Patents

Literature

129results about How to "Low matching accuracy requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

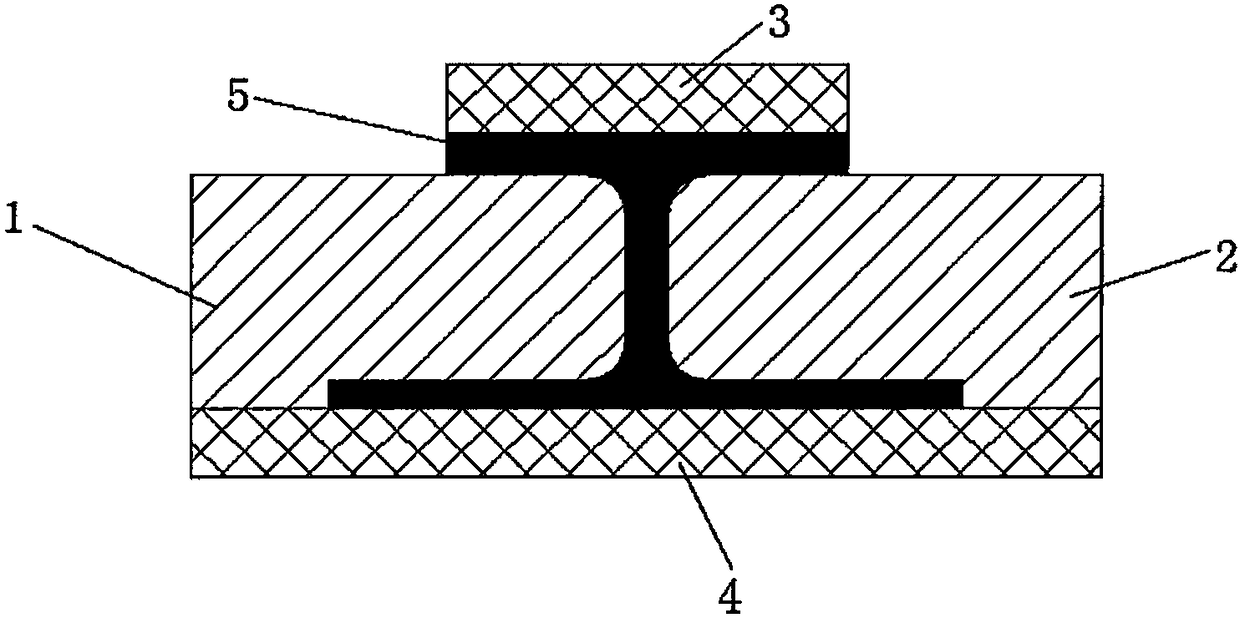

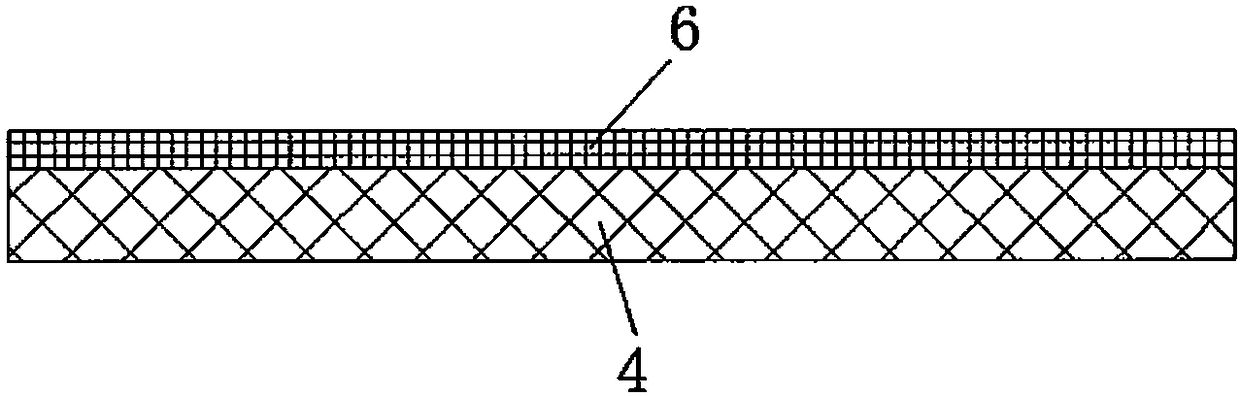

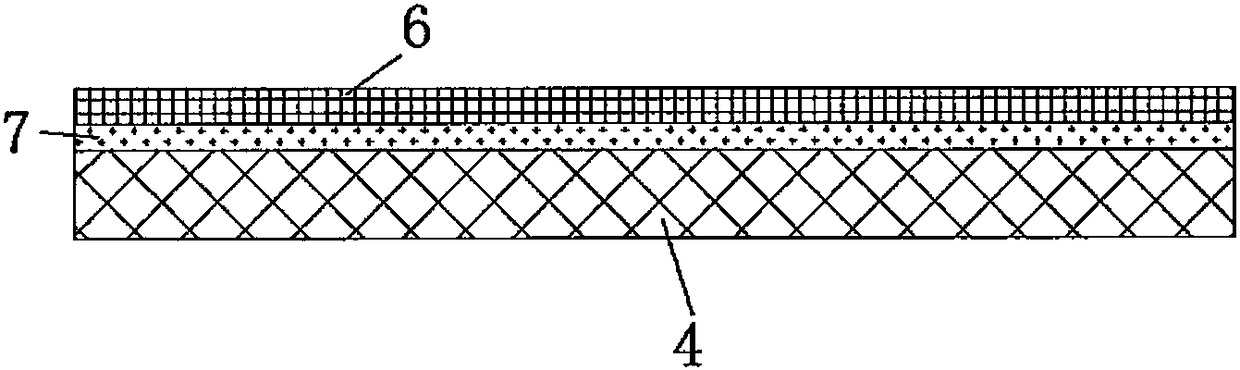

Composite material I-shaped stringer molding process

The invention provides a composite material I-shaped stringer molding process, which comprises: manufacturing a hard mold tool; manufacturing a soft mold process cover plate; manufacturing a lower edge strip soft mold; molding an I-shaped stringer core mold; molding an I-shaped stringer lower edge strip flat plate; molding an I-shaped stringer upper edge strip flat plate; molding a stringer wick strip; combining to obtain an I-shaped stringer tool; preparing a vacuum bag; curing; and demolding. According to the present invention, the part manufactured according to the process has good appearance quality, the generation of internal defects cannot be caused, the molding quality of the thin part can be improved, and the requirements on the manufacture precision and the matching precision of the molding tool are reduced so as to reduce the manufacturing cost of the part.

