Cylinder-type pressurization and pressure release device and pressurization and pressure release method

A technology of pressure relief device and cylinder, which is applied in the direction of pressure vessel, gas/liquid distribution and storage, fixed-capacity gas storage tank, etc. It is difficult to increase the effective cross-sectional area and other issues to achieve the effect of reducing the matching accuracy requirements, avoiding contact, and increasing the exhaust diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

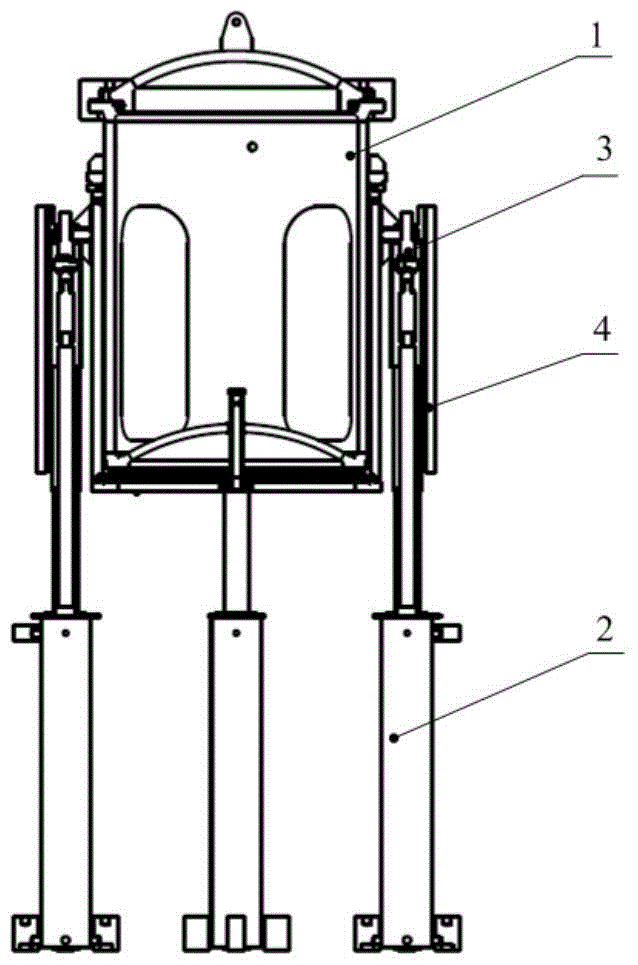

[0032] see figure 1 , The structure of the pressure relief device mainly includes: a separate cylinder sealing device 1, a pneumatic opening mechanism 2, a connecting piece 3, and a guide rail 4.

