Patents

Literature

49results about How to "Rotation does not occur" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

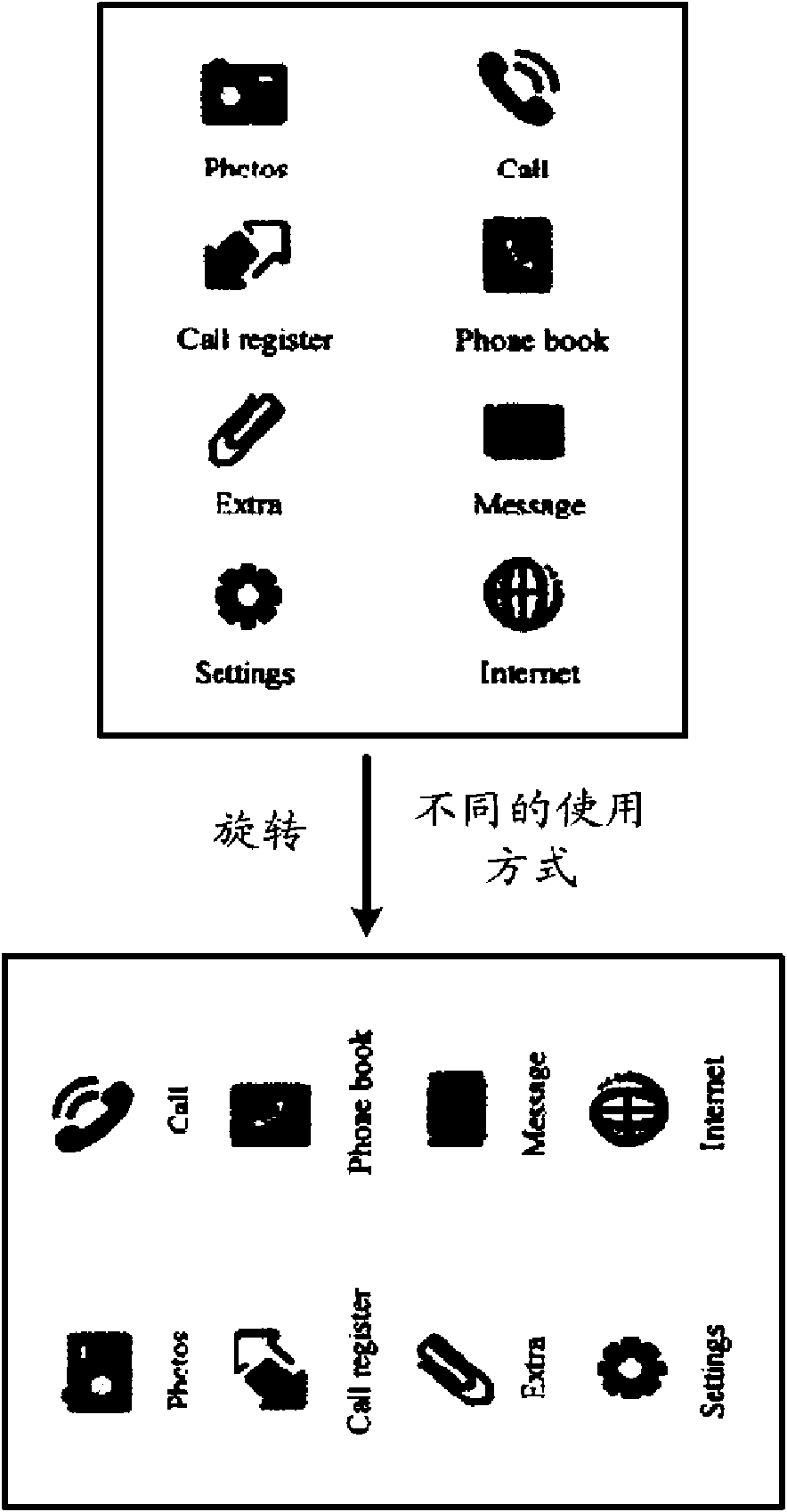

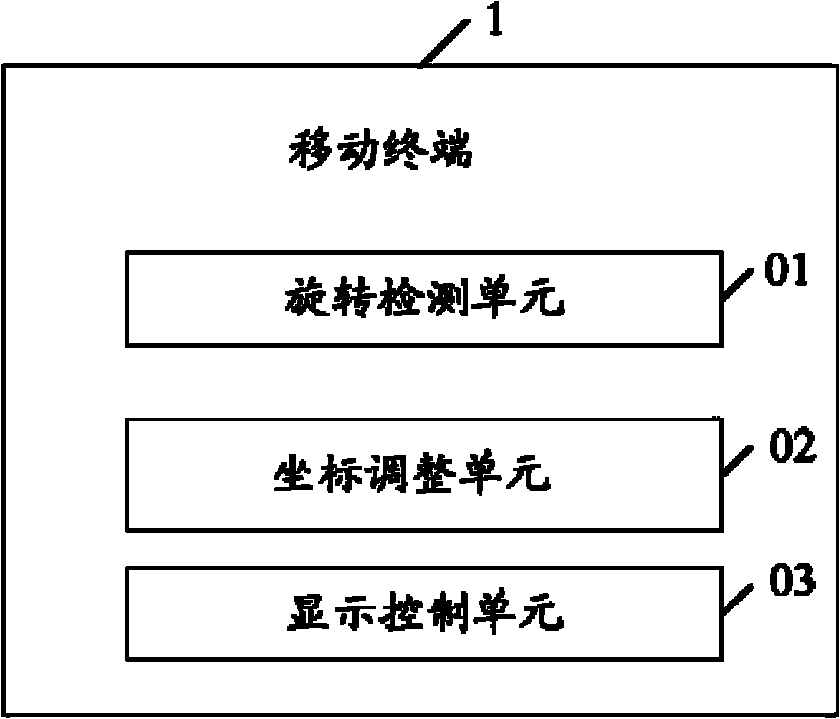

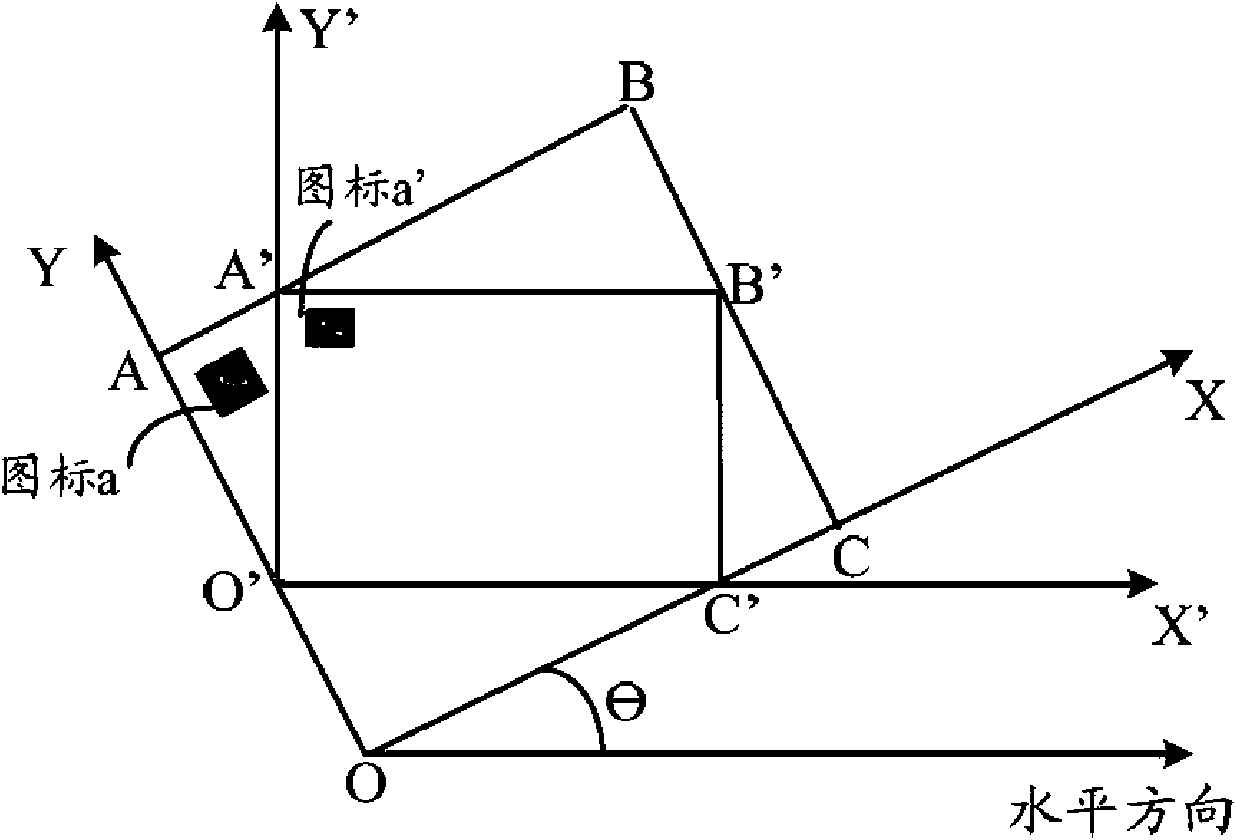

Automatic adjusting system and method for user interface of mobile terminal

InactiveCN101877736ARotation does not occurDigital data processing detailsTelephone sets with user guidance/featuresEngineeringHuman–computer interaction

The invention provides an automatic adjusting method for a user interface of a mobile terminal. The method comprises the following steps of: detecting a rotation angle of the mobile terminal; rebuilding a coordinate system of the user interface according to the detected rotation angle of the mobile terminal and determining a display area of the user interface; calculating a coordinate value and a dimension value of an interface element in the user interface in the rebuilt coordinate system; and controlling the display of the interface element in the display area of the user interface according to the determined coordinate value and the determined dimension value of the interface element. The invention also provides an automatic adjusting system for the user interface of the mobile terminal. When the mobile terminal rotates, the user interface of the mobile terminal and the display mode of the interface element in the user interface are adjusted so that the user interface of the mobile terminal does not rotate on vision and is presented to a user more intuitively.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