Owner:COMAC +1

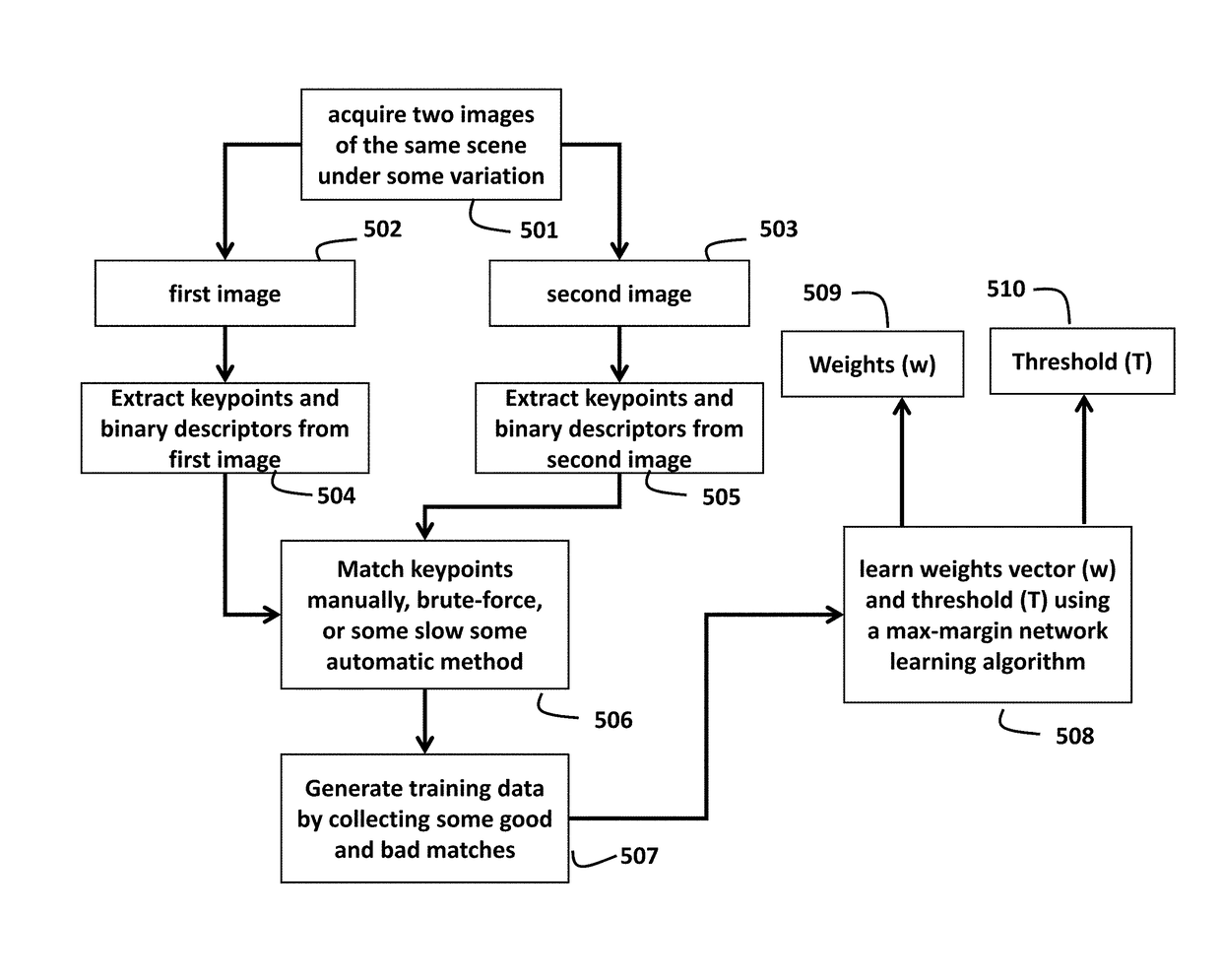

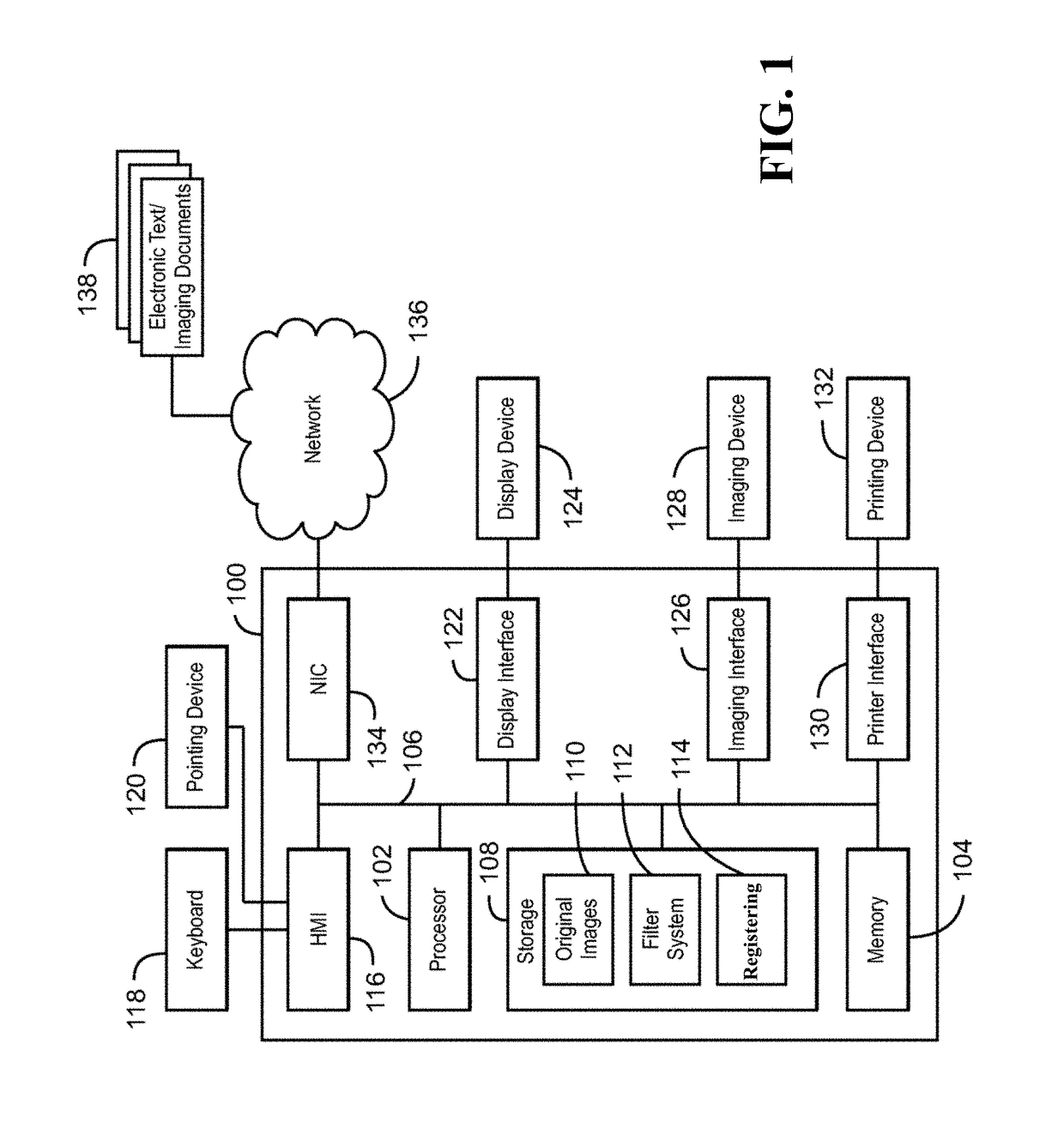

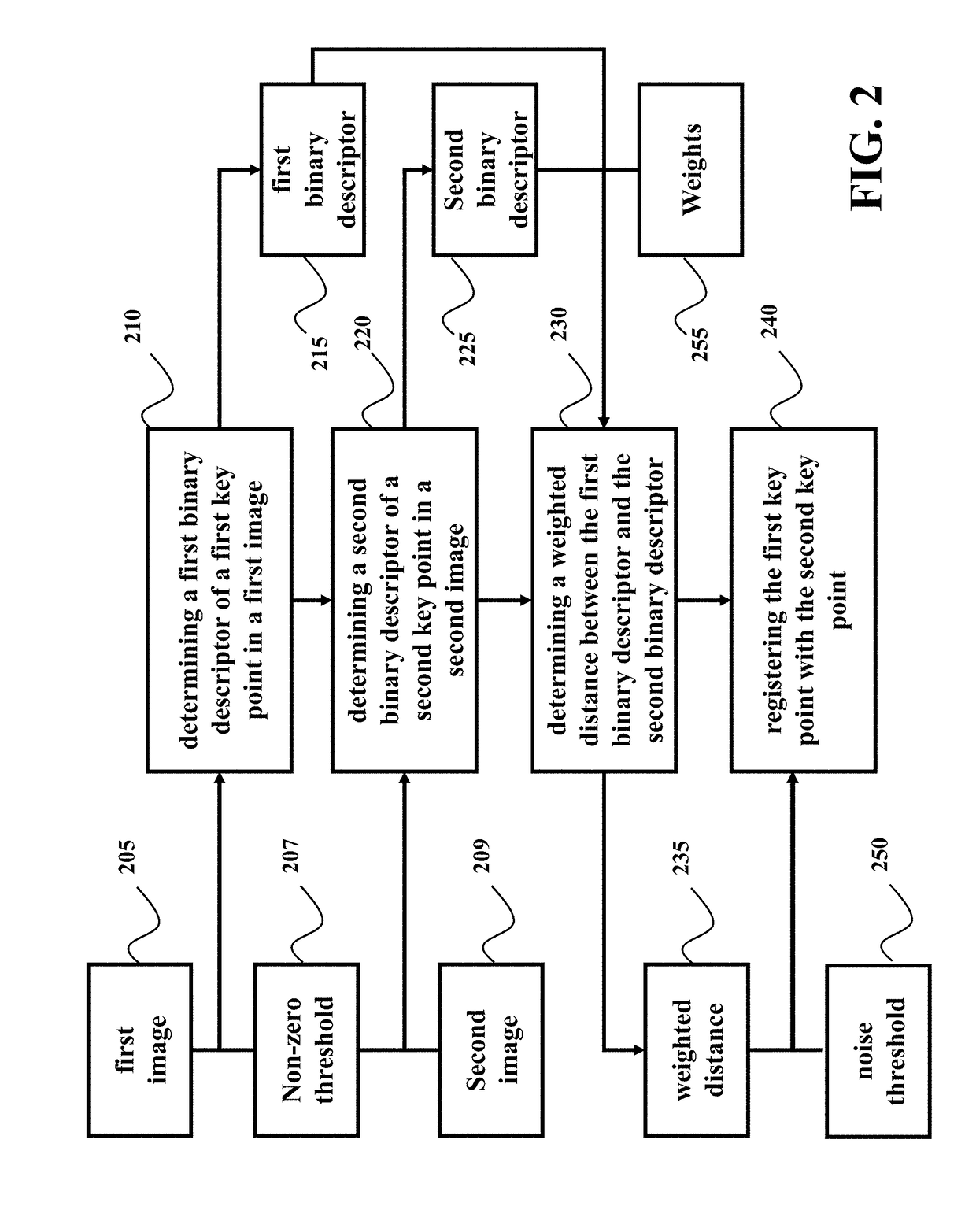

Method and System for Image Registrations

ActiveUS20180053293A1Improving Image Registration AccuracyEffective maintenanceImage enhancementImage analysisHamming distanceNoise threshold

An image registrations includes determining a first binary descriptor of a first key point in a first image, determining a second binary descriptor of a second key point in a second image, determining a weighted Hamming distance between the first binary descriptor and the second binary descriptor, and registering the first key point with the second key point when the weighted Hamming distance is below a noise threshold. At least one element in the first or the second binary descriptor is a result of a comparison of a difference between intensities of at least two pixels of the first or the second image with a threshold. At least two weights of the weighted Hamming distance for comparing at least two elements of the first or the second binary descriptors are different.

Owner:MITSUBISHI ELECTRIC RES LAB INC

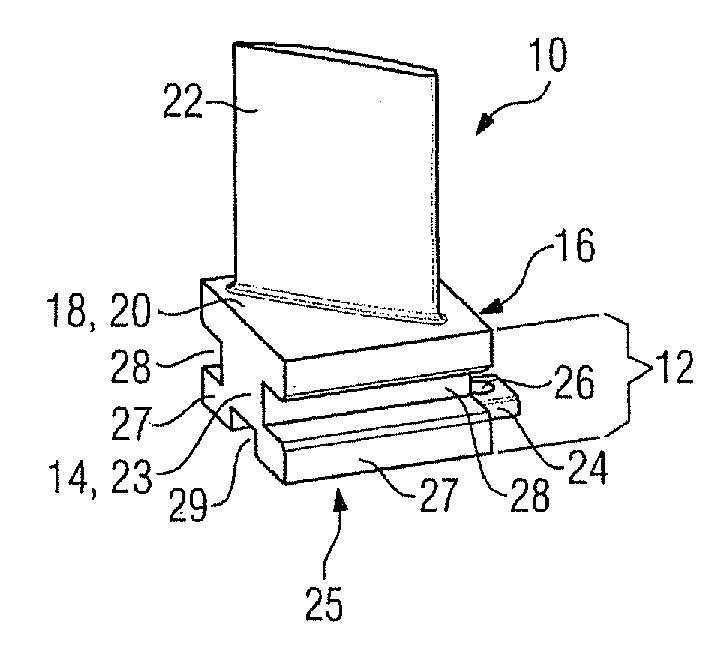

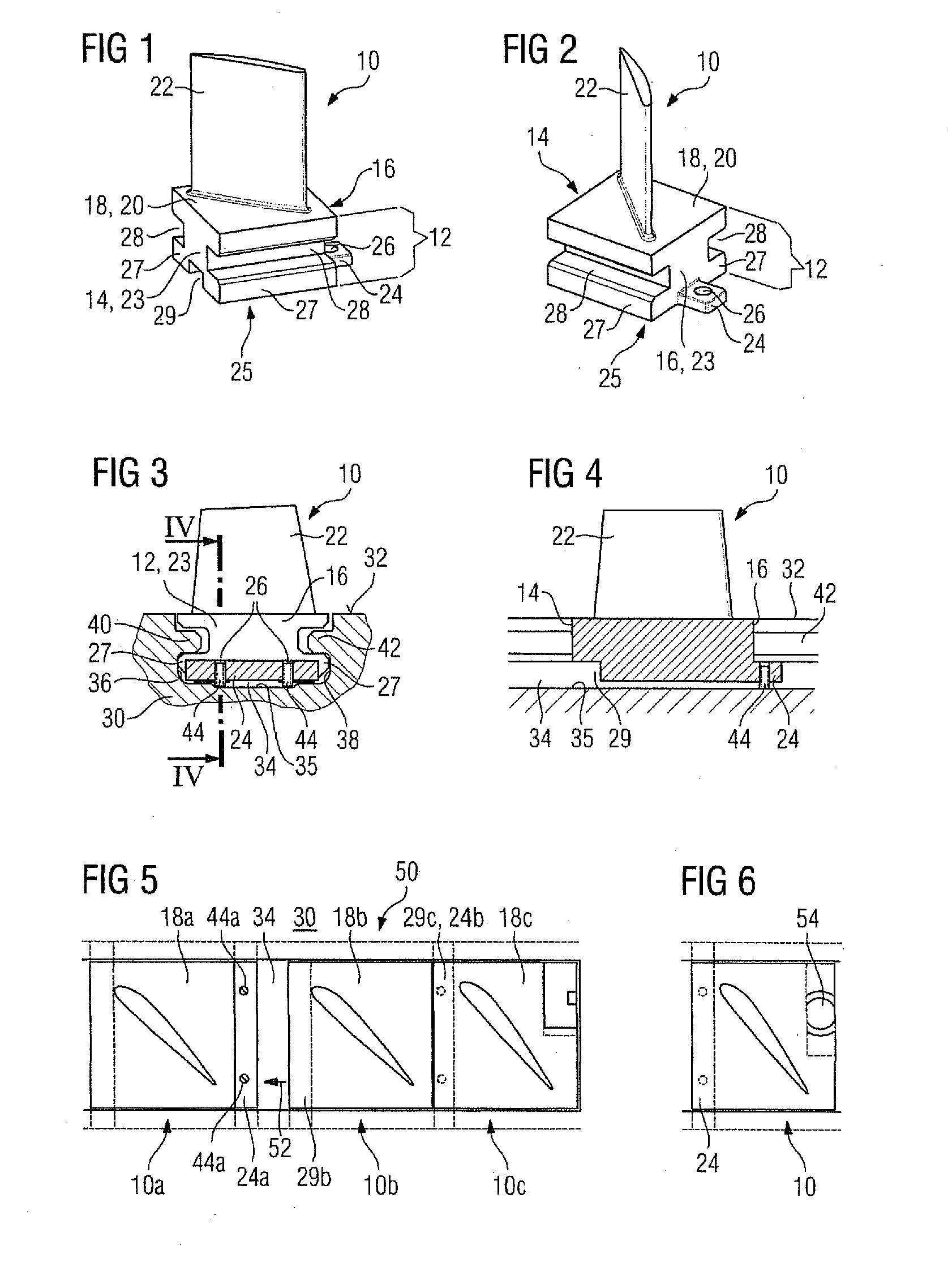

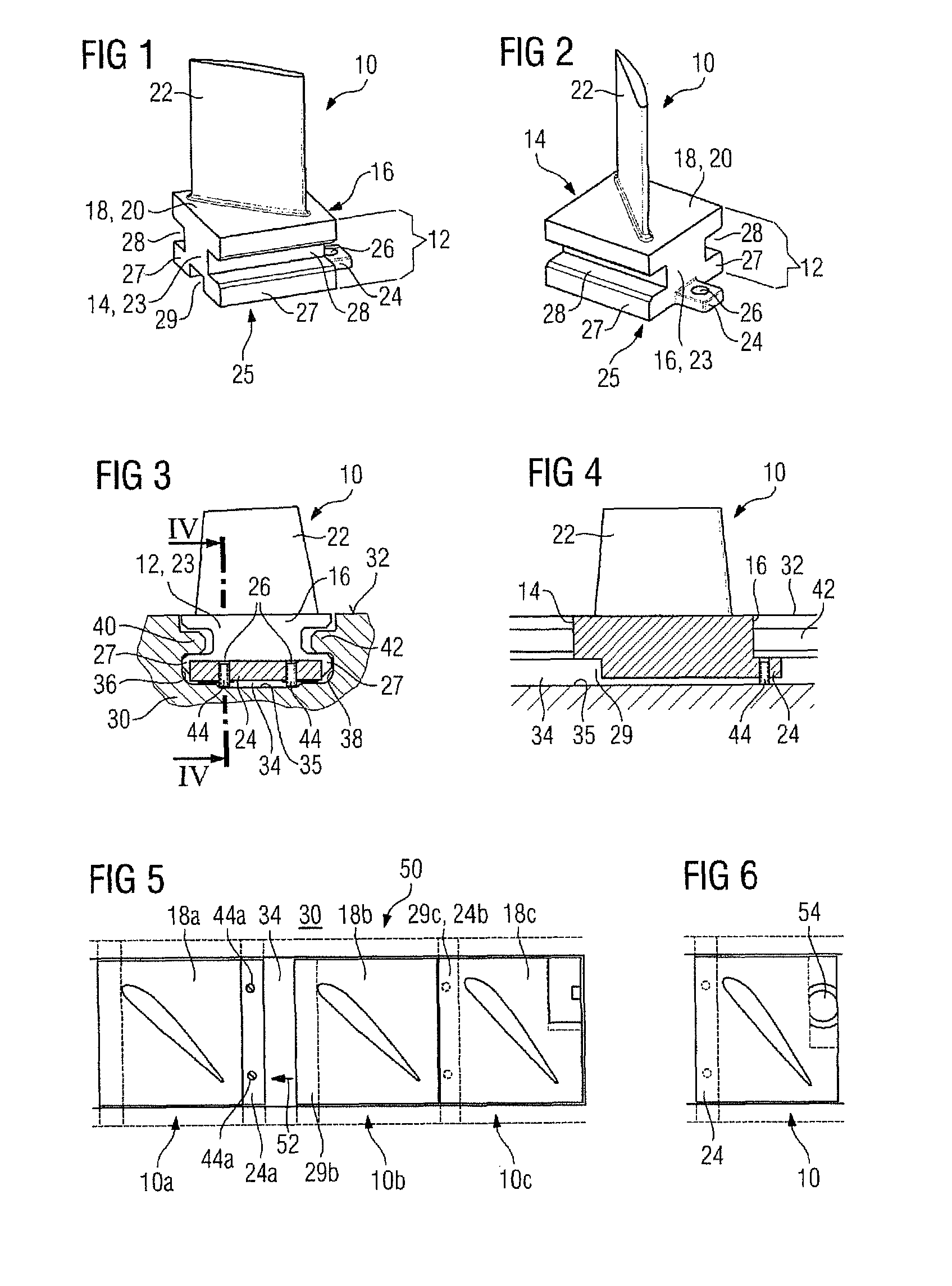

Stator Blade for a Turbomachine which is Exposable to Axial Throughflow, and also Stator Blade Arrangement for It

InactiveUS20110052397A1Easy to insertHinders provisionPropellersRotary propellersEngineeringMechanical engineering

A stator blade and a stator blade arrangement for a turbomachine which is exposable to axial throughflow is provided. Each stator blade is retained via a fixed clamping in a circumferential groove. For the fixed clamping, provision is made on one side of the blade root for a shaped piece with a threaded hole into which a tensioning screw, which is supported on the bottom of the circumferential groove, may be screwed.

