Fixed device for mold material processing of ceramic mold digital controlled lathe

A technology of CNC lathes and ceramic molds, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve problems such as jitter, swing, displacement, deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

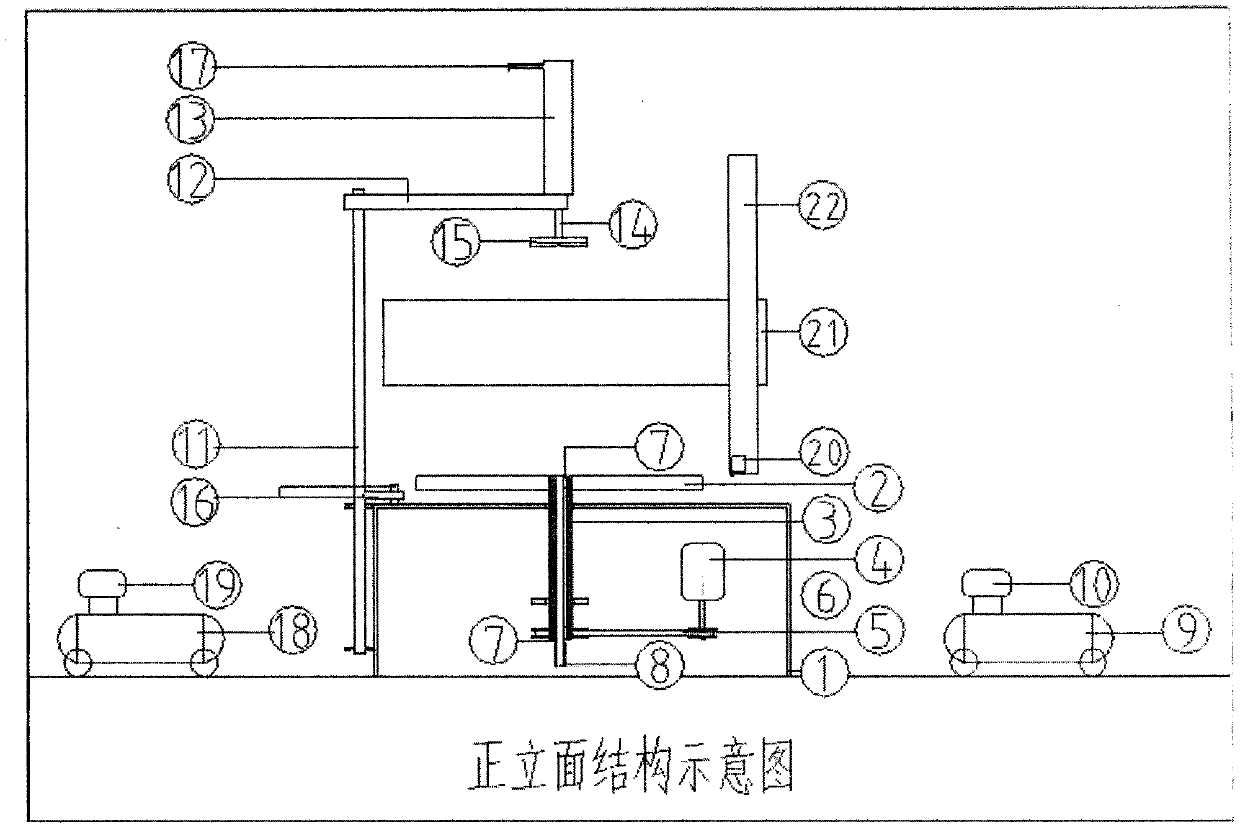

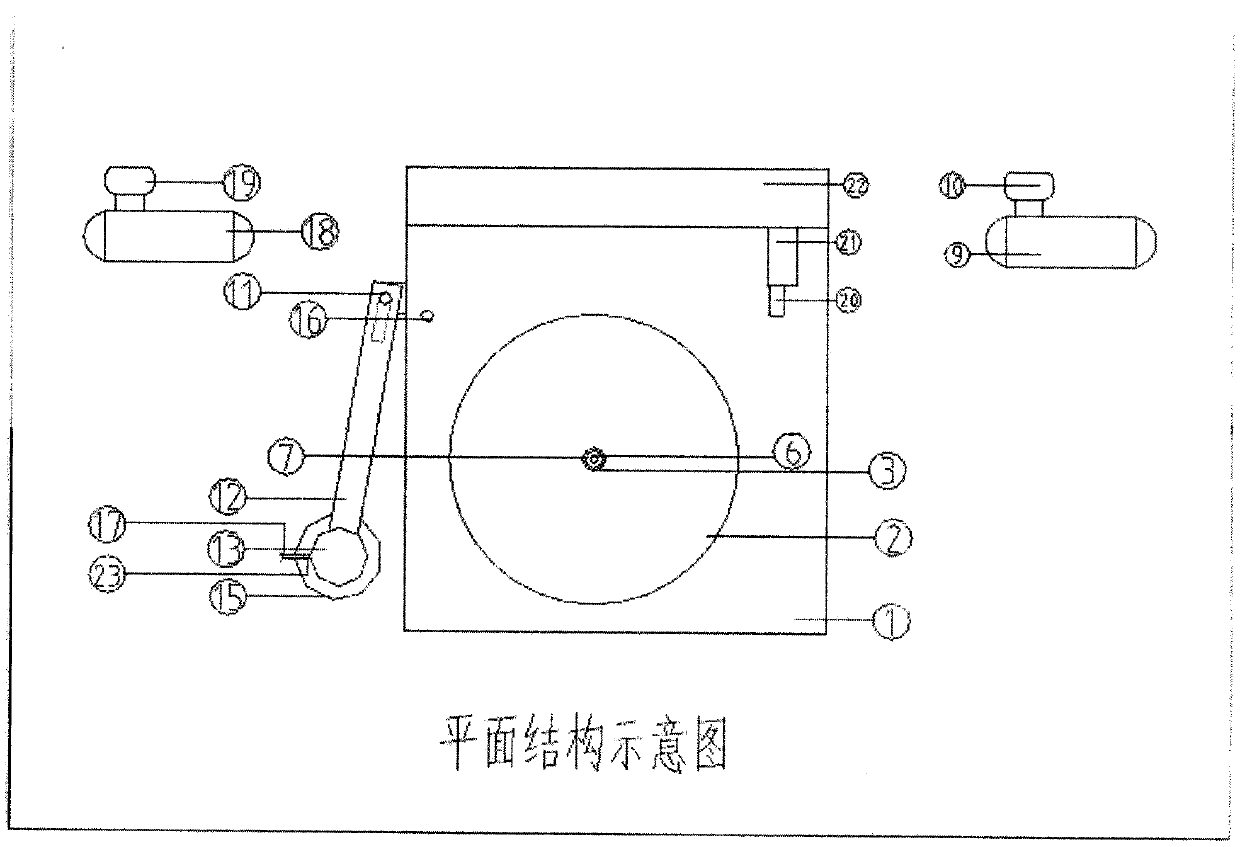

[0022] Utilize the technical scheme of the present invention to add the mold material fixing device to the original ceramic mold CNC lathe, and manufacture a porcelain bottle with a bottom diameter of 200 mm, an upper bottle mouth diameter of 280 mm, a bottle body diameter at breast height of 10-100 mm, and a cylindrical shape with a height of 990 mm. The mold of the vase, the mold material is gypsum mixed mud, the outer dimensions of the mold material are 400mm in diameter, 1200mm in height, cylindrical, and the wall thickness varies from 10-20mm according to the shape model design of different parts.

[0023] 1 Place the molding material for the vase mold on the lathe molding material processing plate (Figure 1), and manually align the center of the mold material with the rotation axis of the mold material processing plate as much as possible;

[0024] 2. Turn on the vacuum pump (Figure 3), the negative pressure value of the pressure gauge reaches a certain value (correspondi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com