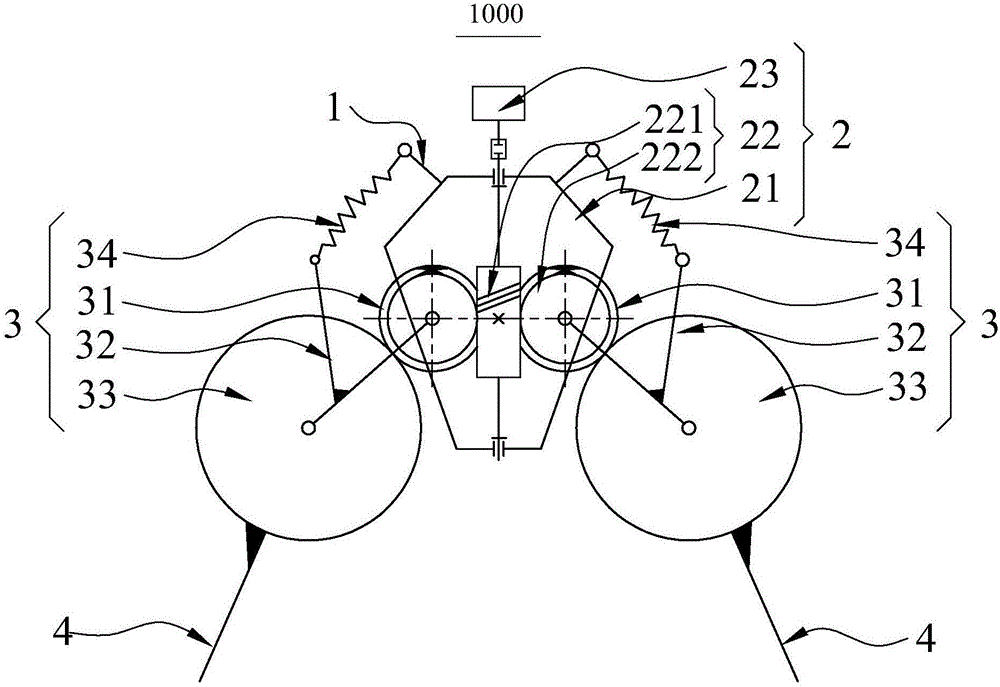

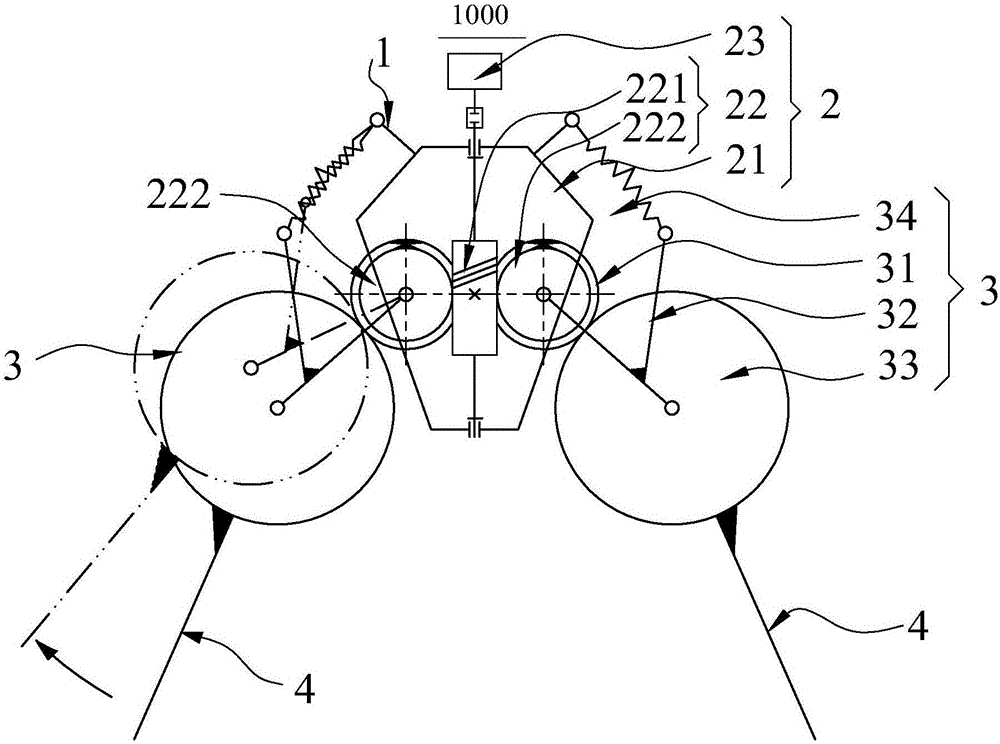

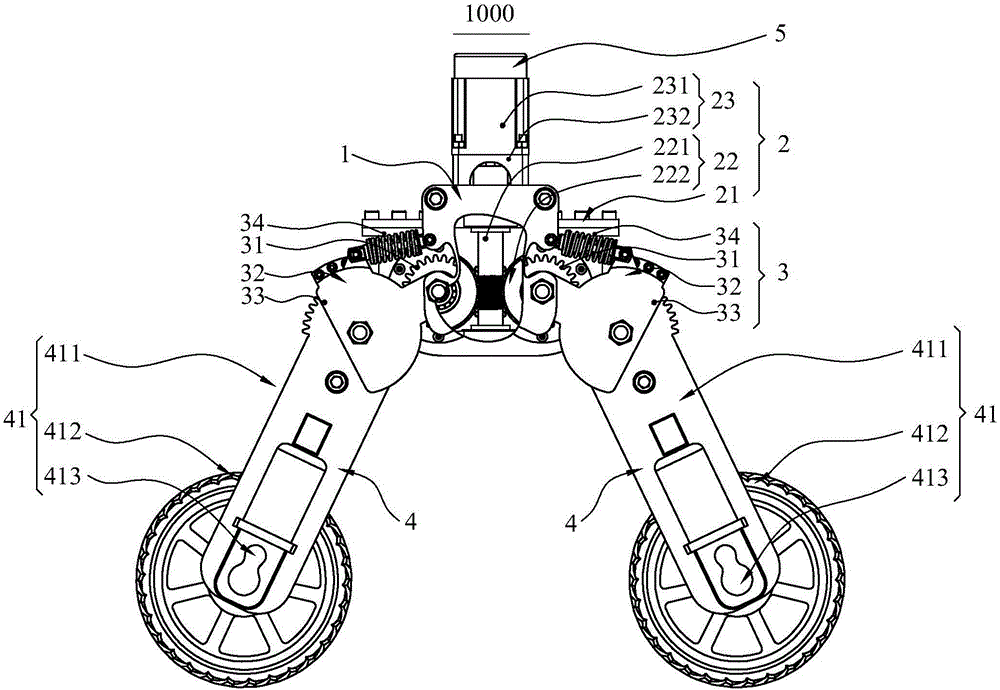

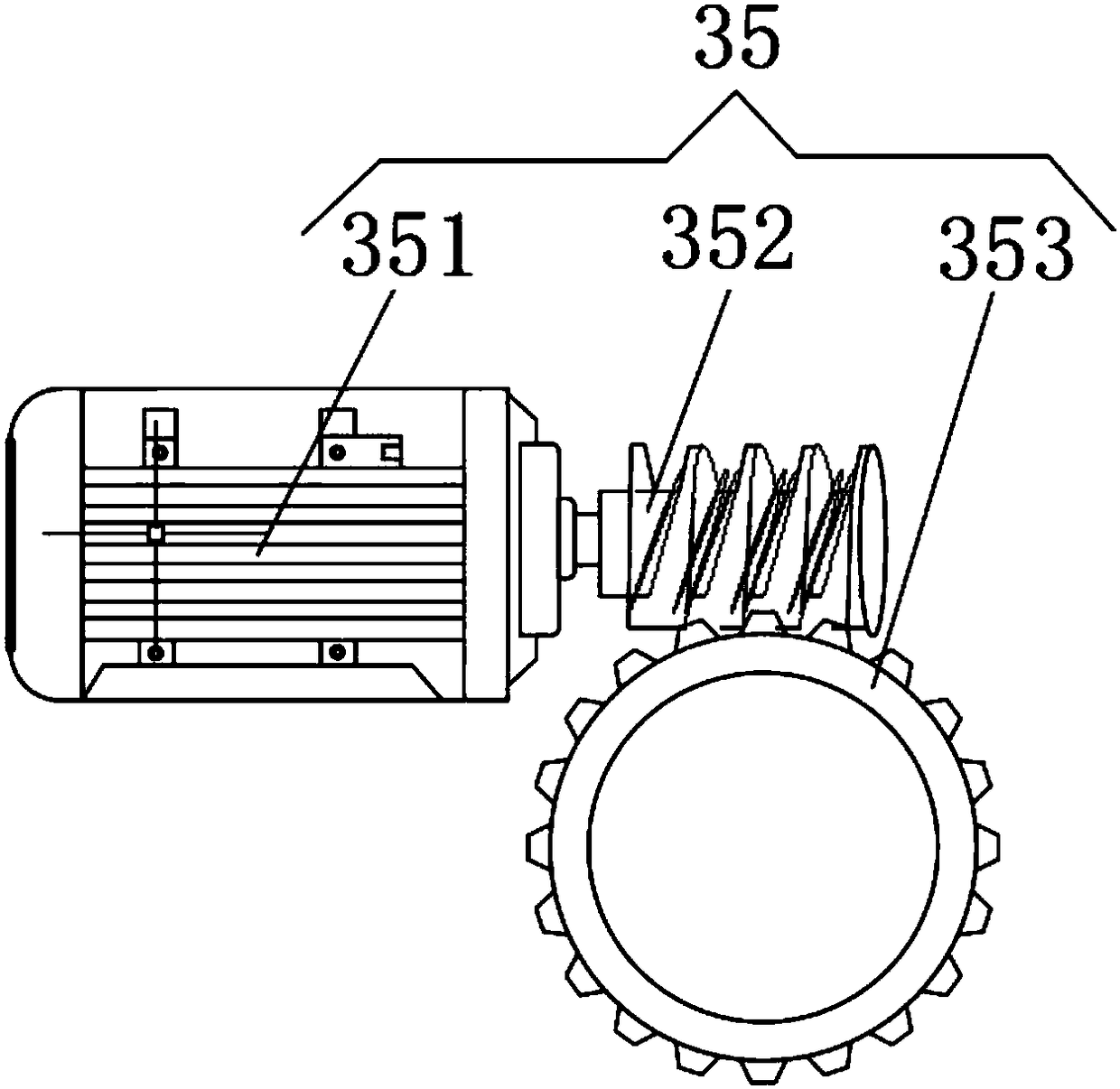

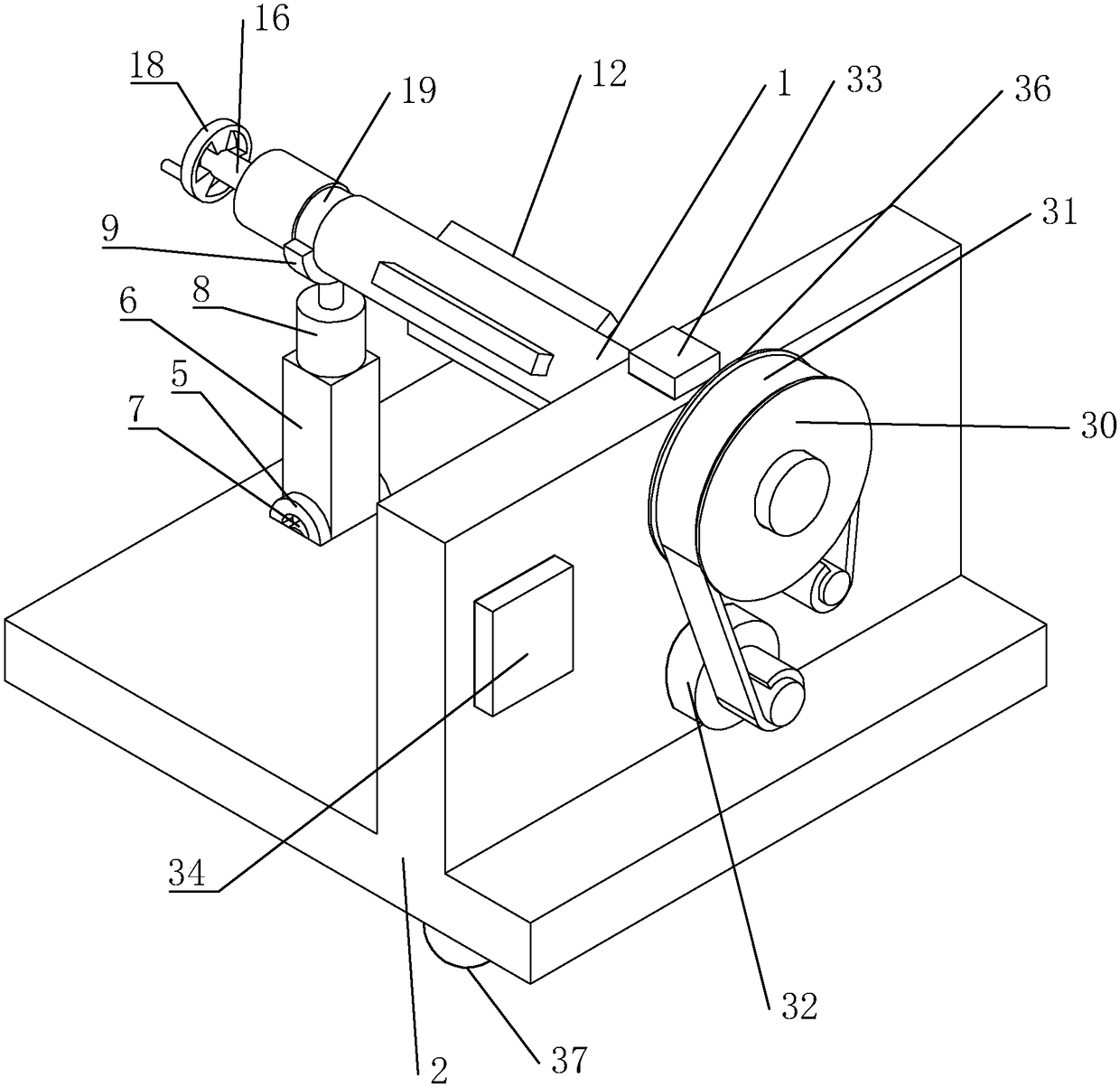

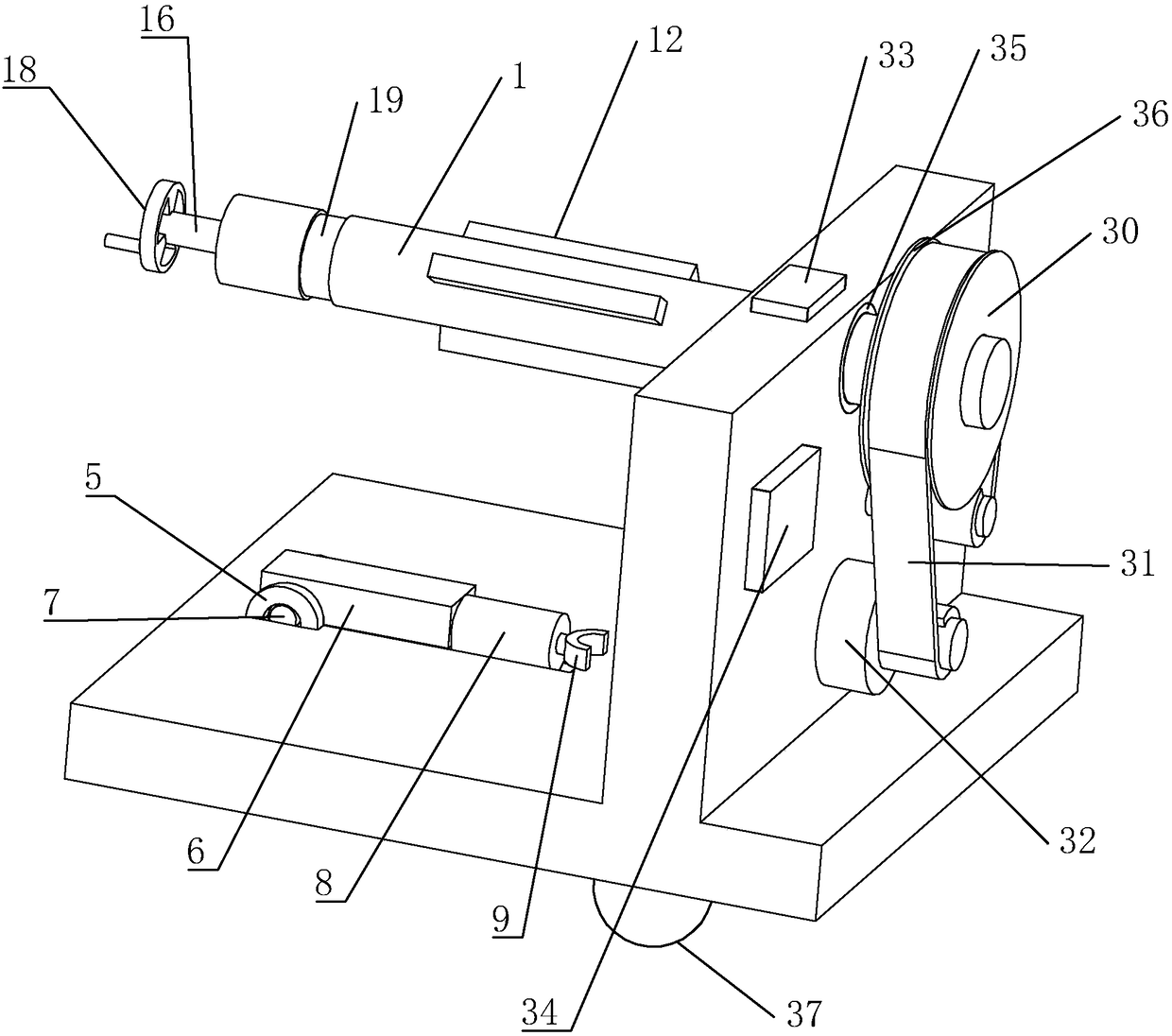

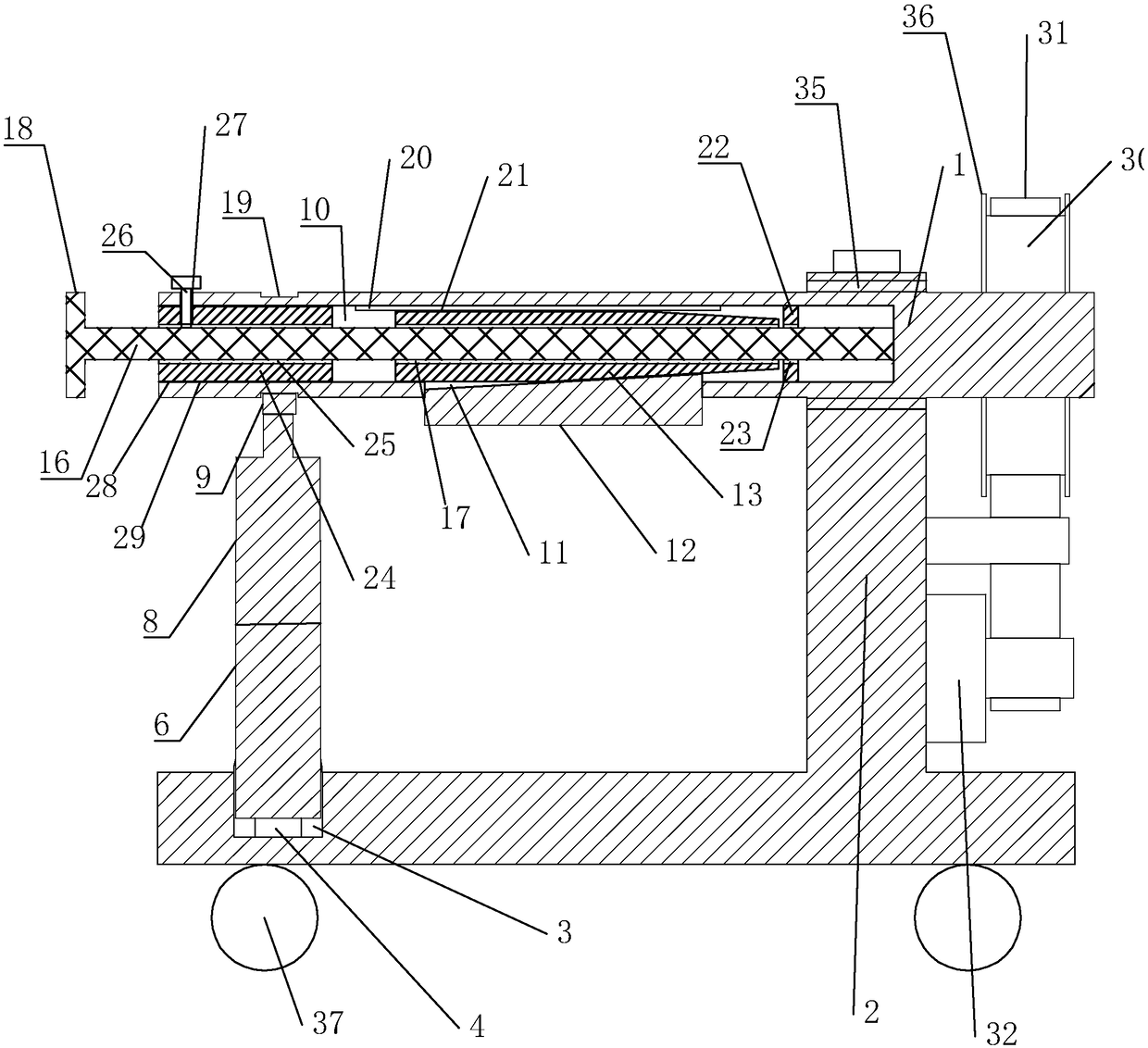

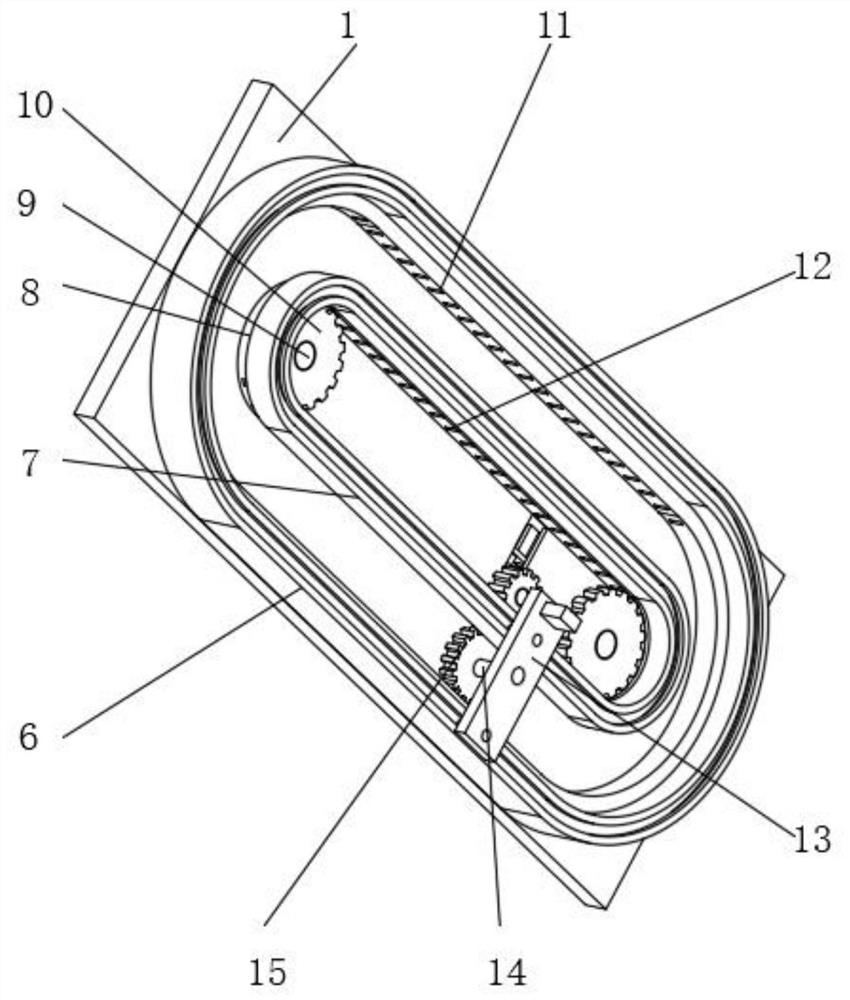

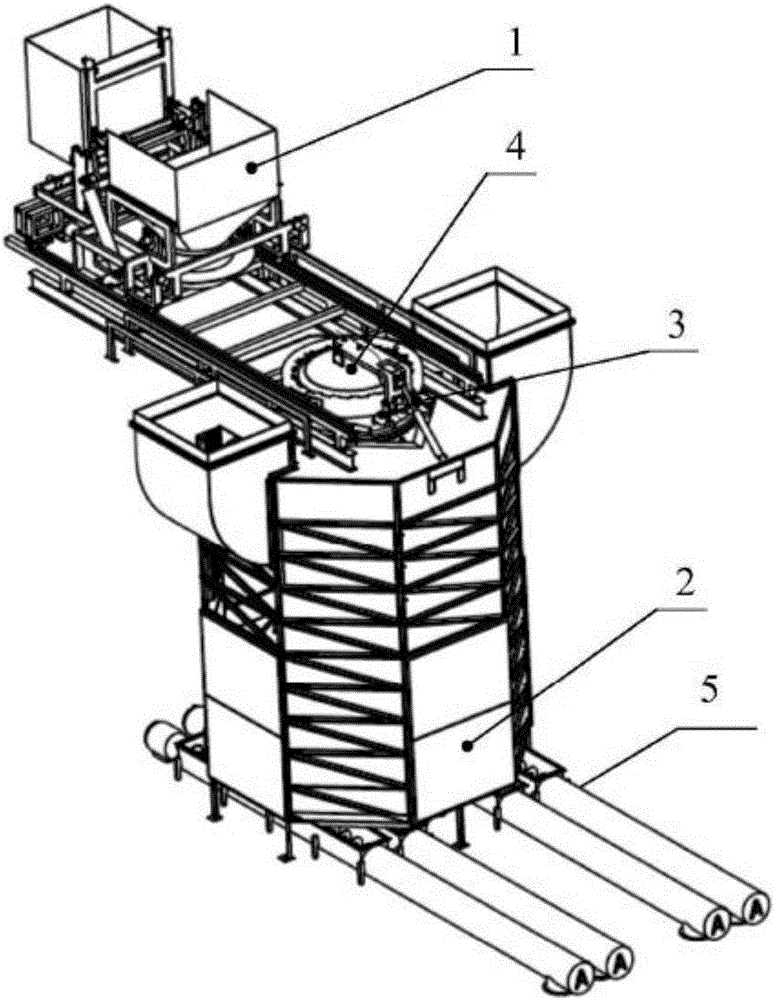

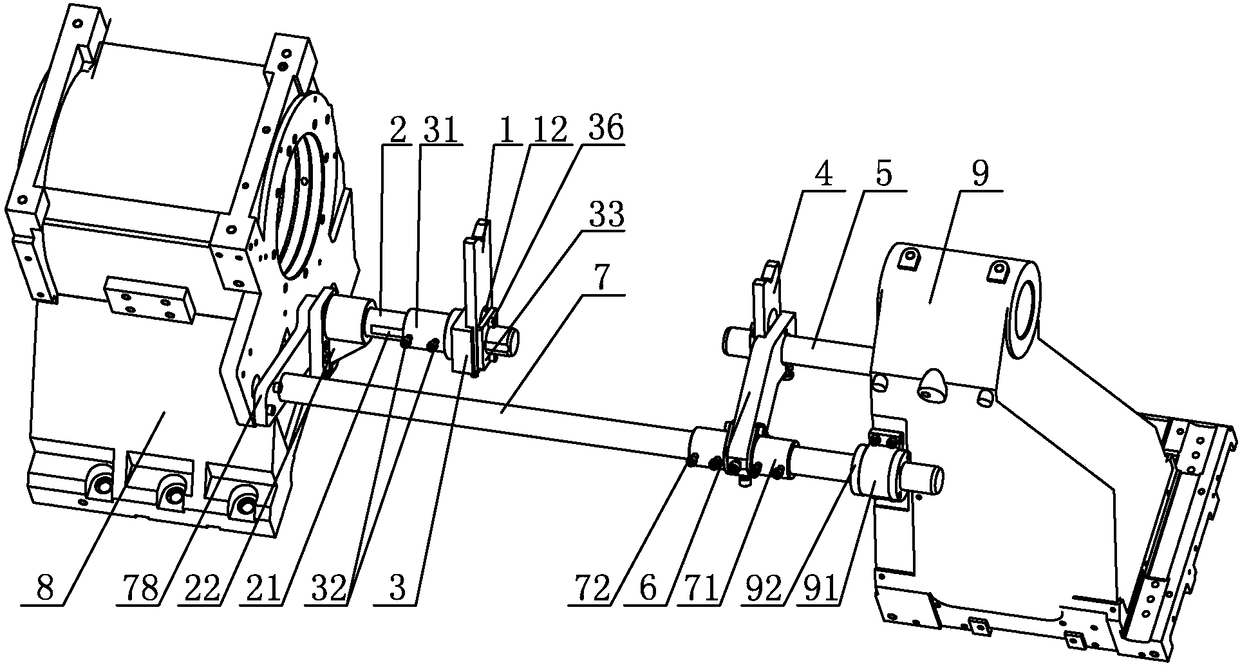

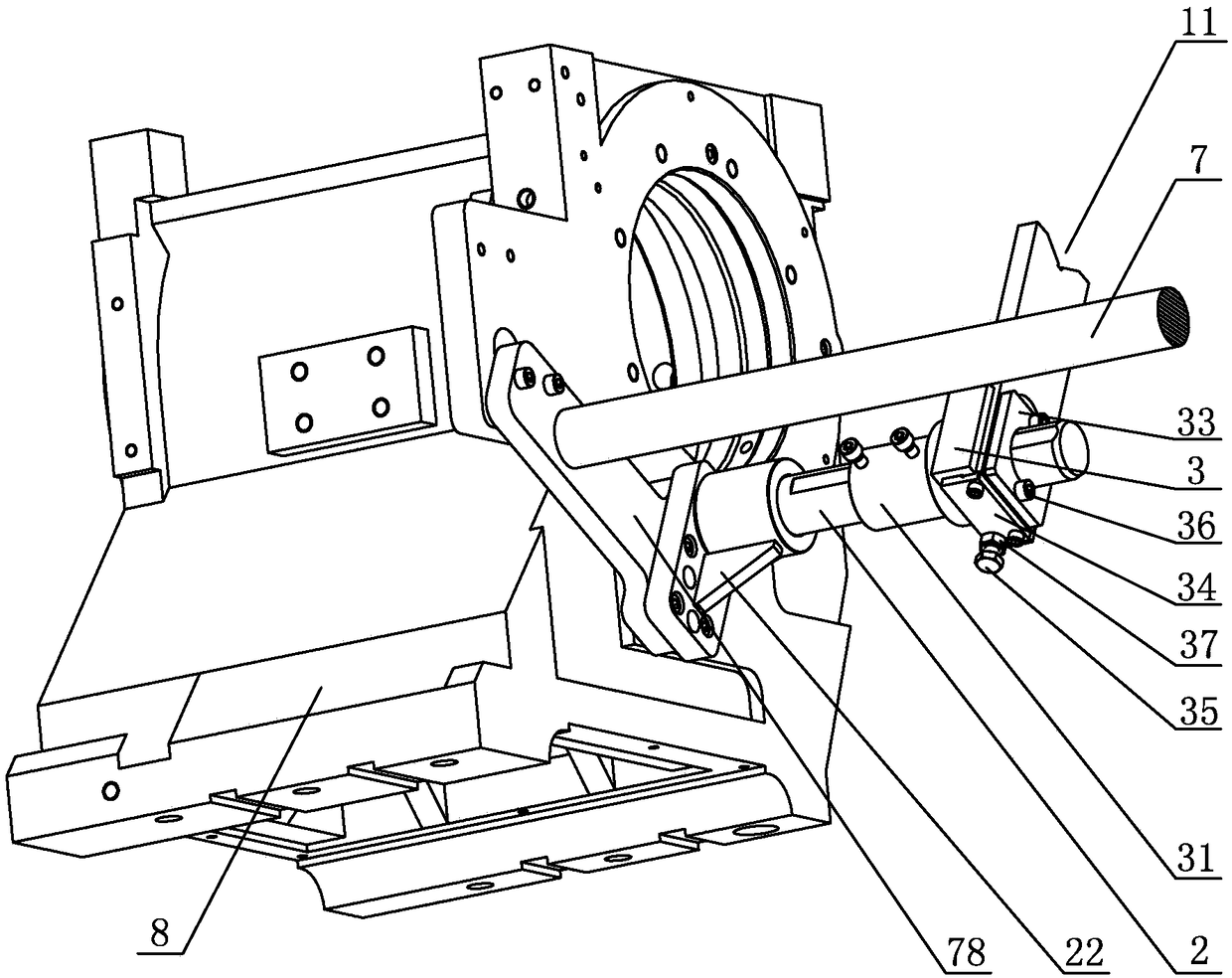

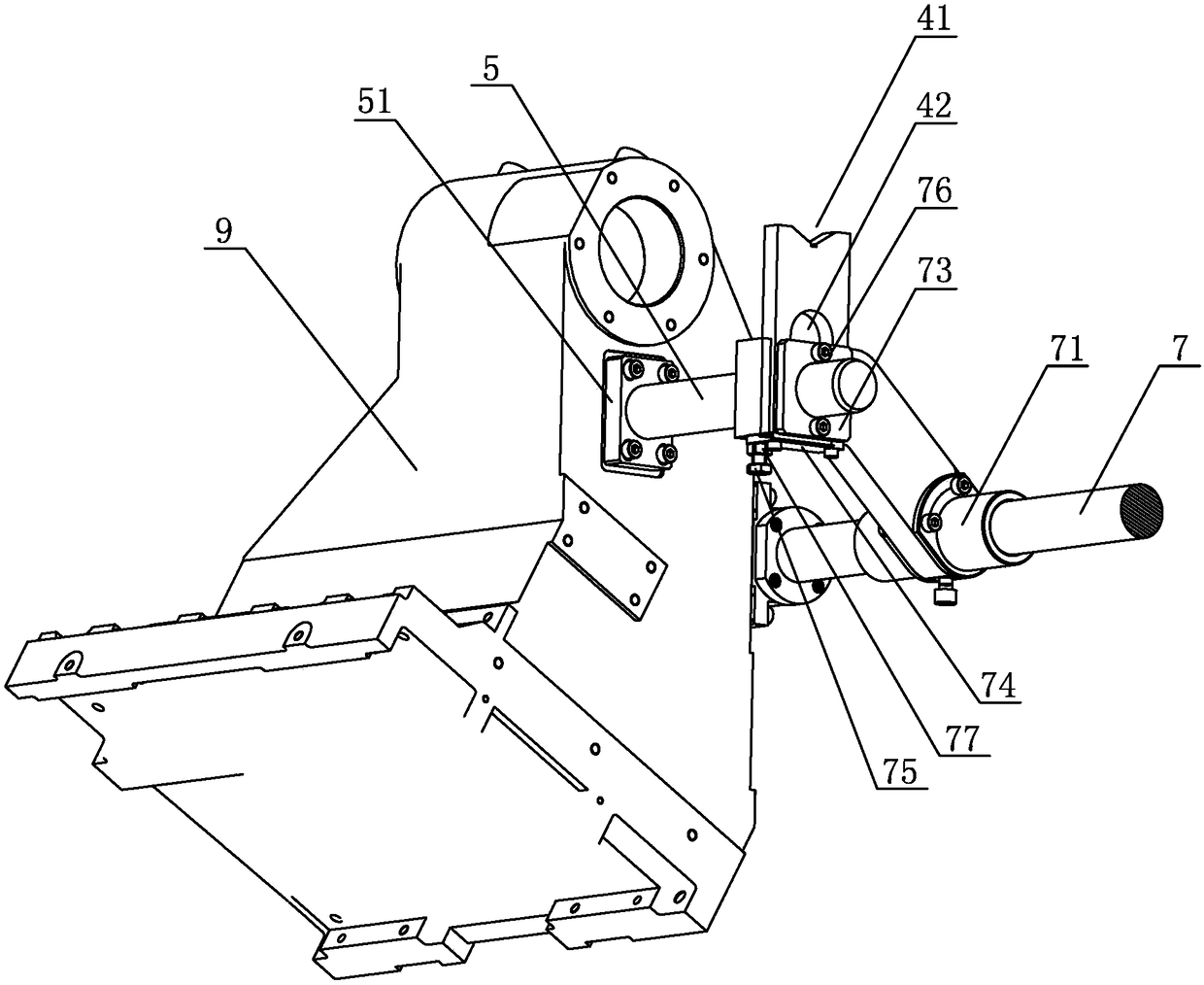

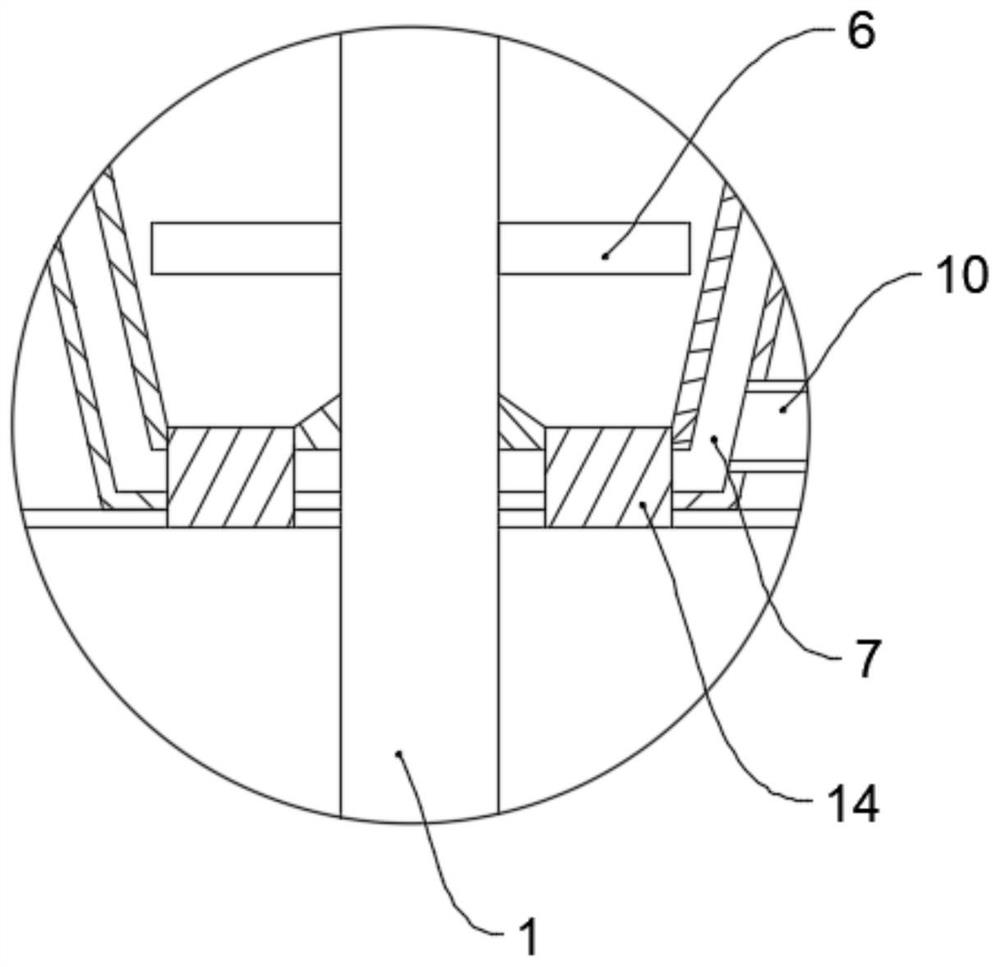

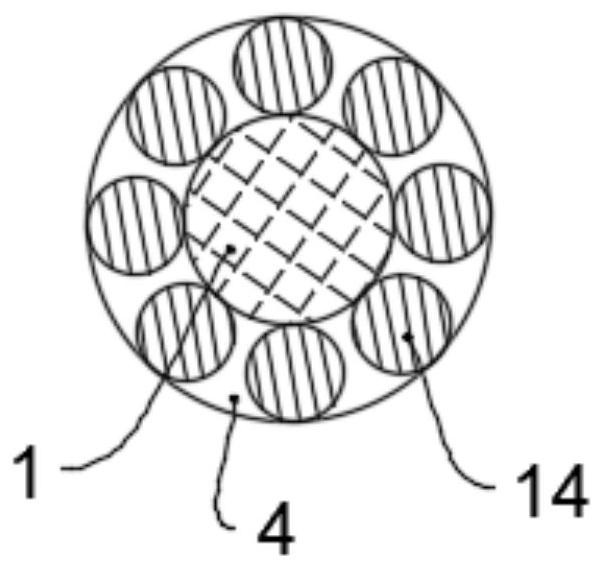

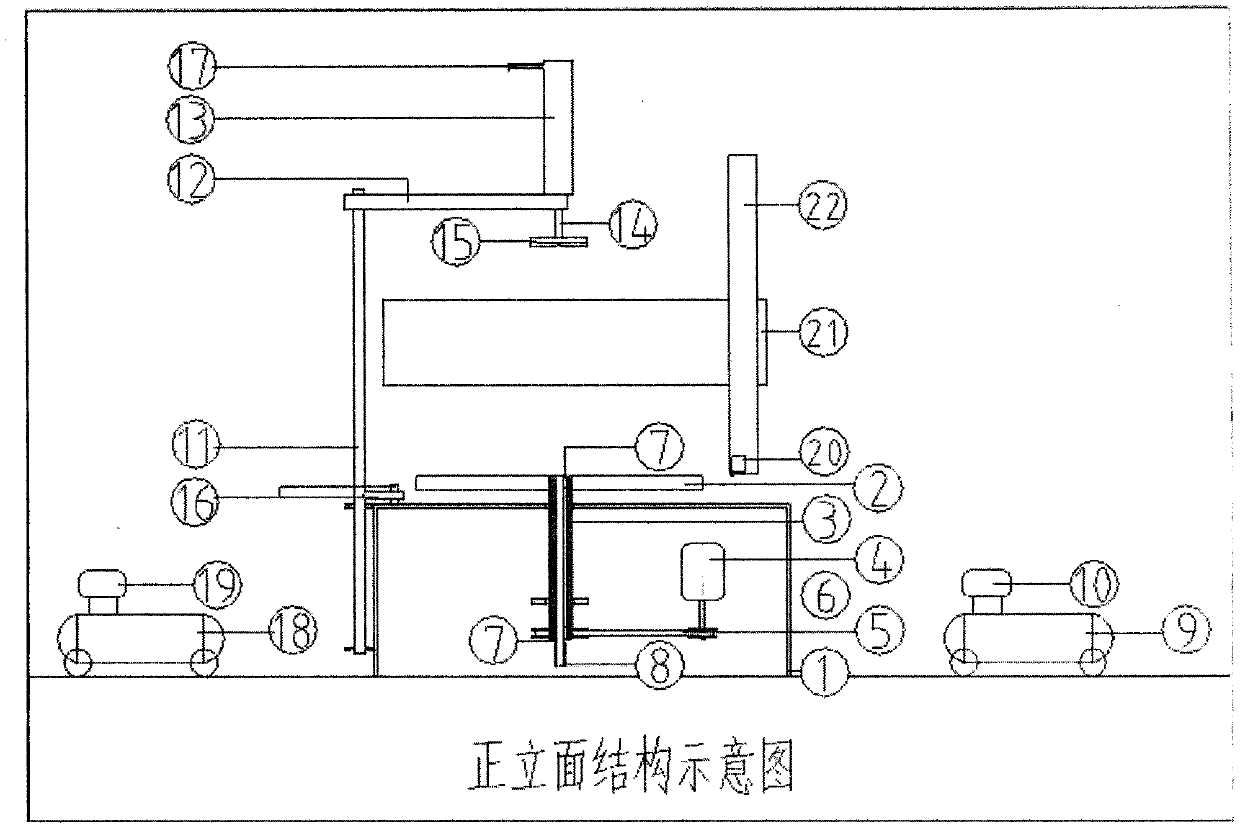

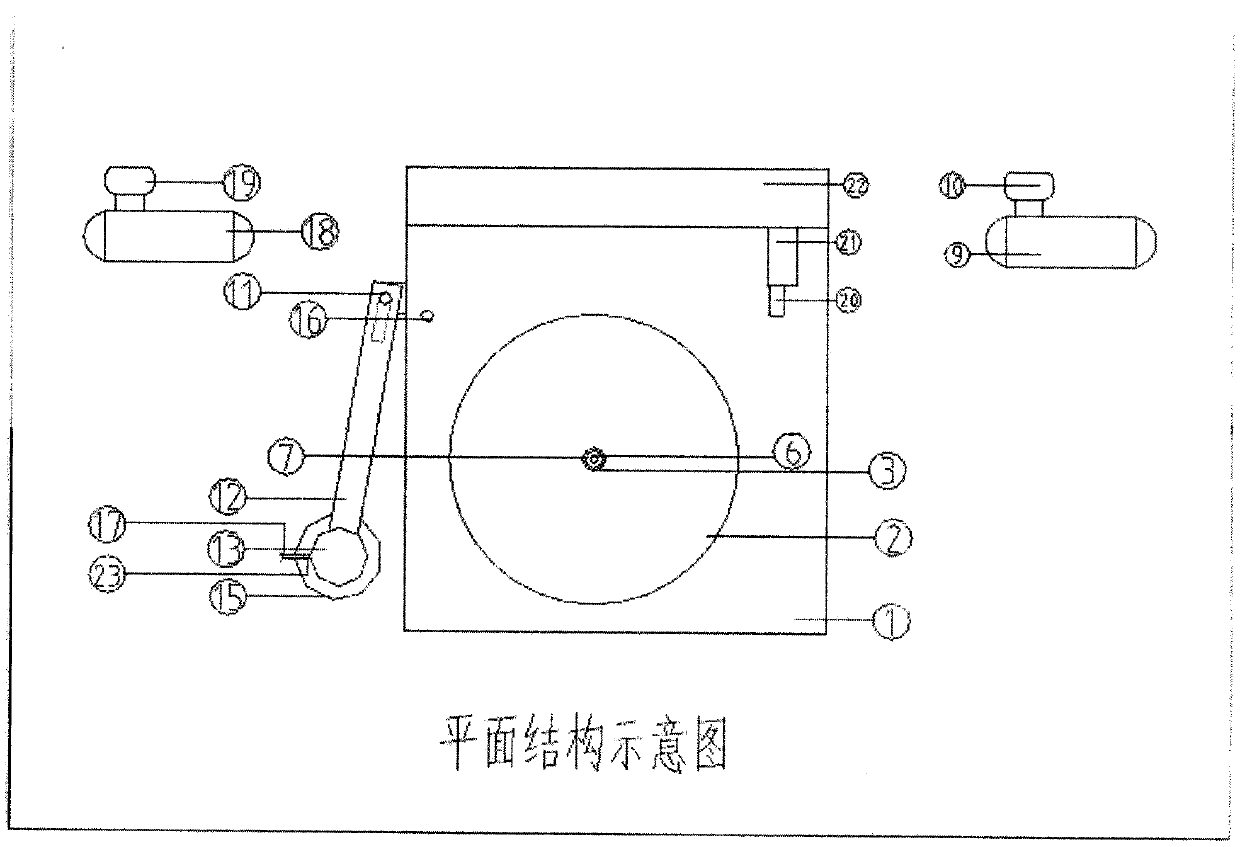

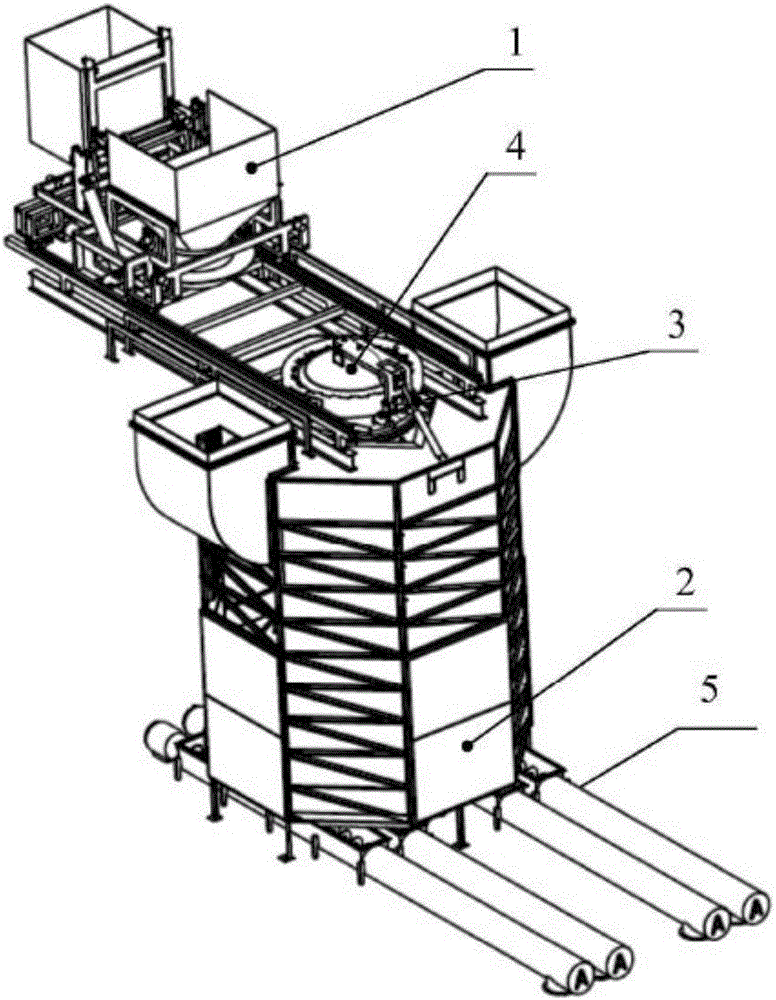

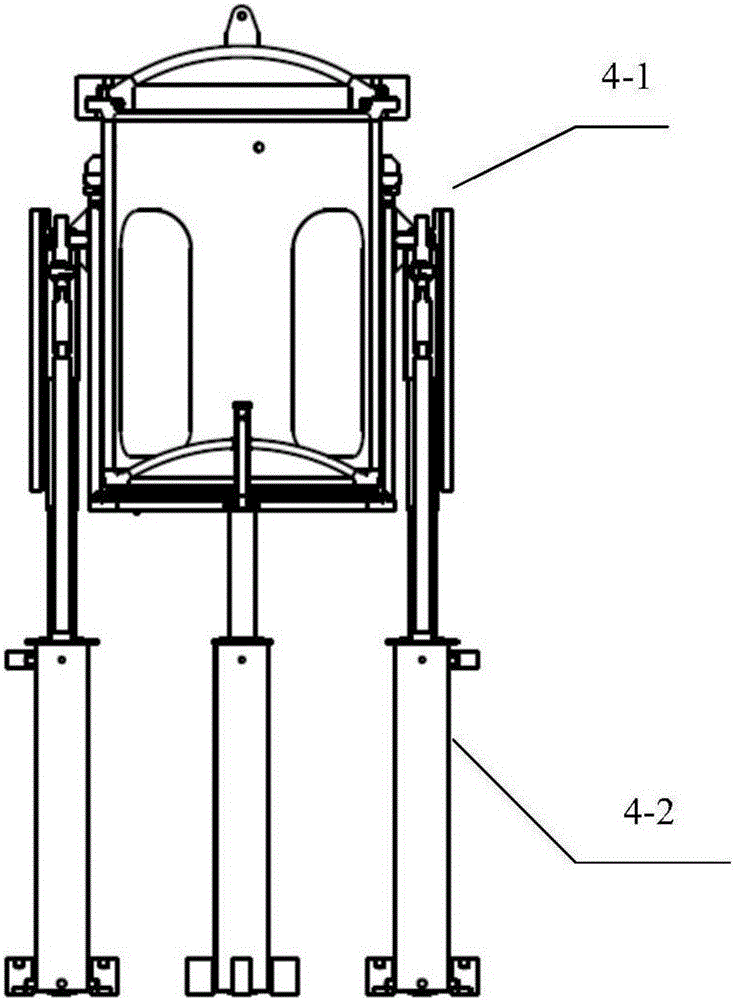

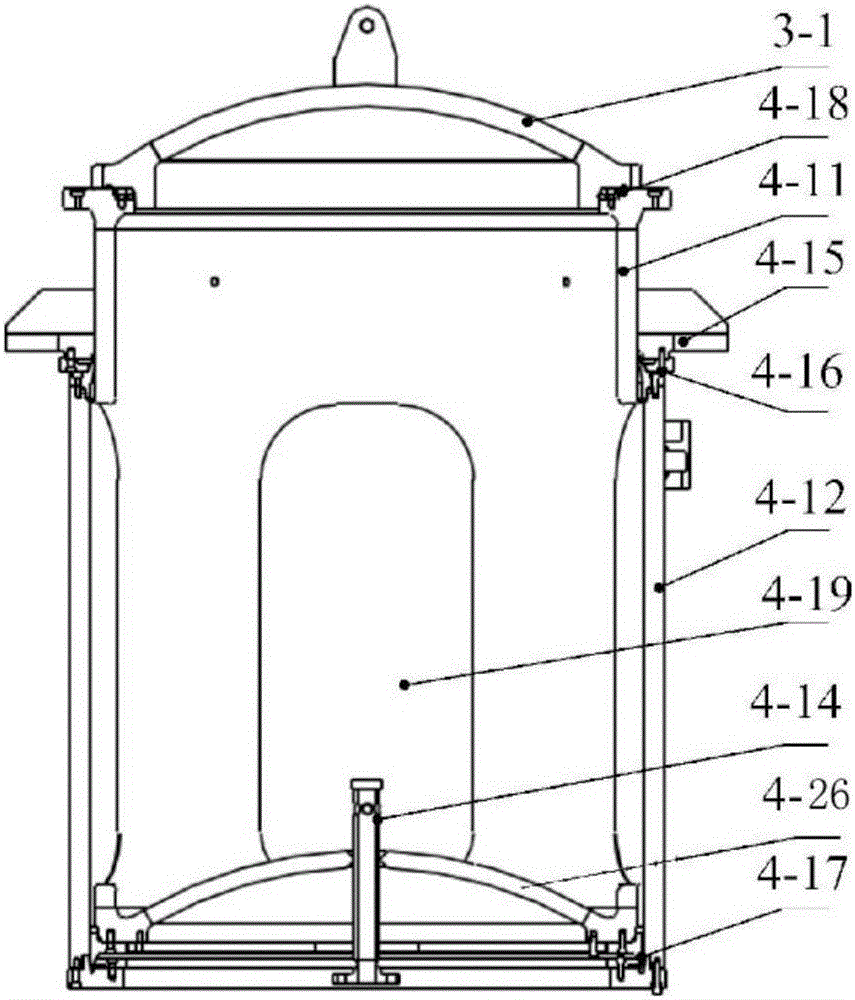

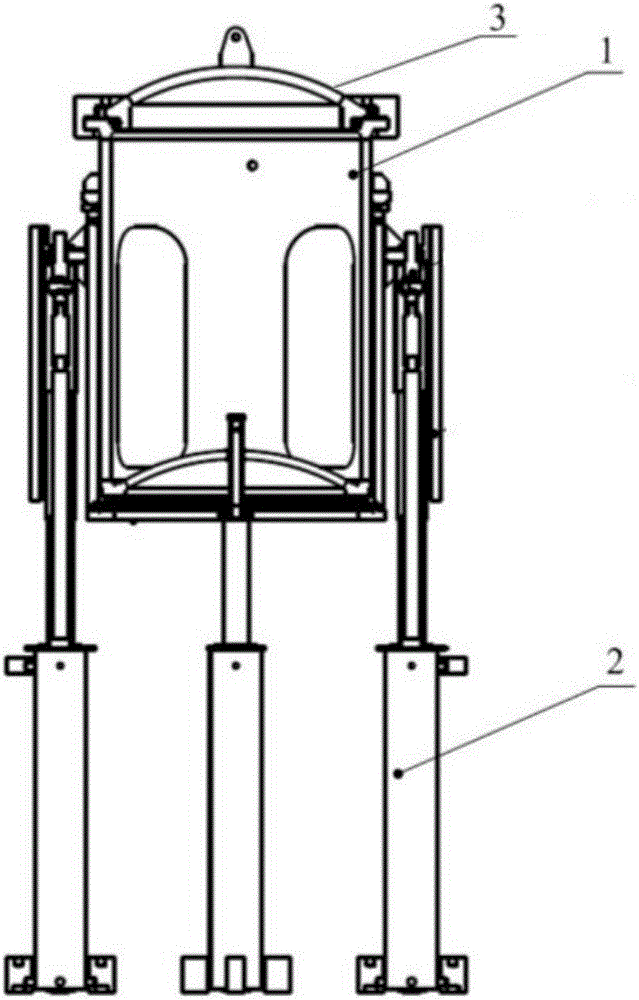

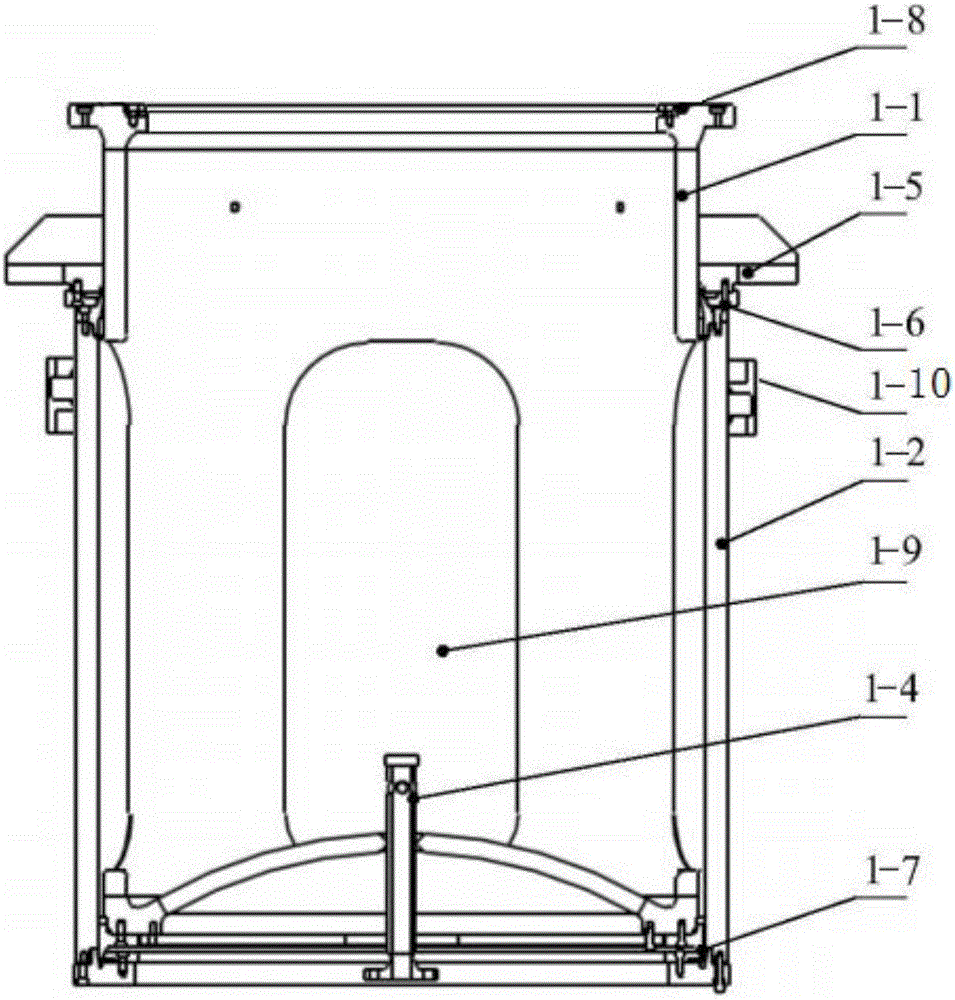

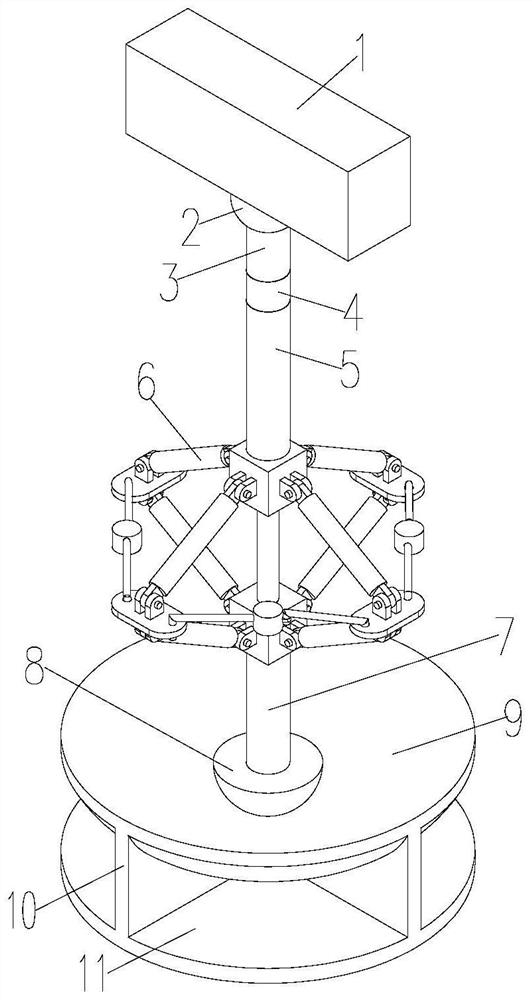

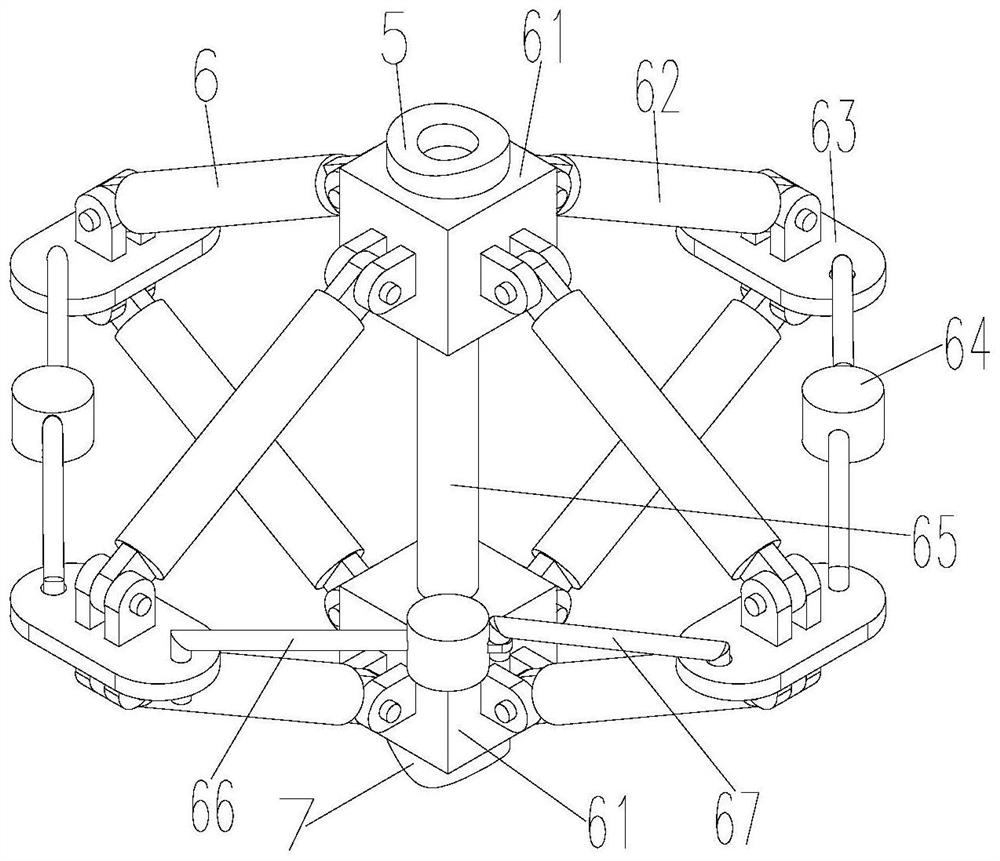

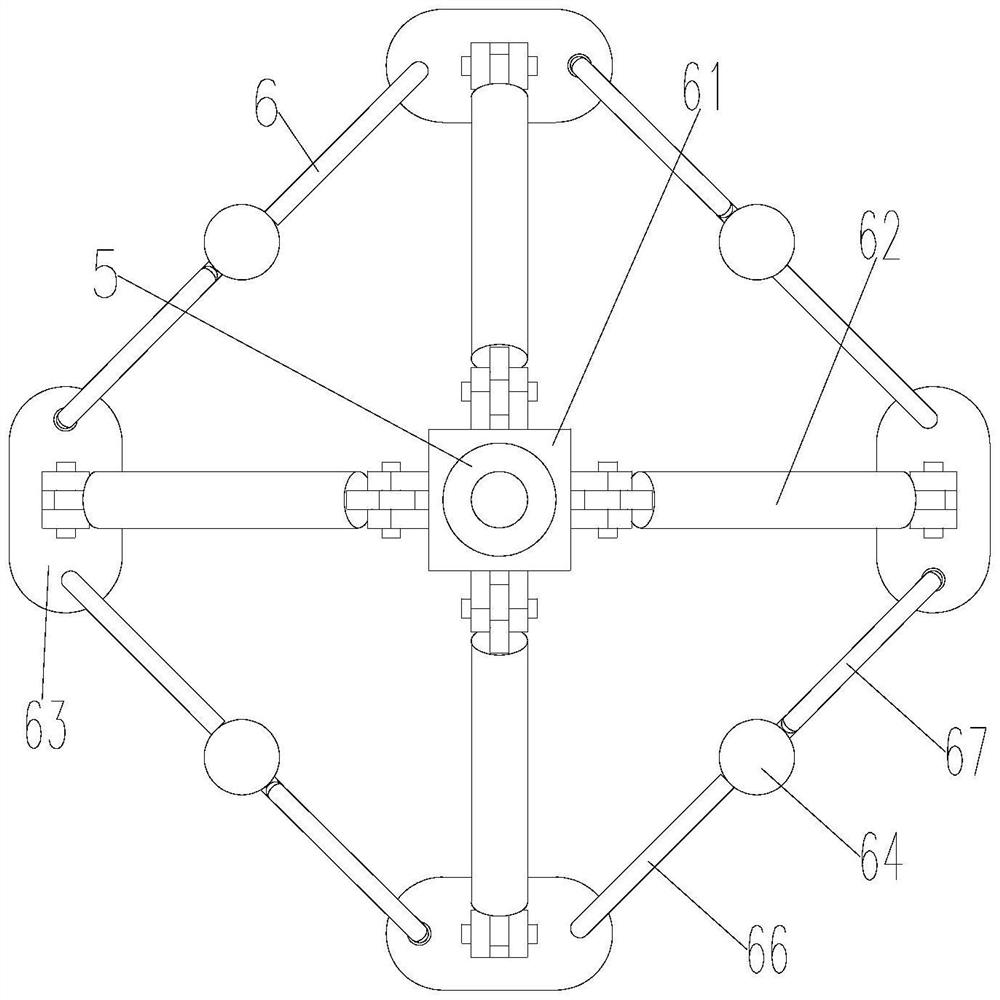

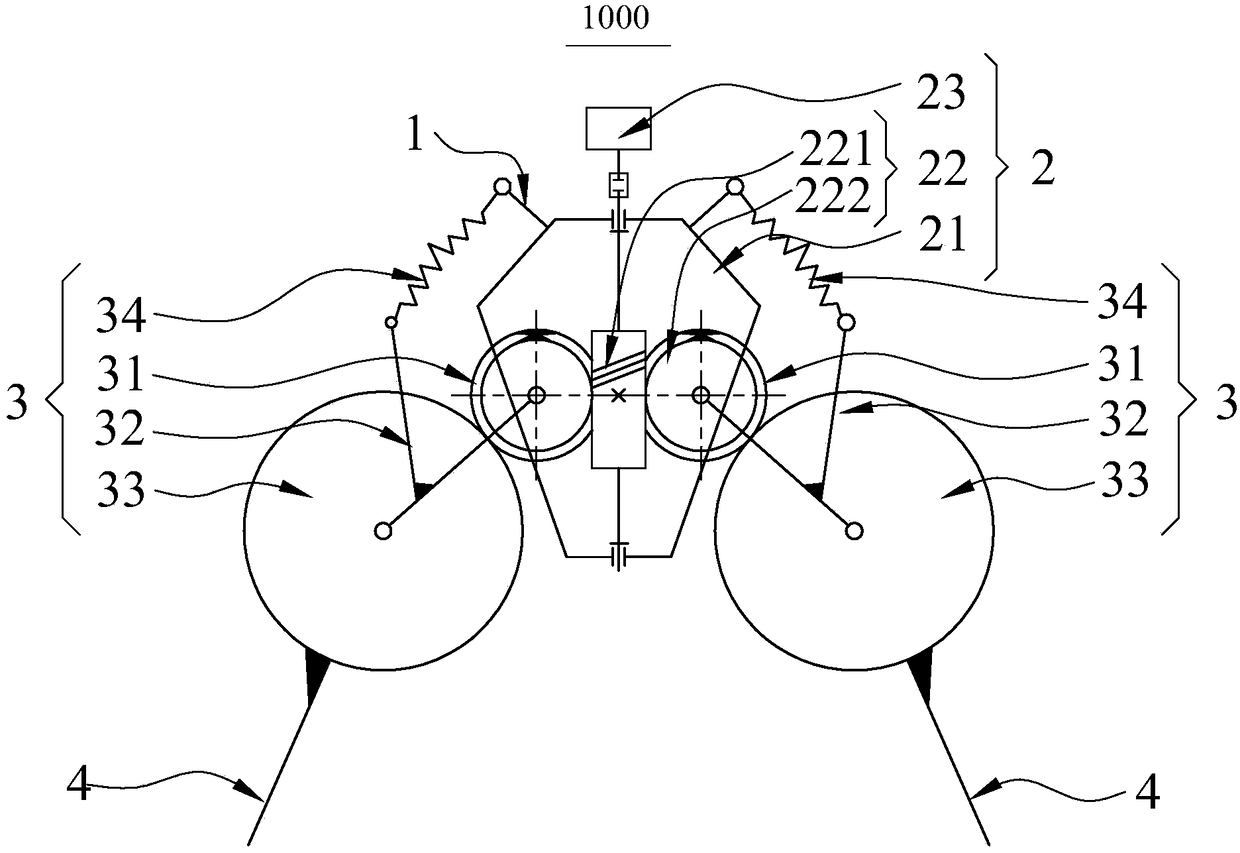

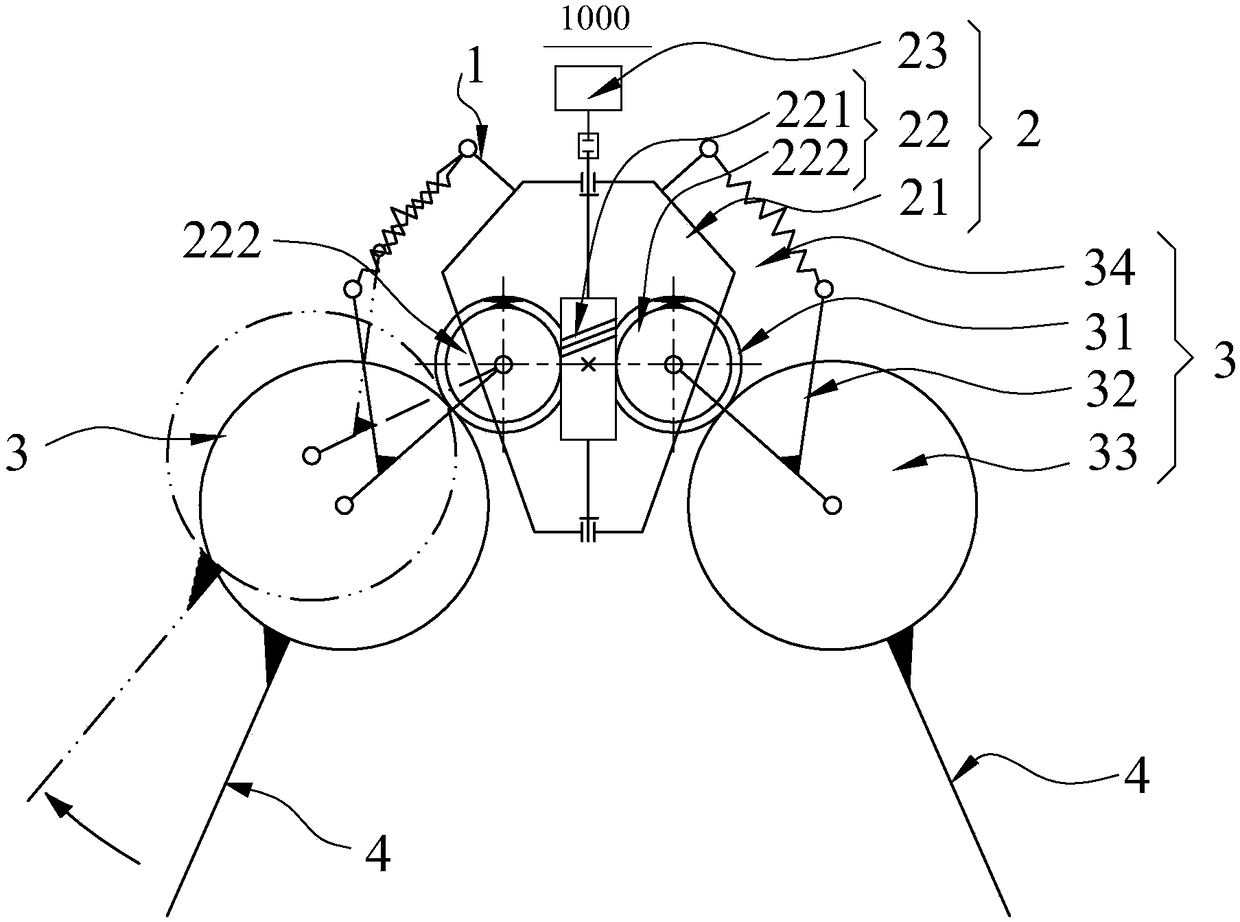

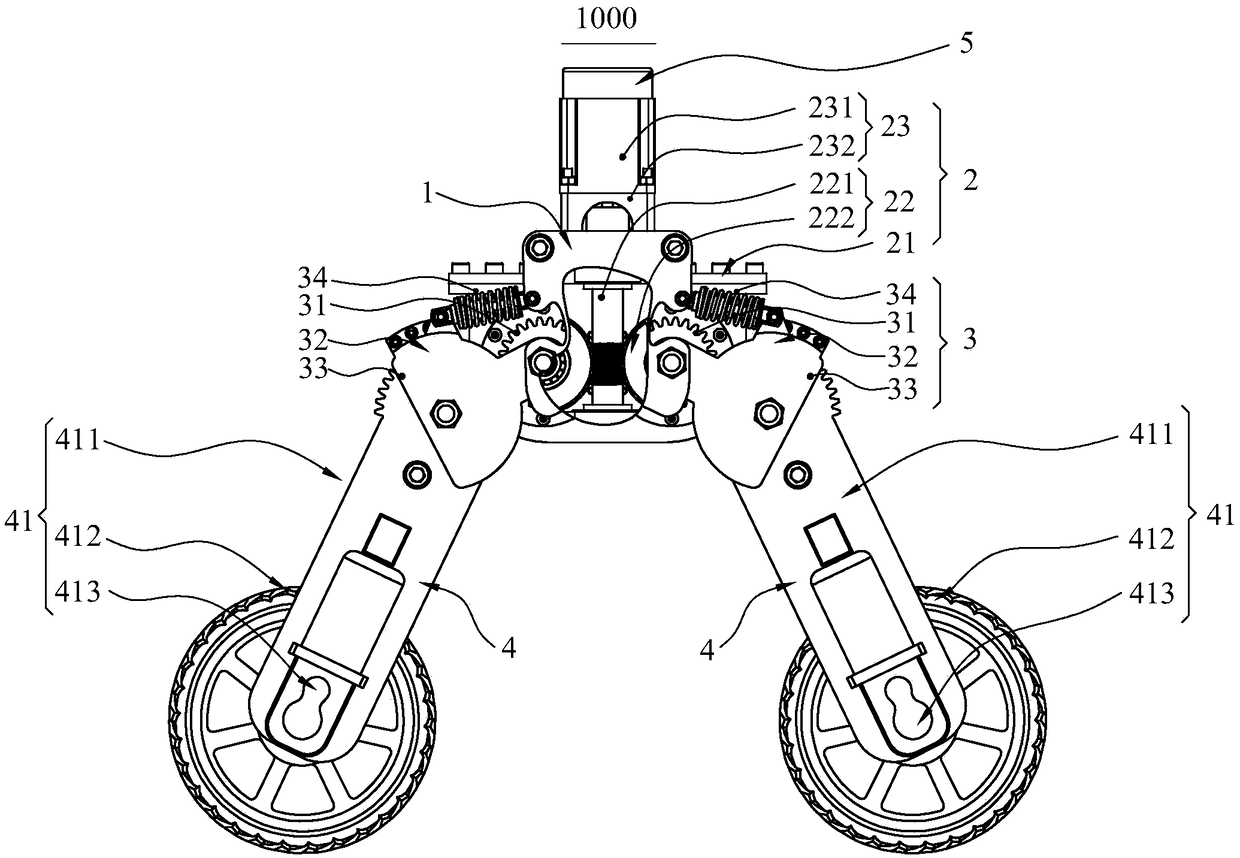

Deformation shock-absorption traveling part of double-worm-gear mechanism and firefighting moving platform with deformation shock-absorption traveling part

ActiveCN106184469AReduce manufacturing costReduce weightInterconnection systemsResilient suspensionsGear wheelEngineering

The invention discloses a deformation shock-absorption traveling part of a double-worm-gear mechanism. The deformation shock-absorption traveling part comprises a stander, an angle adjusting apparatus, epicyclic gear train assemblies and traveling assemblies; the angle adjusting apparatus is connected with the stander, a double-worm-gear mechanism is adopted, and a deformation drive assembly drives a worm to drive two worm gears to rotate; the epicyclic gear train assembly comprises a sun gear, a rocker arm, planetary gears and a shock absorption element; the sun gear is coaxially connected with the worm gears, and the rocker arm is coaxially and pivotally connected with the sun gear; the two planetary gears are pivotally connected with the rocker arm, and the planetary gears are engaged with the sun gear; the shock absorption element is respectively connected with the stander and the rocker arm; and the two epicyclic gear train assemblies are symmetrically arranged, and the two traveling assemblies are respectively connected with the two planetary gears. The invention also provides a firefighting moving platform with the deformation shock-absorption traveling part of the double-worm-gear mechanism. The firefighting moving platform can be used for designing a firefighting robot, so that a robot traveling part is deformable and has shock absorption performance.