Owner:SIEMENS AG

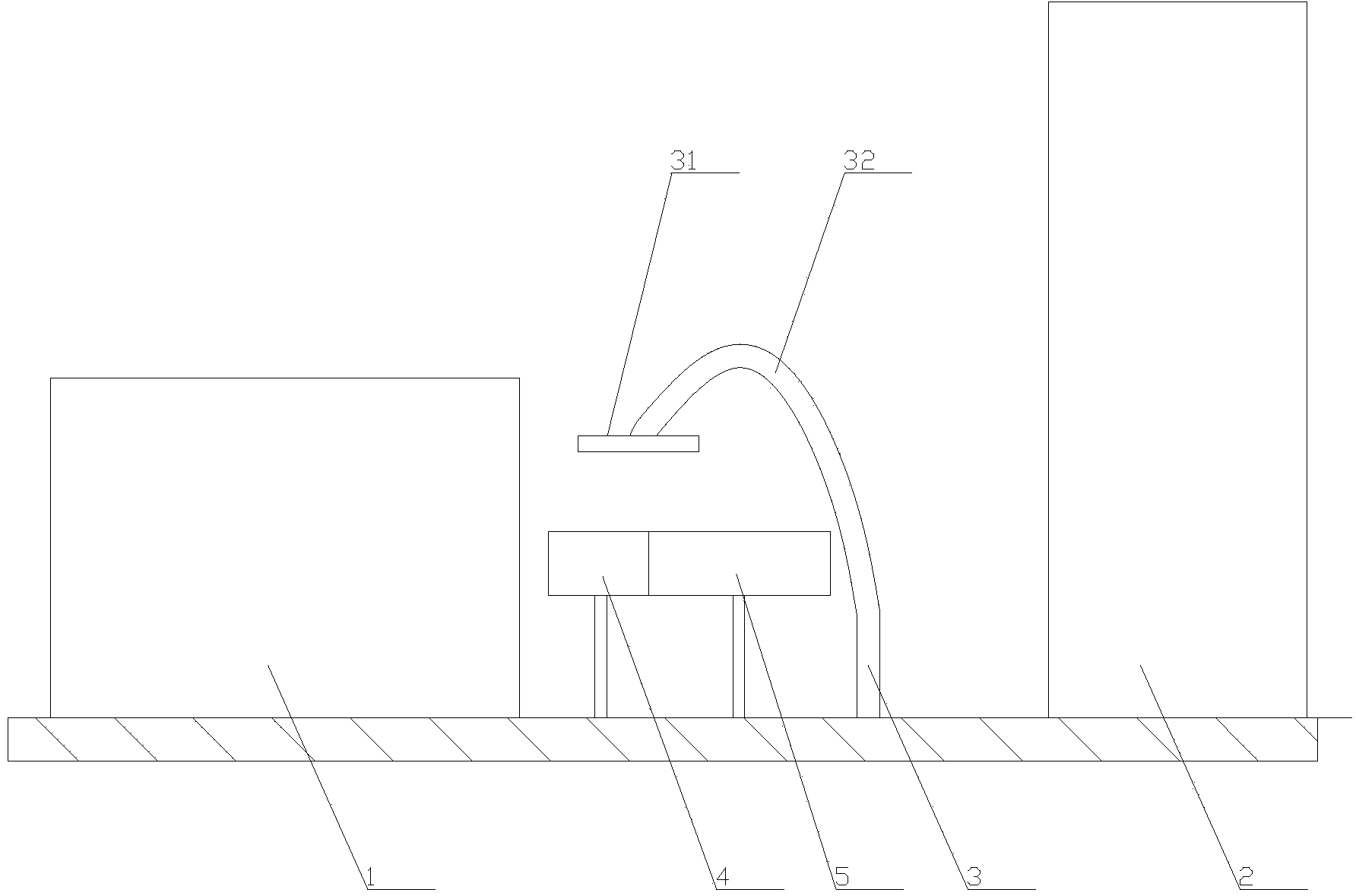

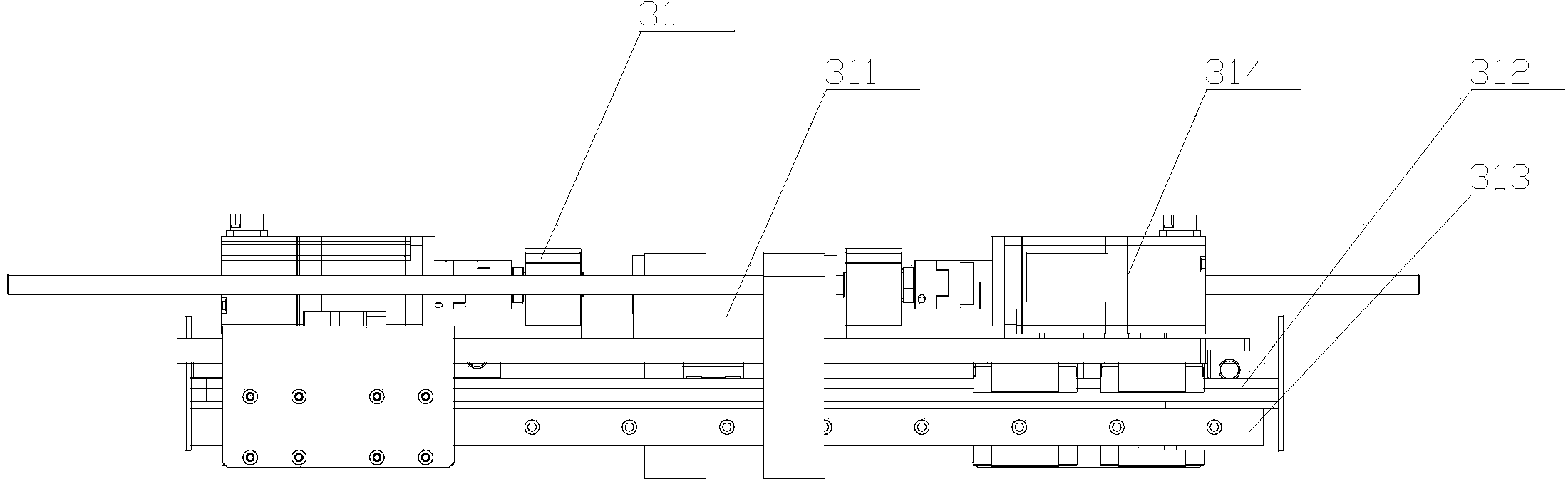

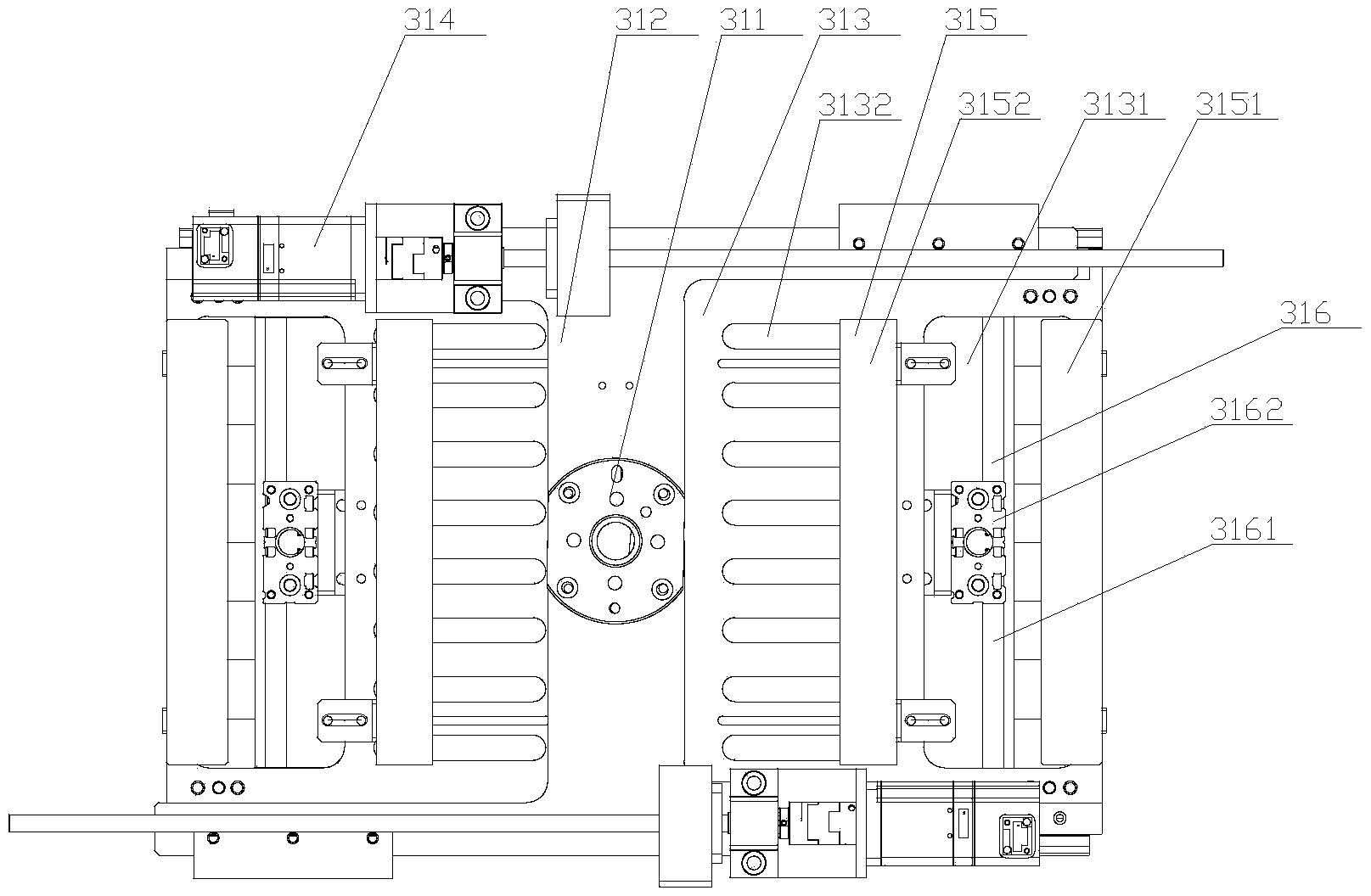

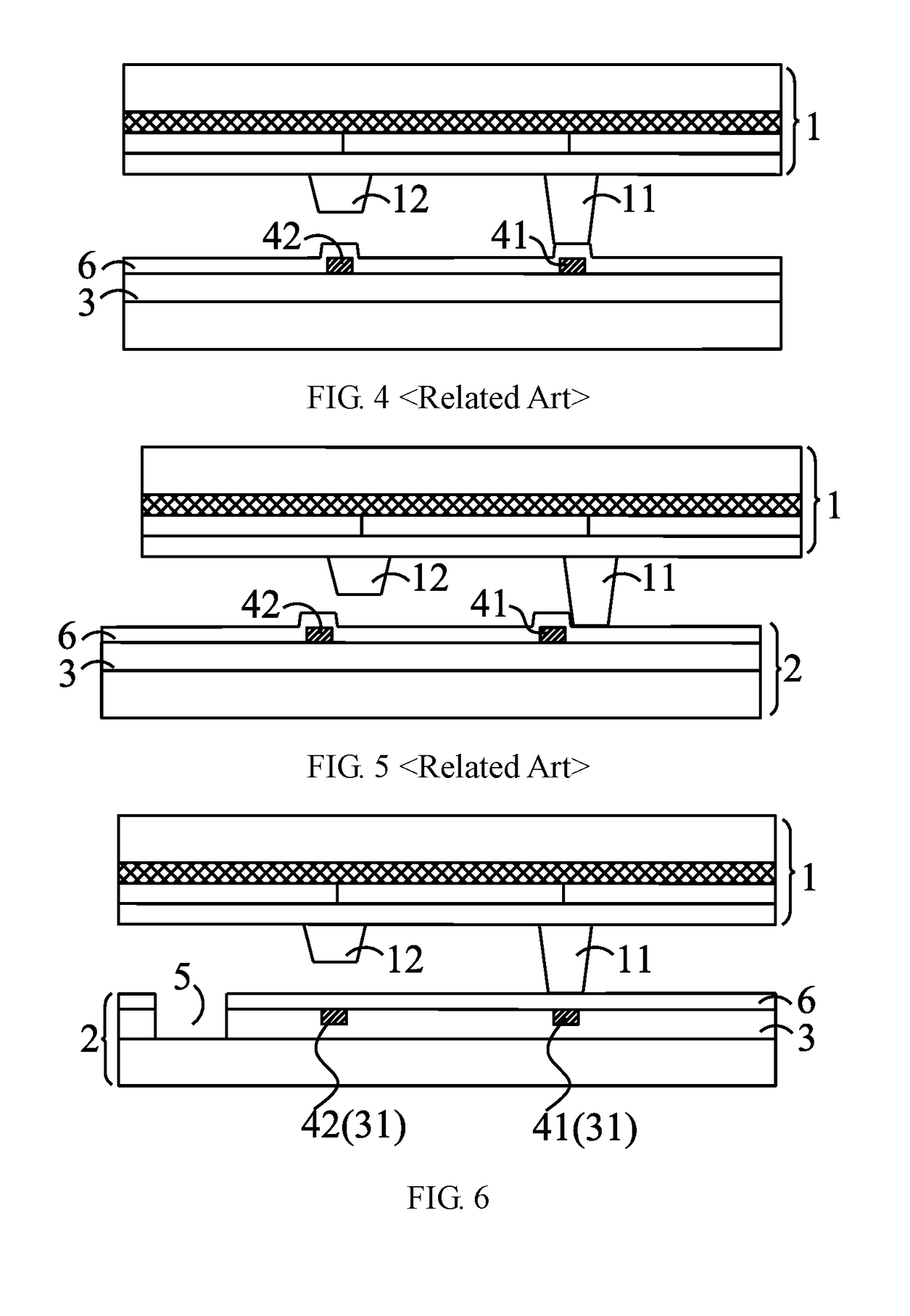

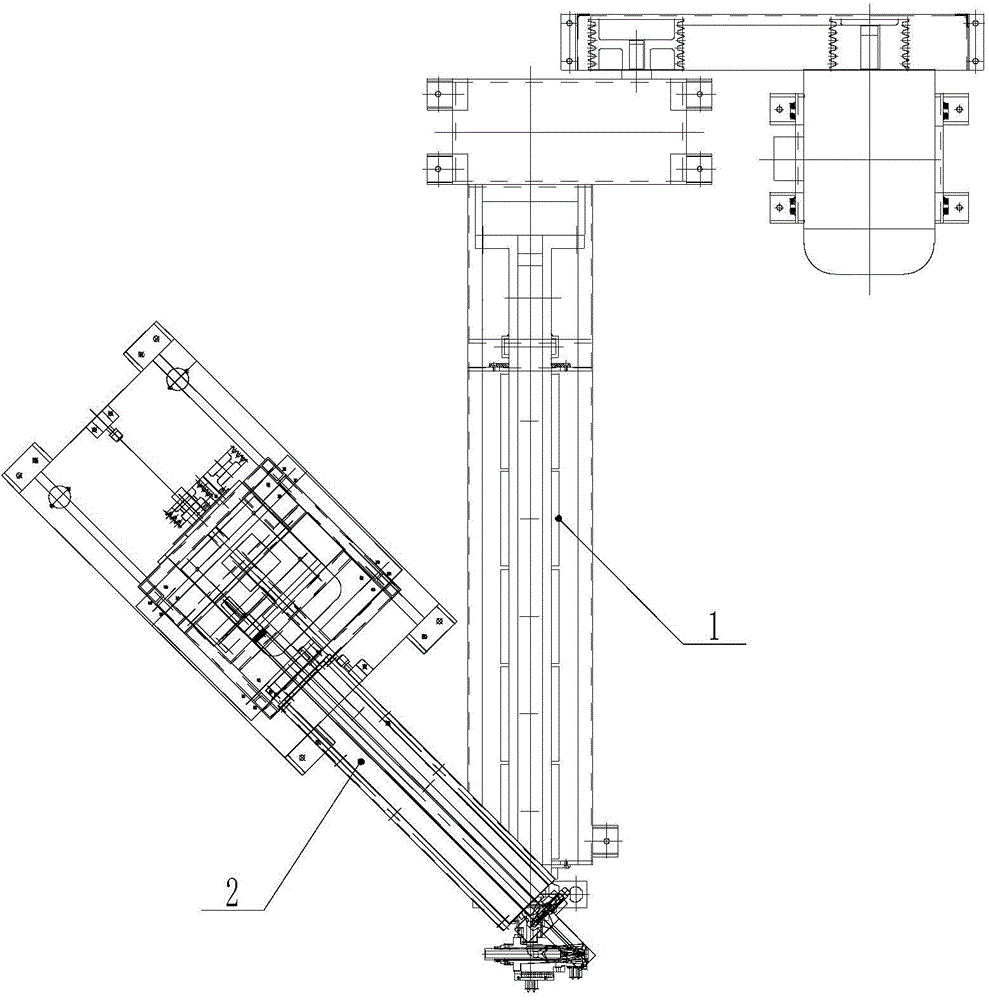

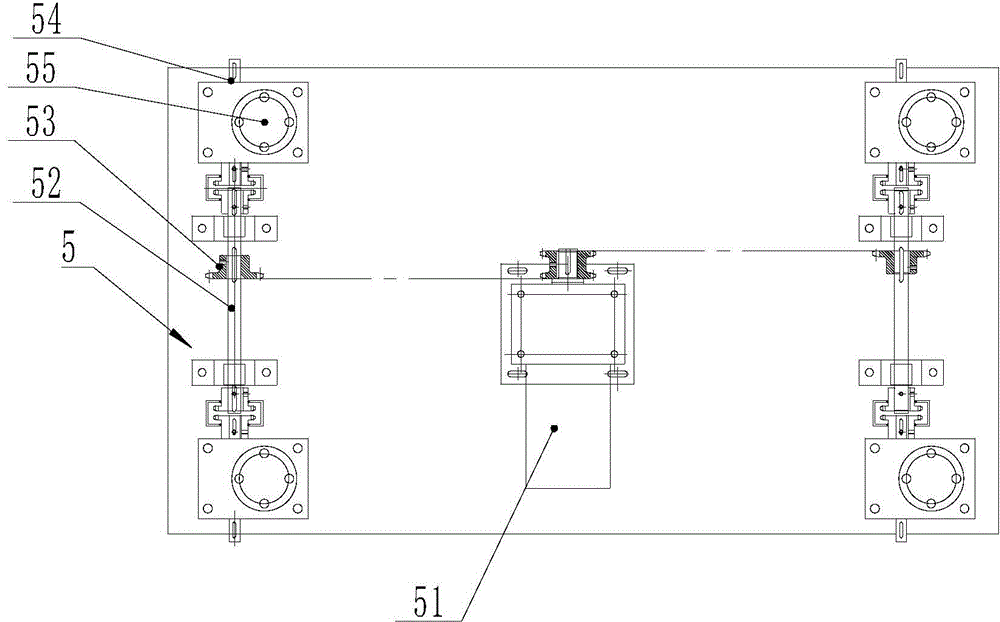

Processing system of toothbrushes and using method of processing system

ActiveCN103660126ALarge batch processing volumeImprove processing efficiencyDomestic articlesBatch processingInjection molding machine

The invention discloses a processing system of toothbrushes and a using method of the processing system. The processing system of secondarily rubber-coated toothbrushes is ingenious in structure, the using method of the processing system is simple and is high in efficiency, and the processing system is high in reliability and large in single-batch processing amount and can finish all grabbing and transferring steps through a single manipulator. The processing system also comprises a transferring mechanism which comprises a mechanical arm and a grabbing device; one end of the mechanical arm is fixedly connected with a forming injection molding machine and a rubber-coating injection molding machine, and the other end of the mechanical arm is connected with the grabbing device. According to the processing system and the using method thereof, two groups of toothbrush bodies produced by the forming injection molding machine can be all processed only through a set of flow, and the characteristics of large single-batch processing amount, high processing efficiency and good processing effect are achieved; in conclusion, all the processing steps can be finished only through the single manipulator, so that the processing system has the characteristics of low matching precision requirement, accurate positioning, good using effect, high integrality, high reliability and high stability.

