Vertical split type pressurizing and pressure relieving cylinder barrel device with material accumulation prevention function

A split-type, anti-accumulation technology, applied in the valve device, packaging, transportation and packaging, etc., can solve the problem that the blasting effect cannot be achieved, it is difficult to increase the effective cross-sectional area, and the pressure relief speed of the pressure relief device is difficult to improve, etc. problems, to achieve the effect of simple and easy structure, reliable sealing, increased life and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

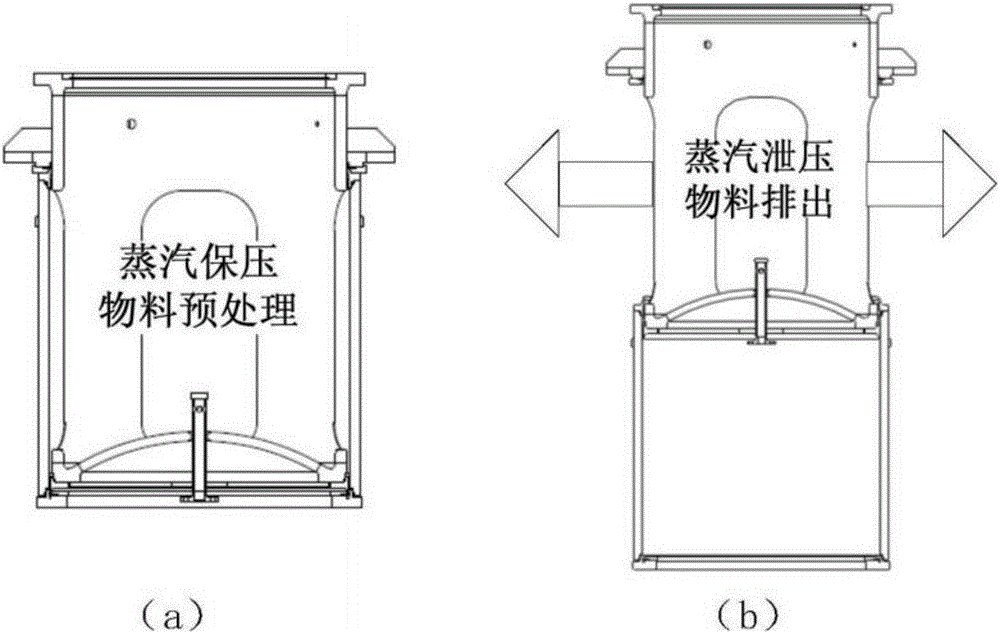

[0032] The utility model relates to an upper and lower split pressurization and pressure relief cylinder device with the function of preventing accumulation of material, which comprises a sub-cylinder sealing device and a cover opening device.