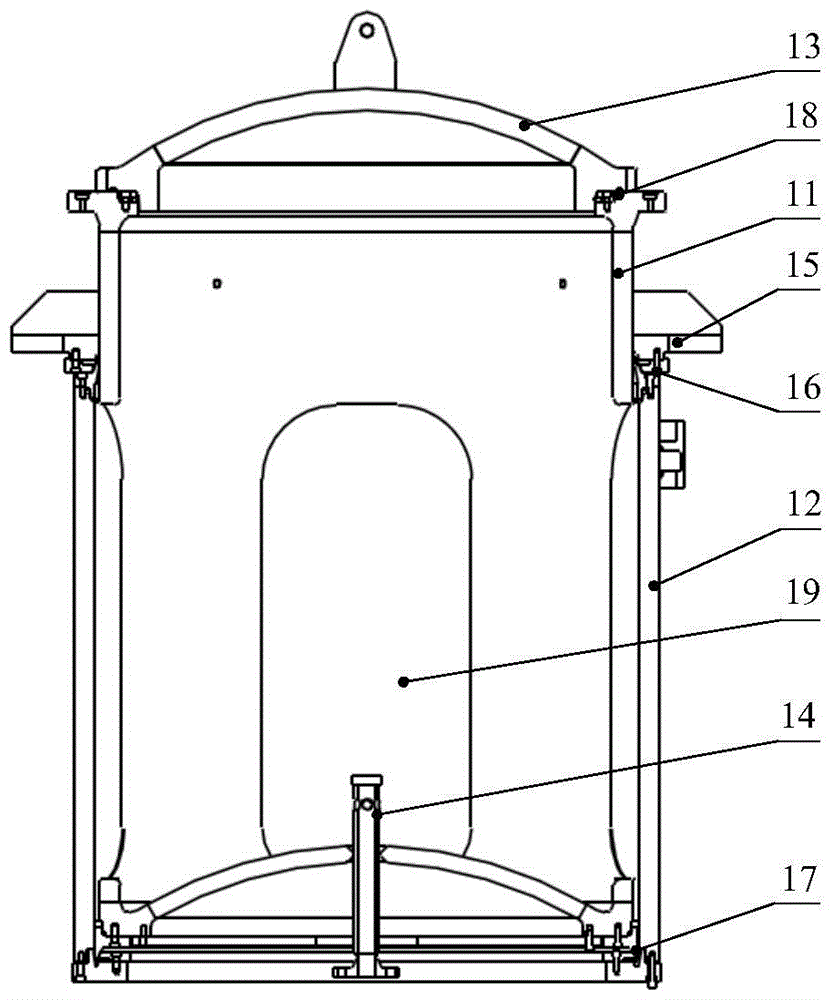

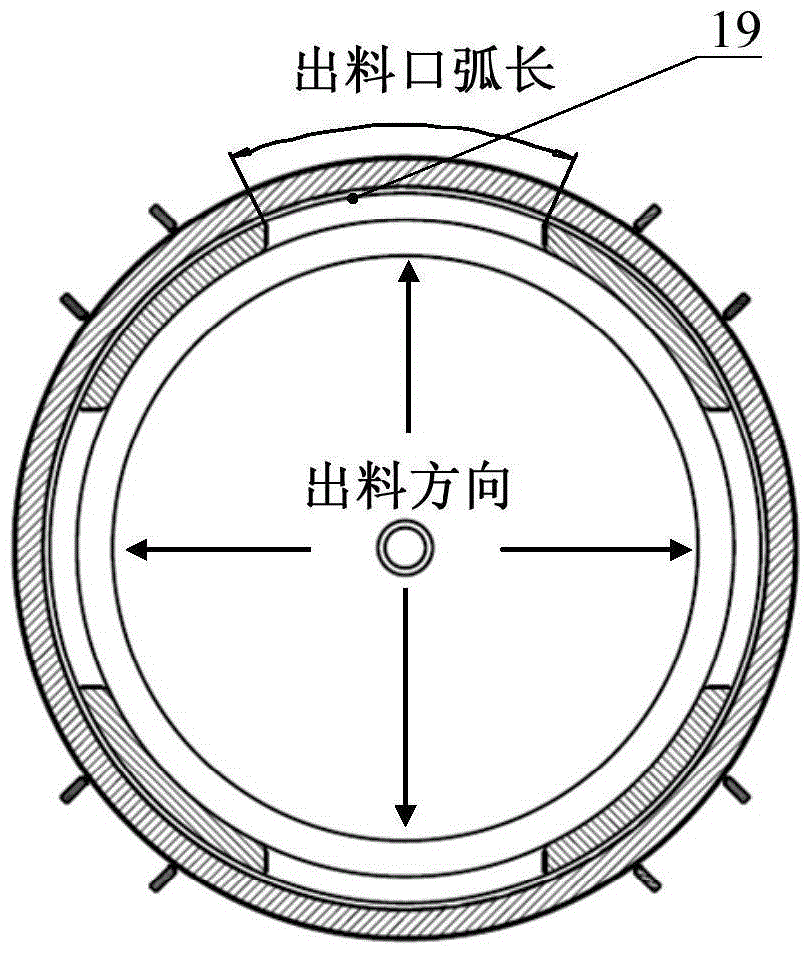

[0033] see figure 2 , The sub-cylinder sealing device includes: upper cylinder 11, lower cylinder 12, upper cover 13, steam filling port 14, mounting lugs 15, middle sealing assembly 16, lower sealing assembly 17, and upper sealing assembly 18. The upper cylinder 11 includes a steam valve port 14 at the bottom and a discharge port 19 at the side; the lower cylinder 12 is a cylindrical structure with openings at both ends, and the steam pipe is connected to the steam valve port 14 through the opening at the lower end, and the lower cylinder is The cylinder tube 12 is slidably connected with the upper cylinder tube 11. When the lower cylinder tube 12 slides to the uppermost end, the lower cylinder tube 12 closes the discharge port 19, and the upper cylinder tube 11 is sealed; when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com