Protective device used for preventing whipping in optical fiber screening process

A protection device and screening device technology, which is applied in the field of optical fiber production, can solve the problems of damaged optical fiber and easy whipping of the fiber head, etc., so as to improve the service life, reduce the risk of missed inspection, and simplify the work process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

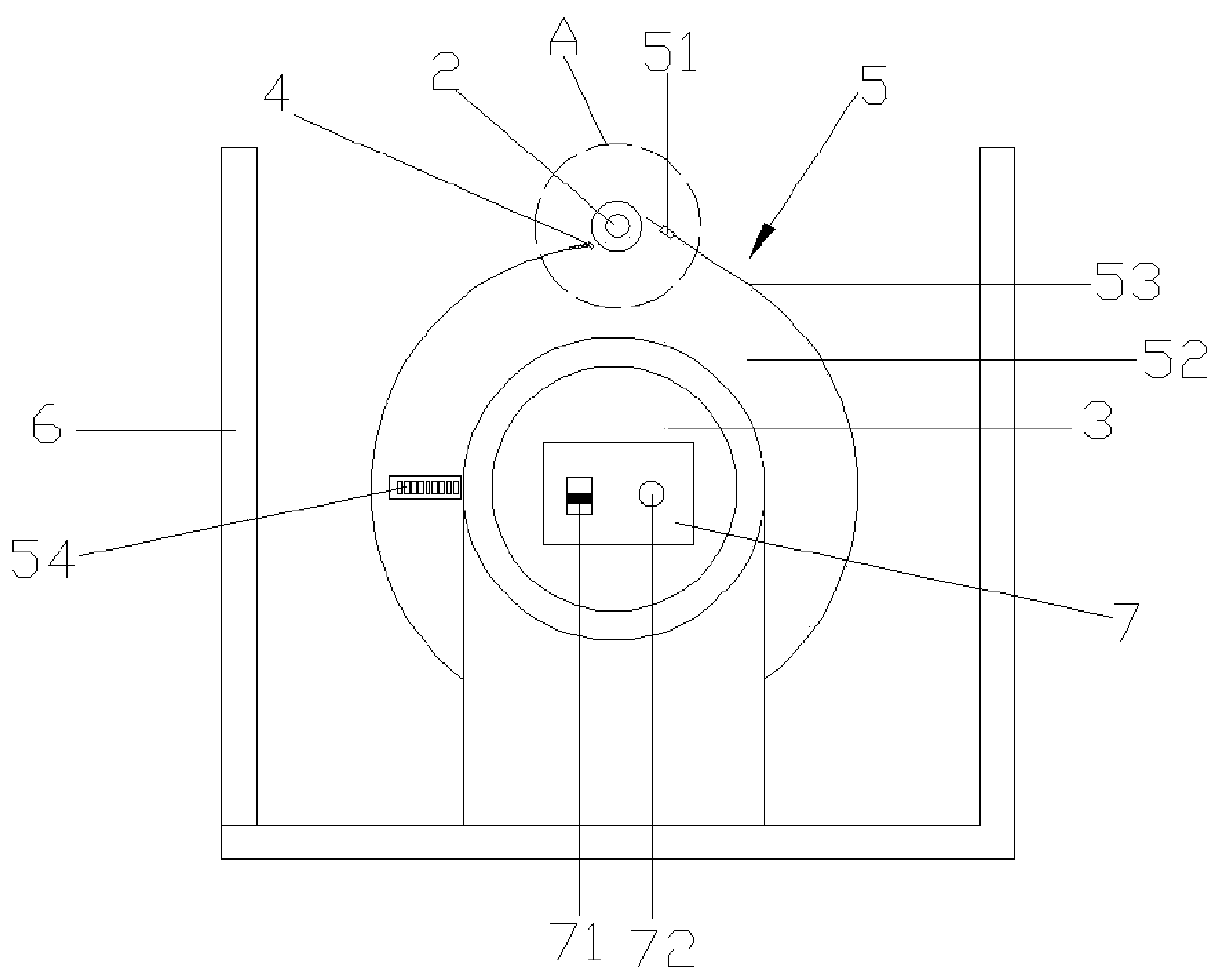

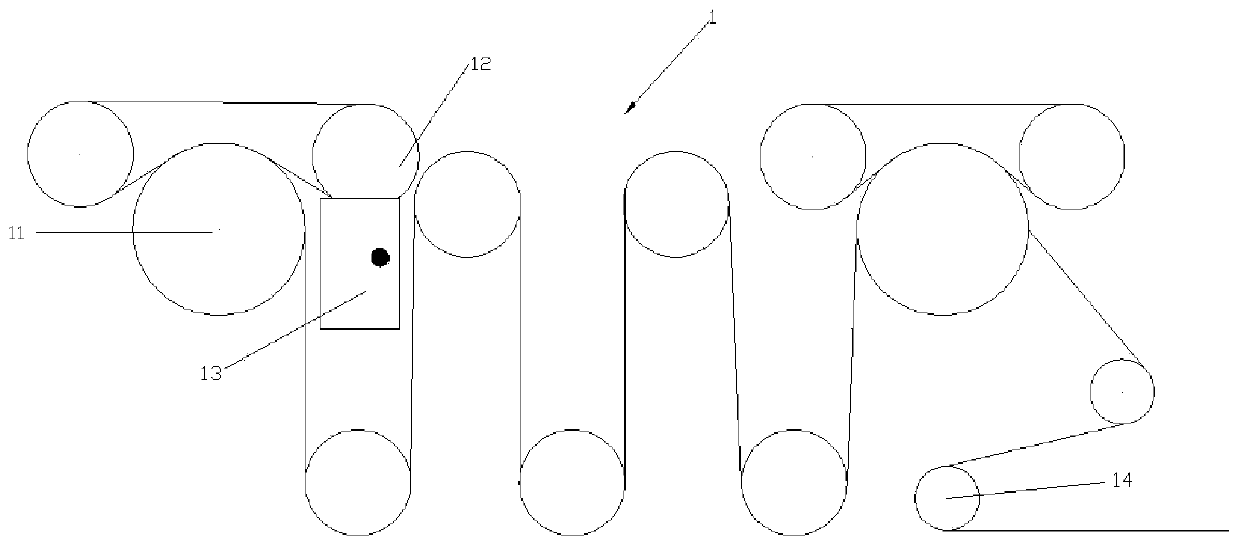

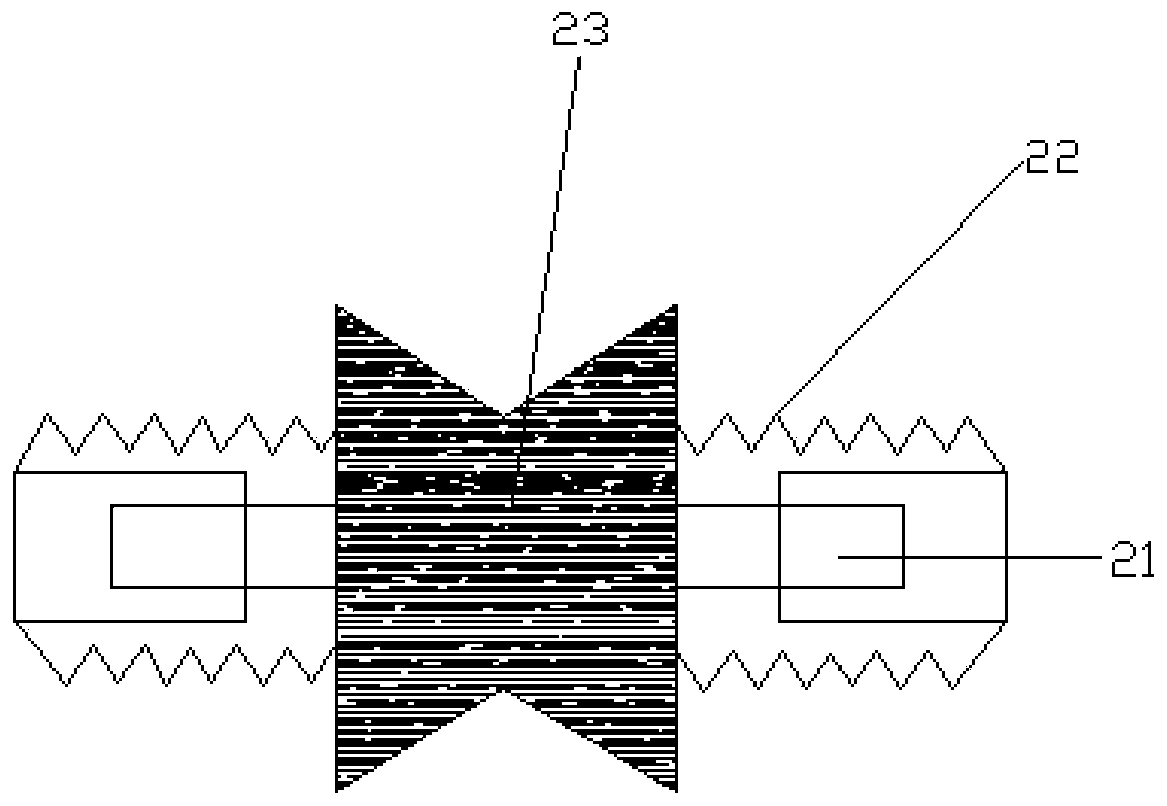

[0034] Such as figure 1 , figure 2 As shown: a protection device for whiplash prevention in the optical fiber screening process, which is characterized in that: it includes a screening device 1, a cable guide wheel 2, a cable reel 3, a limit groove 4, a protective cover 5, a fence plate 6, Motor 7; two screening large guide wheels 11 are provided in the screening device 1, and a broken fiber collection box 13 and several screening small guide wheels 12 are arranged between the two screening large guide wheels 11, and the cable guide wheel 2 guides the optical fiber Enter the cable tray 3 from the screening device 1, and the cable guide wheel 2 is arranged between the openings of the protective cover 5. The opening of the protective cover 5 is strip-shaped, and the upper and lower sides of the opening are staggered. The lower plate surface of the opening of the protective cover 5 There are protrusions on the top, and the tail end of the lower plate surface is provided with a ...

Embodiment 2

[0040] Such as figure 1 , figure 2 As shown: a protection device for whiplash prevention in the optical fiber screening process, which is characterized in that: it includes a screening device 1, a cable guide wheel 2, a cable reel 3, a limit groove 4, a protective cover 5, a fence plate 6, Motor 7; two screening large guide wheels 11 are provided in the screening device 1, and a broken fiber collection box 13 and several screening small guide wheels 12 are arranged between the two screening large guide wheels 11, and the cable guide wheel 2 guides the optical fiber Enter the cable tray 3 from the screening device 1, and the cable guide wheel 2 is arranged between the openings of the protective cover 5. The opening of the protective cover 5 is strip-shaped, and the upper and lower sides of the opening are staggered. The lower plate surface of the opening of the protective cover 5 There are protrusions on the top, and the tail end of the lower plate surface is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com