Owner:CHINA UNIV OF MINING & TECH

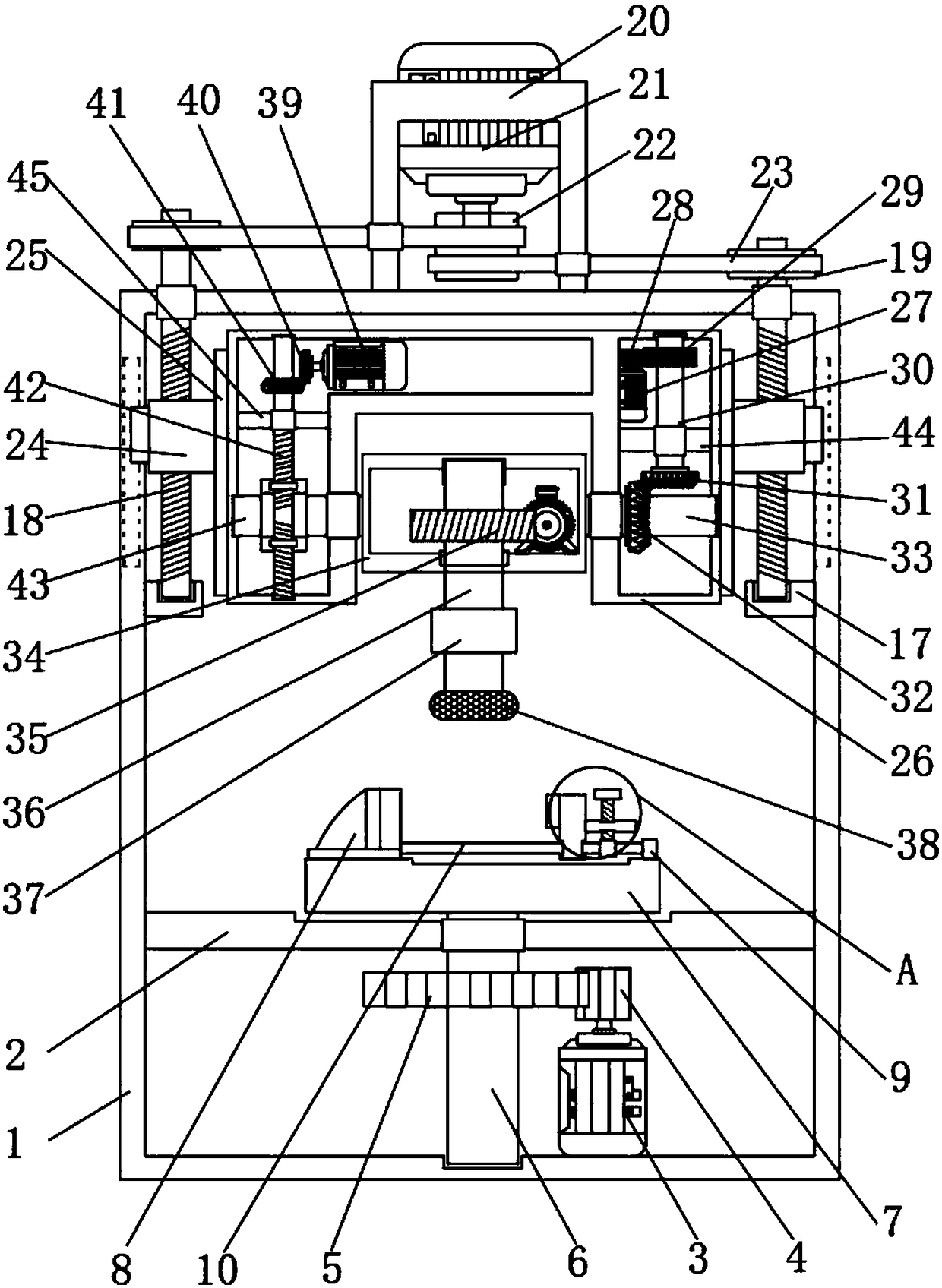

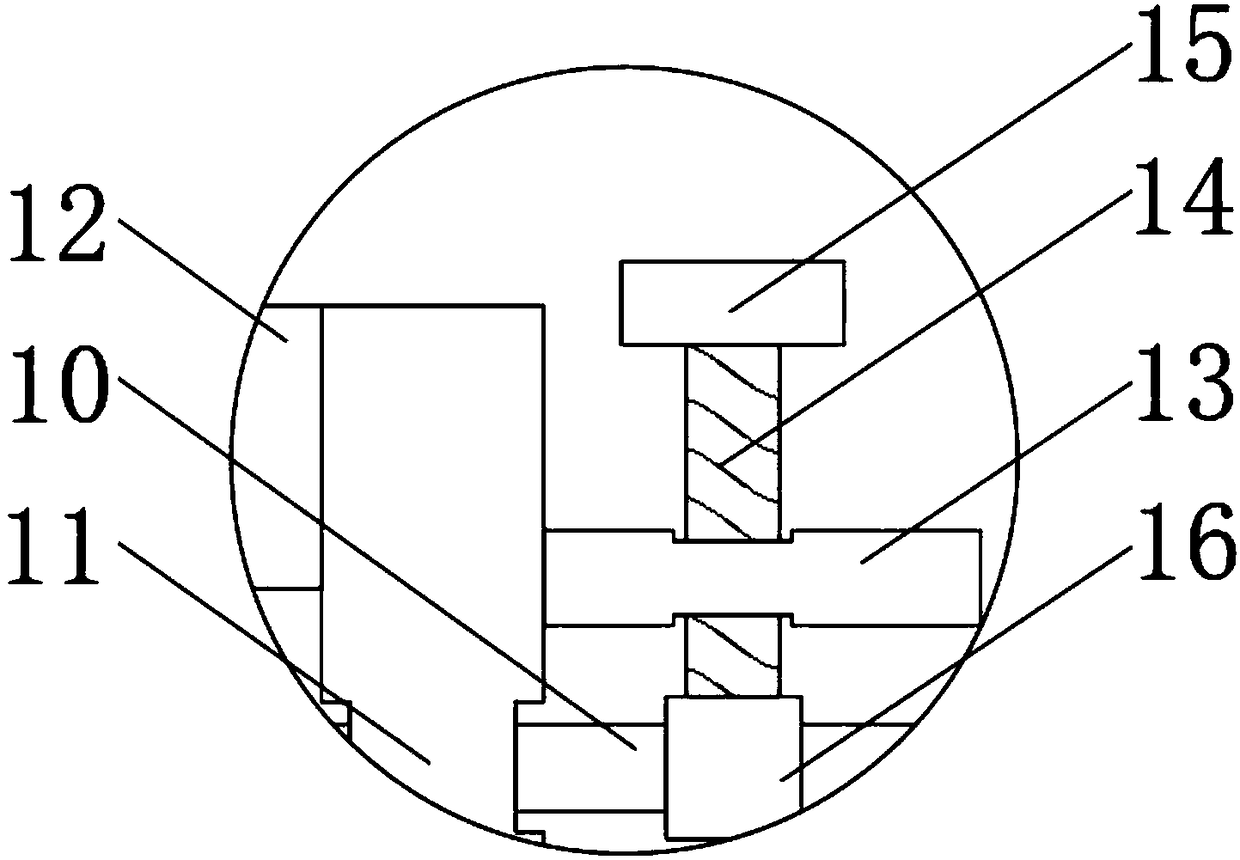

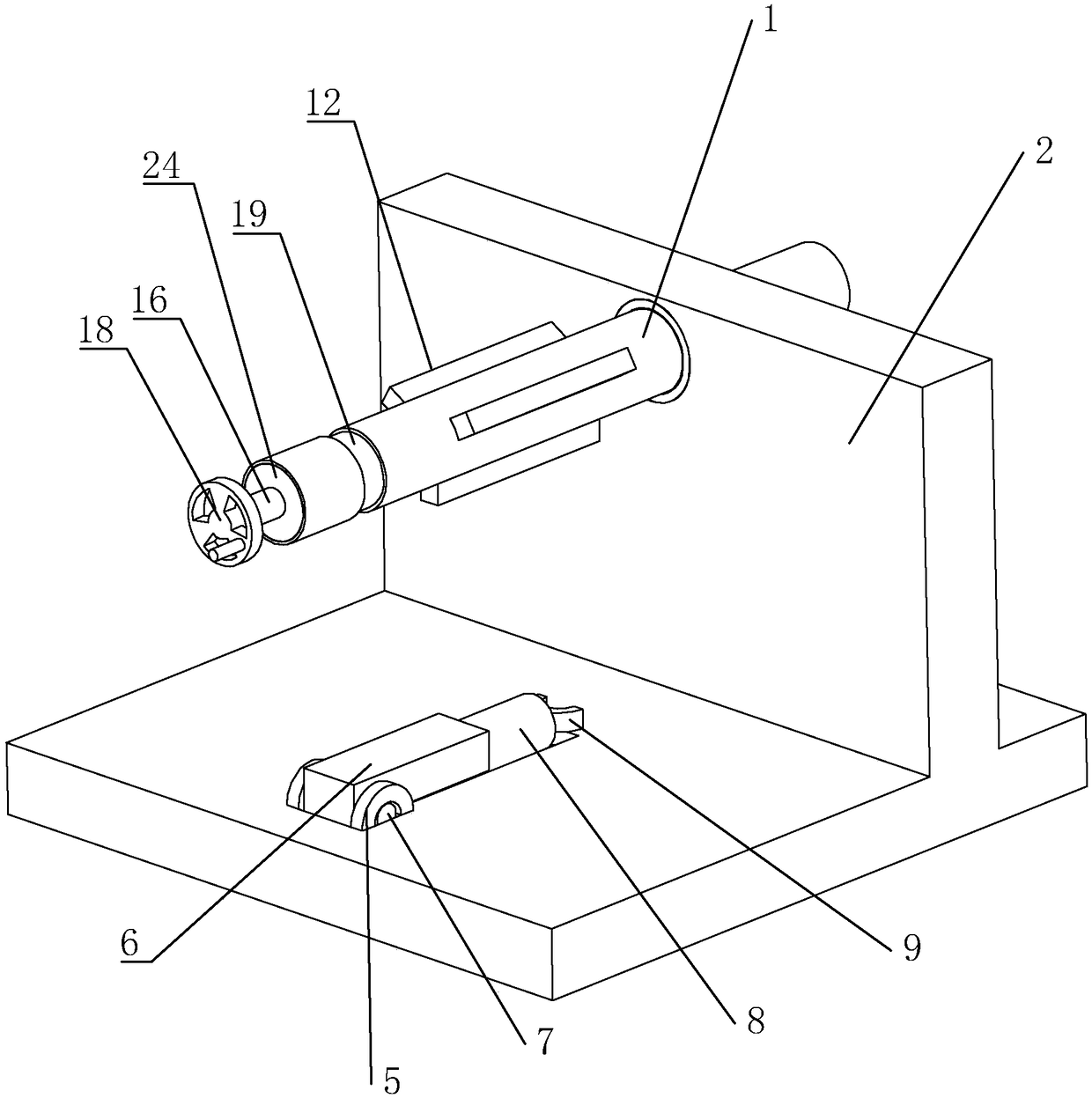

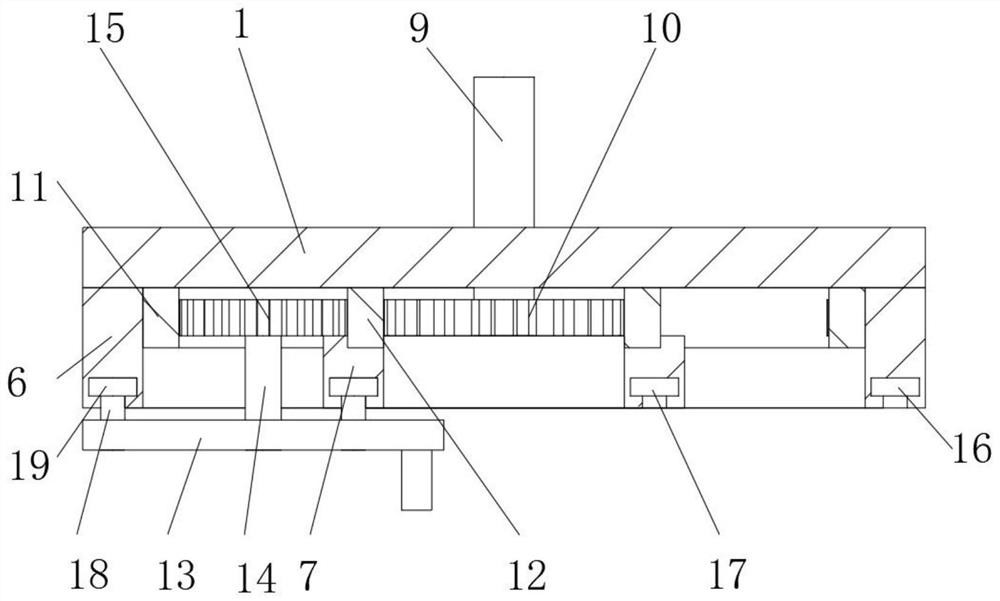

Mould grinding device for aerospace

InactiveCN108177055AEasy to polishImprove work efficiencyGrinding drivesGrinding machinesEngineeringPulley

The invention discloses a mould grinding device for aerospace. The mould grinding device for the aerospace comprises a box body; a fixed plate is fixedly connected between the opposite two sides of the inner wall of the box body; the bottom of the inner wall of the box body is fixedly connected with a first motor; an output shaft end of the first motor is engaged with a second gear trough a firstgear; the centre of the second gear is fixedly connected with a rotating plate through a supporting shaft; each of the two sides of the inner wall of the box body is rotatably connected with a threaded rod through a fixed block; one end of each threaded rod is fixedly connected with a first belt pulley; the surface of each threaded rod is in threaded connection with a threaded block; one side of each threaded block is fixedly connected with a grinding box through a connecting plate; the inner wall of the grinding box is fixedly connected with a rotating box through a first transmission shaft;and the inner wall of the rotating box and one end of the grinding rod are fixedly connected with a grinding head through a driving device. The invention relates to the technical field of aerospace manufacturing. The mould grinding device for the aerospace solves the problem of low efficiency in a multi-angle grinding process and improves the machining efficiency.

Owner:佛山杰致信息科技有限公司

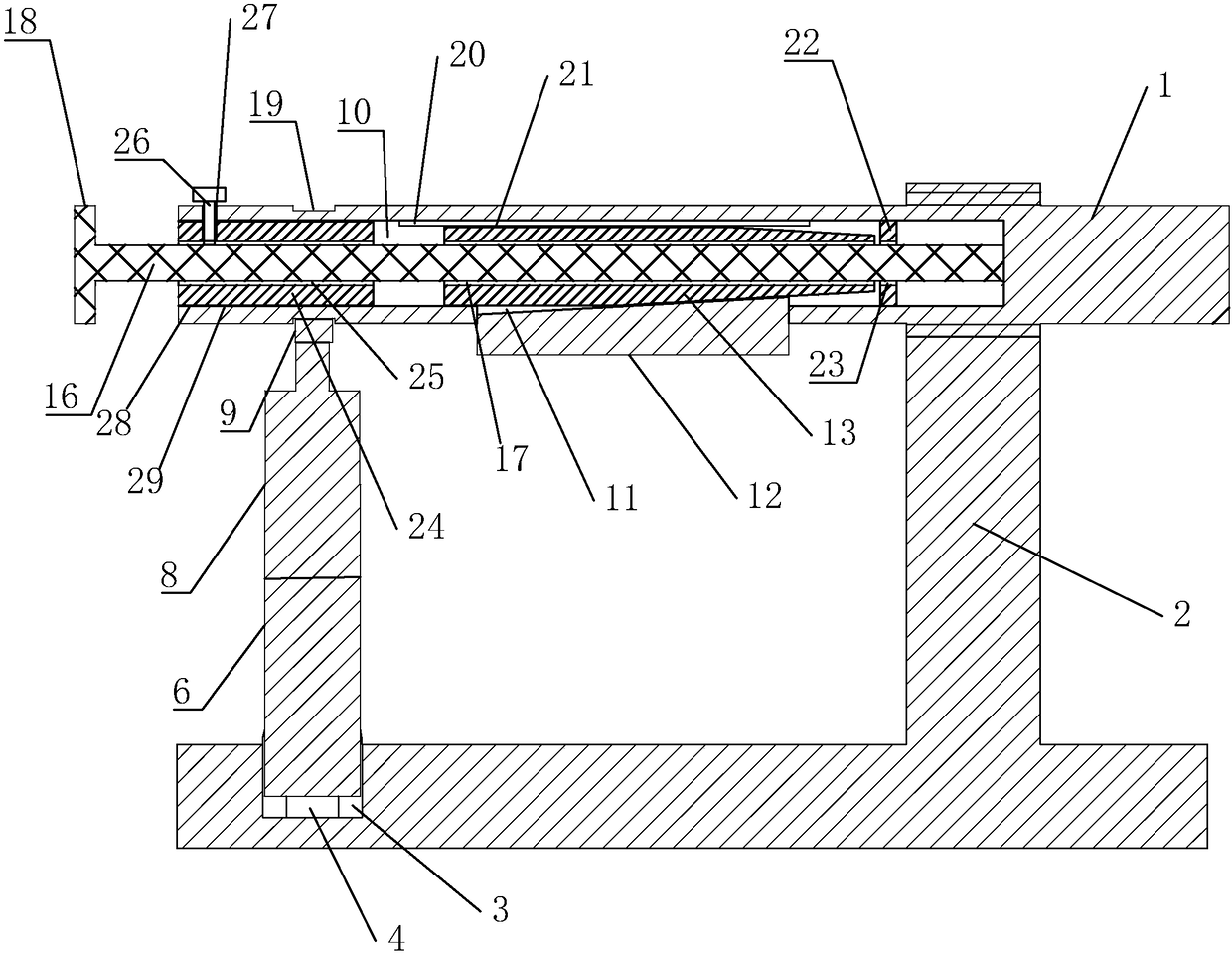

Transformer wire placement rack and method of using the same

PendingCN108666129ASmooth rotationAvoid shaking and falling offInductances/transformers/magnets manufactureHydraulic cylinderTransformer

The invention discloses a transformer wire placement rack and a method of using the same, the technical scheme is characterized by comprising a rack, a rotating shaft, a friction disc, a friction strip, a servo motor, a sensor and a controller, wherein a square groove is arranged at one end of the rack directly facing the rotating shaft protruding from the shaft barrel; a square rod is arranged inthe square groove in a sliding manner; a hydraulic cylinder is arranged at one end of the square rod away from the square groove; a semicircular bearing matched with the rotating shaft is arranged atthe top end of a piston rod of the hydraulic cylinder; a sliding block is mounted in a through groove in a sliding mode, a push block is installed in a circular cavity in a sliding mode, and a screwis mounted in the circular cavity in a rotating mode. According to the transformer wire placement rack, the rotating shaft can be dynamically loaded and output, the situation that the output load andthe preset parameters are the same in the wire drawing process are improved, the product quality rate and the production efficiency are improved, the stability of the shaft barrel on the rotating shaft can be improved, and the shaking situation of the rotating shaft on the rack can be avoided.

Owner:浙江派尔电气有限公司

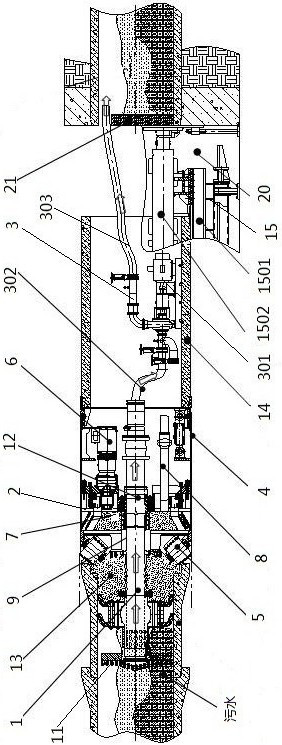

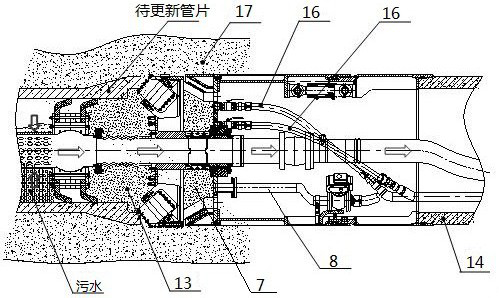

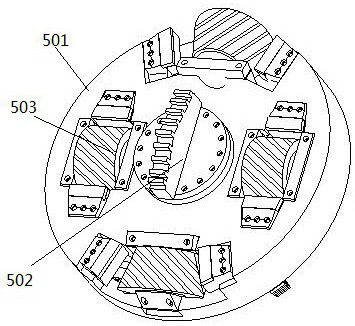

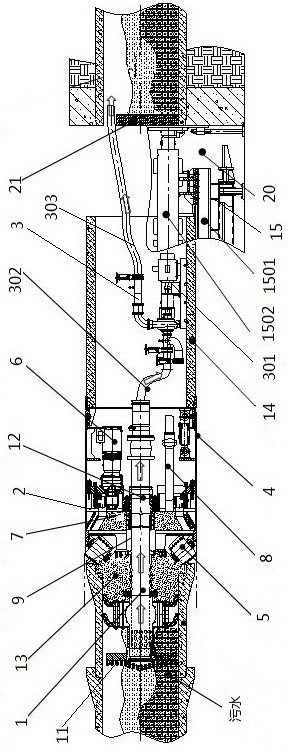

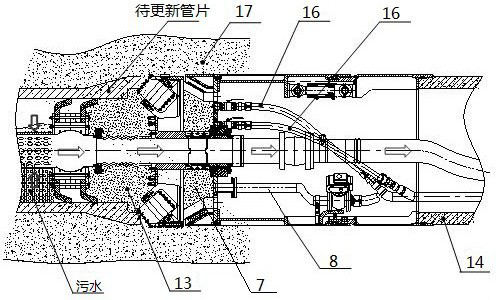

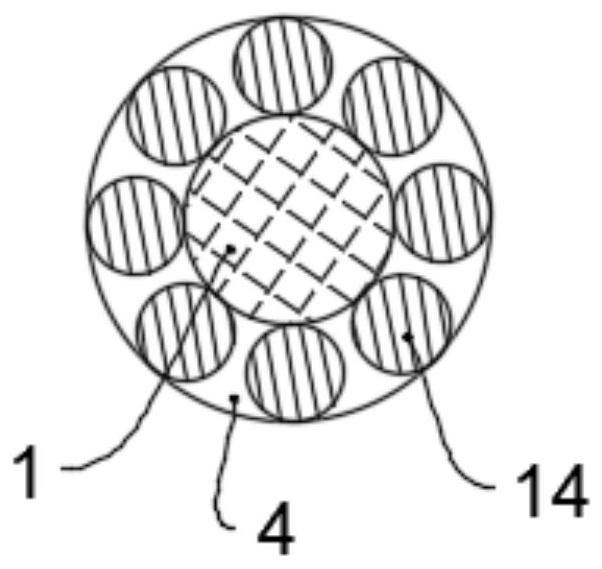

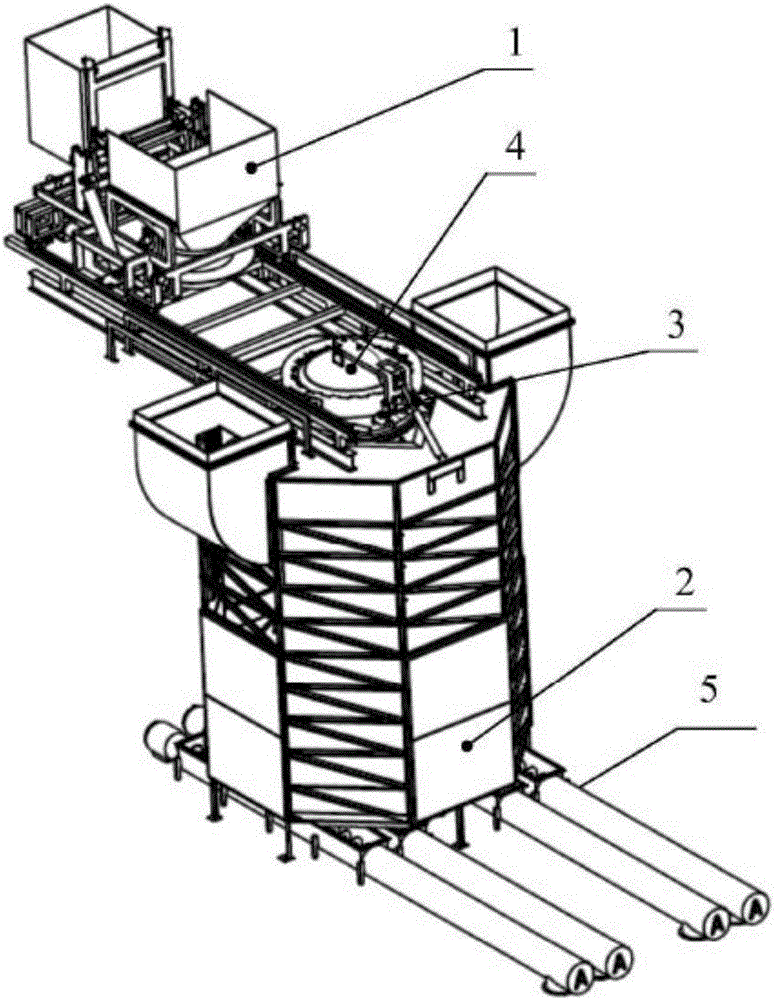

Pipe renewal tunneling machine and construction method thereof

ActiveCN111852493AWith the ability to ensure flow without interceptionRealize the security functionUnderground chambersTunnel liningSludgeSlurry

The invention discloses a pipe renewal tunneling machine and a construction method thereof. The pipe renewal tunneling machine comprises a main tunneling unit and a dredging circulating system, wherein a sludge-removing dredging device is arranged on the front portion of the main tunneling unit, and the sludge-removing dredging device penetrates through the main tunneling unit to be connected withthe dredging circulating system. The main tunneling unit comprises a shield body and a breaking and tunneling cutter head, a main drive is arranged in the shield body, the main drive is connected with the breaking and tunneling cutter head, an excavation bin is arranged between the breaking and tunneling cutter head and the main drive, a slurry inlet pipe is arranged on the upper portion of the excavation bin, and a sludge discharging system is connected with the lower portion of the excavation bin. The sludge-removing dredging device penetrates through the main tunneling unit to be connectedwith the dredging circulating system, in the tunneling process, the sludge-removing dredging device goes ahead of the cutter head of the main tunneling unit, sludge in a pipeline is removed, waste water in the pipeline flows backwards through the dredging circulating system, and it is ensured that a fluid medium in a renewed pipeline is not unblocked in the construction process, the renewed pipeline can keep unblocked and cannot be cut off, and it is achieved that pipeline breaking and renewal laying are synchronously completed.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

