk of the tab is reduced; and the three correlation sensors are arranged in a triangular shape at the same time, so that the turnover condition of each side of the tab can be accurately judged.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com