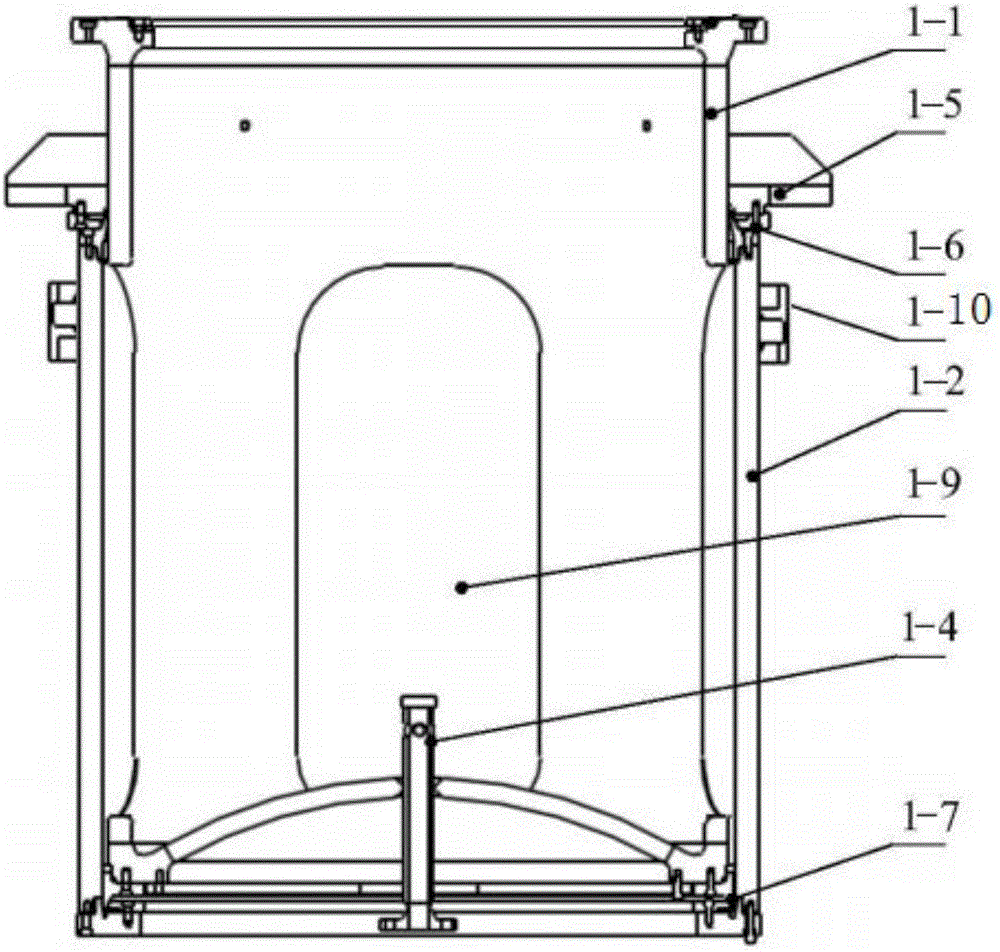

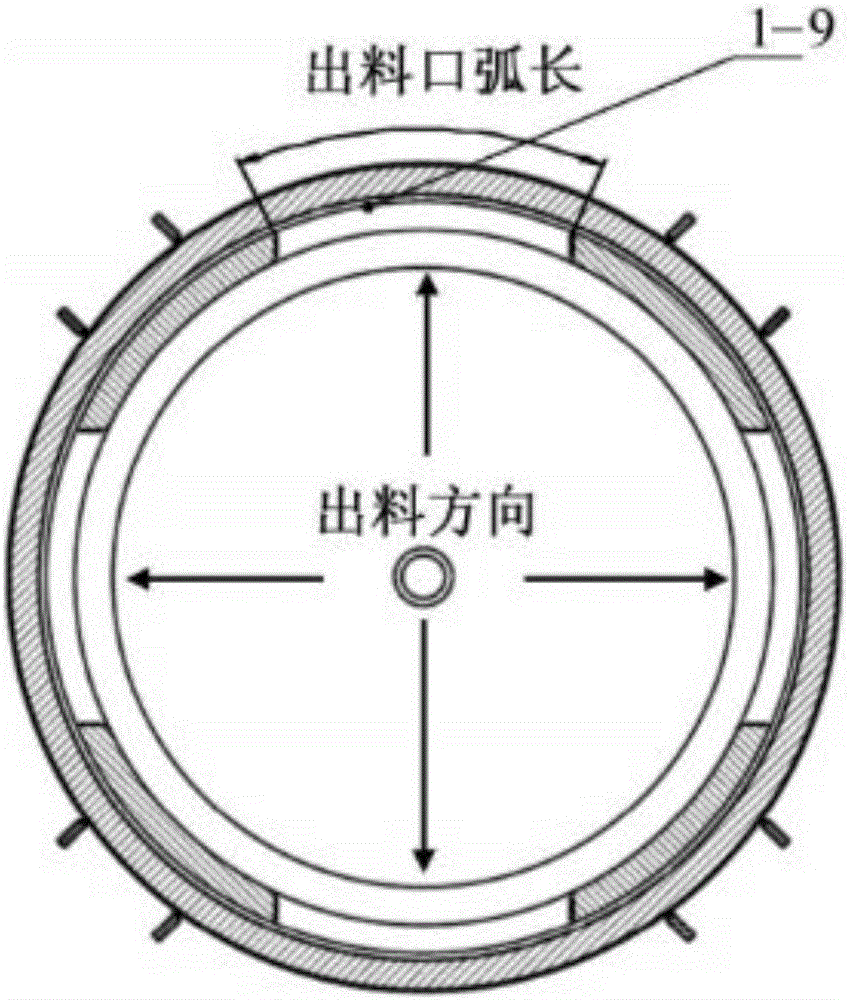

[0033] see figure 1 , The sub-cylinder sealing device includes: upper cylinder 1-1, lower cylinder 1-2, steam filling port 1-4, mounting lug 1-5, middle sealing assembly 1-6, lower sealing assembly 1-7 . The upper cylinder 1-1 includes a steam valve port 1-4 at the bottom and a discharge port 1-9 at the side; the lower cylinder 1-2 is a cylindrical structure with openings at both ends, and the steam pipe passes through the opening at the lower end Connect with the steam valve port 1-4, the lower cylinder 1-2 is slidingly connected with the upper cylinder 1-1, when the lower cylinder 1-2 slides to the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com