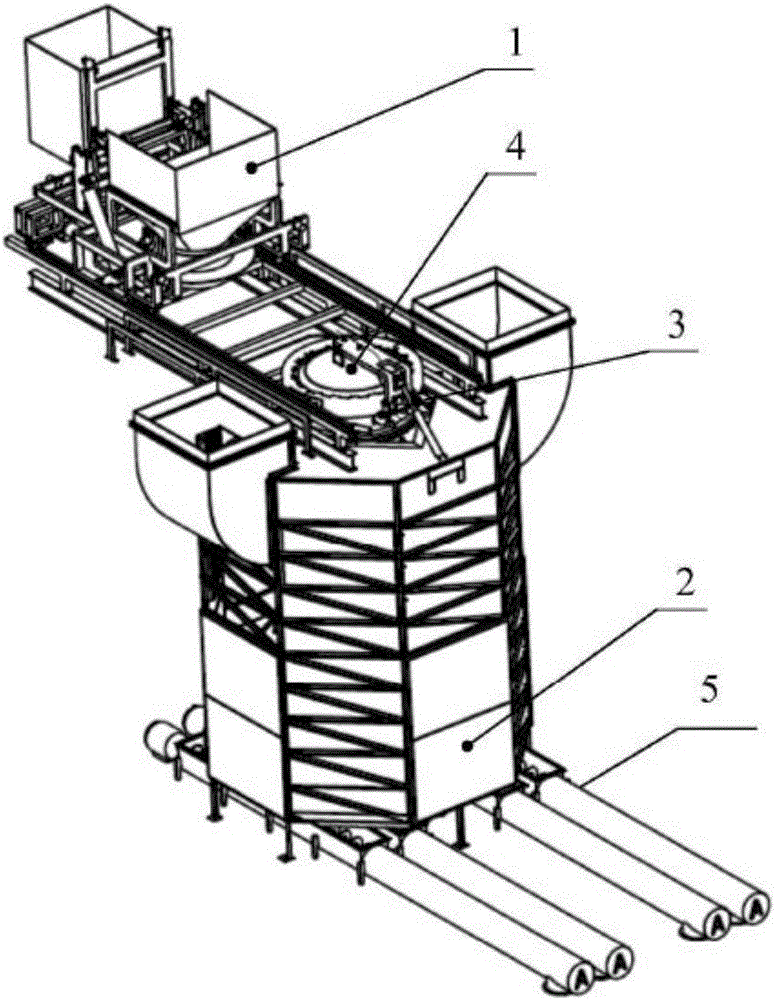

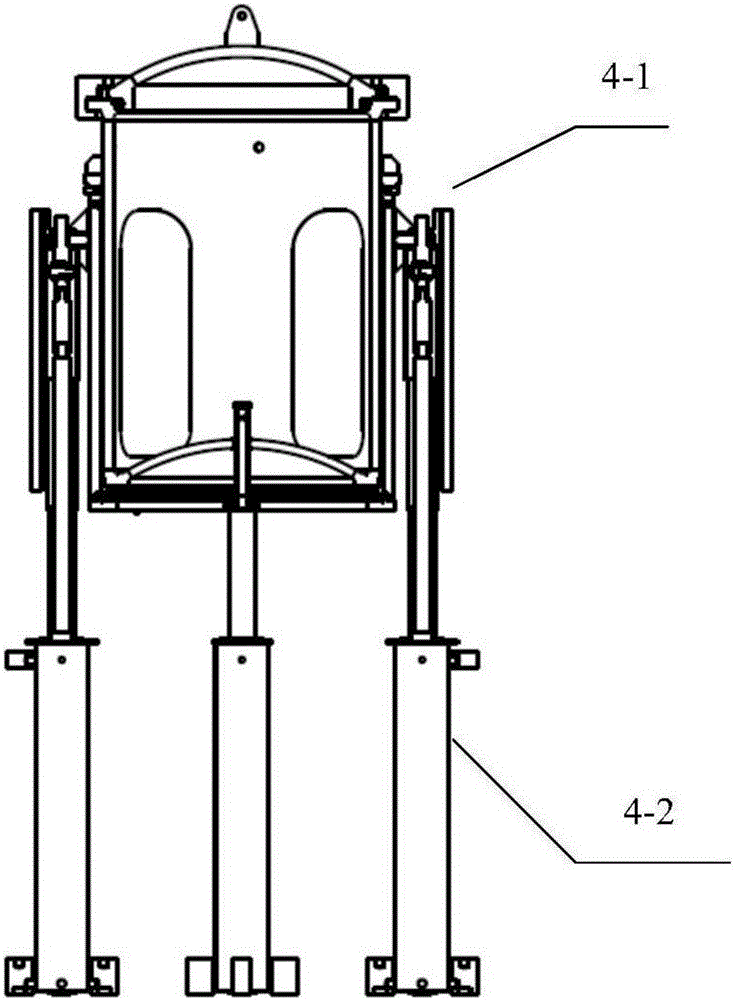

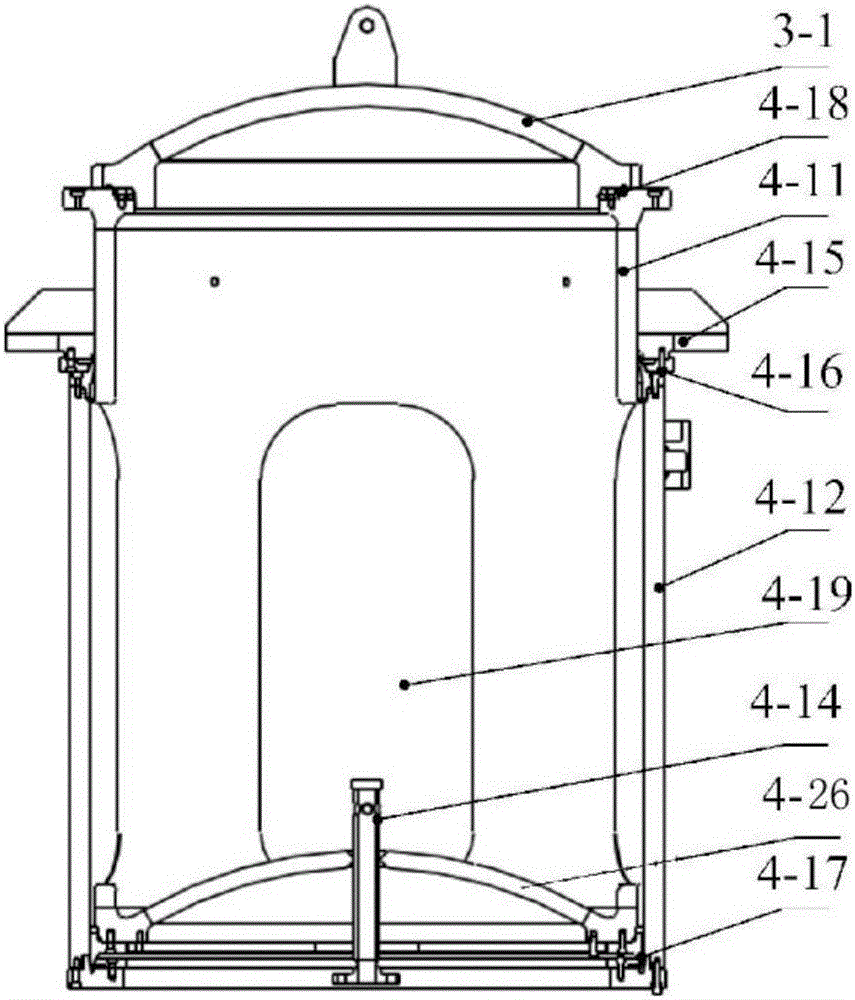

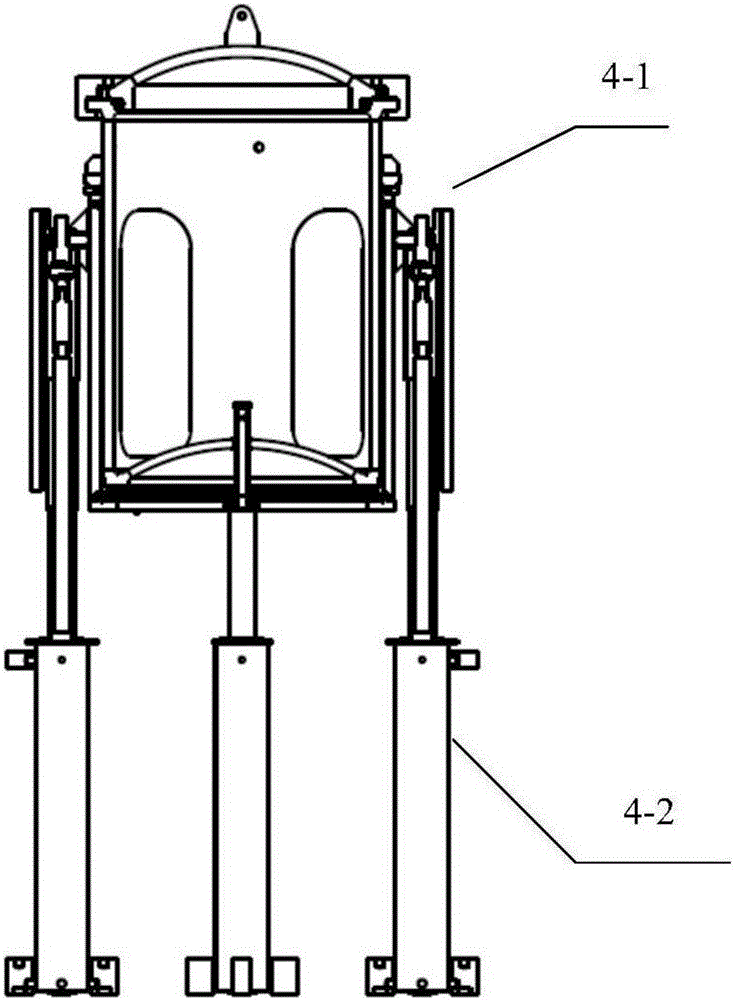

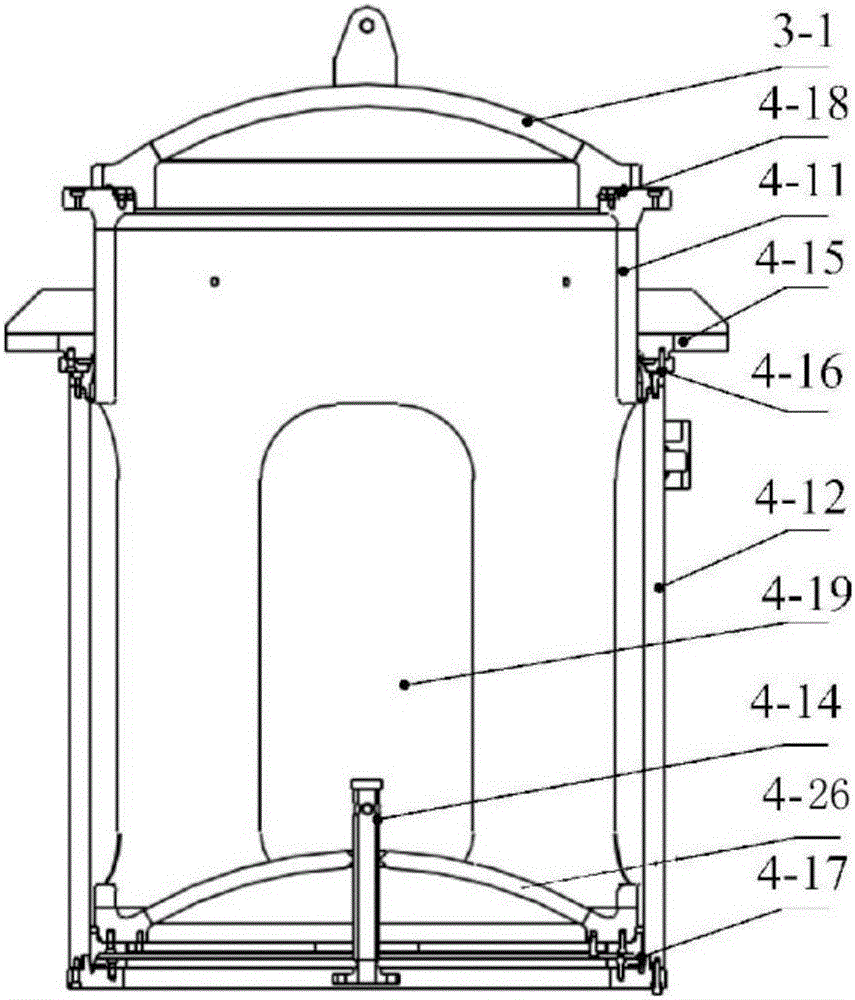

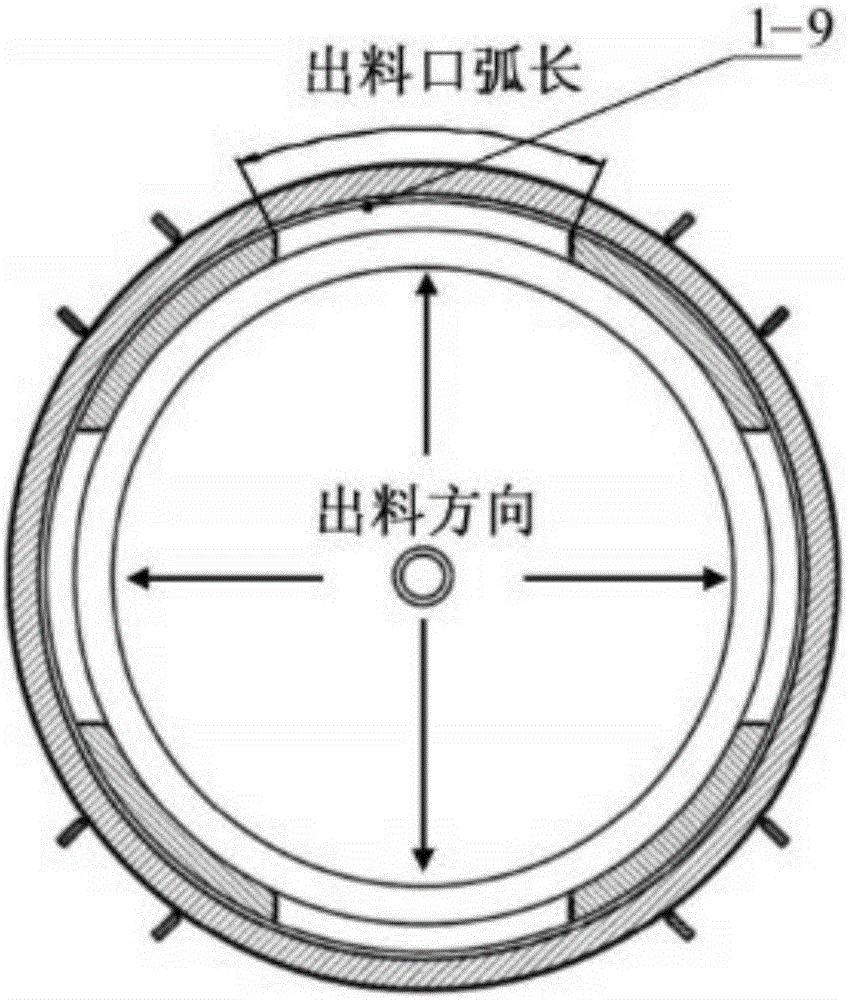

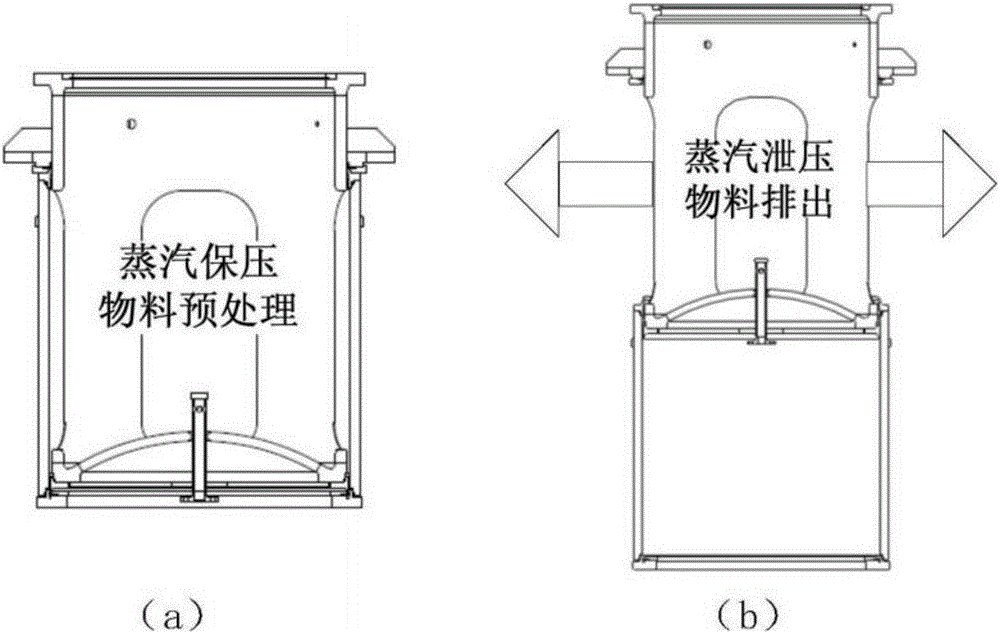

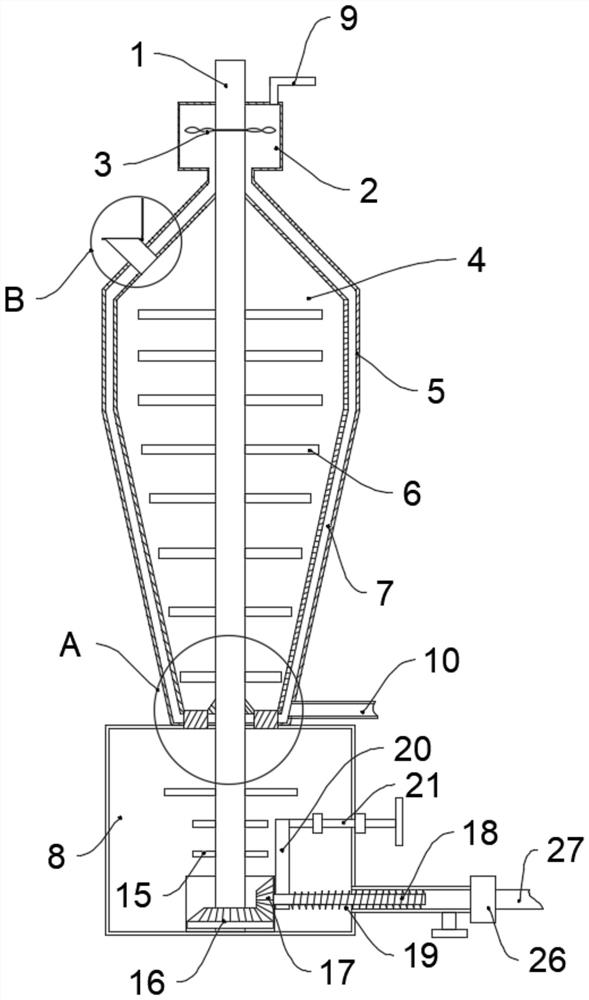

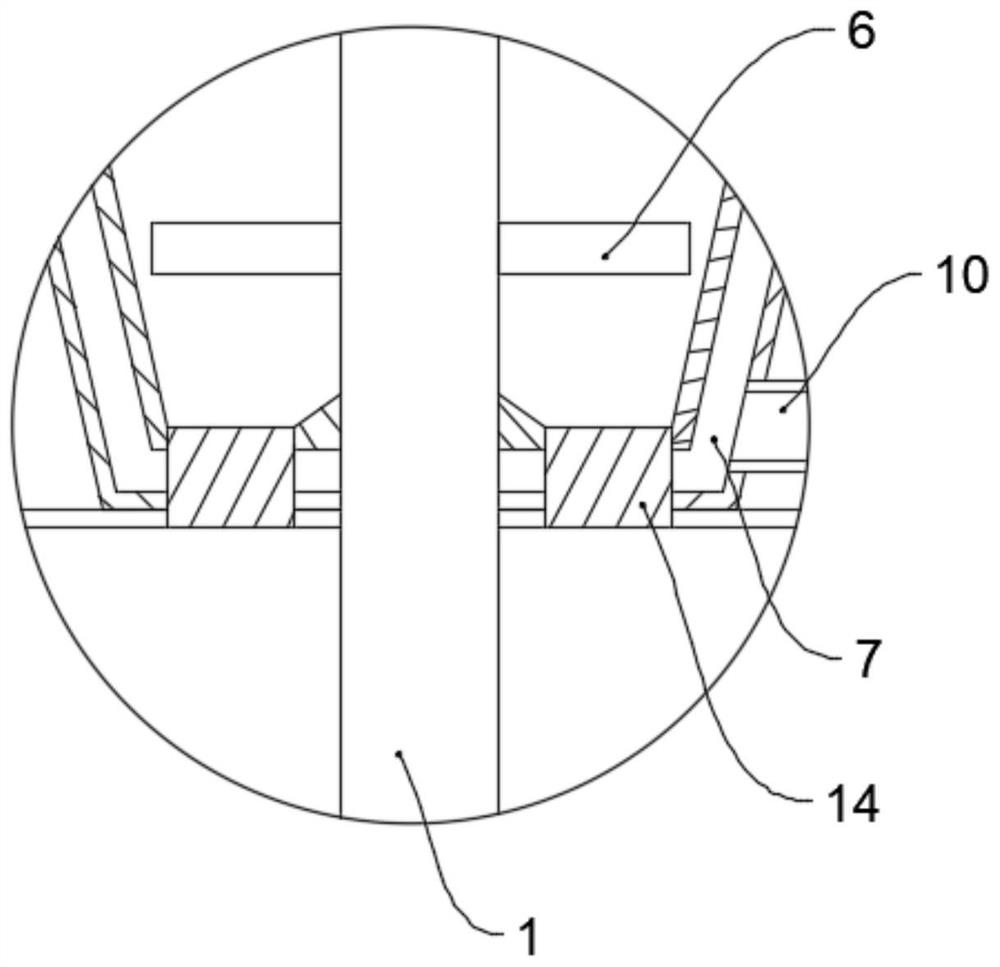

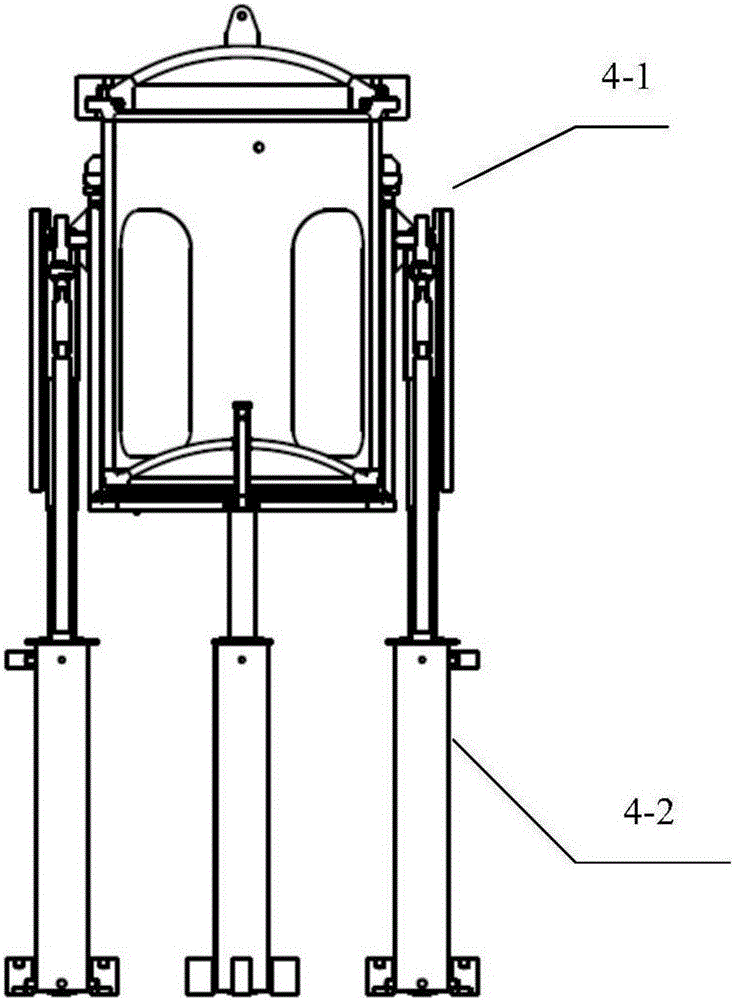

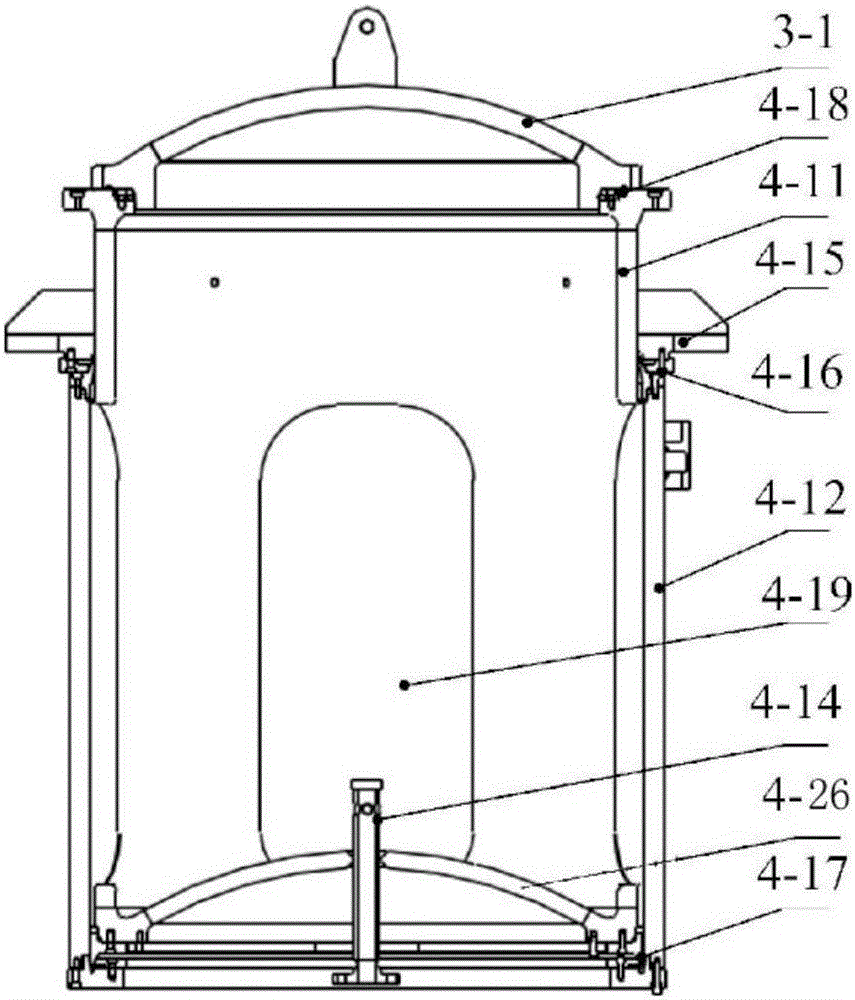

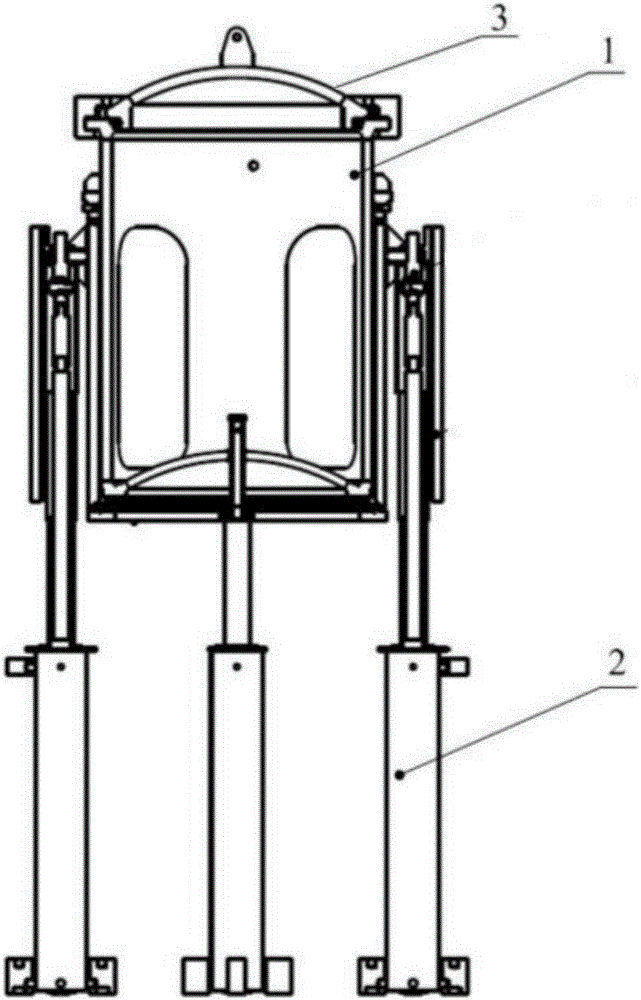

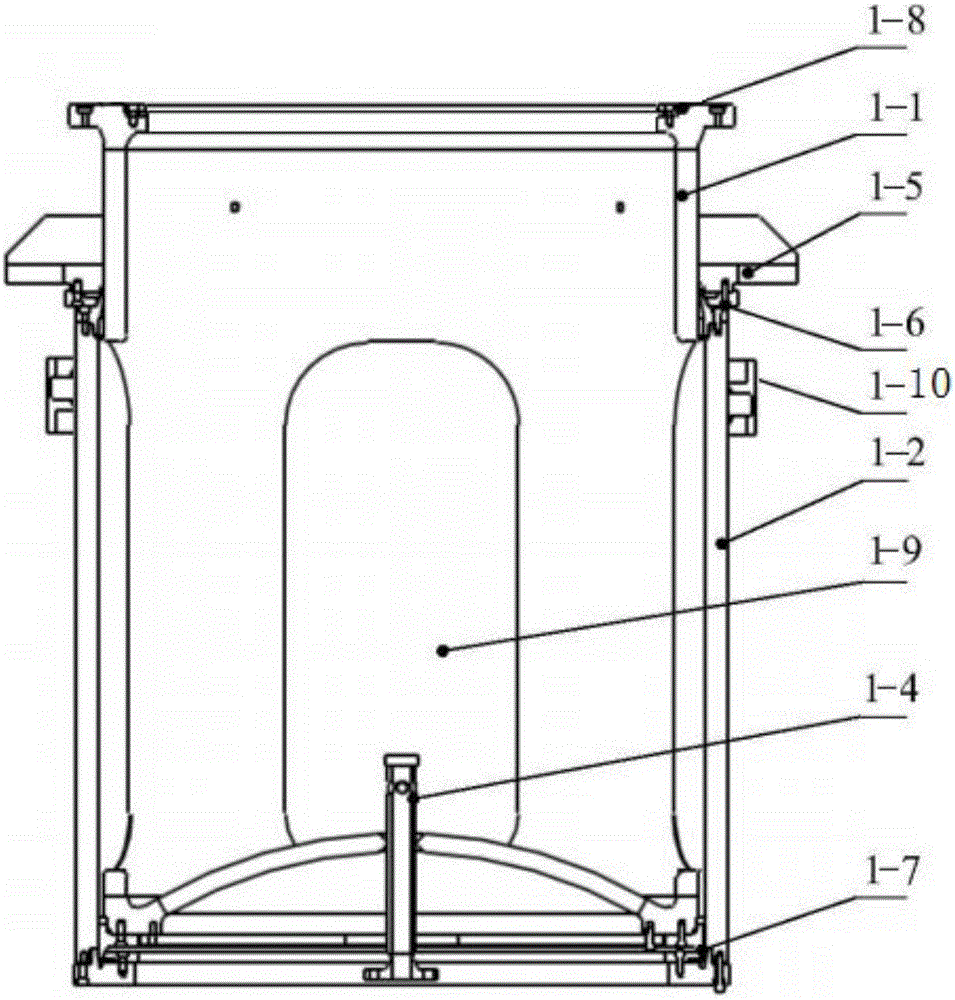

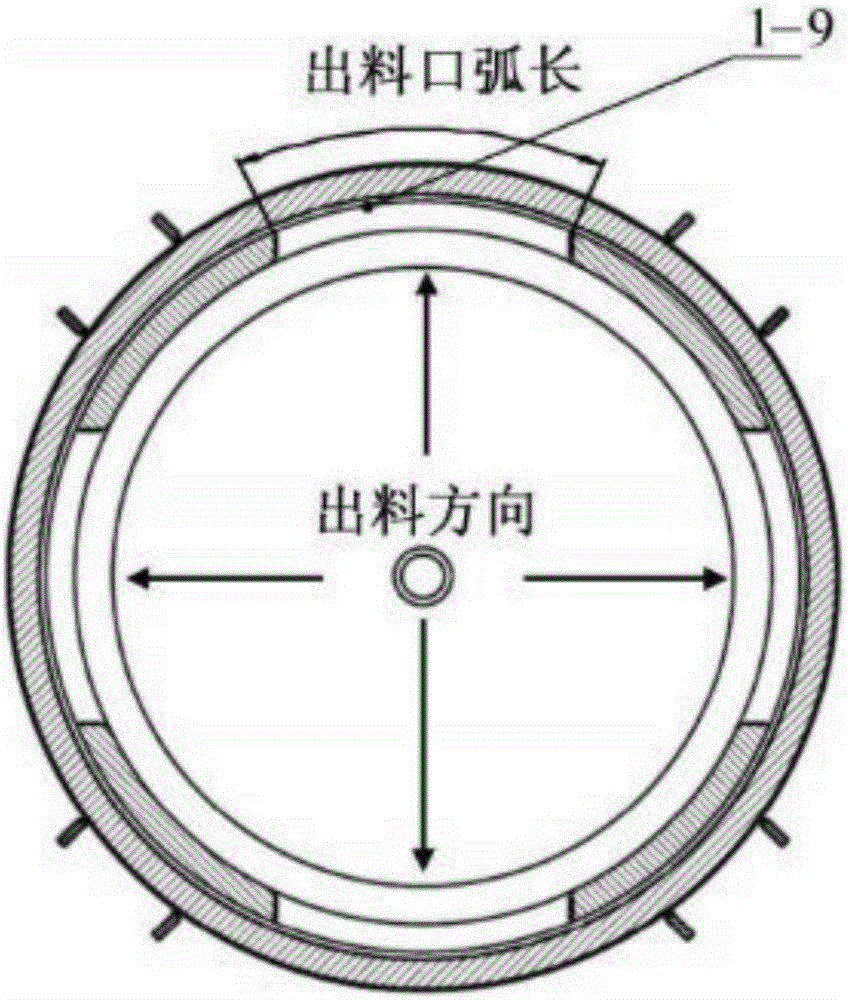

Organic matter processing equipment with high sealing performance

InactiveCN106040711AAvoid accumulationIncrease the exhaust discharge areaEngine sealsSolid waste disposalEngineeringOrganic matter

The invention discloses organic matter processing equipment with high sealing performance. The organic matter processing equipment comprises a feeding device, a separator, a cover opening device and a pressure increasing and releasing device which is installed inside the separator. The separator conducts gas-solid separation on processed materials. The feeding device and the cover opening device are both arranged at the upper portion of the pressure increasing and releasing device, namely the top of the separator. The feeding device injects the materials into the pressure increasing and releasing device through the cover opening device. In the pressure increasing and releasing device, the material weight and steam outward pressure are borne by an upper cylinder barrel, an air cylinder is only used for supporting and pushing a lower cylinder barrel, and the requirement for thrust of the supporting air cylinder is lowered; and meanwhile a half-hidden type sealing structure is adopted, materials are directly prevented from making contact with the sealing position in the discharging process, the service life of a sealing piece is prolonged, and the reliability of the sealing piece is improved.

Owner:TIANZI ENVIRONMENTAL PROTECTION EQUIP MFG TIANJIN

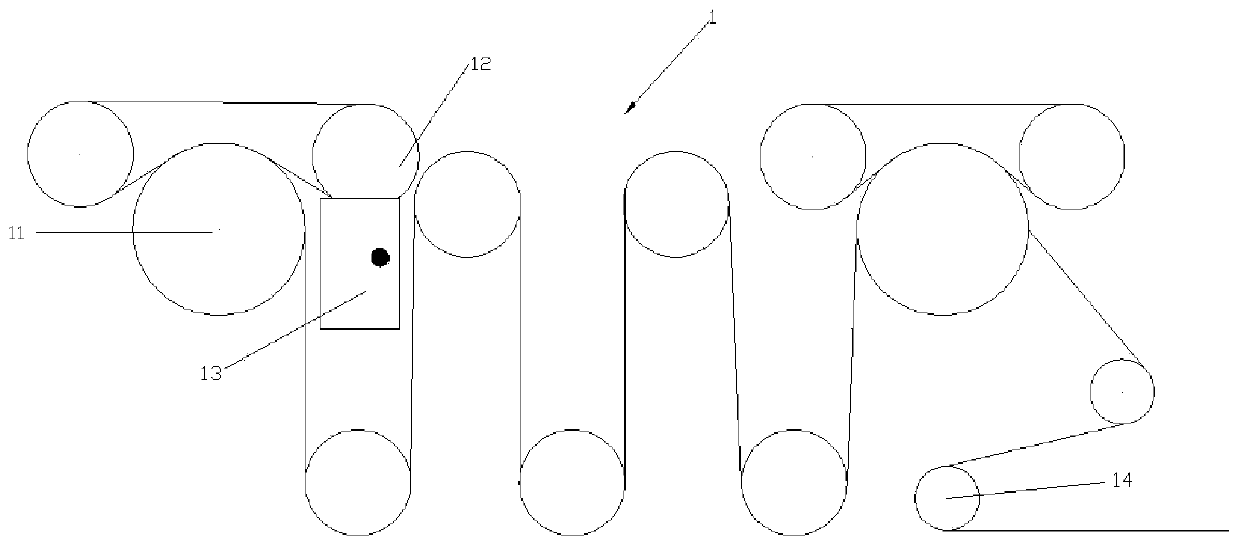

Protective device used for preventing whipping in optical fiber screening process

ActiveCN109911704ASimplify your workflowReduce the risk of missed detectionFilament handlingFiberMechanical engineering

The invention provides a protective device used for preventing whipping in an optical fiber screening process. The protective device is characterized by comprising a screening device, a winding displacement guide wheel, a winding displacement disc, a limiting slot, a protective cover, a barrier plate and a motor, wherein two screening large guide wheels are arranged in the screening device; a broken fiber collecting box and a plurality of screening small guide wheels are arranged between the screening large guide wheels; the winding displacement guide wheels are used for guiding optical fibersto enter the winding displacement disc from the screening device; the winding displacement guide wheels are arranged between openings of the protective cover; the openings of the protective cover arestrip-shaped, and upper and lower surfaces of the openings are alternated; bulges are arranged on lower plate surfaces of the openings of the protective cover; a limiting slot is formed in the tail ends of the lower plate surfaces; and an electrostatic elimination rod is embedded into the upper plate surfaces of the opening of the protective cover. In the technical field of optical fiber production, in order to solve the problem that normal optical fibers are damaged as broken fiber heads in an optical fiber screening process easily whip small disc surfaces of qualified optical fibers in front, the invention provides the protective device which is simple in structure and is easy in operation.

