Multi-caliber organic matter garbage blasting treatment equipment

A technology for processing equipment and organic matter, applied in mechanical equipment, grain processing, engine components, etc., can solve the problems of difficult to increase the pressure relief speed of the pressure relief device, difficult to increase the effective cross-sectional area, unable to achieve the blasting effect, etc. To achieve the effect of simple and easy structure, lower requirements for matching accuracy, and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

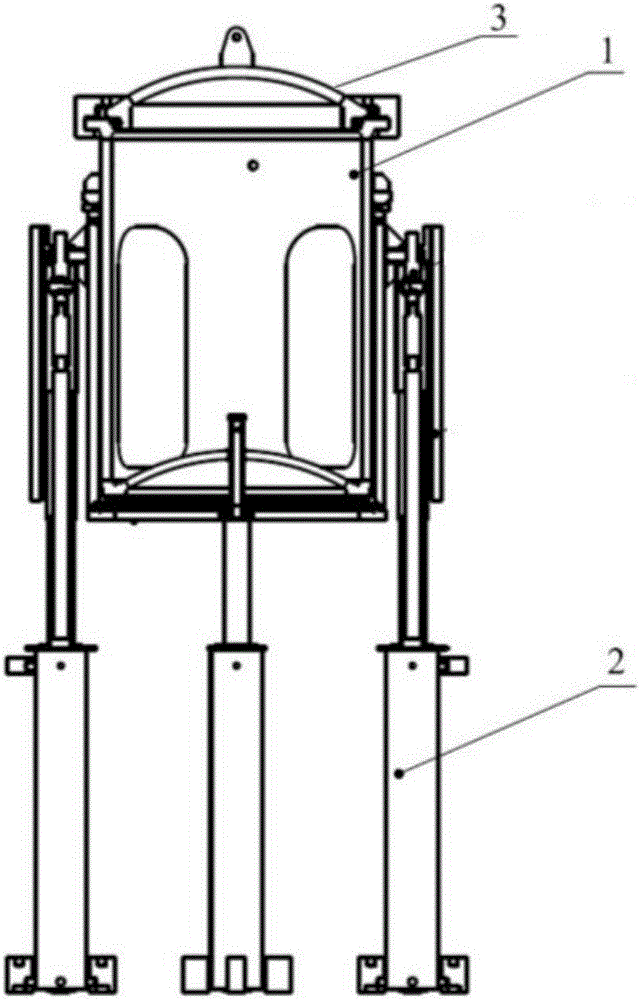

[0048] see figure 1 And attached Figure 19 , a multi-caliber organic waste blasting treatment equipment, including a sub-cylinder sealing device 1, a pneumatic opening mechanism 2, a cover opening device 3, a mounting frame 6 and a separator 4.