Owner:PERFECT GRP CORP LTD

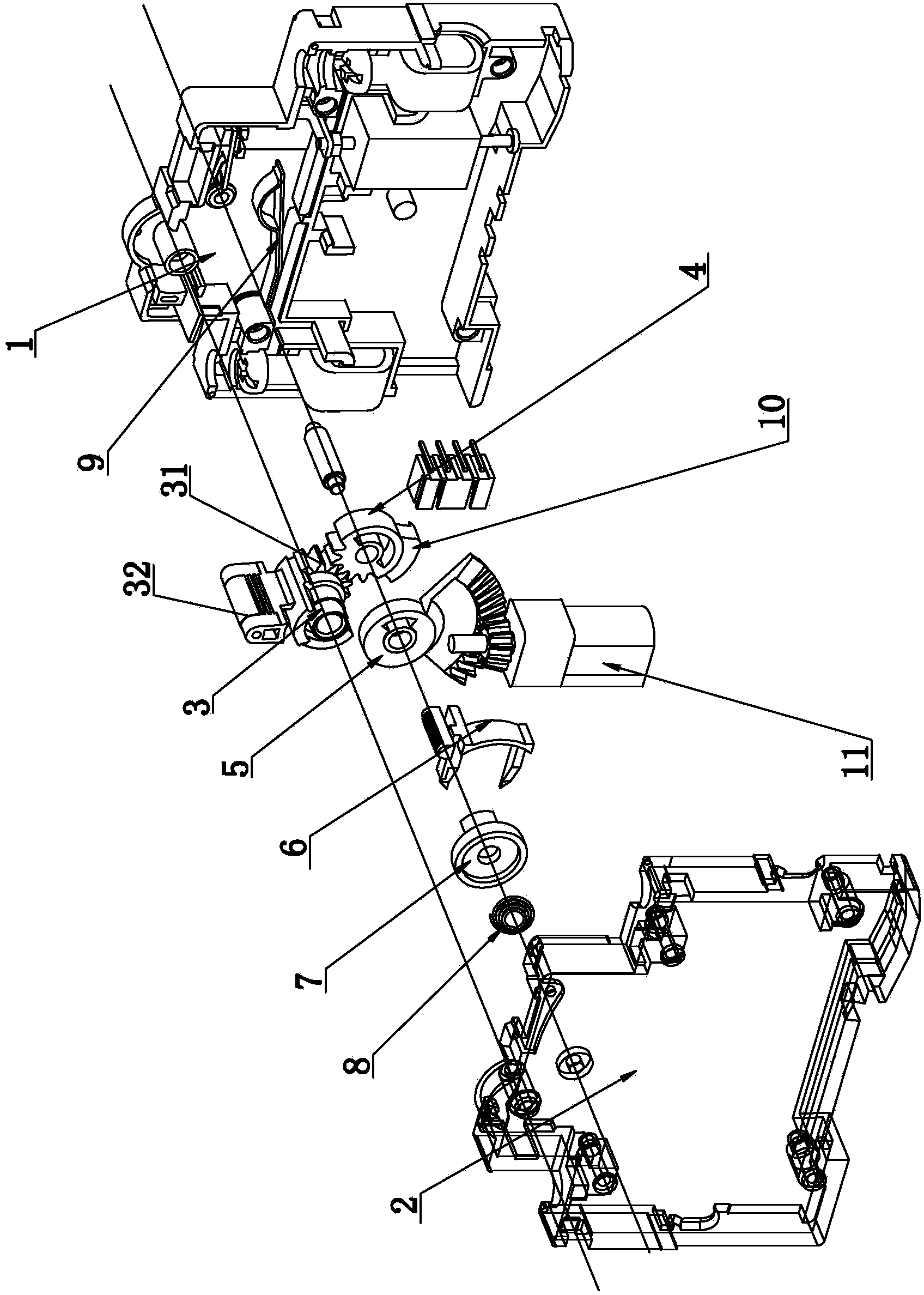

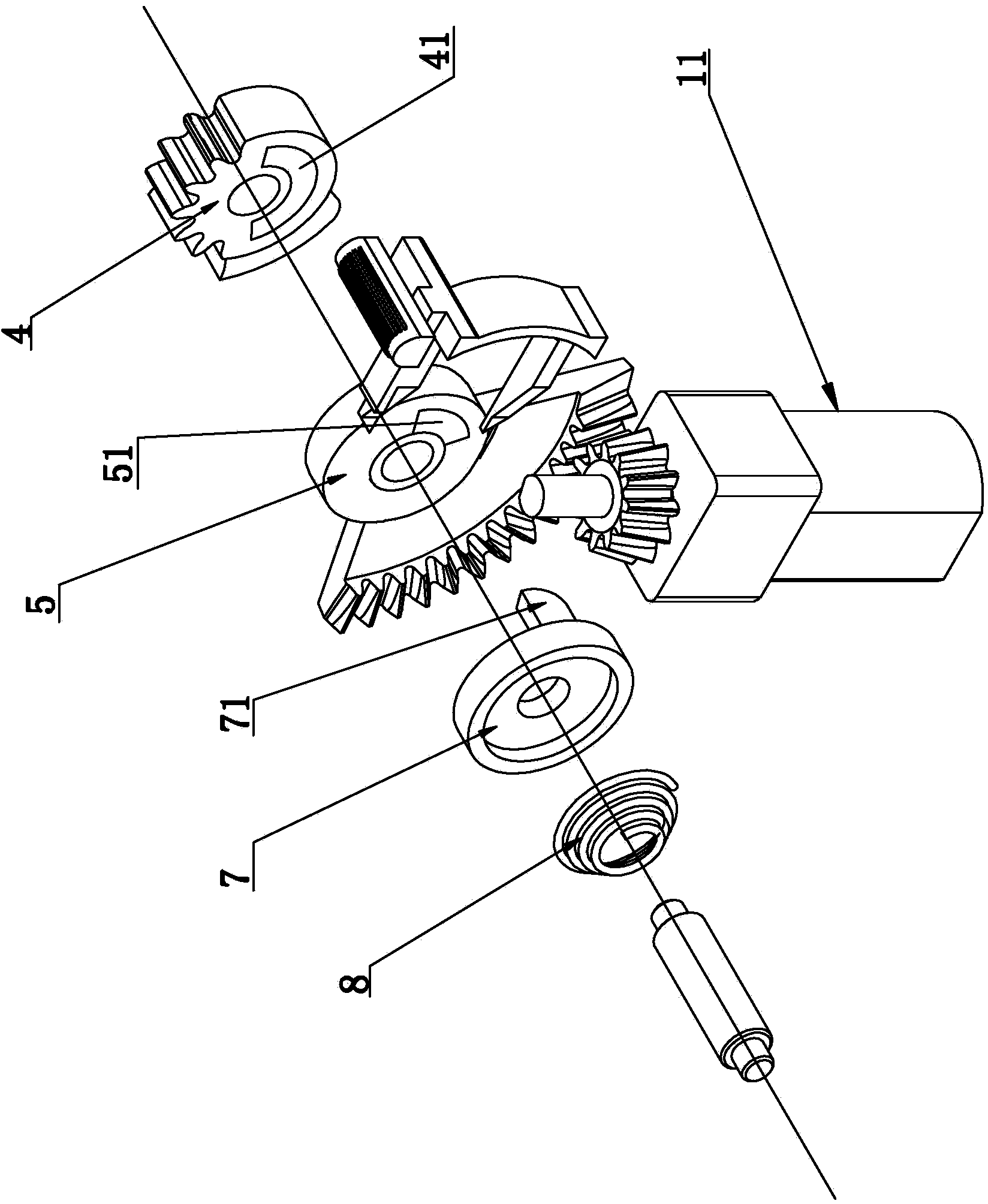

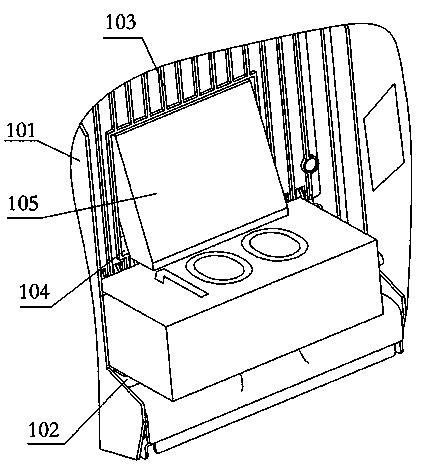

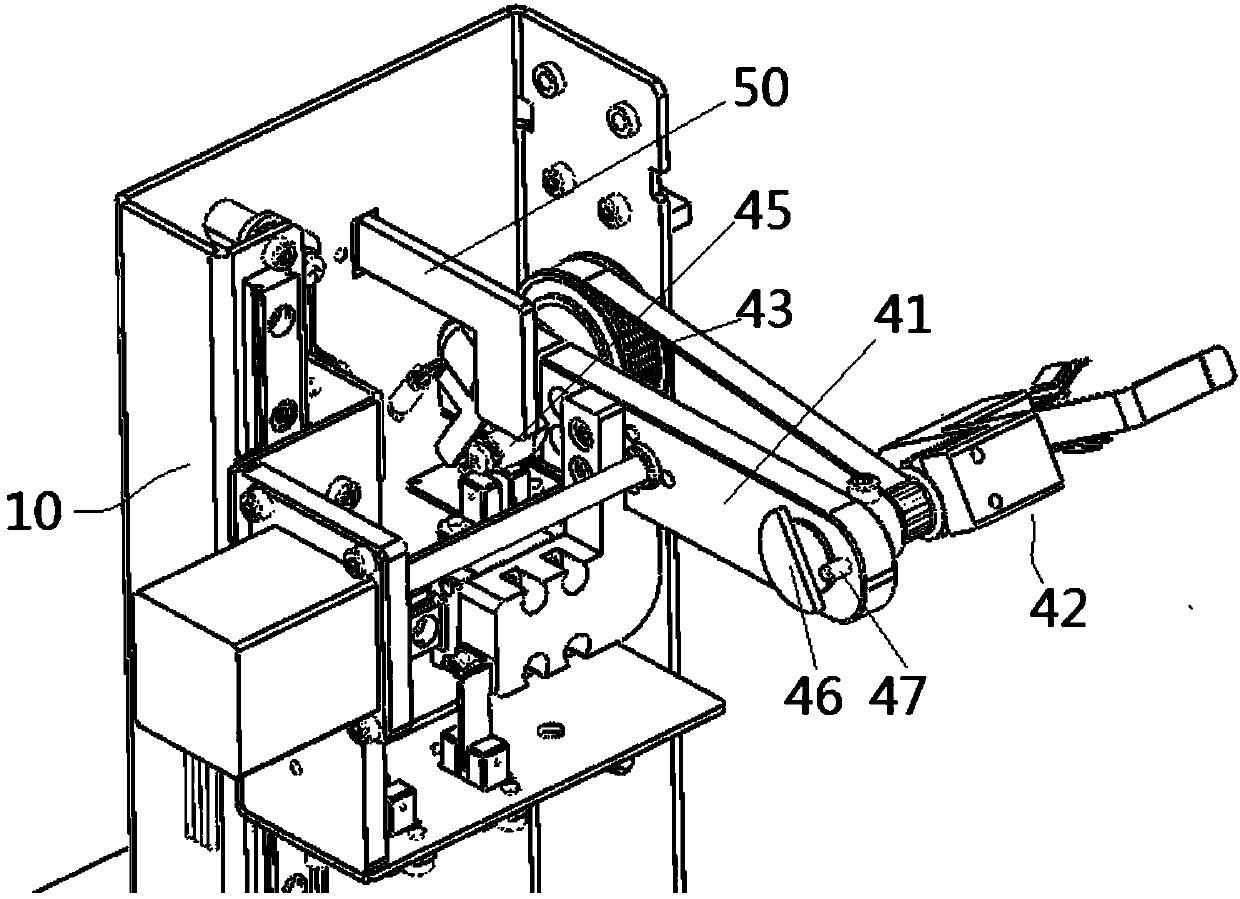

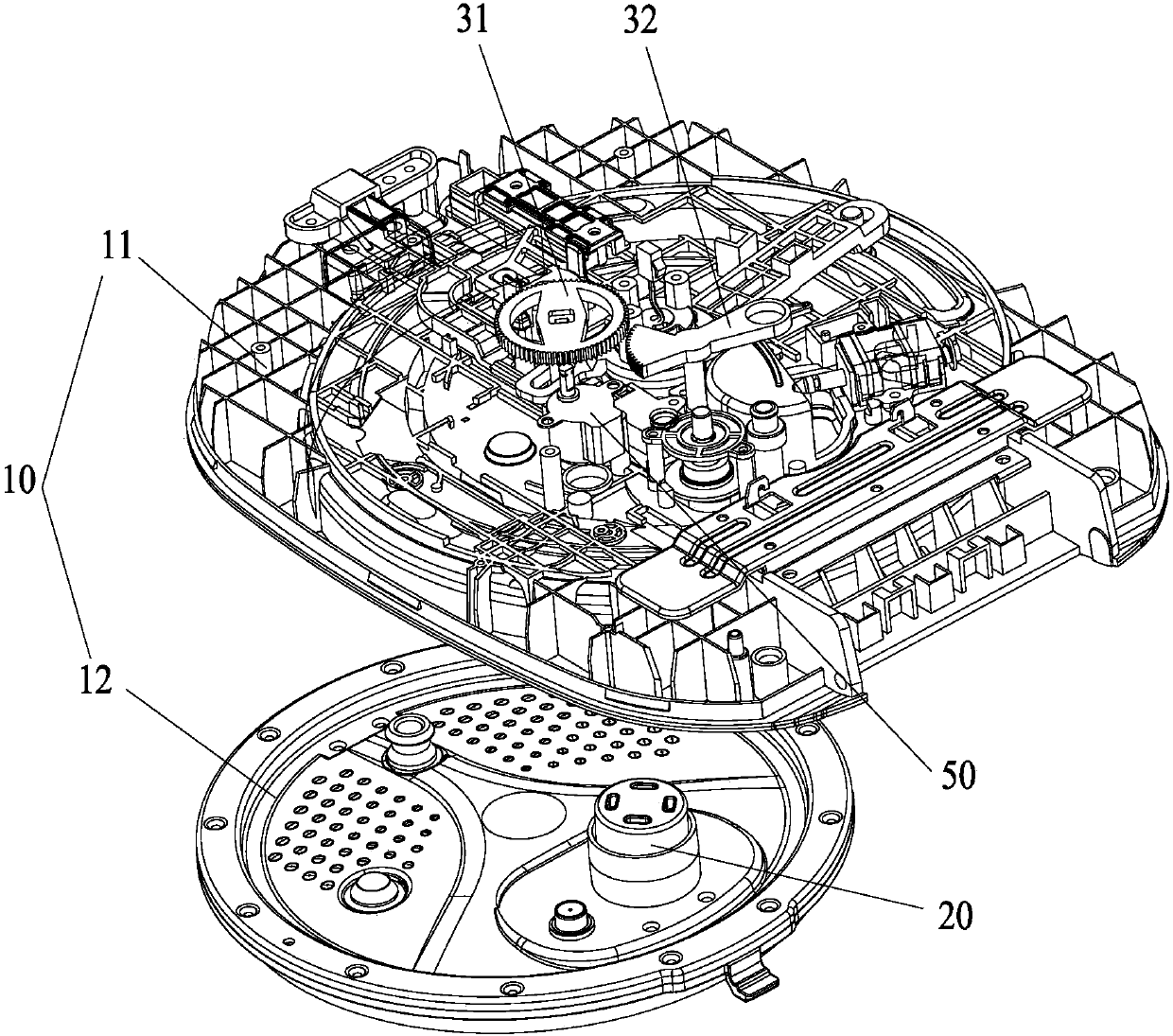

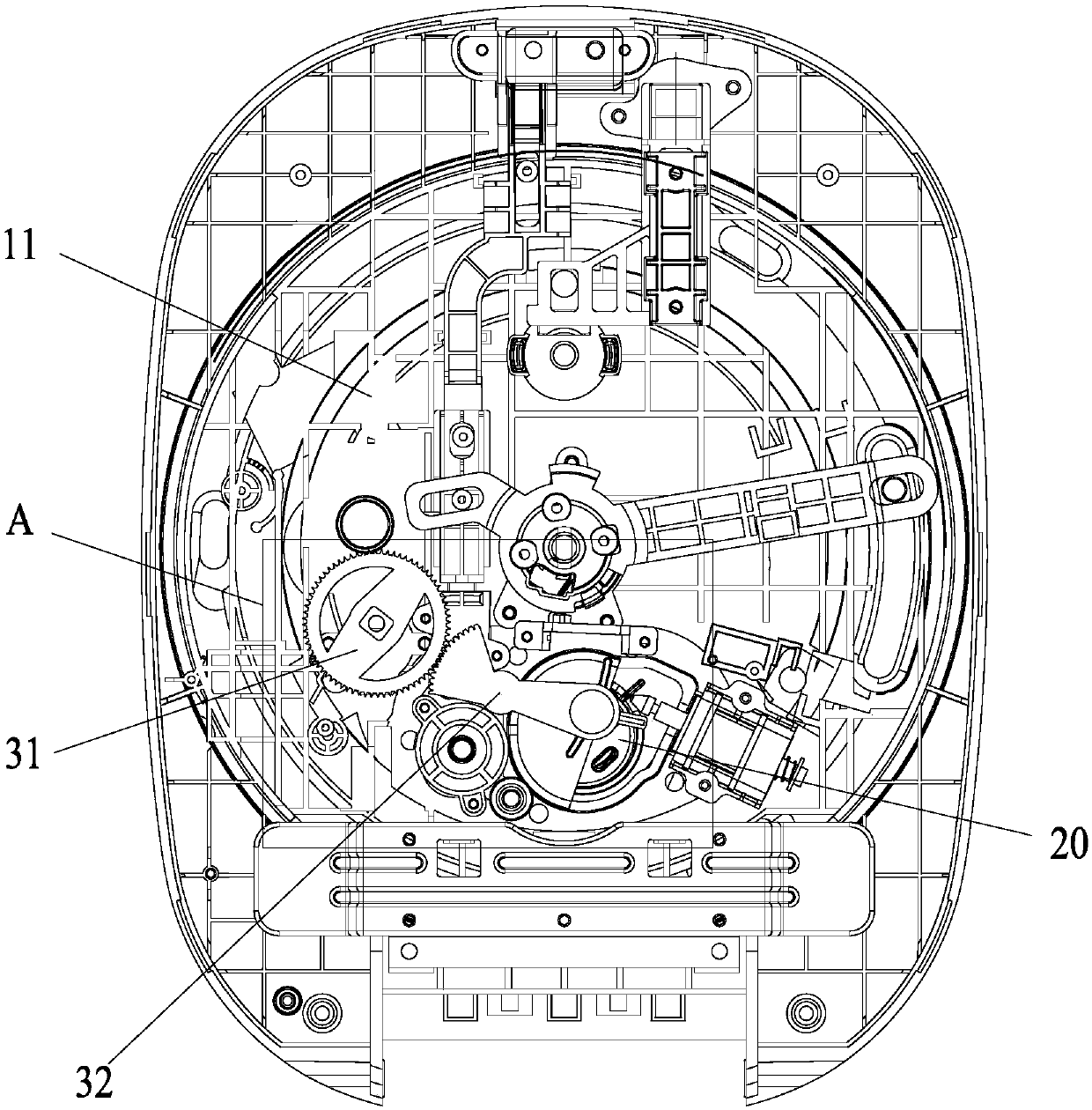

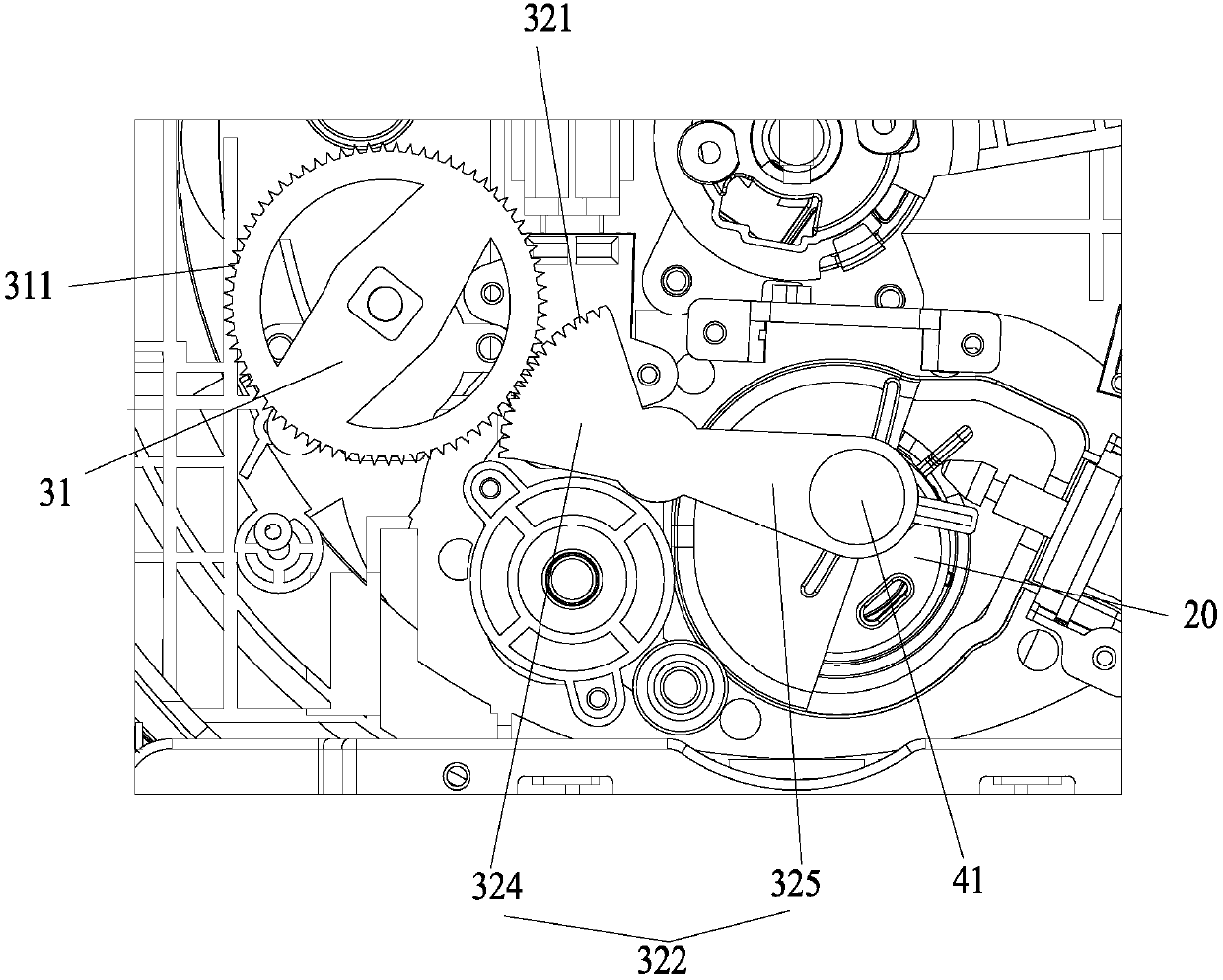

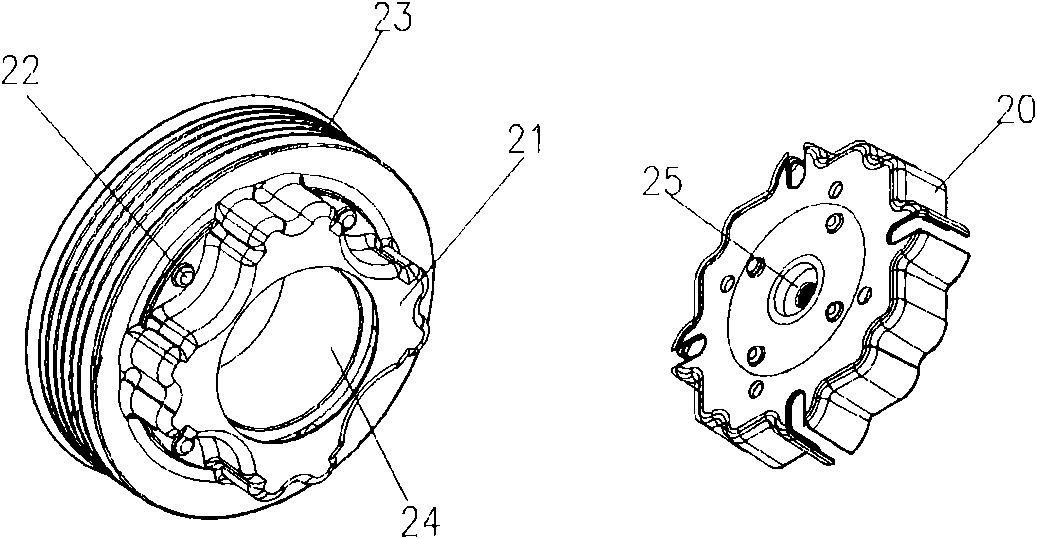

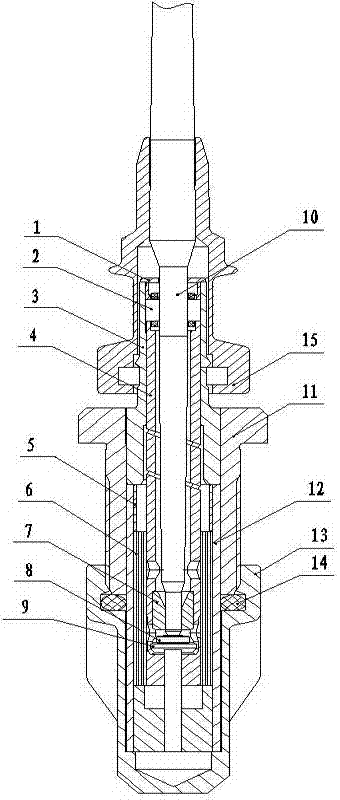

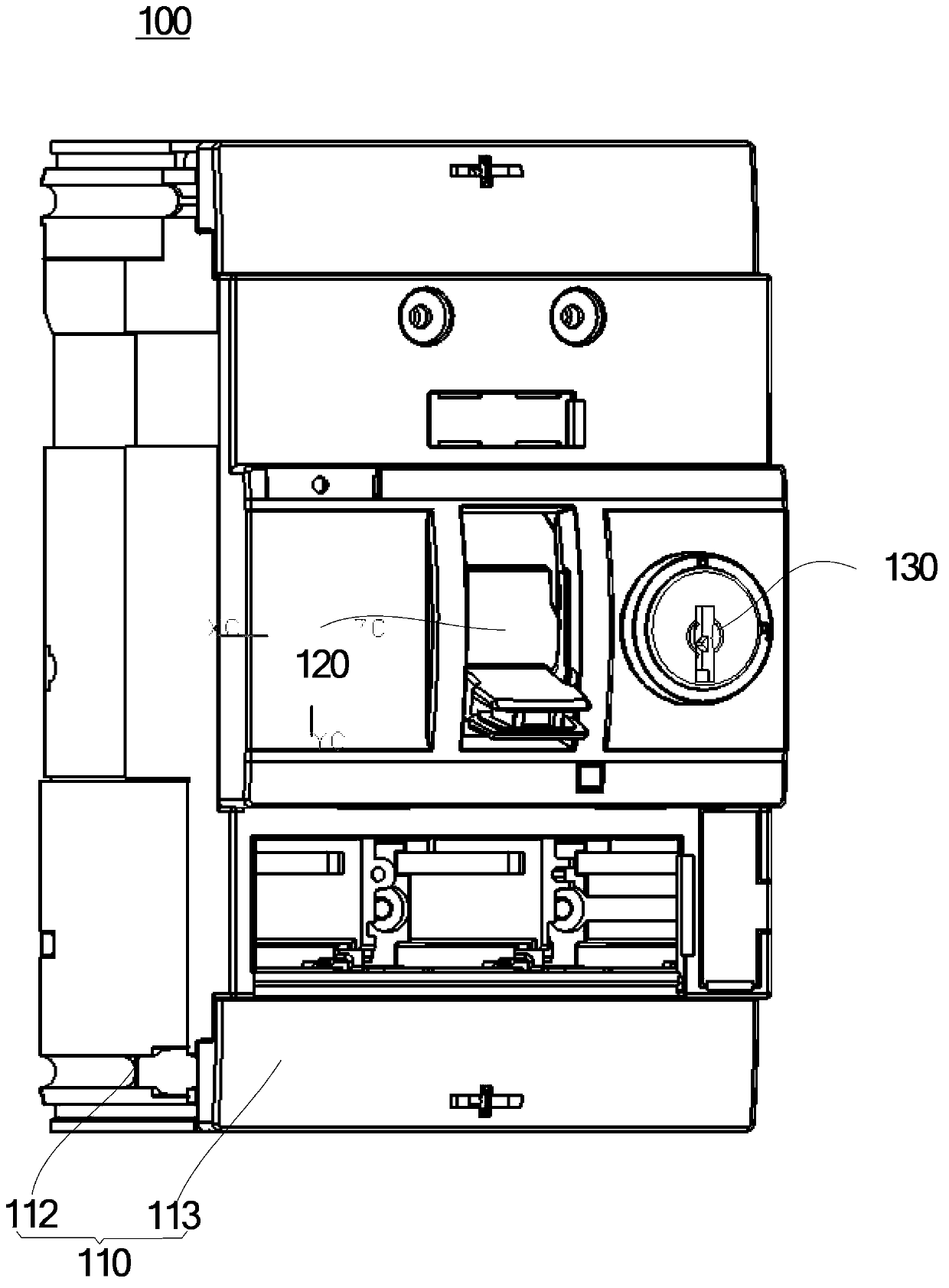

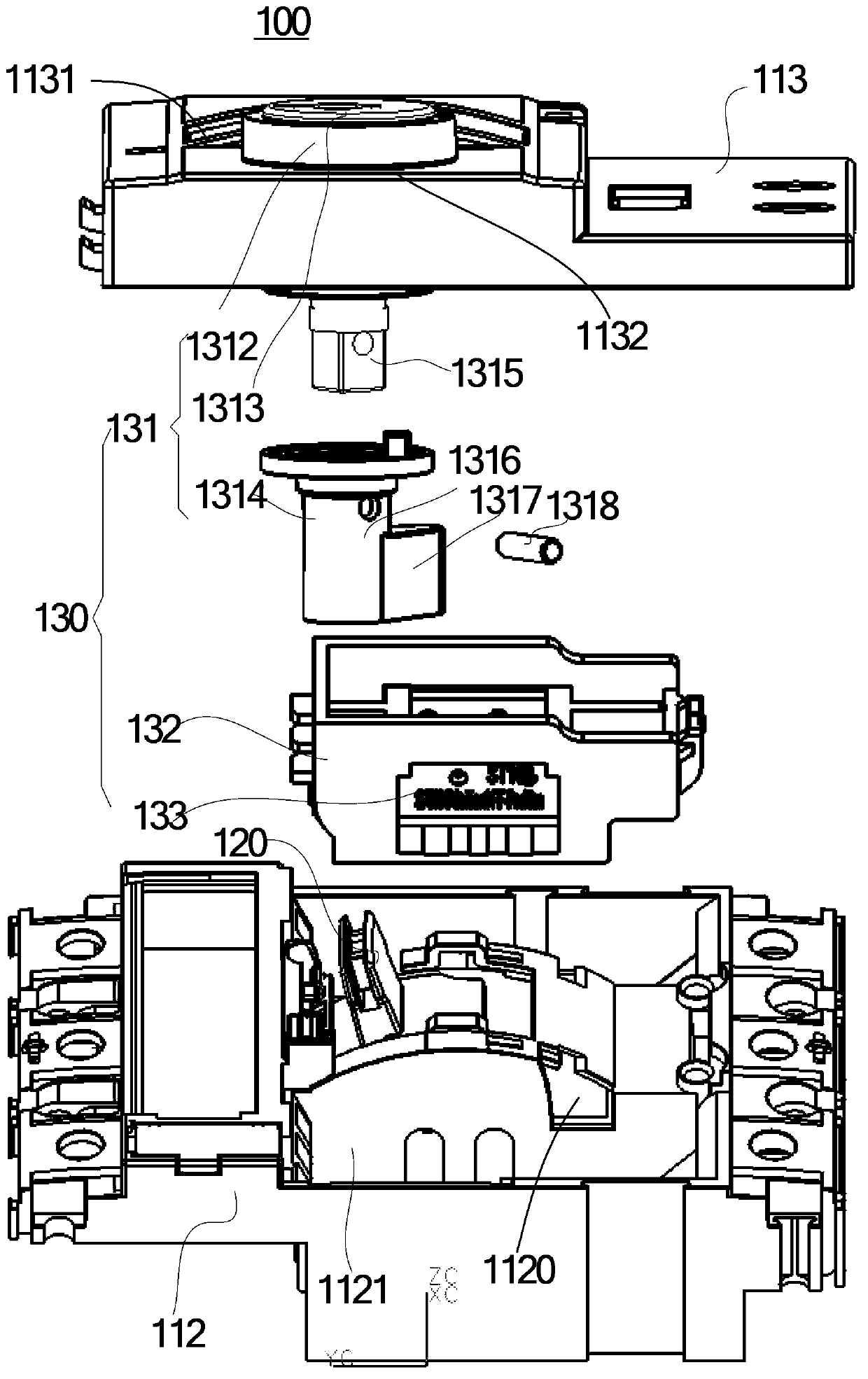

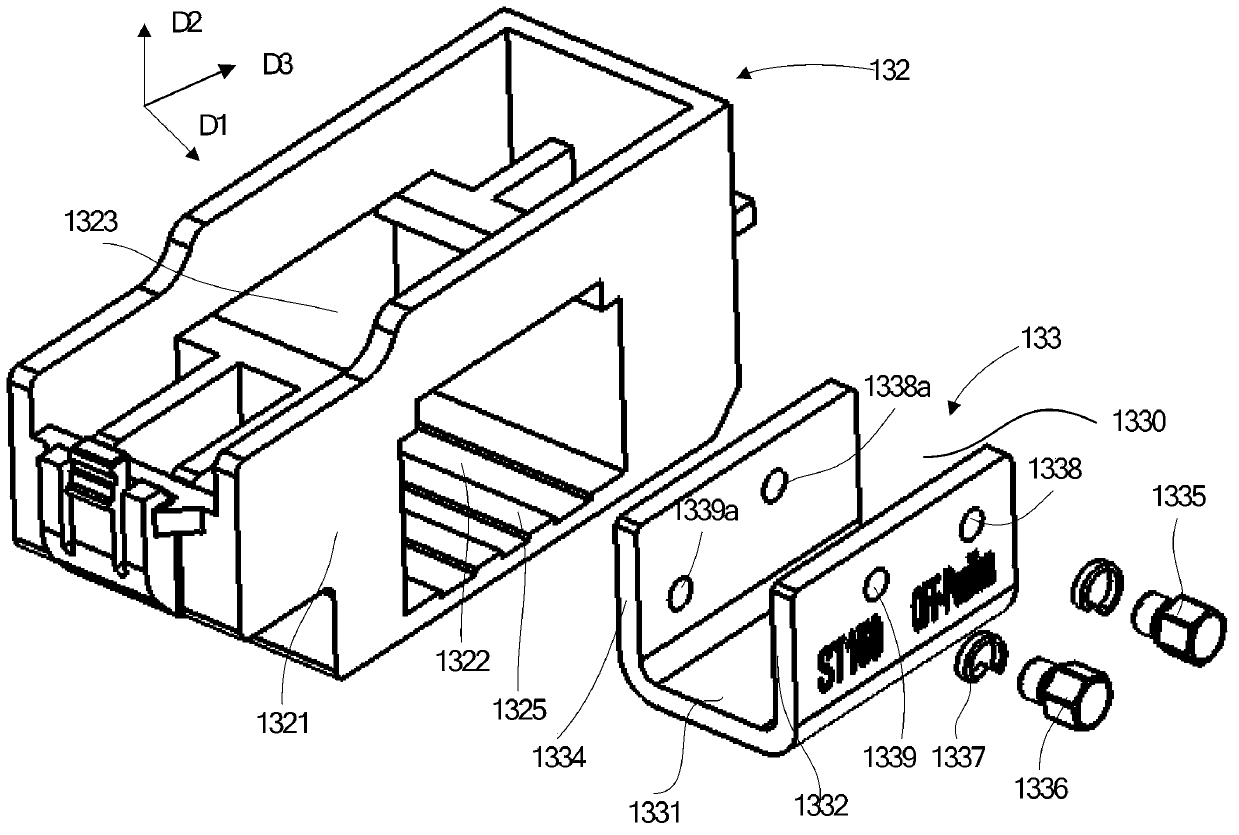

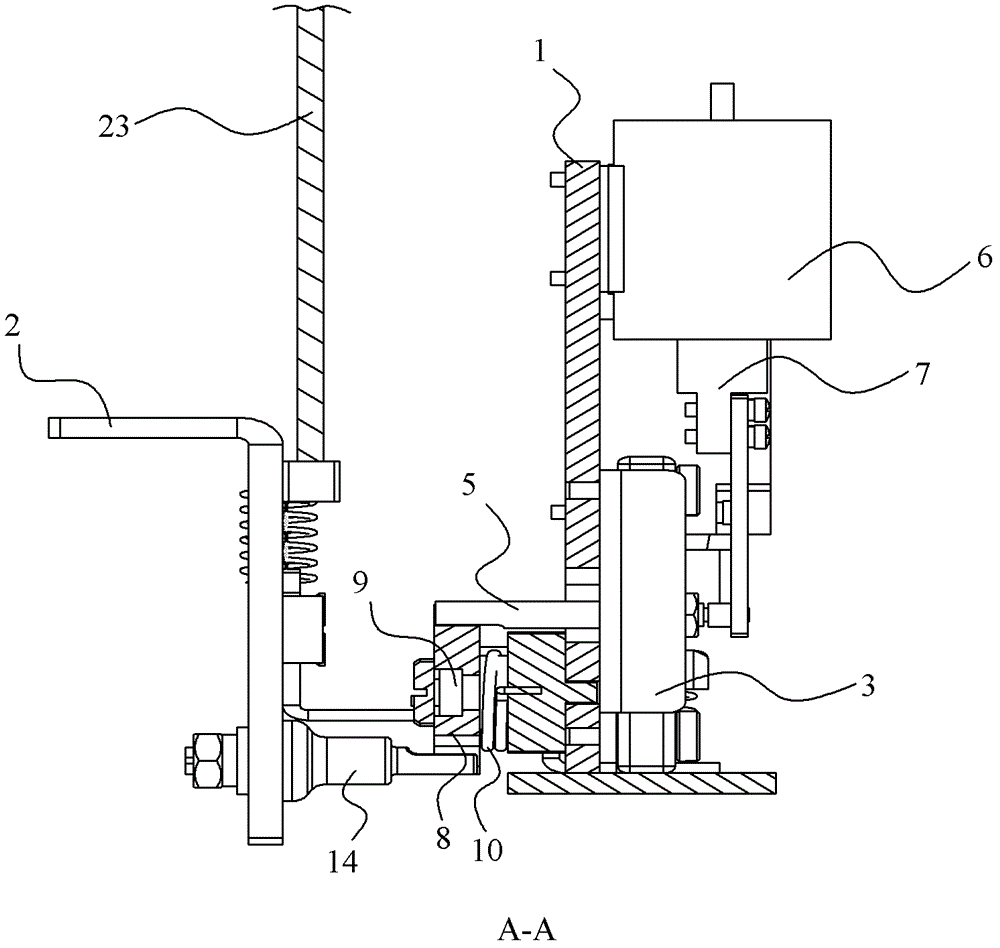

Miniature circuit breaker reclosure device with clutch function

ActiveCN104167338ATo achieve linkageRealize automatic operationProtective switch operating/release mechanismsGear wheelDrive motor

The invention relates to a miniature circuit breaker reclosure device with the clutch function. The miniature circuit breaker reclosure device with the clutch function comprises a handle device, a shaft sleeve stirring gear and a driving device. The handle device comprises a handle wheel body, and one side of the handle wheel body is provided with handle wheel body wheel teeth which are meshed with the shaft sleeve stirring gear. The driving device comprises a shaft sleeve sector gear and a driving motor, and the shaft sleeve sector gear and the shaft sleeve stirring gear are coaxially arranged. The miniature circuit breaker reclosure device is characterized by further comprising a shaft sleeve clutch key and a clutch bolt, the shaft sleeve sector gear is connected with the shaft sleeve stirring gear through the shaft sleeve clutch key, the clutch bolt is connected with a shell in a sliding mode, and the clutch bolt drives the shaft sleeve clutch key to do axial movement so that the shaft sleeve sector gear can be connected with or separated from the shaft sleeve stirring gear. The miniature circuit breaker reclosure device has the advantages that a switch can be manually or automatically switched during using so that the handle can be disengaged from power, and it can be ensured that a handle and a moving contact can reset in case of power failure during the automatic switching-on of a miniature circuit breaker.