Owner:JIANGSU STERLITE TONGGUANG FIBER

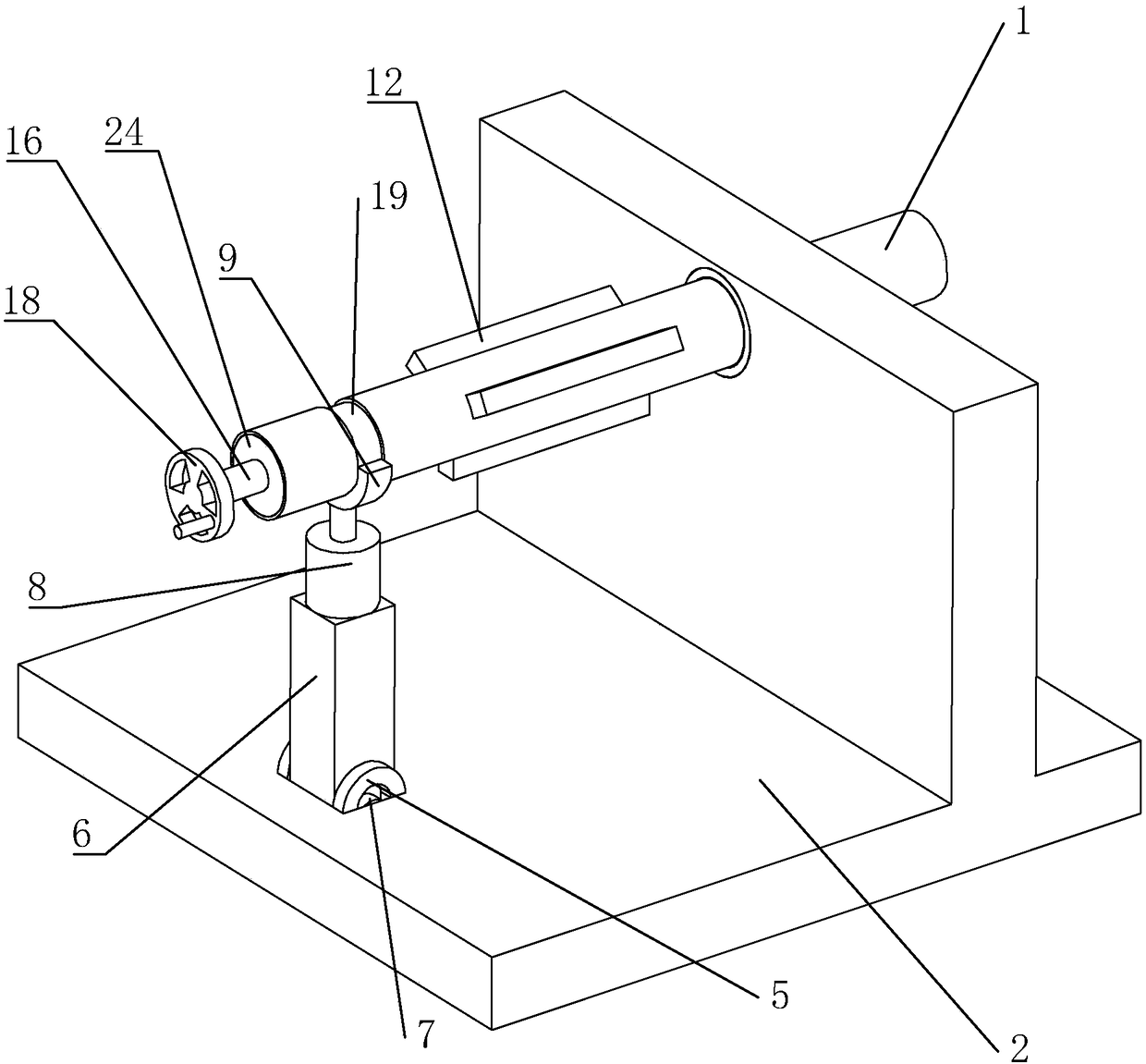

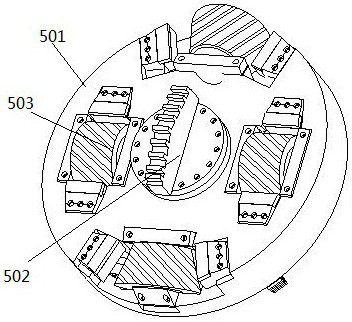

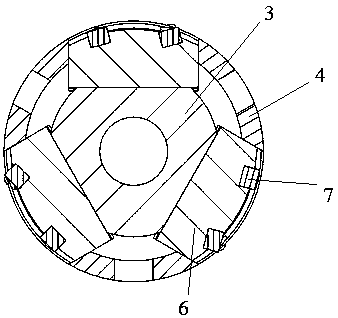

Rolling bulging device for metal round pipe

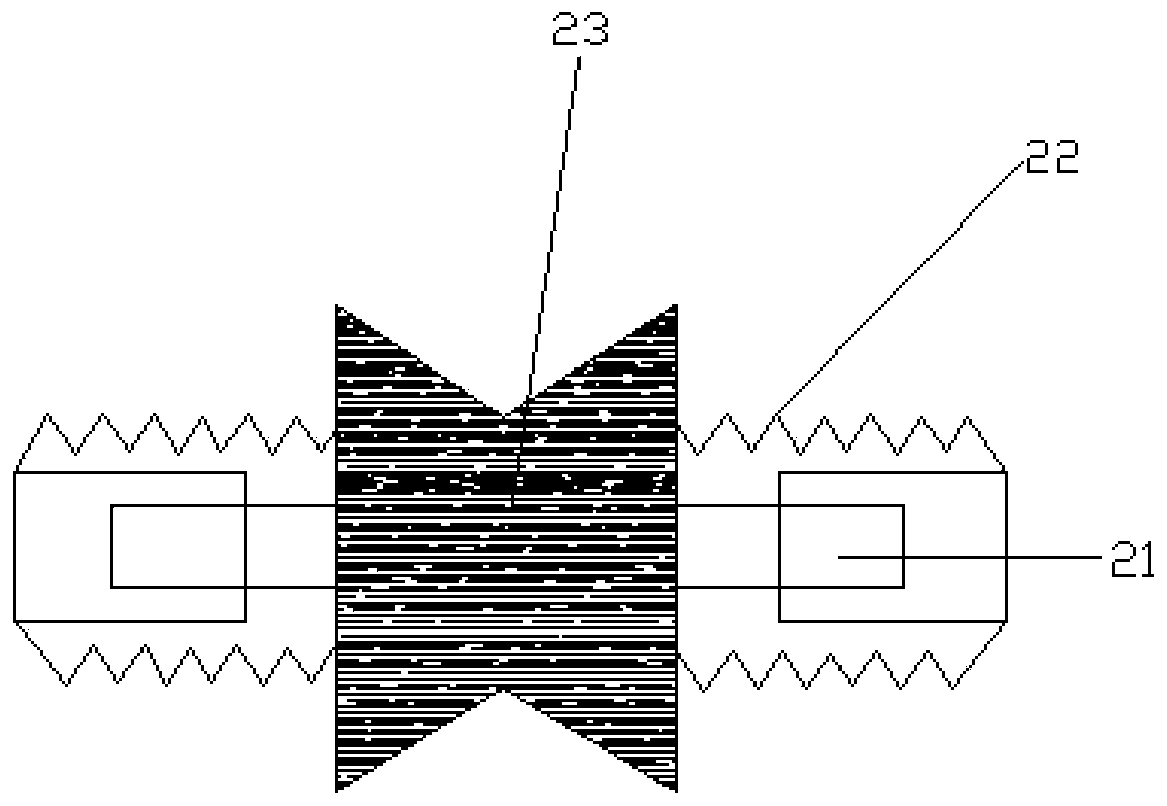

PendingCN111389988AImprove structural strengthPrevent rotationClassical mechanicsStructural engineering

The invention discloses a rolling bulging device for a metal round pipe. The device comprises a base, a rolling bulging mechanism, a driving feeding mechanism and a positioning clamping mechanism. Therolling bulging mechanism is mounted on the driving feeding mechanism, then the driving feeding mechanism and the positioning clamping mechanism are mounted on the base, and then a pipe is horizontally mounted on the positioning clamping mechanism. For operation of the rolling bulging mechanism, firstly, the rolling bulging mechanism is moved to the position needing to be rolled and bulged of thepipe by the driving feeding mechanism, then a bulging ring is enabled to start to rotate, then an opening rod is moved to a designated position by the driving feeding mechanism, and then is slowly fed to slowly open a rolling wheel mechanism in the bulging ring, so that the purpose of rolling bulging is achieved. A bulging wheel of the rolling wheel mechanism can be selected in an optimized way according to a bulging ripple shape, so that different ripple requirements are met, and meanwhile, the ripple height can also select different elliptical surface shapes of opening rods to meet the requirements of different heights.

Owner:ZHEJIANG UNIV OF TECH

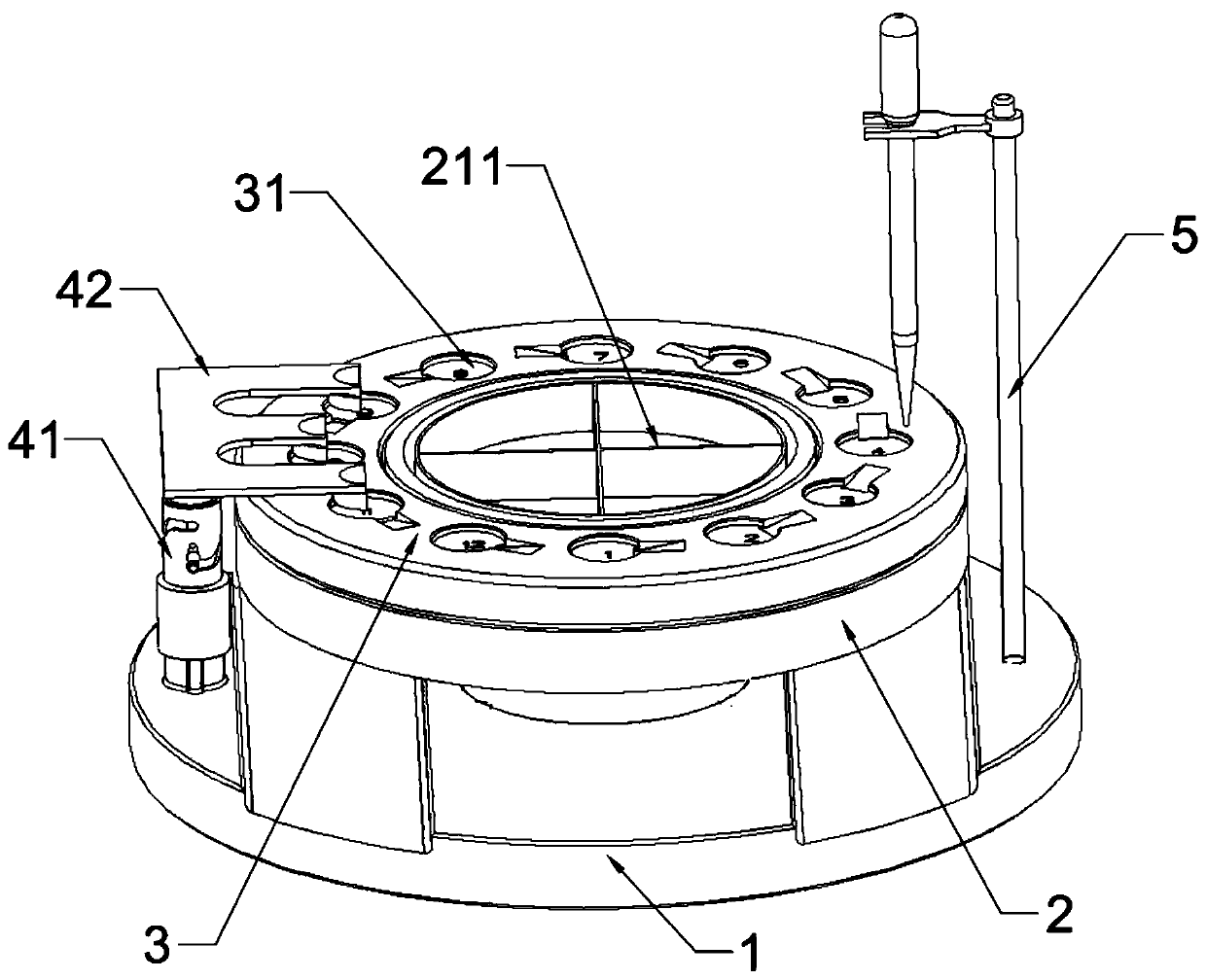

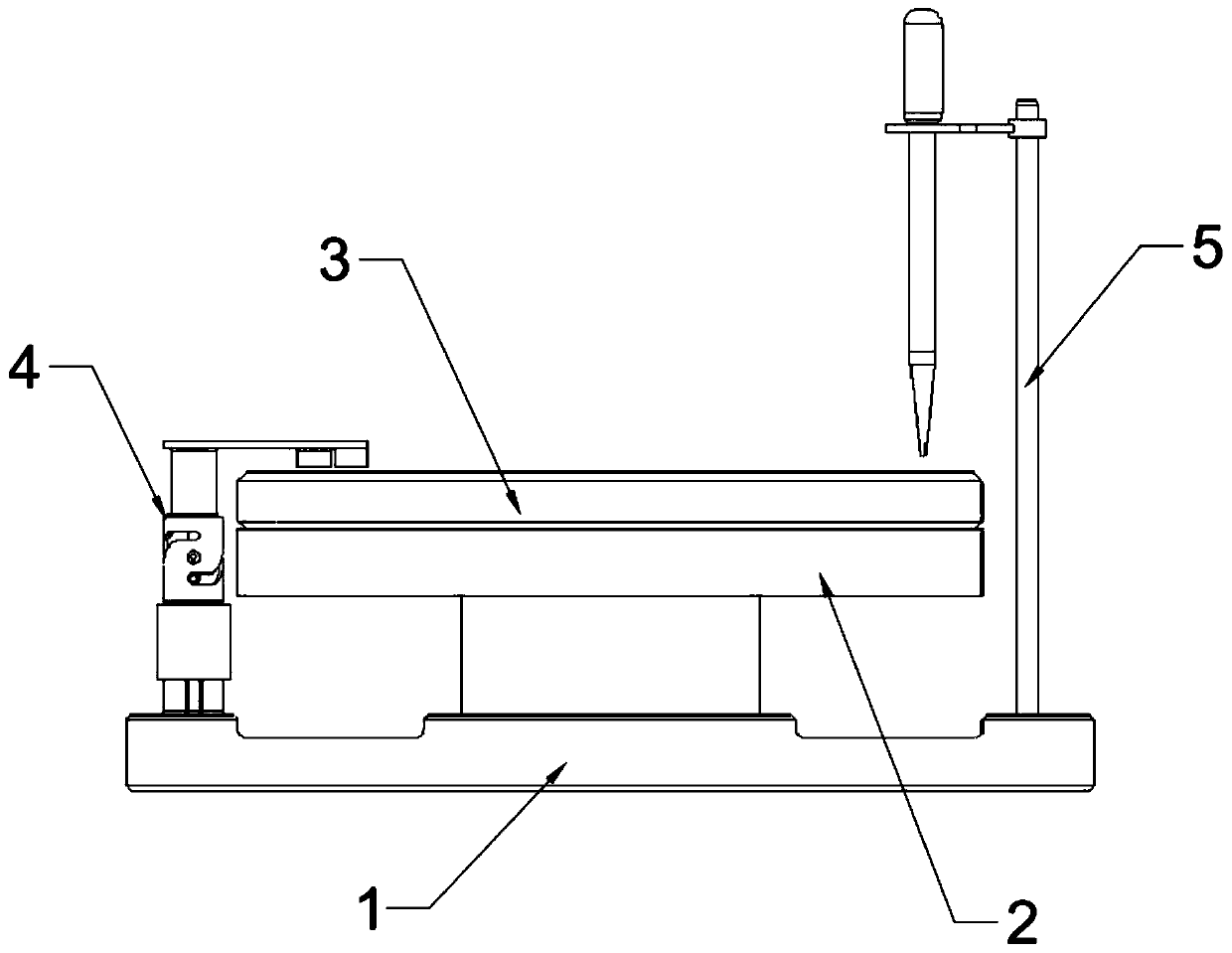

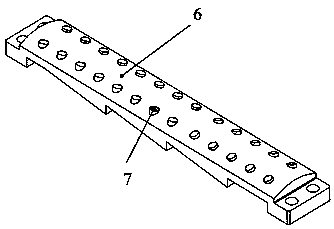

Rotary worktable for assembling button cell

PendingCN111261921AEasy to operateImprove labor efficiencyPrimary cell manufactureAssembling battery machinesPhysicsEngineering

The invention provides a rotary worktable for assembling a button cell. The rotary worktable comprises a base; a rotating mechanism, a rotating disc, a positioning mechanism and a liquid dropping mechanism are arranged on the base; a plurality of circular grooves are uniformly formed in the top surface of the rotating disc; the rotating mechanism is connected with the base; the positioning mechanism comprises a lifting mechanism and a positioning plate; the lifting mechanism comprises a connecting rod, a fixed sleeve and a cylindrical cam which are sleeved with one another from inside to outside; a shaft pin is arranged at one end of the connecting rod; a vertical sliding groove is formed in the fixed sleeve; a spiral sliding groove and a handle are arranged on the side wall of the cylindrical cam; the shaft pin penetrates through the vertical sliding groove and the spiral sliding groove; the cylindrical cam is rotated through the handle; the spiral sliding groove drives the shaft pinto slide along the vertical sliding groove, so that the positioning plate is driven to limit the position of the circular grooves and assist electrode plates and gaskets in being guided into the circular grooves; the liquid dropping mechanism injects electrolyte into the button cell. The rotary worktable for assembling the button cell, provided by the invention, is simple in structure, can realizeaccurate alignment and assembly, improve labor efficiency and reduce labor intensity.

Owner:HUNAN UNIV OF ARTS & SCI

Transformer electric wire arranging frame capable of improving stability and using method thereof

PendingCN108657870AAvoid shaking situationsPrevent disengagementFilament handlingHydraulic cylinderTransformer

The invention discloses a transformer electric wire arranging frame capable of improving the stability. The technical scheme of the transformer electric wire is characterized by comprising a rotatingshaft and a machine frame, wherein a square groove is formed in the position, located right opposite to one end of the rotating shaft, of the machine frame, and the end extends out of a shaft barrel;a square rod is slidingly arranged in the square groove, a hydraulic cylinder is arranged on the end, far away from the square groove, of the square rod, and the top end of a piston rod of the hydraulic cylinder is provided with a semi-circular bearing matched with the rotating shaft; a circular cavity is formed in the rotating shaft in the axial direction, three through grooves are formed in theside face of the rotating shaft, and a sliding block is slidingly arranged in each through groove; and a push block is slidingly arranged in the circular cavity, a lead screw rod is rotationally arranged in the circular cavity, and a lead screw threaded hole matched with the lead screw rod is formed in the axis of the push block. According to the transformer electric wire arranging frame, the fixation stability of the shaft barrel on the rotating shaft can be improved, and the situation that the rotating shaft shakes on the machine frame can be avoided.

Owner:浙江派尔电气有限公司

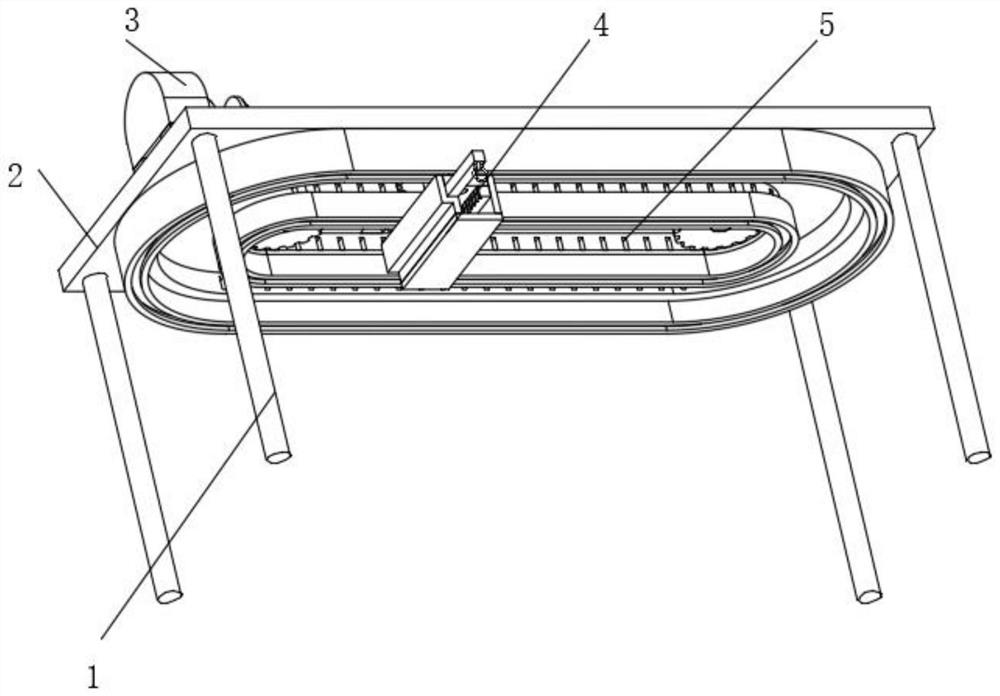

Efficient conduction equipment for garment processing production line

InactiveCN112124855AIncrease productivityGuarantee running stabilityConveyorsControl devices for conveyorsProcess engineeringAssembly line

The invention discloses efficient conduction equipment for a garment processing production line, and relates to the technical field of garment processing. The efficient conduction equipment is aimed at solving the problem of low production efficiency, and specially comprises a top plate, a main moving mechanism, a power mechanism, a station sensing mechanism, and a telescopic mechanism, wherein the top plate is fixed to the ground through supporting legs; the main moving mechanism is used for conducting, limiting and supporting the whole garment; the power mechanism is used for driving the main moving mechanism; the station sensing mechanism is used for sensing the conveying position; the telescopic mechanism is used for stretching the garment to a processing station; the main moving mechanism comprises a rotating component and a sliding component. When the efficient conduction equipment is in use, the garment can be hung on the telescopic mechanism, the power mechanism can drive the main moving mechanism to drive the telescopic mechanism to rotate according to a preset path, the station sensing mechanism can sense whether the garment runs to a processing station or not; and when the garment runs to the processing station, the telescopic mechanism is started to stretch the garment hung on the telescopic mechanism to the processing station. The whole conduction assembly line isformed, and the production efficiency is improved to a great extent.

Owner:SANMING UNIV

High sealing performance sealing device with separate cylinder barrels

InactiveCN106051198AImprove discharge efficiencyThe treatment effect is safe and reliableEngine sealsSolid waste disposalEngineeringHigh pressure

The invention discloses a high sealing performance sealing device with separate cylinder barrels, which comprises an upper cylinder battle and a lower cylinder; the lower cylinder is of a cylindrical structure with openings in two ends and sleeves the outer side of the upper cylinder barrel; the upper cylinder barrel comprises a steam valve port located in the bottom and a discharging port located in the side part, an outside steam pipeline is connected to the steam valve port and is used for injecting high temperature high pressure steam into the upper cylinder barrel, the lower cylinder barrel is connected to the upper cylinder barrel in a sliding manner, when the lower cylinder barrel slides to the uppermost end, the lower cylinder barrel closes the discharging port, and the upper cylinder barrel is sealed; and a cylinder cover of a cover opening device covers the top end of the upper cylinder barrel. The structure of the cover opening device is innovatively deigned, the cylinder cover and a locking ring adopt a wedge-shaped tooth interlocking structure, and the sealing is reliable; and a bolt can be adjusted such that the in-place precision of the cover opening and closing actions are is ensured.

Owner:TIANZI ENVIRONMENTAL PROTECTION EQUIP MFG TIANJIN

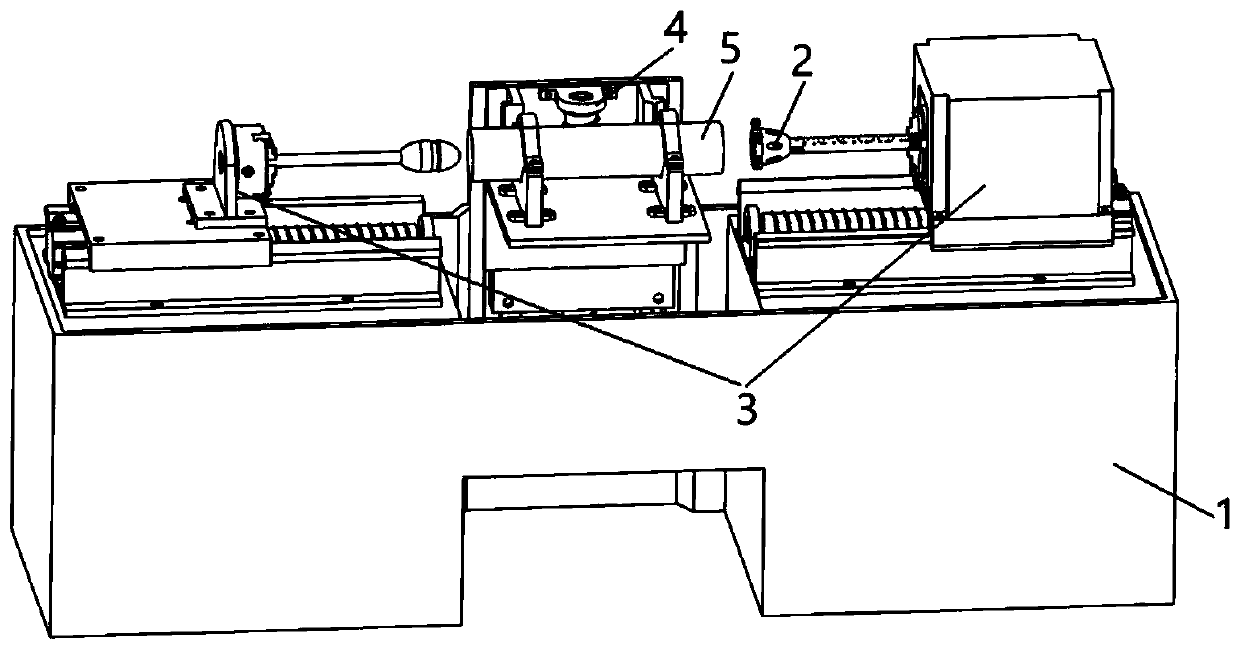

Numerical control lathe support frame

ActiveCN108296494AEasy to adjustQuick adjustabilityMetal working apparatusNumerical controlFailure rate

The invention discloses a numerical control lathe support frame. The numerical control lathe support frame comprises a first support unit mounted on a main shaft box, and a second support unit mountedon a servo tail base; the first support unit comprises a first V-shaped block, a first guide rod and a first slide way bracket; the second support unit comprises a second V-shaped block, a second guide rod, a second slide way bracket and a guide shaft; when the support frame is used, the outer surfaces of workpieces are supported through the first V-shaped block and the second V-shaped block; andthe heights and the axial positions of the first V-shaped block and the second V-shaped block are adjustable; in addition, the first V-shaped block and the second V-shaped block cannot generate the rotating condition; and the support frame cannot generate such problems as front end dropping and twisting, can reduce the labor intensity of workers, reduces the requirements on self skill level and proficiency of operators, improves the lathe production efficiency, accelerates the production beat, improves the adjusting efficiency by above 15% compared with a traditional general support frame, reduces the long-time use failure rate by above 30%, and is higher in adaptability to the workpieces.