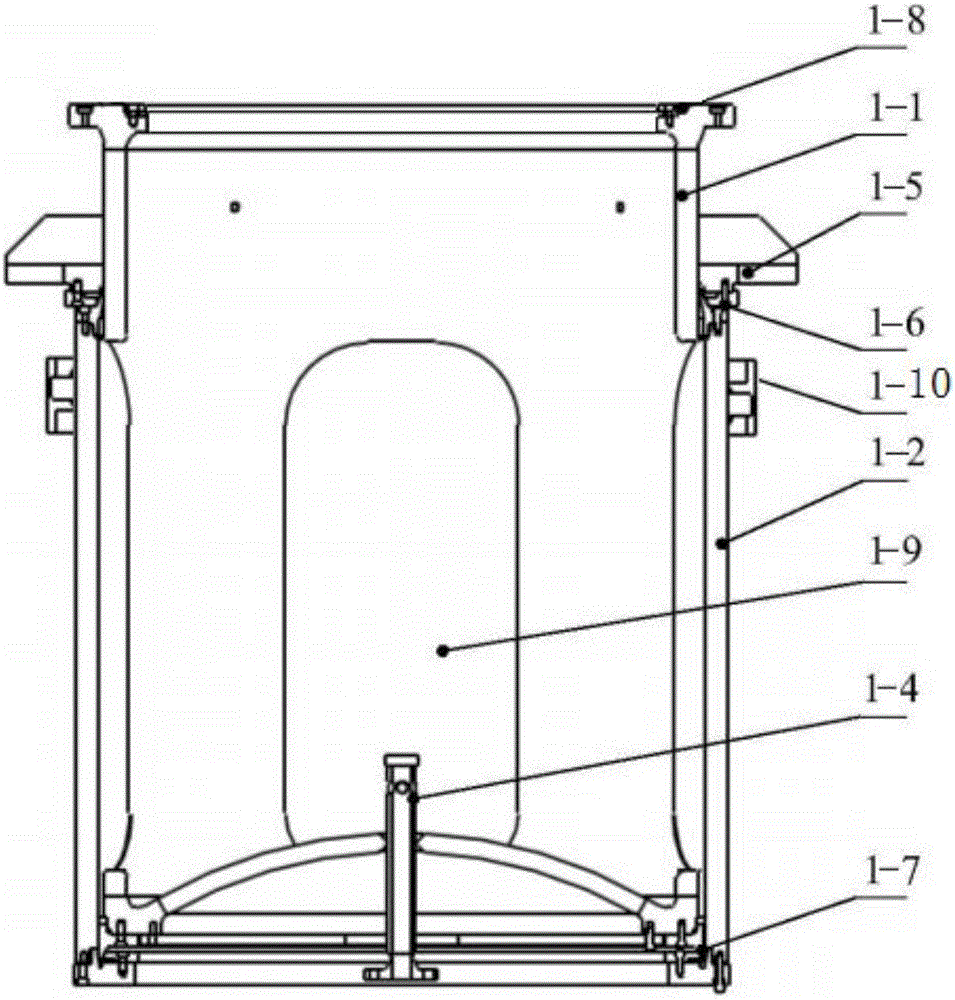

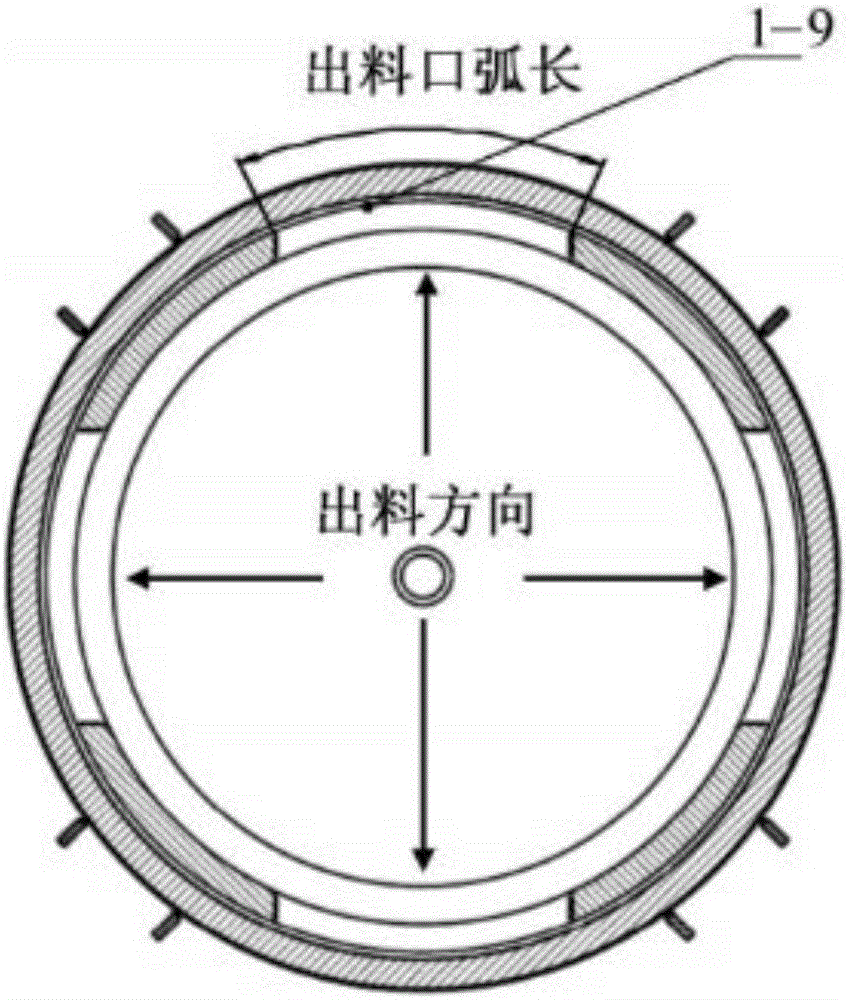

[0049] see figure 2 , The sub-cylinder sealing device 1 includes: upper cylinder 1-1, lower cylinder 1-2, steam filling port 1-4, mounting lug 1-5, middle sealing assembly 1-6, lower sealing assembly 1- 7. Upper seal assembly 1-8. The upper cylinder 1-1 includes a steam valve port 1-4 at the bottom and a discharge port 1-9 at the side; the lower cylinder 1-2 is a cylindrical structure with openings at both ends, and the steam pipe passes through the opening at the lower end Connect with the steam valve port 1-4, the lower cylinder 1-2 is slidingly connected with the upper cylinder 1-1, when the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com