Owner:圣普电气有限公司

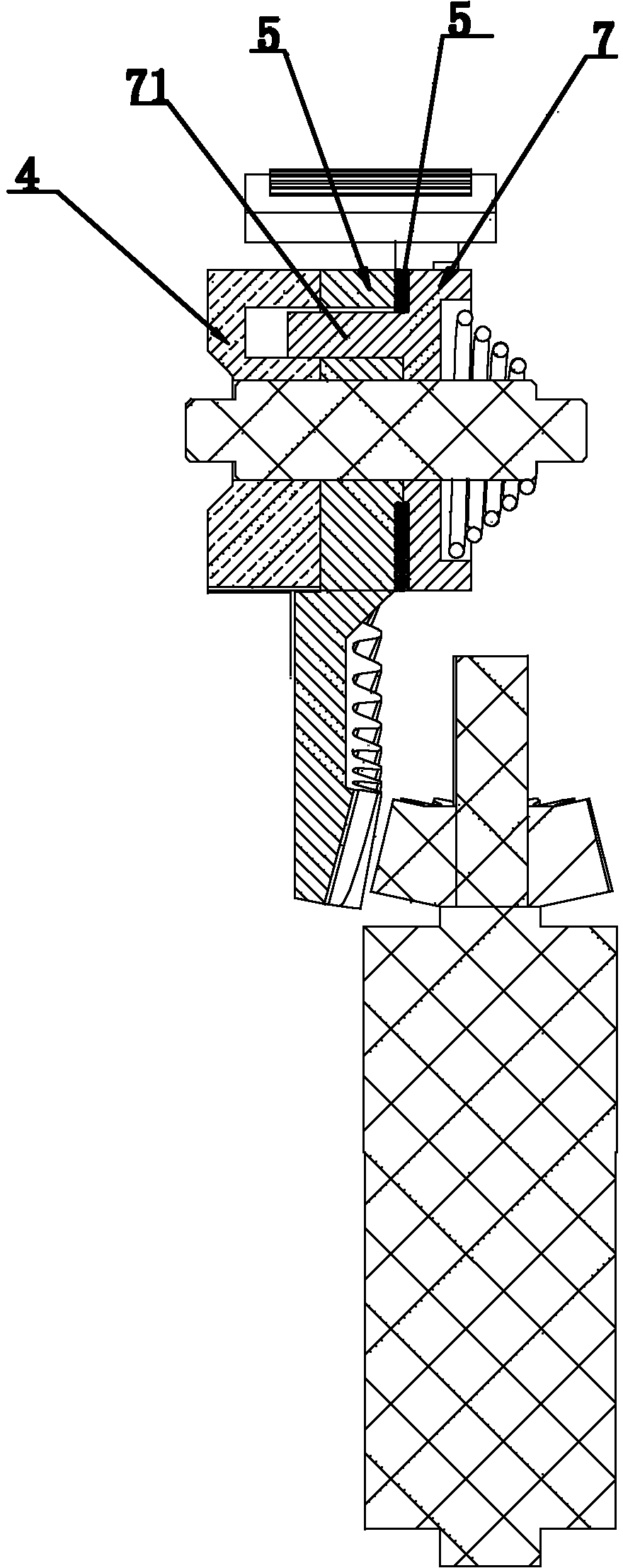

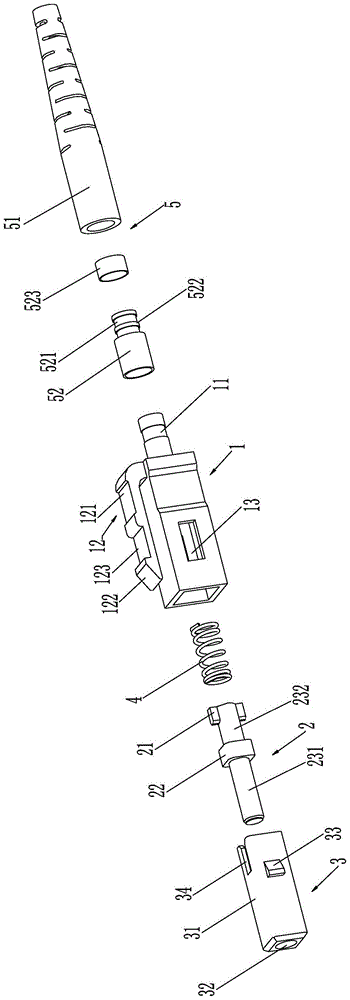

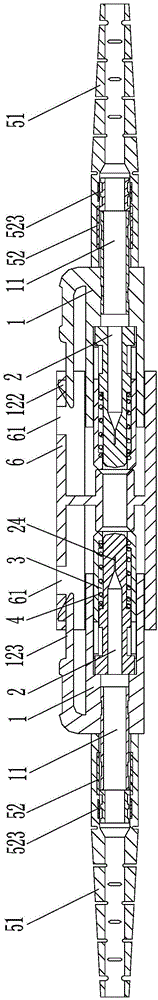

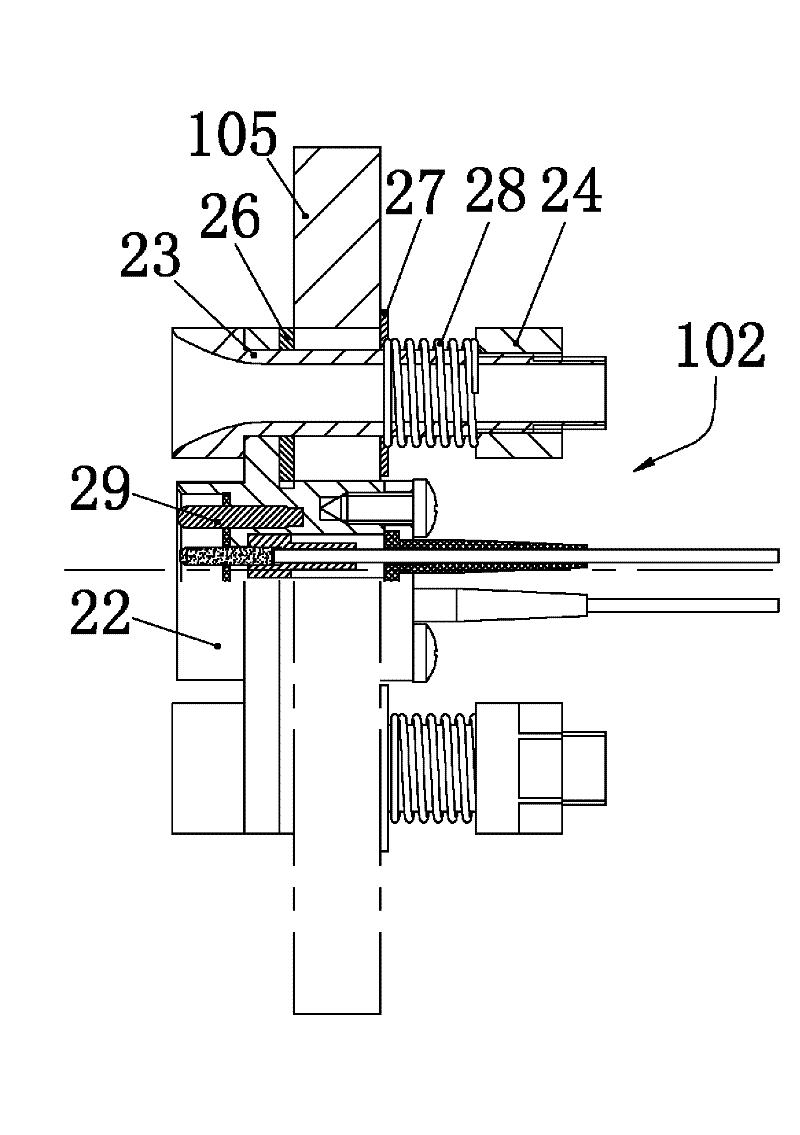

Optical fiber connector and manufacturing method thereof

ActiveCN104965262AReduce assembly requirementsLow matching accuracy requirementsCoupling light guidesFiberElastic component

The invention relates to an optical fiber connector and a manufacturing method thereof. The optical fiber connector comprises a housing and a fiber insertion core arranged in the housing. The end surface of the fiber insertion core is provided with at least one lens. The cavity at one end of the housing is equipped with an insertion core protection structure for protecting the end surface of the insertion core so as to prevent the lens surface at the end surface of the fiber insertion core from being damaged or scraped. The insertion core protection structure is internally provided with the fiber insertion core and an elastic component sleeved on a fiber insertion core tubular body to ensure free telescoping of the insertion core protection structure. The other end of the housing is provided with an extension pipe. The extension pipe is connected with a tail sheath assembly which carries out bending protecting on an optical cable and guarantees that the optical fiber connector can transmit optical signals normally under the bending pressure condition. An elastic buckle structure for enabling the optical fiber connector to be buckled to a corresponding insertion hole of an adapter is integrated to the outer wall of the housing.

Owner:SHENZHEN EPLU SCI TECH

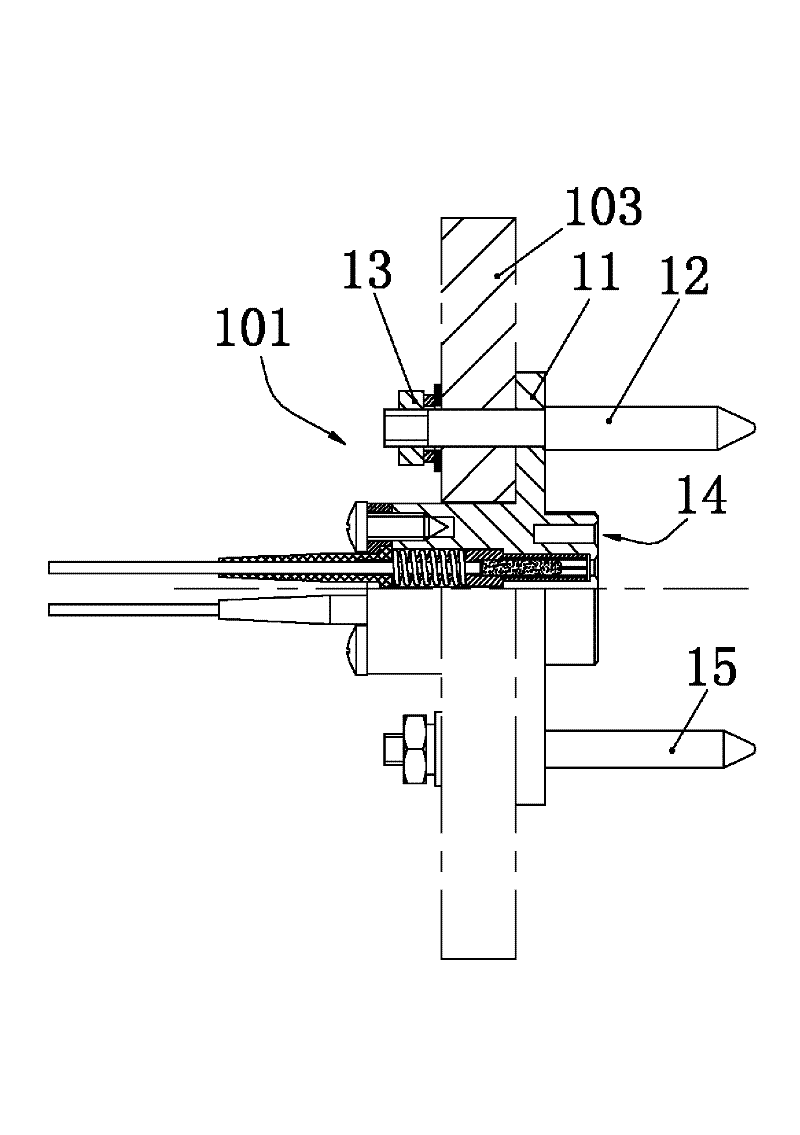

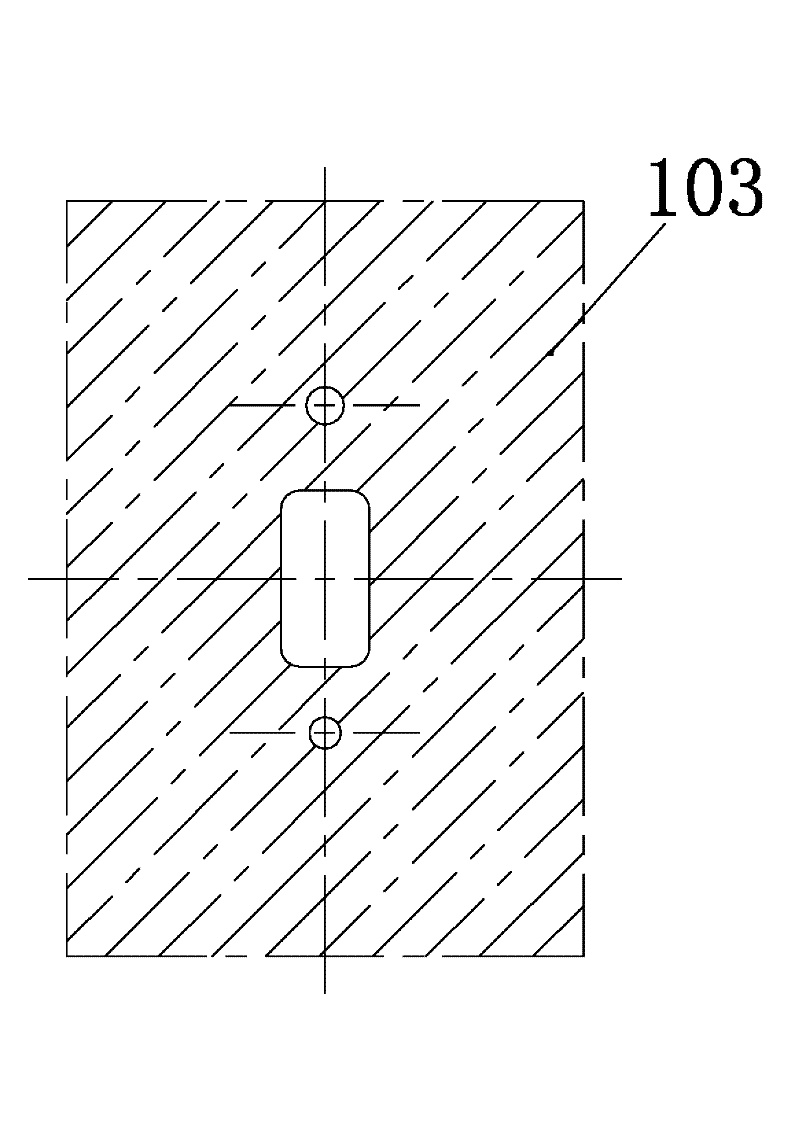

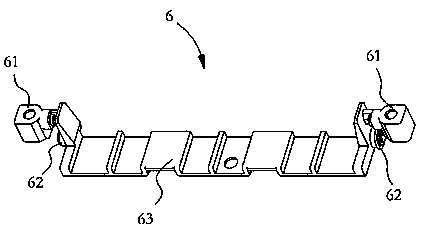

Floating connector component and floating connector thereof

InactiveCN102403620ARealize automatic alignmentLow matching accuracy requirementsCoupling parts mountingEngineeringSurface plate

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

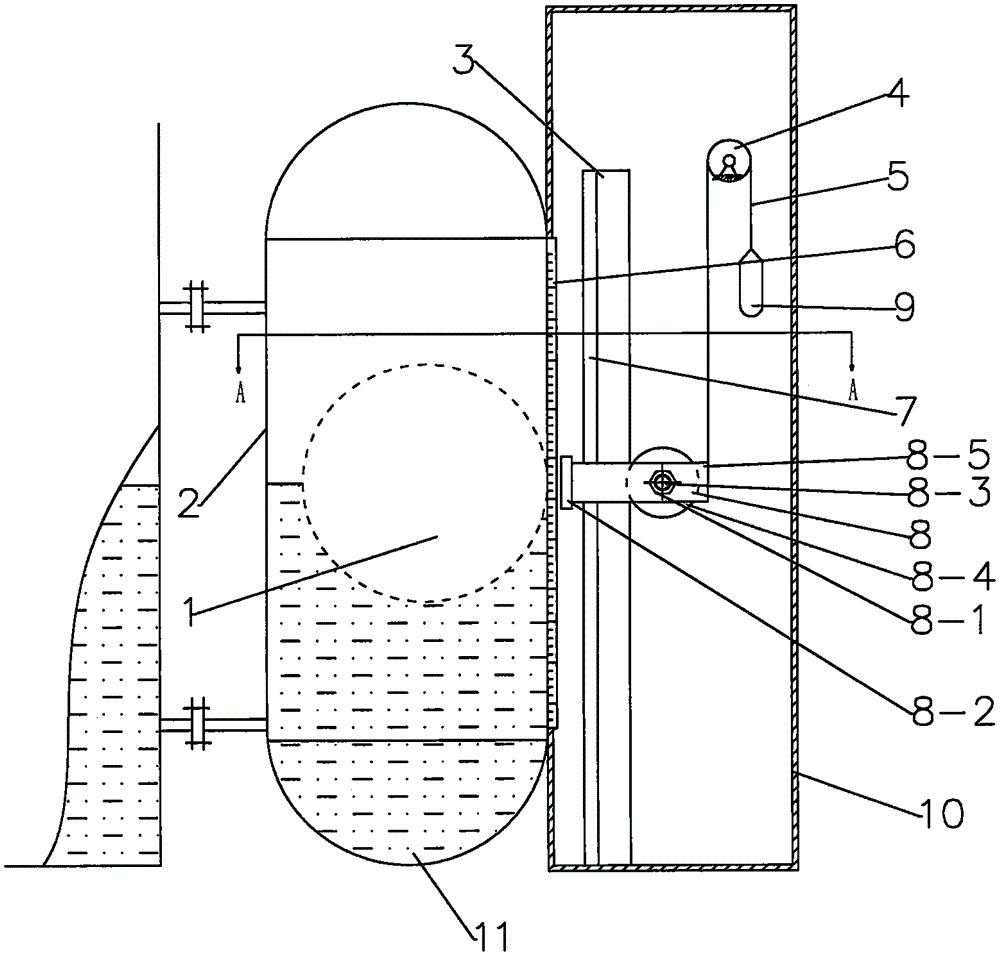

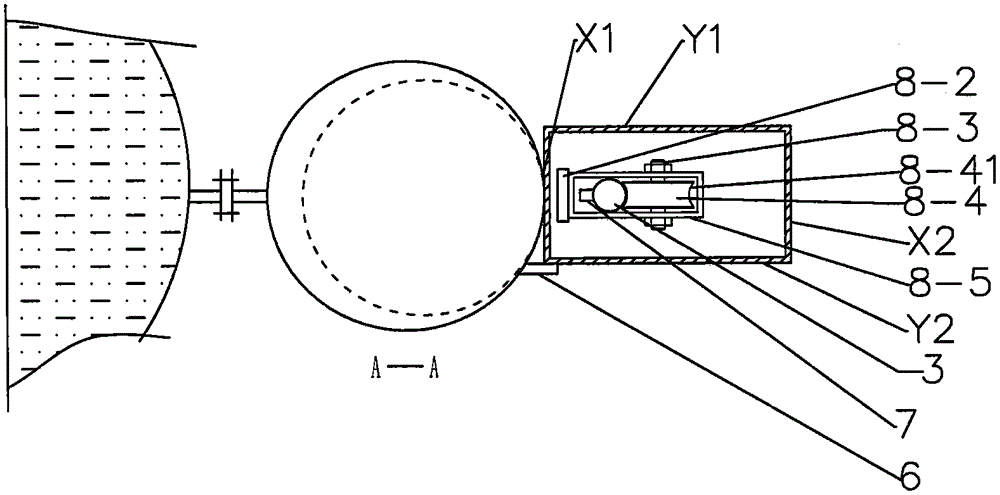

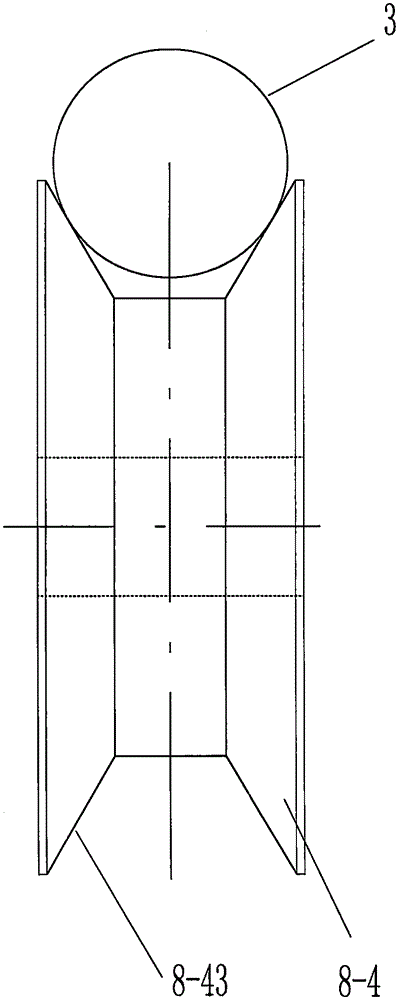

Ball float type liquidometer with vernier display

ActiveCN105277258AIncrease stiffnessGuaranteed measurement accuracyLevel indicators by floatsFloat chamberRolling-element bearing