Owner:NINGBO HAITIAN PRECISION MASCH CO LTD

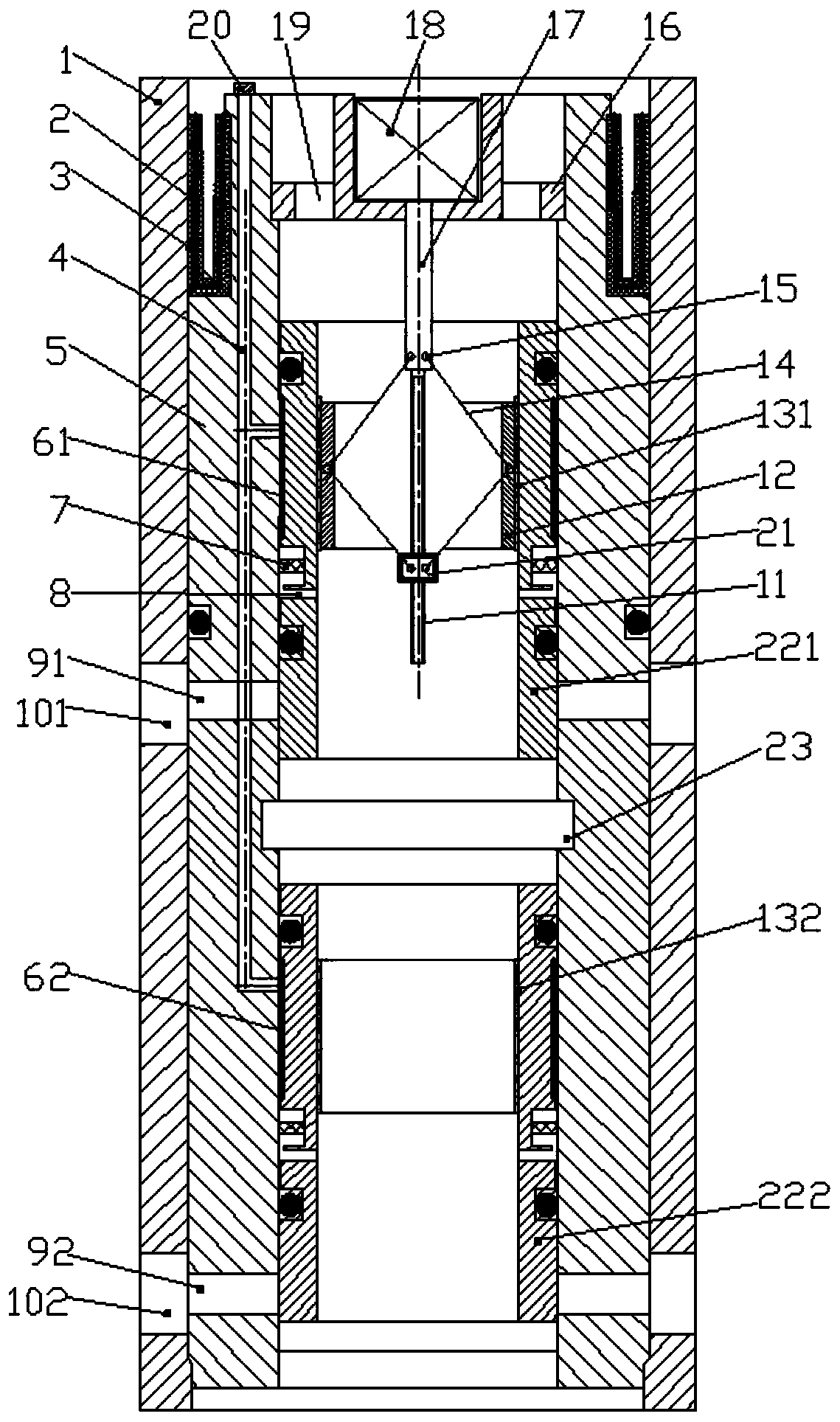

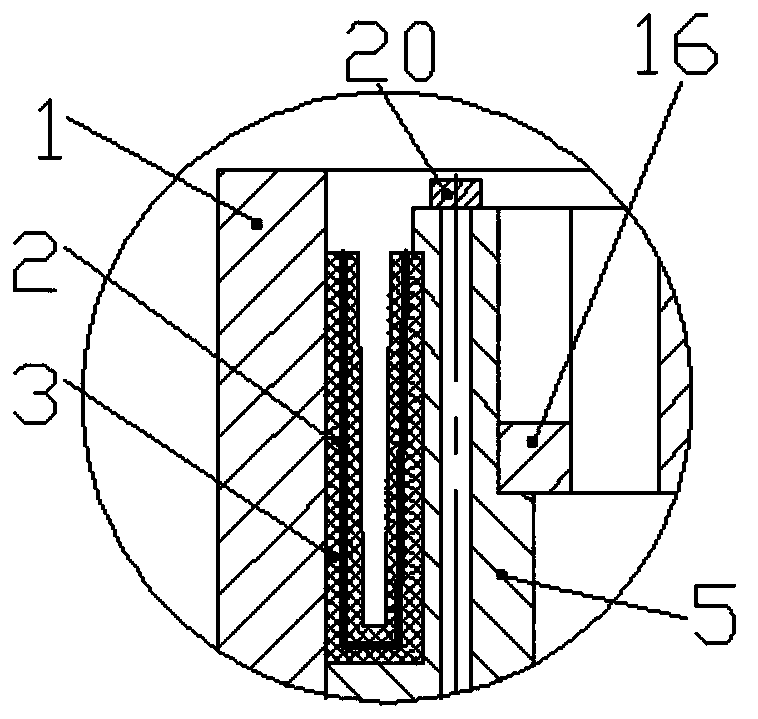

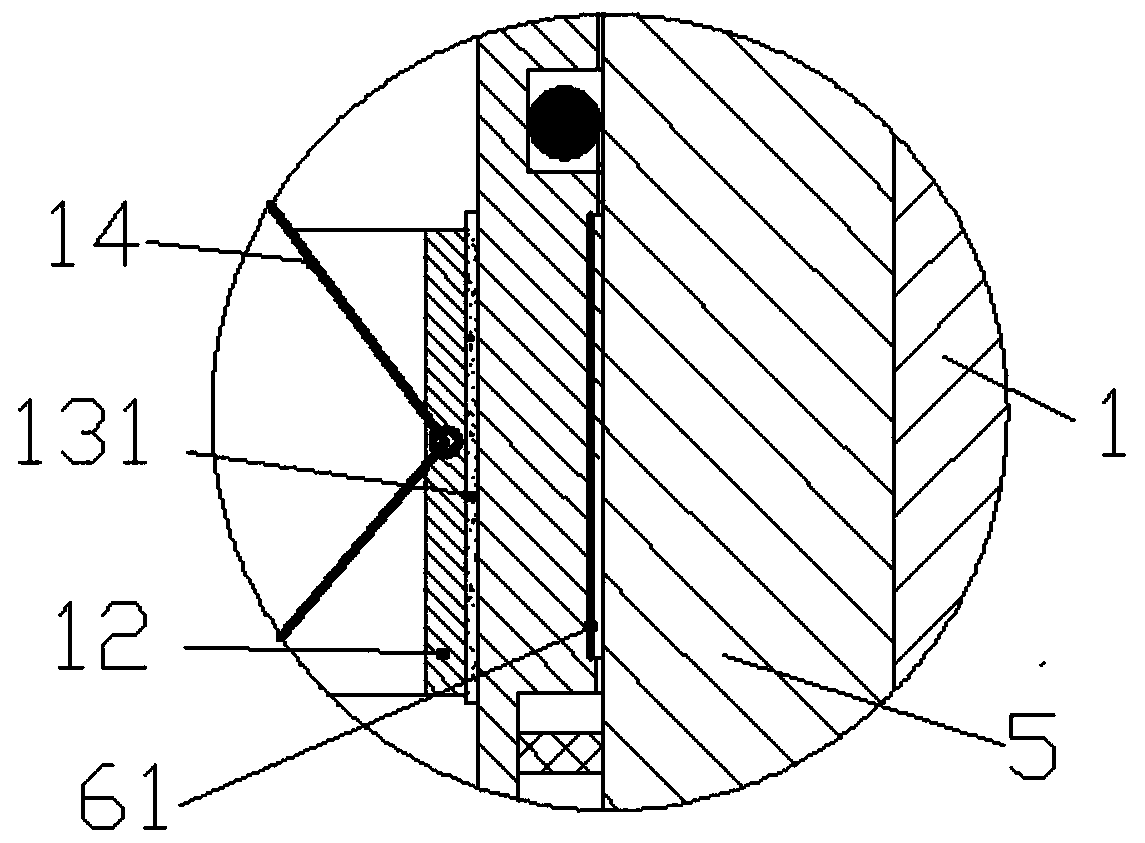

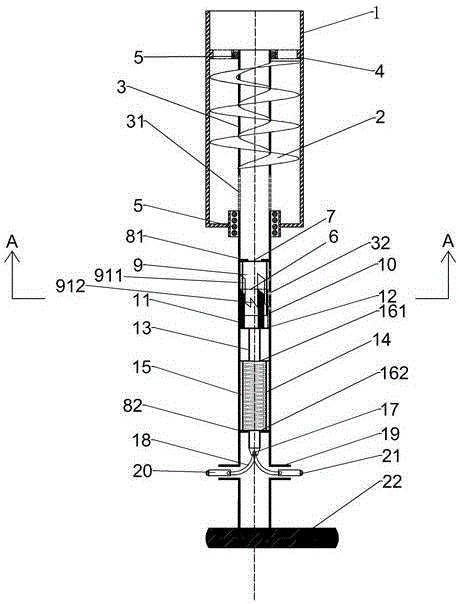

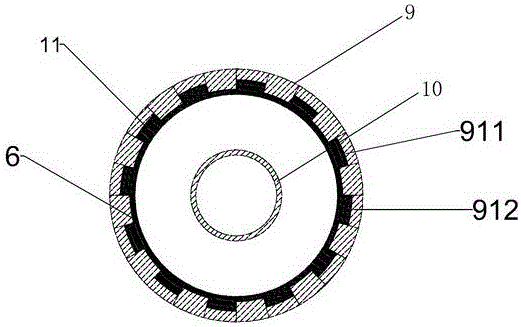

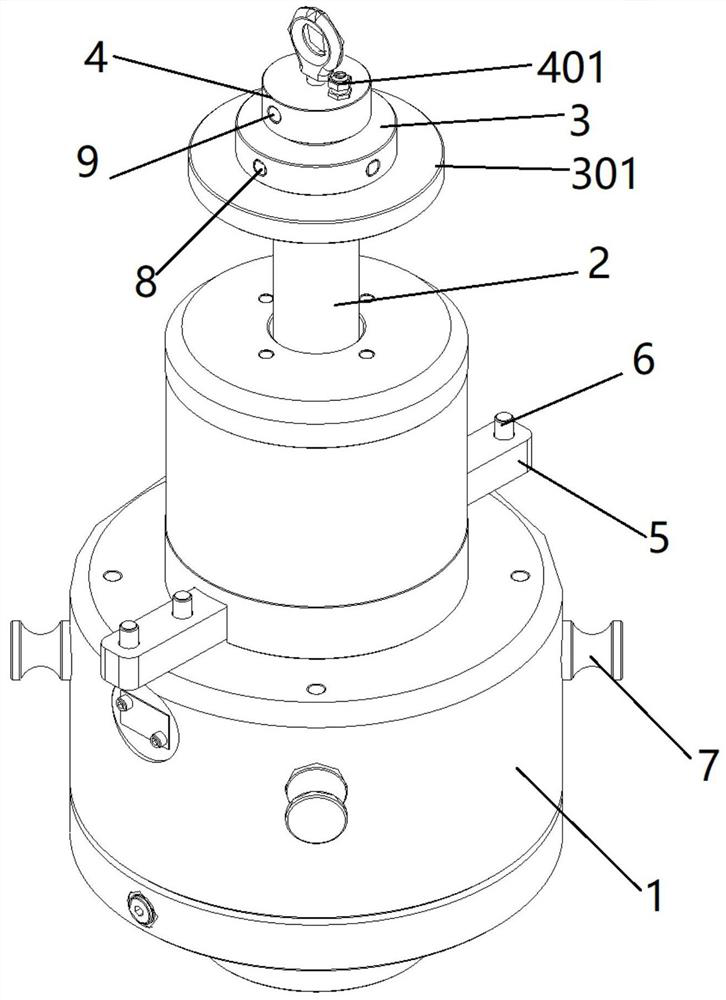

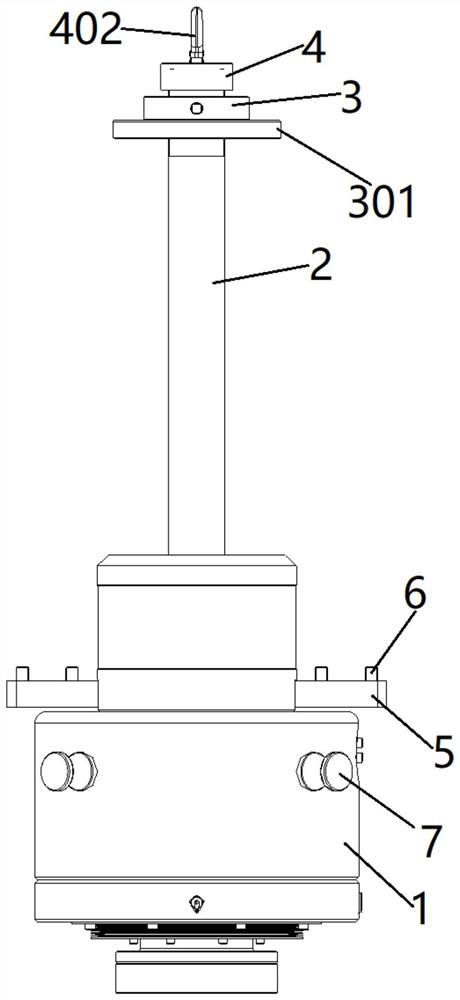

Split type concentric water distributor suitable for scaling well and separate injection process

ActiveCN111101912AAvoid blockingLow profile and high work efficiencyFluid removalControl engineeringElectric machinery

The invention relates to a split type concentric water distributor suitable for a scaling well and a separate injection process. The split type concentric water distributor comprises a working cylinder, a core body and an adjusting mechanism; the adjusting mechanism comprises a motor, a motor base with four water passing holes in the circumferential direction, a hollow shaft, a screw rod, a transmission block, an adjusting cylinder, an adjusting arm and a thrust block, wherein the motor is mounted on the motor base, and the motor base is mounted on the upper part of the inner cavity of the core body; and the two ends of the hollow shaft are respectively connected with an output shaft and a lead screw of the motor, the transmission block is in threaded connection with the lead screw, and the side surface of the thrust block is tightly attached to the inner wall of the adjusting cylinder. The split type concentric water distributor overcomes the defects that an integrated water injectionwater distributor needs to remove an oil pipe and replace the working cylinder and the working efficiency is low; a core and the adjusting cylinder can be put into the water distributor once, and then the adjusting cylinder is rotated through a steel wire suspension adjusting mechanism, so that the opening degree of a water nozzle is adjusted, the two layers of water injection operation can be completed after placing once, the operation efficiency can be greatly improved, and the water injection cost is reduced.

Owner:四川富利斯达石油科技发展有限公司 +2

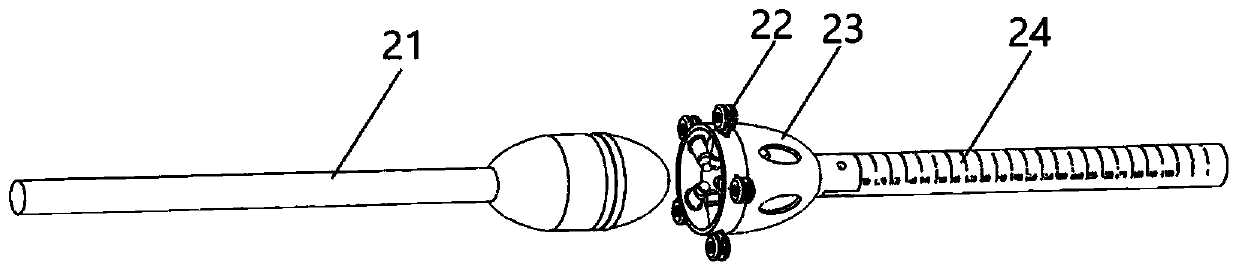

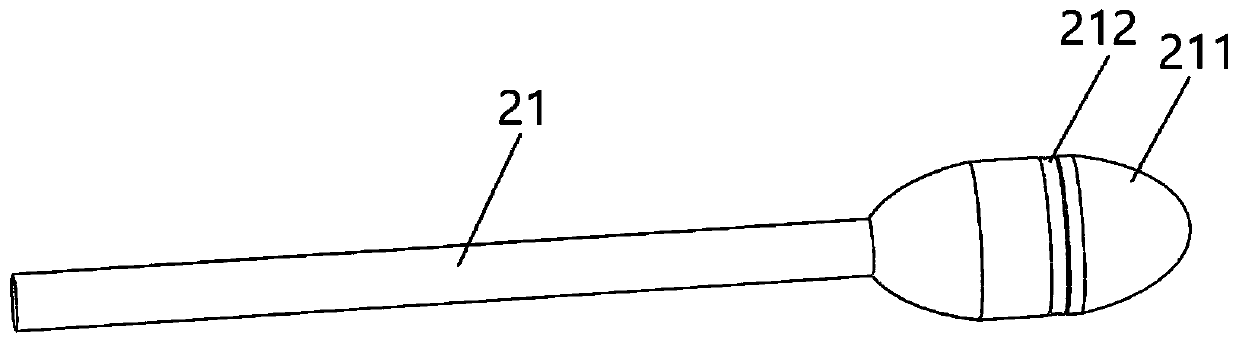

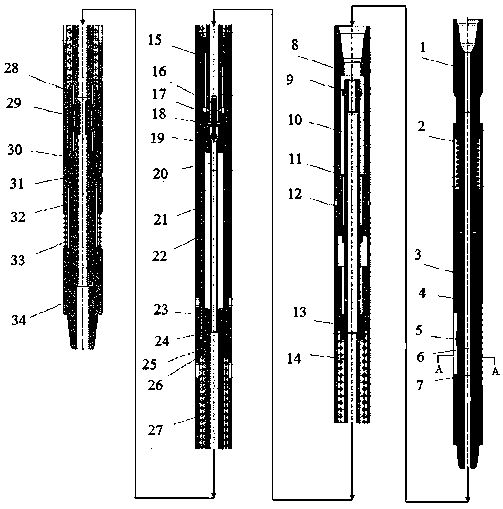

Highly pressurized liquid driven eccentric sheave type bottom hole sleeve cutter

ActiveCN106437587ARotation does not occurSimple structureBorehole/well accessoriesEngineeringLower limit

A highly pressurized liquid driven eccentric sheave type bottom hole sleeve cutter comprising an upper cylinder, spiral blades, a spiral blade mount shaft, a spiral blade limit seat, a plurality of balls, a lower cylinder sleeve, an automatic rebound mechanism upper pedestal, an upper limit seat, a lower limit seat, an upper cylinder outer sleeve, an upper cylinder inner sleeve, a lower cylinder outer slide column, an automatic rebound lower pedestal, a connecting pole, a spring centralizing barrel, a normally loose spring, a spring upper pedestal, a spring lower pedestal, a pin shaft, a crank connecting rod, a cutting tooth slideway, a cutting tooth pedestal, cutting teeth, and a detachable eccentric sheave 22; the highly pressurized liquid driven eccentric sheave type bottom hole sleeve cutter is simple in structure, low in cost, high in usage efficiency, easy to operate, saves materials, and is hard to be fatigued and damaged.

Owner:JILIN UNIV

A pipeline renewal boring machine and its construction method

ActiveCN111852493BWith the ability to ensure flow without interceptionRealize the security functionUnderground chambersTunnel liningSludgeSlag

The invention discloses a tunneling machine for updating pipelines and a construction method thereof. It comprises a tunneling main engine and a ventilation protection circulation system. A slag cleaning and ventilation device is provided at the front of the tunneling main engine. system is connected. The excavation host includes a shield body and a digging cutter head, a main drive is arranged in the shield body, the main drive is connected with the digging cutter head, an excavation cabin is arranged between the digging cutter head and the main drive, and an excavation cabin is arranged on the upper part of the excavation cabin. There is a slurry inlet pipe, and a slag discharge system is connected to the lower part of the excavation cabin. The slag removal device of the present invention passes through the tunneling main engine and is connected with the ventilation circulation system. During the excavation process, it goes ahead of the cutter head of the tunneling main engine to desilt the silt in the pipeline, and the sewage in the pipeline flows backward through the ventilation circulation system. Circulation, to ensure the circulation of the fluid medium in the pipeline to be renewed during the construction process, so that the pipeline renewal has the ability to ensure flow without closure, and realize the simultaneous completion of pipeline demolition and renewal laying.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

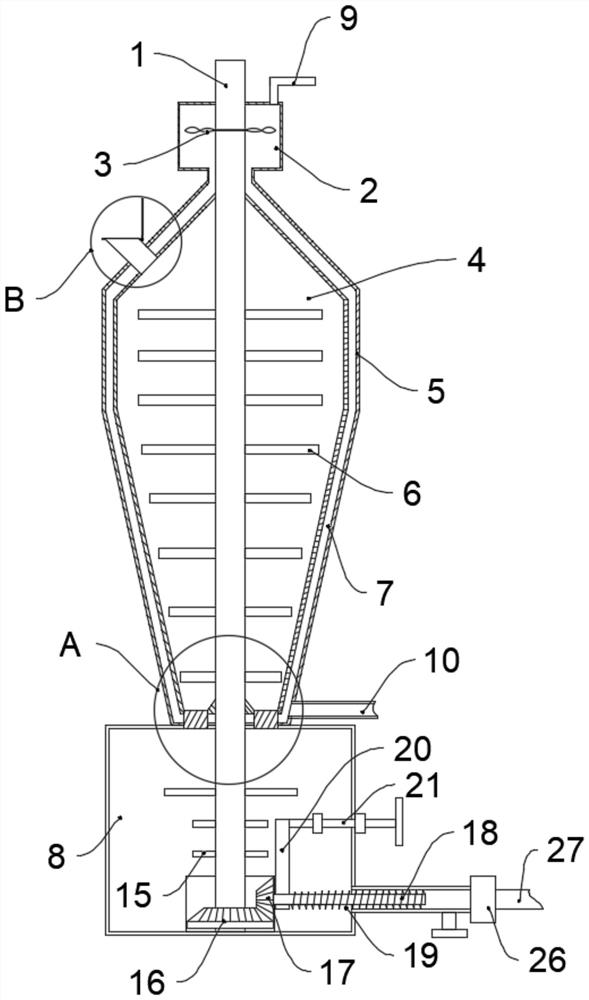

Coating sand mill for producing environment-friendly low-carbon coating

ActiveCN112473892ALow failure rateIncrease productivityDirt cleaningGrain treatmentsCarbon coatingImpeller

The invention belongs to the technical field of coating production equipment, and particularly relates to a coating sand mill for producing an environment-friendly low-carbon coating. The coating sandmill comprises a motor output end fixedly connected with a motor, a cold water chamber is arranged on the lower portion of the motor output end, a drainage impeller is arranged in the cold water chamber, the drainage impeller is fixedly arranged at the motor output end in a sleeving mode, a sand milling cylinder is arranged below the cold water chamber, a plurality of grinding pieces are fixedlyconnected to the side face of the motor output end, the outer side of the sand milling cylinder is sleeved with a cooling outer partition plate, a water passing cooling layer is arranged between the cooling outer partition plate and the sand milling cylinder, the upper end of the water passing cooling layer communicates with the lower side of the cold water chamber, a plurality of sieve holes which are annularly distributed by taking the motor output end as the circle center are formed in the bottom of the sand milling cylinder, a screen is arranged in each sieve hole, and a storage chamber isarranged at the lower end of the sand milling cylinder. According to the coating sand mill, cooling water can be greatly saved, and meanwhile, the cooling effect of the sand milling cylinder is guaranteed.

Owner:CHONGQING XINGYU POLYMER PAINT +1

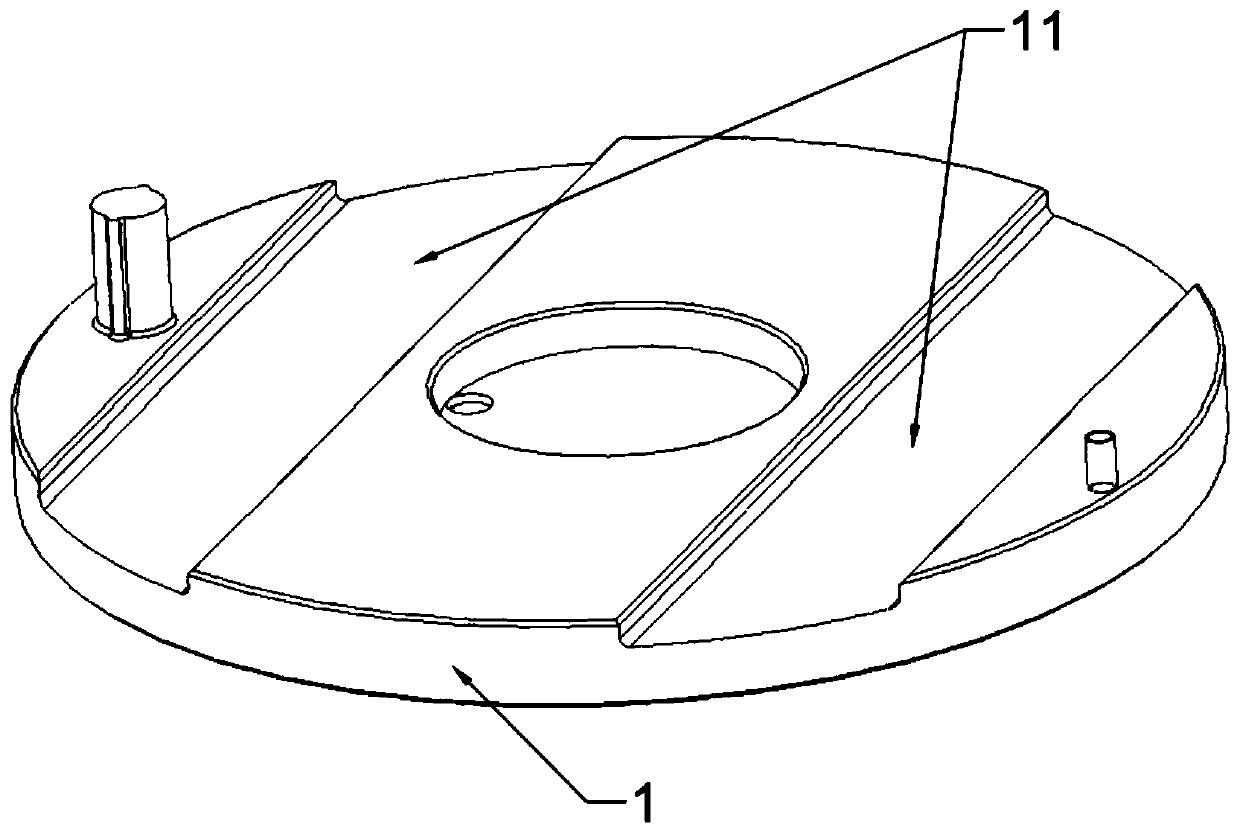

Fixed device for mold material processing of ceramic mold digital controlled lathe

InactiveCN111408959AAvoid material swingAvoid Displacement DefectsPositioning apparatusMetal-working holdersControl switchMaterials processing

The invention discloses a fixed device for mold material process of a ceramic mold digital controlled lathe, and belongs to the field of ceramic mold processing and manufacturing equipment. The fixeddevice comprises a set of vacuum adsorption devices of a mold material processing plate. According to the technical scheme, a simple method that an existing ceramic mold digital controlled lathe onlyrelies on the friction force between the mold material and a processing platform in the mold material fixation is mainly changed, a set of vacuum adsorption devices of the mold material processing plate, a set of mold material cantilever pressure plate devices and two sets of pressure sensing control switches are additionally installed on the mold digital controlled lathe, the defects such as jitter, swing, displacement, deformation of existing equipment in the process of ceramic mold material processing are overcome, the processing accuracy of a mold is improved, the problems of large concentricity deviation inside and outside the processing mold, uneven wall thickness, uncertain product weight and the like are solved, and the fixed device is widely suitable for the processing of ceramicmolds with different mass and shapes.

Owner:PINGDING YINGYU PORCELAIN

A hydraulic buckle

ActiveCN107489387BEasy to processEasy to replaceBorehole/well accessoriesElectric power transmissionActuator

The invention discloses a novel hydraulic back-off device comprising an anchoring device, a pressurizing device, a power transmission device and a power output device. The pressurizing device used for increasing the pressure is arranged on the lower portion of the anchoring device. The power transmission device used for power transmission is arranged on the lower portion of the pressurizing device. The power output device for outputting the hydraulic pressure is arranged on the lower portion of the power transmission device. Compared with the prior art, hydraulic drive is adopted as driving force; an axial power shaft, a quick-replacement drive head and a rotating power shaft are taken as a main power actuator; the axial power shaft and the quick-replacement drive head are of a split type structure so that parts can be machined, replaced and maintained easily; a double ratchet set is designed for power output, an inner ratchet and an outer ratchet are mutually independent, the inner ratchet is not affected by the lower rotary torque, and the outer ratchet guarantees that rotating of the back-off torque is avoided, so that reliable and safe operation of the tool is guaranteed, the output torque is large, and operation is easy.

Owner:山东科瑞石油装备有限公司

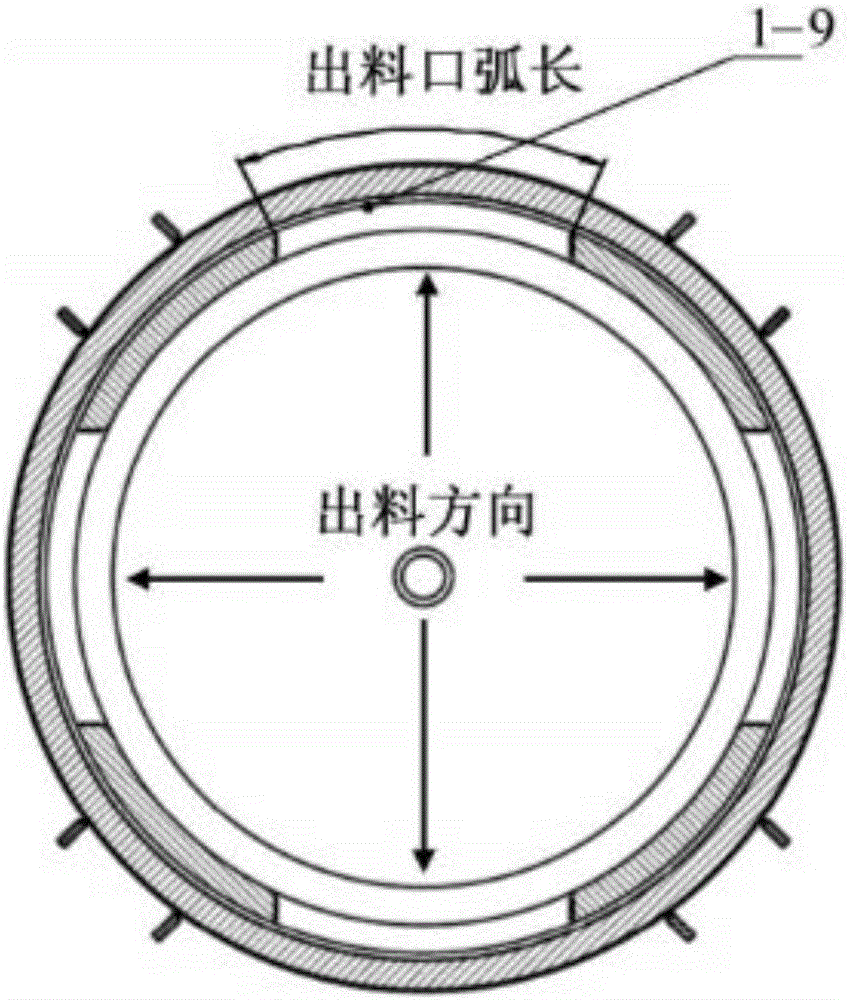

Pressurization and pressure relief device with high pressure relief speed

InactiveCN106040708AImprove discharge efficiencyThe treatment effect is safe and reliableEngine sealsSolid waste disposalDischarge efficiencyEngineering

The invention discloses a pressurization and pressure relief device with a high pressure relief speed. The pressurization and pressure relief device comprises a separate cylinder barrel sealing device and a pneumatic opening mechanism. The separate cylinder barrel sealing device comprises an upper cylinder barrel and a lower cylinder barrel. The lower cylinder barrel is of a cylinder structure with the two ends opened. The lower cylinder barrel is installed on the outer side of the upper cylinder barrel in a sleeving manner. The upper cylinder barrel comprises a steam valve port located in the bottom and discharging openings located in the side portion. An external steam pipeline is connected with the steam valve port. The lower cylinder barrel is in sliding connection with the upper cylinder barrel. The pneumatic opening mechanism is used for driving the lower cylinder barrel to slide up and down. A cylinder cover of a cover opening device covers the top end of the upper cylinder barrel. The pressurization and pressure relief device overcomes limitation of the net sectional area of a traditional method, multi-directional discharging is adopted, the exhausting and discharging area is increased, the discharging efficiency of the pressurization and pressure relief device is improved remarkably, the pressure relief speed is increased, the better exploding and smashing effect is achieved, the organic matter treatment effect is safer and more reliable, and the efficiency is higher.

Owner:TIANZI ENVIRONMENTAL PROTECTION EQUIP MFG TIANJIN

Waste steam flash explosion treatment equipment

InactiveCN106040715AIncrease the exhaust discharge areaImprove discharge efficiencyEngine sealsSolid waste disposalDischarge efficiencyPulp and paper industry

The invention discloses waste steam flash explosion treatment equipment which comprises a branch cylinder barrel sealing device, a pneumatic opening mechanism and a cover opening device, wherein the branch cylinder barrel sealing device comprises an upper cylinder barrel and a lower cylinder barrel; the lower cylinder barrel is slidingly connected with the upper cylinder barrel; when the lower cylinder barrel slides to the uppermost end, the lower cylinder barrel seals a discharge port, and the upper cylinder barrel is sealed; when the lower cylinder barrel slides to the undermost end, the discharge port is opened completely, and a pressing and pressure relief device discharges steam and a material; the pneumatic opening mechanism is connected with the lower cylinder barrel and is used for driving the lower cylinder barrel to slide up and down; a cylinder cover in the cover opening device seals and covers the top end of the upper cylinder barrel; and the cover opening device controls the opening and closing of the cylinder cover. With the adoption of multidirectional discharge, the exhaust discharge area is increased, and the discharge efficiency of the waste steam flash explosion treatment equipment can be improved; a response speed of the pneumatic opening mechanism is increased; in addition, the waste steam flash explosion treatment equipment is provided with a dust blowing device, so that the effect that no material is accumulated can be ensured structurally.

Owner:TIANZI ENVIRONMENTAL PROTECTION EQUIP MFG TIANJIN

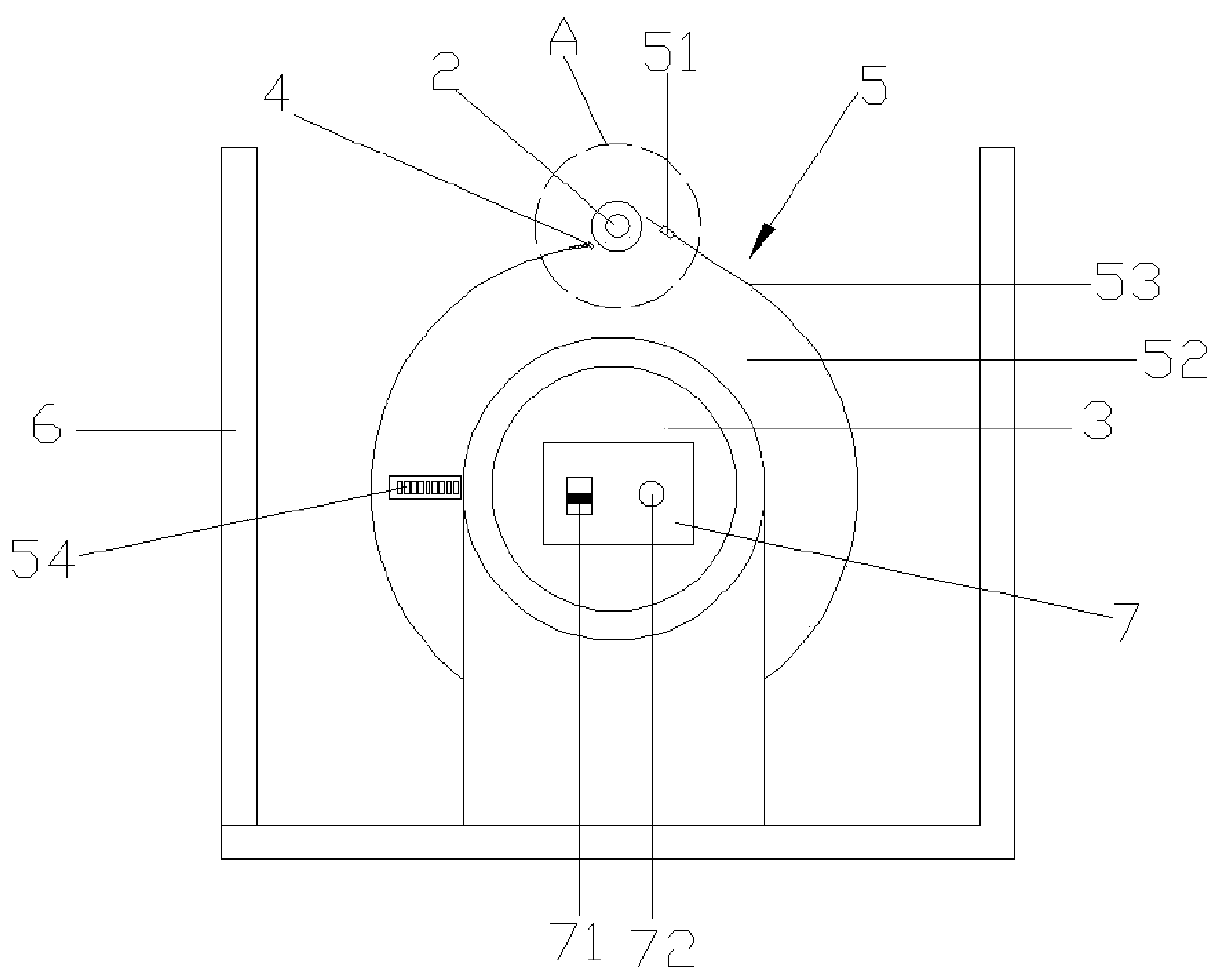

Centrifugal compound pendulum damping structure for super high-rise building and working method of centrifugal compound pendulum damping structure

PendingCN114673272ALarge centrifugal forceFast rotationProtective buildings/sheltersShock proofingCircular discCentrifugal force

According to the centrifugal compound pendulum damping structure for the super high-rise building and the working method of the centrifugal compound pendulum damping structure, a universal hinge collects force of a force bearing beam and transmits the force to a damping telescopic sleeve rod, and the damping telescopic sleeve rod telescopically deforms to drive a centrifugal force conversion section to rotate; the centrifugal force conversion section drives the first double-circular-steel-pipe concrete combined sleeve and the centrifugal energy dissipation structure to rotate, and in the rotating process of a load bearing block body in the centrifugal energy dissipation structure, a spring connecting piece on one side of the load bearing block body deforms and dissipates energy under the action of centrifugal force; the top of the super high-rise building swings, so that the semicircular sliding body swings and rotates repeatedly in the supporting U-shaped disc, the structure returns to the axis position through the concave curved surface structure of the supporting U-shaped disc, the structure acts on the centrifugal energy dissipation structure again, and deformation energy dissipation is achieved through the spring connecting piece. Therefore, the curvature of the rotation curve of the top of the super high-rise building in the horizontal plane is effectively reduced, namely the swing amplitude of the top of the super high-rise building is reduced.

Owner:CHINA UNITED NORTHWEST INST FOR ENG DESIGN & RES

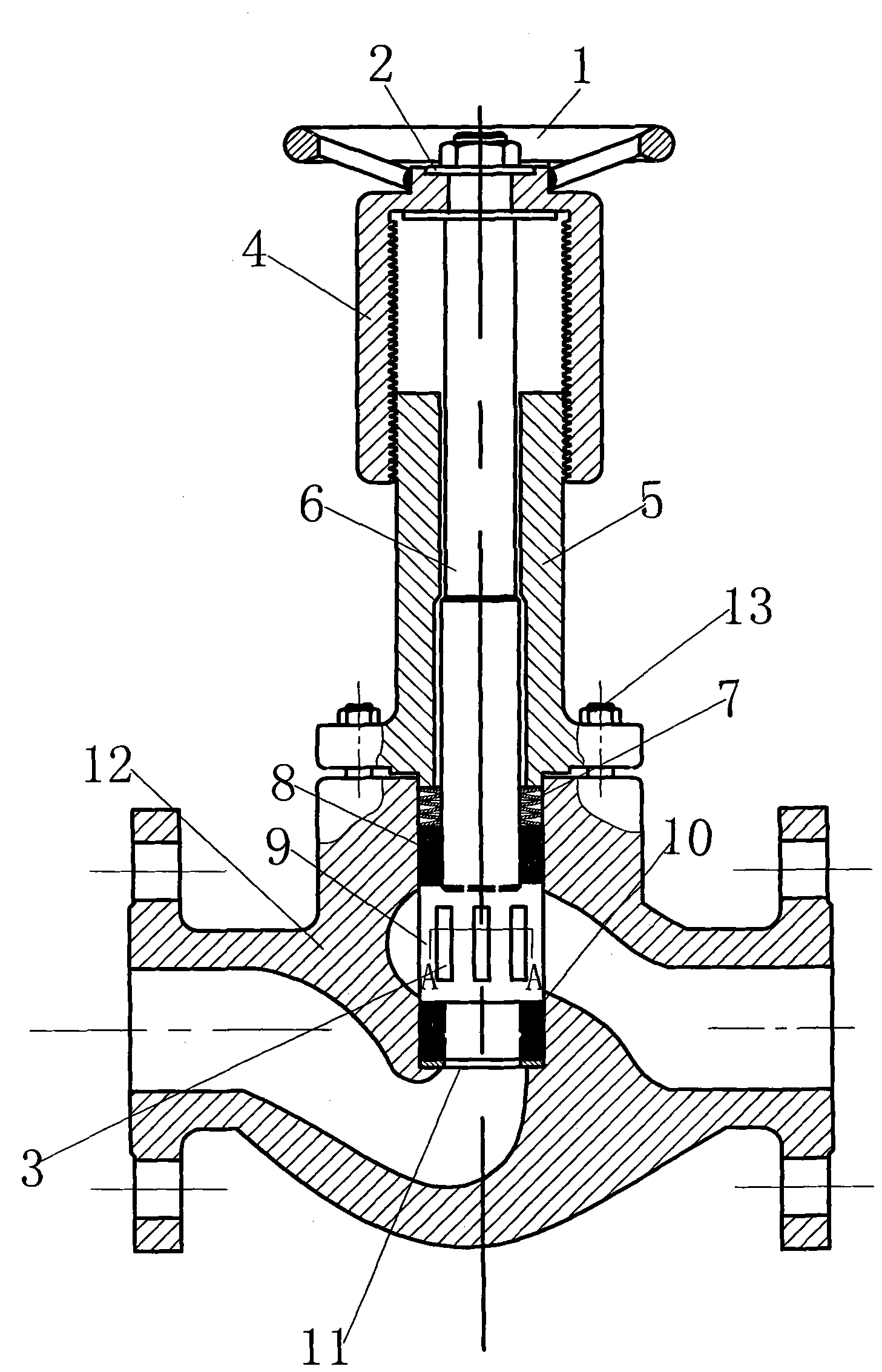

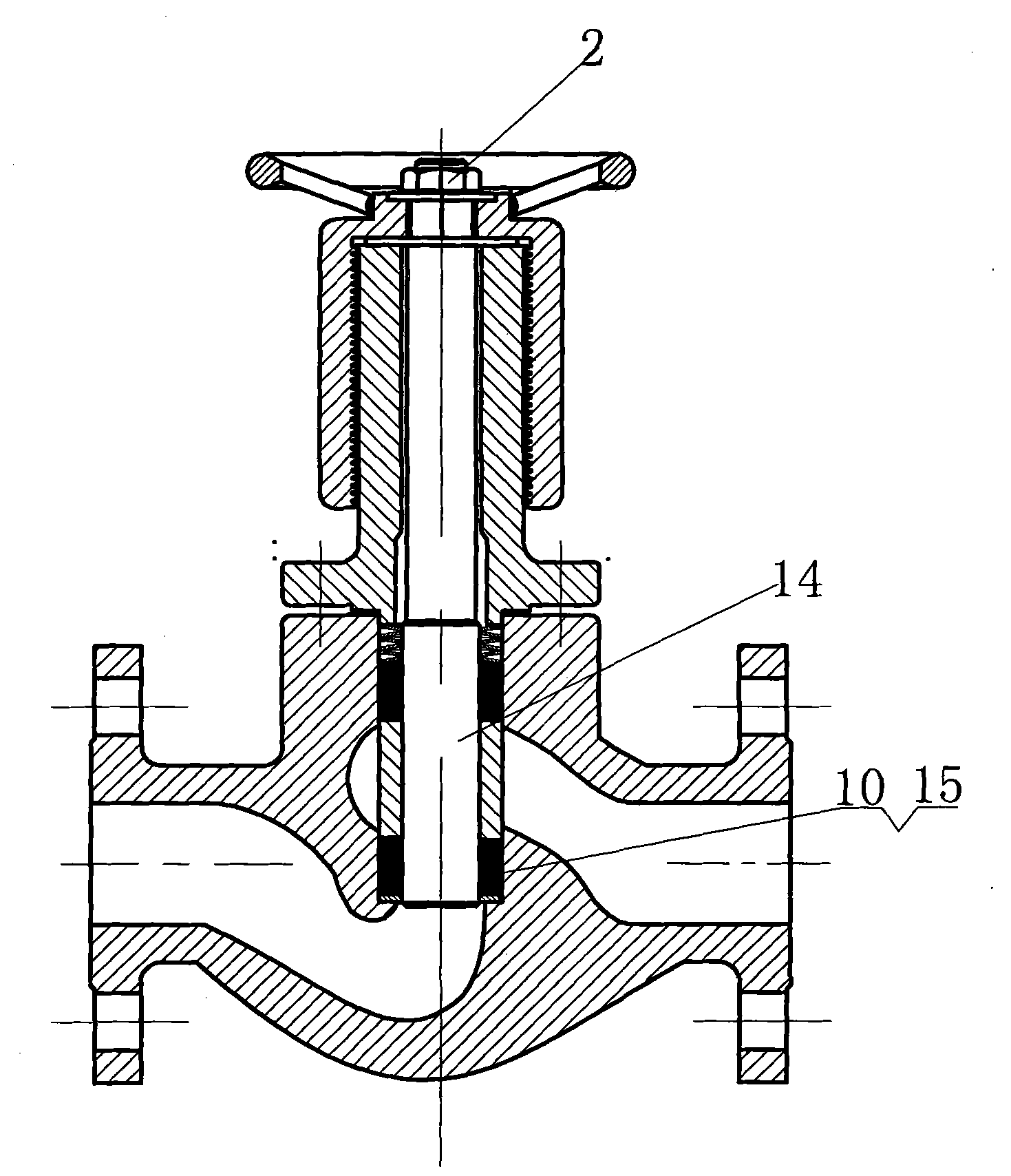

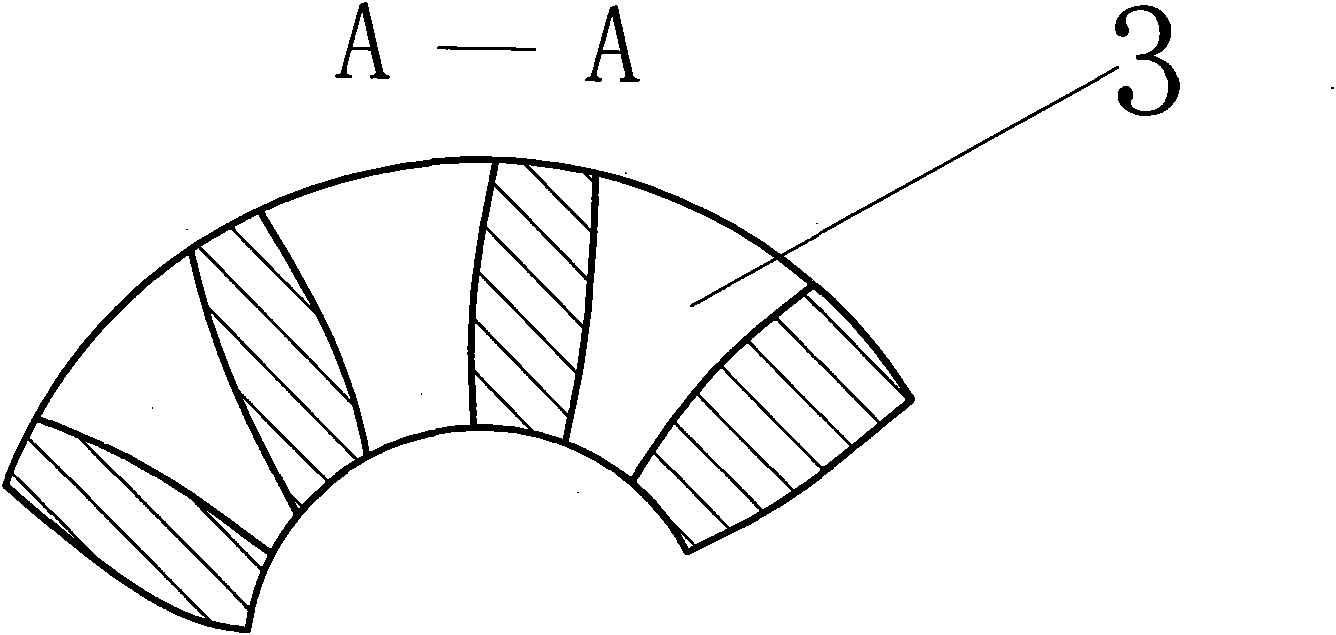

Mute steam blow through valve

InactiveCN101922582ASolve technical problems of noise pollution sourcesImprove sealingSpindle sealingsOperating means/releasing devices for valvesCoil springGraphite

The invention relates to a mute steam blow through valve which comprises a valve body, a hand wheel, a valve rod, a valve element, a valve rod cap, a press cap and a dual sealing assembly, wherein the lower end port of a valve cavity in the middle of the valve body is provided with a washer; the dual sealing assembly comprises a coiled spring, an upper graphite stainless steel sealing ring, a valve element sleeve and a lower graphite stainless steel sealing ring which are sequentially sleeved on the valve element and then loaded in the valve cavity in the middle of the valve body; the upper graphite stainless steel sealing ring and the lower graphite stainless steel sealing ring are respectively and tightly matched with the inner wall of the valve cavity in the middle of the valve body; the press cap is sleeved on the valve rod, and a cap bolt is fixed on the valve body; the lower end surface of the lower graphite stainless steel sealing ring is abutted against the washer, the lower end surface of the upper graphite stainless steel sealing ring is abutted against the valve element sleeve, and the lower end of the coiled spring is abutted against the upper graphite stainless steel sealing ring; the upper end of the coiled spring is abutted against the press cap; the valve rod cap is sleeved on the valve rod and connected with the outer wall of the press cap through a thread; and a nut is screwed at the upper end of the valve rod. The mute steam blow through valve has the advantages of good sealing property and long service life.

Owner:渤海造船厂集团有限公司

Vertical split type pressurizing and pressure relieving cylinder barrel device with material accumulation prevention function

InactiveCN106040721AIncrease the exhaust discharge areaImprove discharge efficiencyEngine sealsSolid waste disposalDischarge efficiencyPulp and paper industry

The invention discloses a vertical split type pressurizing and pressure relieving cylinder barrel device with the material accumulation prevention function. The device comprises a cylinder barrel divided seal device and a cover opening device; the cylinder barrel divided seal device comprises an upper cylinder barrel and a lower cylinder barrel; the lower cylinder barrel is in sliding connection with the upper cylinder barrel, and when the lower cylinder barrel slides to the upmost end, the lower cylinder barrel closes a discharging opening, and the upper cylinder barrel is sealed; when the lower cylinder barrel slides to the lowest end, the discharging opening is completely opened, and a pressurizing and pressure relieving device exhausts steam and materials; a cylinder cover in the cover opening device is sealed on the top end of the upper cylinder barrel in a covering manner, and the cover opening device controls the cylinder cover to be opened and closed; and multi-direction discharging is adopted, the exhaust discharging area is increased, the discharging efficiency of the device can be improved, through the cover opening device, the top of the upper cylinder barrel is reliably controlled to be sealed, meanwhile, the device is provided with a dust blowing device, and it can be ensured that the device is structurally free of material accumulation.

Owner:TIANZI ENVIRONMENTAL PROTECTION EQUIP MFG TIANJIN

A coating sand mill for producing environmentally friendly low-carbon coatings

ActiveCN112473892BLow failure rateIncrease productivityDirt cleaningGrain treatmentsCarbon coatingSander

Owner:CHONGQING XINGYU POLYMER PAINT +1

Exploding type organic matter treatment equipment

InactiveCN106040710AAvoid accumulationIncrease the exhaust discharge areaEngine sealsSolid waste disposalOrganic matterMechanical engineering

The invention discloses exploding type organic matter treatment equipment which comprises a feeding device, a separator, a cover opening device, a discharging device and a pressurization and pressure relief device. The pressurization and pressure relief device is installed in the separator. The separator carries out gas-solid separation on treated materials. The discharging device is located below the separator and conveys separated solids out. The feeding device and the cover opening device are installed on the pressurization and pressure relief device, namely on the top of the separator. The feeding device fills the materials into the pressurization and pressure relief device through the cover opening device. In the pressurization and pressure relief device, pressure exerted on the outside from the material weight and steam is borne by the upper cylinder barrel. An air cylinder is just used for supporting and pushing the lower cylinder barrel, and the requirement for thrust for supporting the air cylinder is lowered. Meanwhile, a semi-hidden type sealing structure is adopted, the situation that the materials make contact with the sealing position in the discharging process is directly avoided, the life of a sealing part is prolonged, and the reliability of the sealing part is improved.

Owner:TIANZI ENVIRONMENTAL PROTECTION EQUIP MFG TIANJIN

Large-diameter flash explosion equipment for waste recycling treatment

InactiveCN106040717AIncrease the exhaust discharge areaImprove discharge efficiencyEngine sealsSolid waste disposalDischarge efficiencyPulp and paper industry

The invention discloses large-diameter flash explosion equipment for waste recycling treatment. The large-diameter flash explosion equipment comprises a branch cylinder barrel sealing device, a pneumatic opening mechanism, a cover opening device and a mounting rack, wherein the branch cylinder barrel sealing device comprises an upper cylinder barrel and a lower cylinder barrel; the lower cylinder barrel is slidingly connected with the upper cylinder barrel; when the lower cylinder barrel slides to the uppermost end, the lower cylinder barrel seals a discharge port, and the upper cylinder barrel is sealed; when the lower cylinder barrel slides to the undermost end, the discharge port is opened completely, and a pressing and pressure relief device discharges steam and a material; the pneumatic opening mechanism is connected with the lower cylinder barrel and is used for driving the lower cylinder barrel to slide up and down; a cylinder cover in the cover opening device seals and covers the top end of the upper cylinder barrel; and the cover opening device controls the opening and closing of the cylinder cover. With the adoption of multidirectional discharge, the exhaust discharge area is increased, and the discharge efficiency of the large-diameter flash explosion equipment can be improved; a response speed of the pneumatic opening mechanism is increased; in addition, the large-diameter flash explosion equipment is provided with a dust blowing device, so that the effect that no material is accumulated can be ensured structurally.

Owner:TIANZI ENVIRONMENTAL PROTECTION EQUIP MFG TIANJIN

Deformation shock-absorbing walking part of double worm gear mechanism and fire-fighting mobile platform with it

ActiveCN106184469BWith self-locking abilityWith shock absorption functionInterconnection systemsResilient suspensionsEngineeringGear train

The invention discloses a deformation shock-absorption traveling part of a double-worm-gear mechanism. The deformation shock-absorption traveling part comprises a stander, an angle adjusting apparatus, epicyclic gear train assemblies and traveling assemblies; the angle adjusting apparatus is connected with the stander, a double-worm-gear mechanism is adopted, and a deformation drive assembly drives a worm to drive two worm gears to rotate; the epicyclic gear train assembly comprises a sun gear, a rocker arm, planetary gears and a shock absorption element; the sun gear is coaxially connected with the worm gears, and the rocker arm is coaxially and pivotally connected with the sun gear; the two planetary gears are pivotally connected with the rocker arm, and the planetary gears are engaged with the sun gear; the shock absorption element is respectively connected with the stander and the rocker arm; and the two epicyclic gear train assemblies are symmetrically arranged, and the two traveling assemblies are respectively connected with the two planetary gears. The invention also provides a firefighting moving platform with the deformation shock-absorption traveling part of the double-worm-gear mechanism. The firefighting moving platform can be used for designing a firefighting robot, so that a robot traveling part is deformable and has shock absorption performance.

Owner:CHINA UNIV OF MINING & TECH

Servo cylinder structure convenient to install

PendingCN114382742AReduce processing timeReduce the number of repeated processingFluid-pressure actuatorsControl engineeringMachining time

The invention provides a servo cylinder structure convenient to install. The servo cylinder structure comprises a servo cylinder body and a fixing rod. One end of the fixed rod is fixedly connected with the servo cylinder body, and the other end is provided with a fixed mounting assembly; the fixed mounting assembly is used for fixing the servo cylinder body on a rack; the fixed installation assembly comprises a fixed column and a gland, the gland is connected to the fixed rod in a sleeving mode, the fixed column is in threaded connection with the fixed rod, and the fixed column is arranged above the gland. According to the servo cylinder structure convenient to install, the servo cylinder is installed on the rack through the thick fixing rod, the machining time of a traditional long and thin deep hole and the repeated machining frequency of the hole are reduced, the machining cost is greatly saved, and the machining efficiency is improved.

Owner:中重科技(天津)股份有限公司

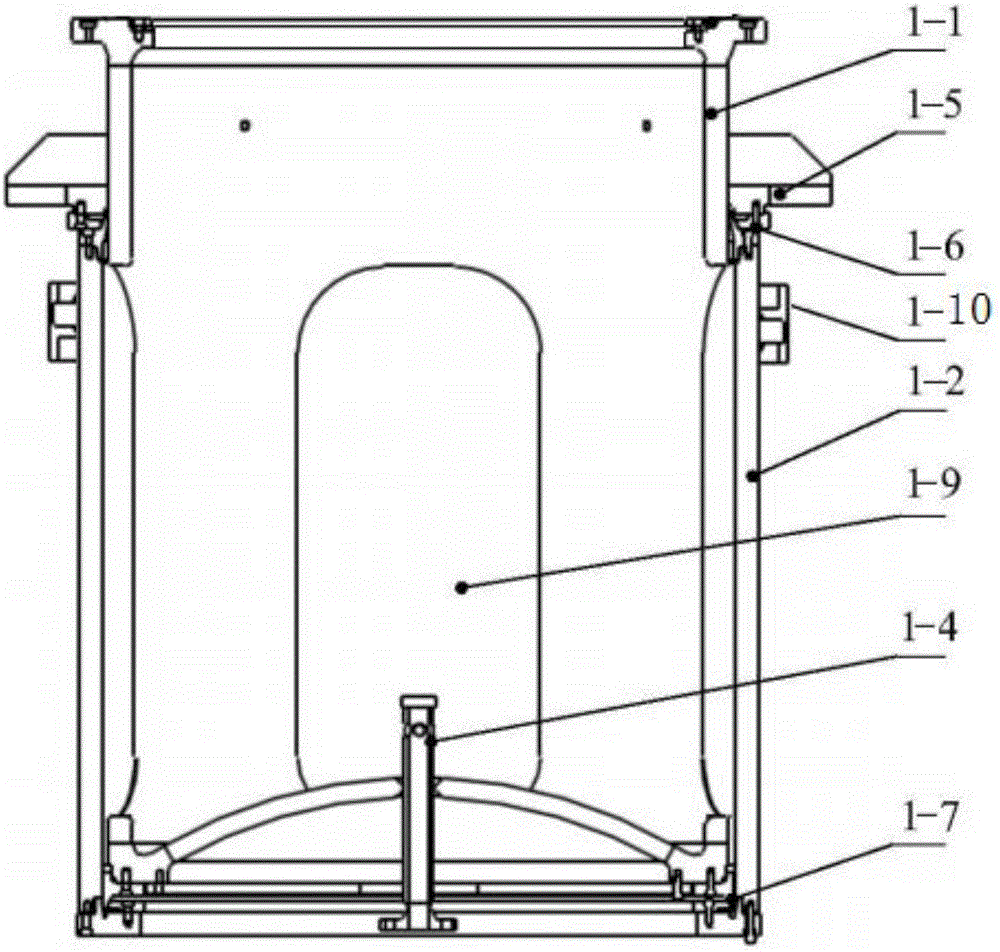

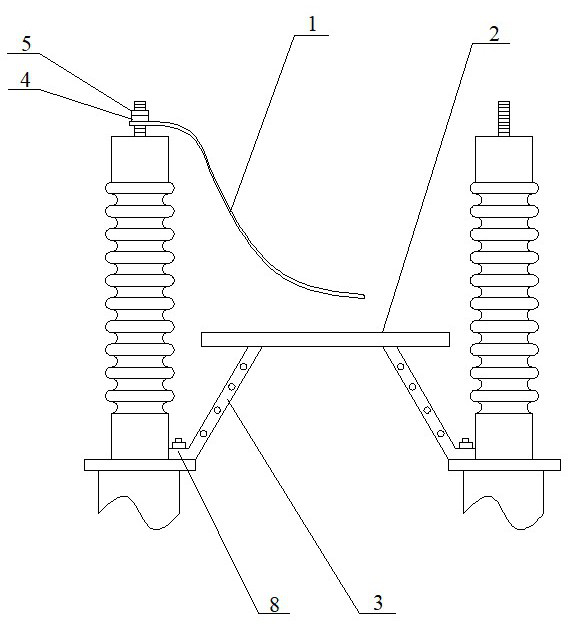

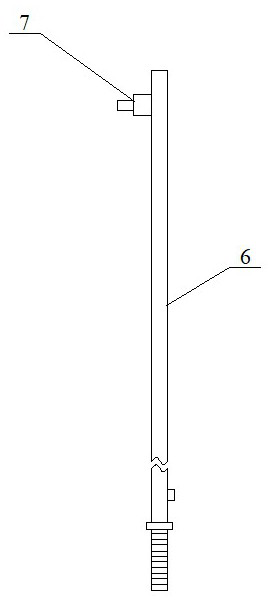

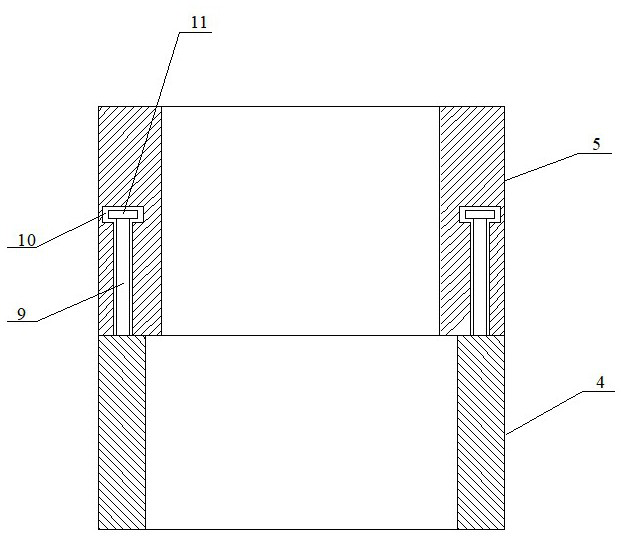

Extra-high voltage transformer maintenance operation device and maintenance method

ActiveCN112054422AEnsure safetyCompliance with operating specificationsSwitchgearSafe operationHigh voltage transformer

The invention discloses an extra-high voltage transformer maintenance operation device and a maintenance method, and belongs to the technical field of transformer maintenance, the extra-high voltage transformer maintenance operation device comprises a safety belt suspension mechanism fixed on a bolt at the top of a transformer, and a maintenance operation platform arranged on a panel of a low-voltage bushing ascending flanged base of the transformer; the safety belt hanging mechanism comprises a safety belt, a connecting piece arranged at the upper end of the safety belt and a mounting assembly used for mounting the connecting piece to a bolt at the top of a transformer. The maintenance operation platform comprises a supporting plate, ladders and mounting bases, the ladders are arranged onthe two sides of the supporting plate respectively, the mounting bases are arranged on the lower portions of the two ladders respectively, and the two mounting bases are connected with two transformer low-voltage bushing ascending flanged base panels through bolts respectively. The device conforms to safety operation specifications, personal safety of maintainers is guaranteed, and the device ishigh in use convenience.

Owner:国网河南省电力公司超高压公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com