The invention relates to a ball float type liquidometer with vernier display. The ball float type liquidometer comprises a ball float chamber and a ferromagnetic spherical floating ball arranged therein, a vernier outside the ball float chamber, a calibrated scale and a vernier guide rail. The vernier comprises magnetic steel, a frame and a rolling system which is horizontally fixed and sleeved in the frame; the rolling system comprises rolling wheels which are provided with radial grooves along a circumferential surface, rolling bearings and shafts; the magnetic steel is disposed between the ball float chamber and the frame and is fixed outside one side surface close to the ball float chamber on the frame, and the magnetic pole of the magnetic steel is right oriented towards the floating ball; the vernier guide rail is sleeved in the frame and is disposed between the magnetic steel and the rolling system; and the rolling system enables the rolling wheels to roll vertically along the vernier guide rail at groove positions through a magnetic coupling force between the magnetic steel and the floating ball. The ball float type liquidometer is simple and scientific in structure, reliable in application performance, easy to manufacture and low in cost, reduces defects in the prior art and effectively meets needs in correlation fields.

Owner:DALIAN JIAXIN ELECTROMECHANICAL INSTR CO TD

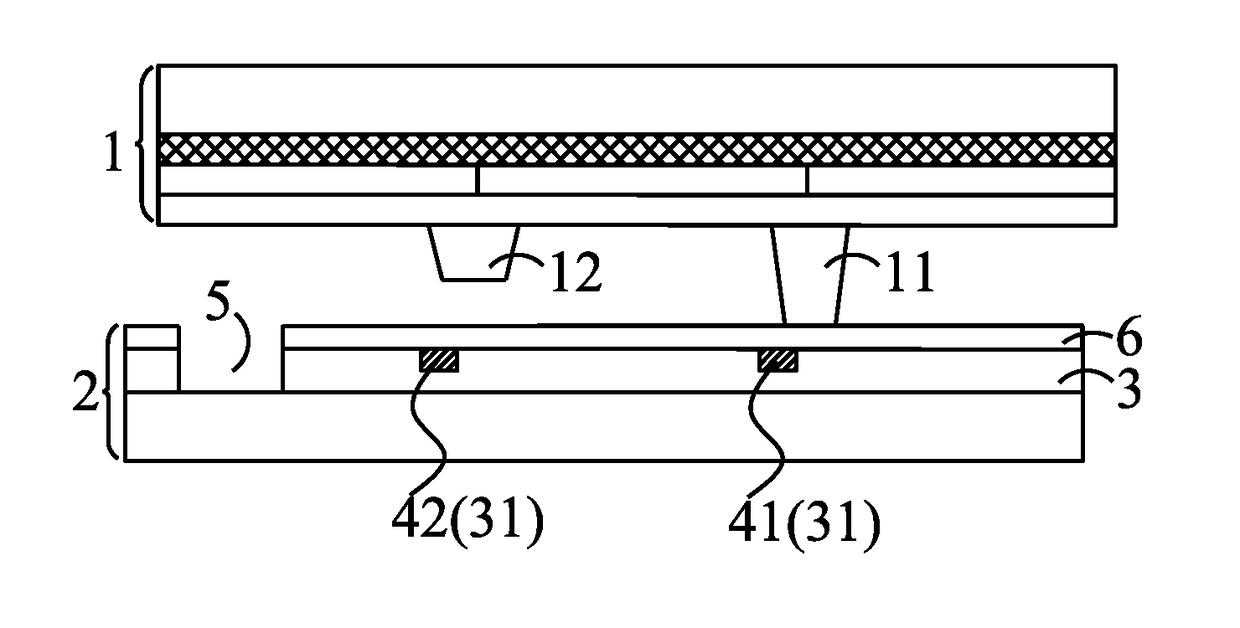

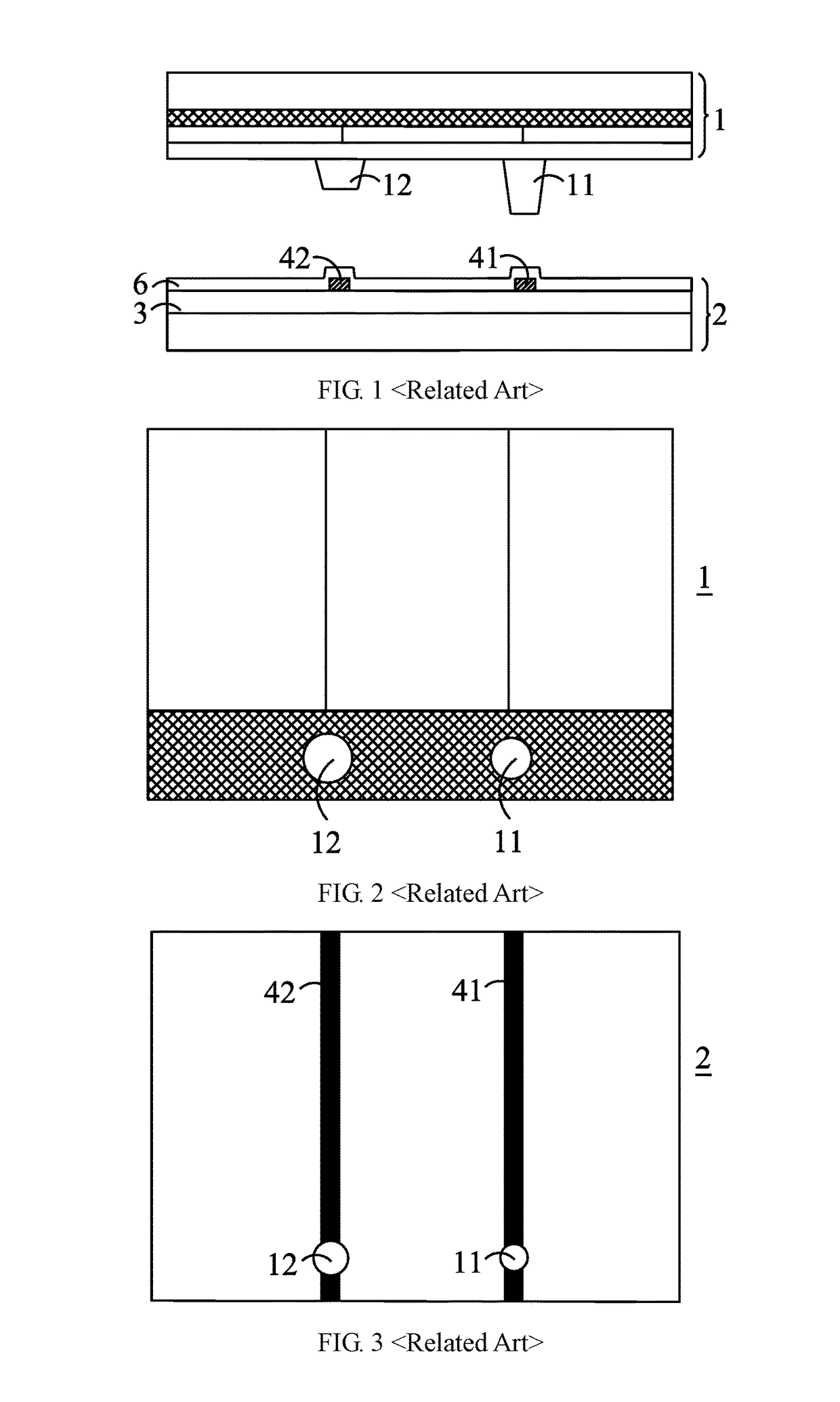

Thin film transistor array substrate, manufacturing method thereof and touch display panel

InactiveUS20170235396A1Reduce thicknessDeteriorated on display effectSolid-state devicesSemiconductor/solid-state device manufacturingTransistor arrayColor gel

The invention provides a thin film transistor array substrate, a manufacturing method thereof, and a touch control display panel. The touch control display panel includes a color filter substrate, a thin film transistor array substrate mentioned above, and a liquid crystal layer and photo spacers located between the two substrates. When the color filter substrate combined with the thin film transistor array substrate face to face, the photo spacers is located therebetween. The thin film transistor array substrate has a planarization layer therein. The planarization layer is recessed to a plurality of grooves arranged at intervals. A plurality of touch control electrode lead wires are received in the plurality of grooves. Upper surfaces of the plurality of touch control electrode lead wires and an upper surface of the planarization layer are in a same plane.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

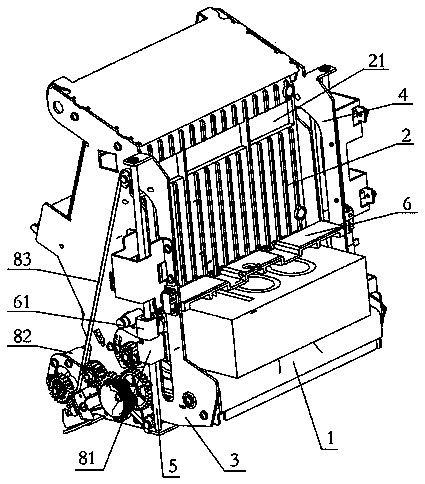

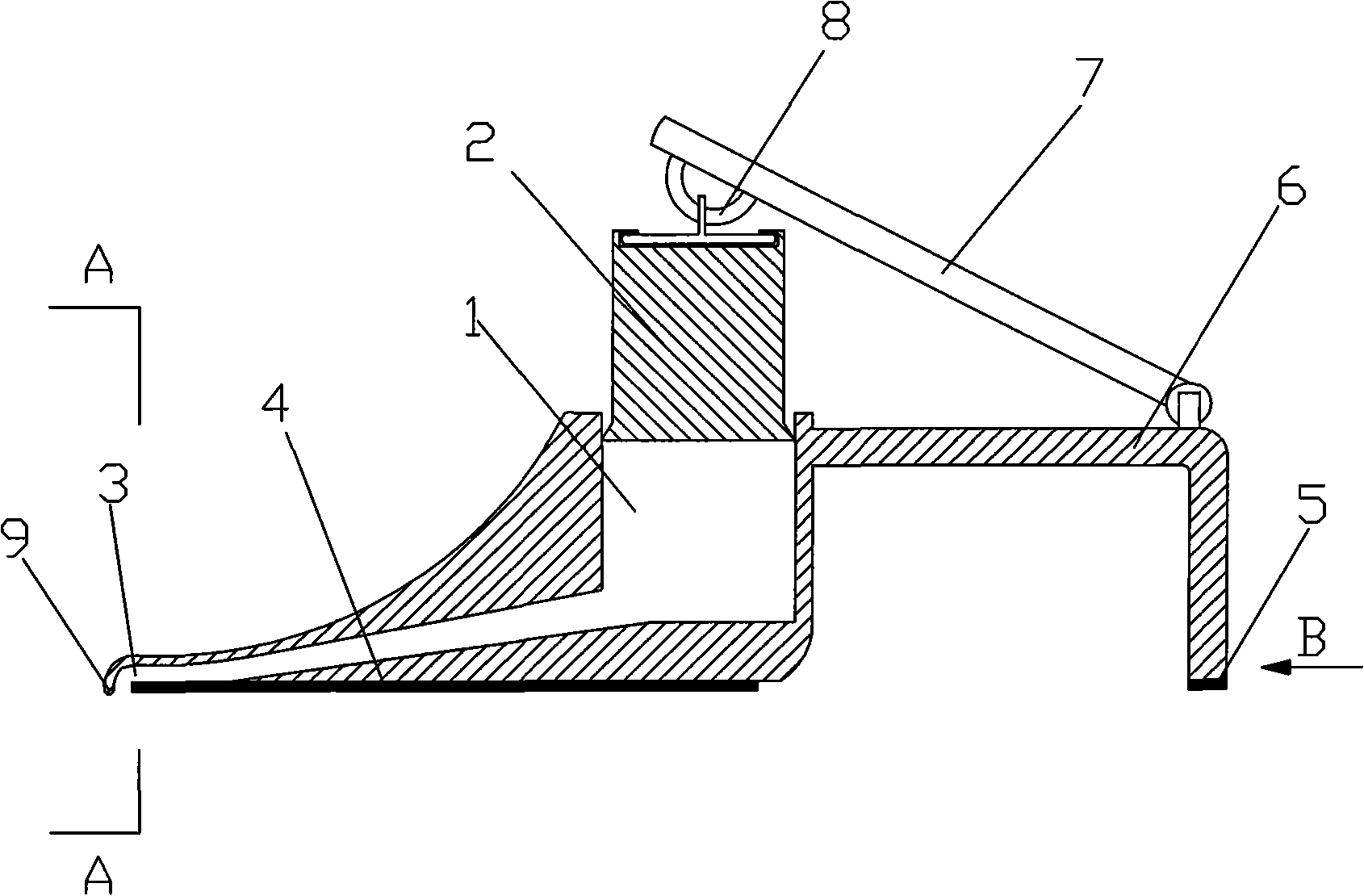

Paper currency pressing device of counting and sorting machine

InactiveCN103714621ASimple structureLow matching accuracy requirementsCoin/paper handlersPulp and paper industrySelf weight

Provided is a paper currency pressing device of a counting and sorting machine. Guide rods are arranged on the outer sides of side plates on the two sides of the counting and sorting machine, and a paper currency pressing plate descends along the guide rods under self weight and presses the surface of paper currency to apply pressure on the paper currency or ascends to be in a standby mode under the action of a driving mechanism. The paper currency pressing device of the counting and sorting machine simply completes paper currency pressing work through the guide rods, the paper currency pressing plate and the driving mechanism, and is simple in structure, easy to maintain and low in cost. The requirement for the fit accuracy between the paper currency pressing plate and the guide rods is extremely low, matching is easy to achieve, sufficient fit accuracy can be available after long time working, technological requirements are effectively lowered, needed production cost and needed maintenance cost are lowered, the service life is prolonged, and working stability is high.

Owner:GUANGZHOU KINGTELLER TECHNOLOGY CO LTD

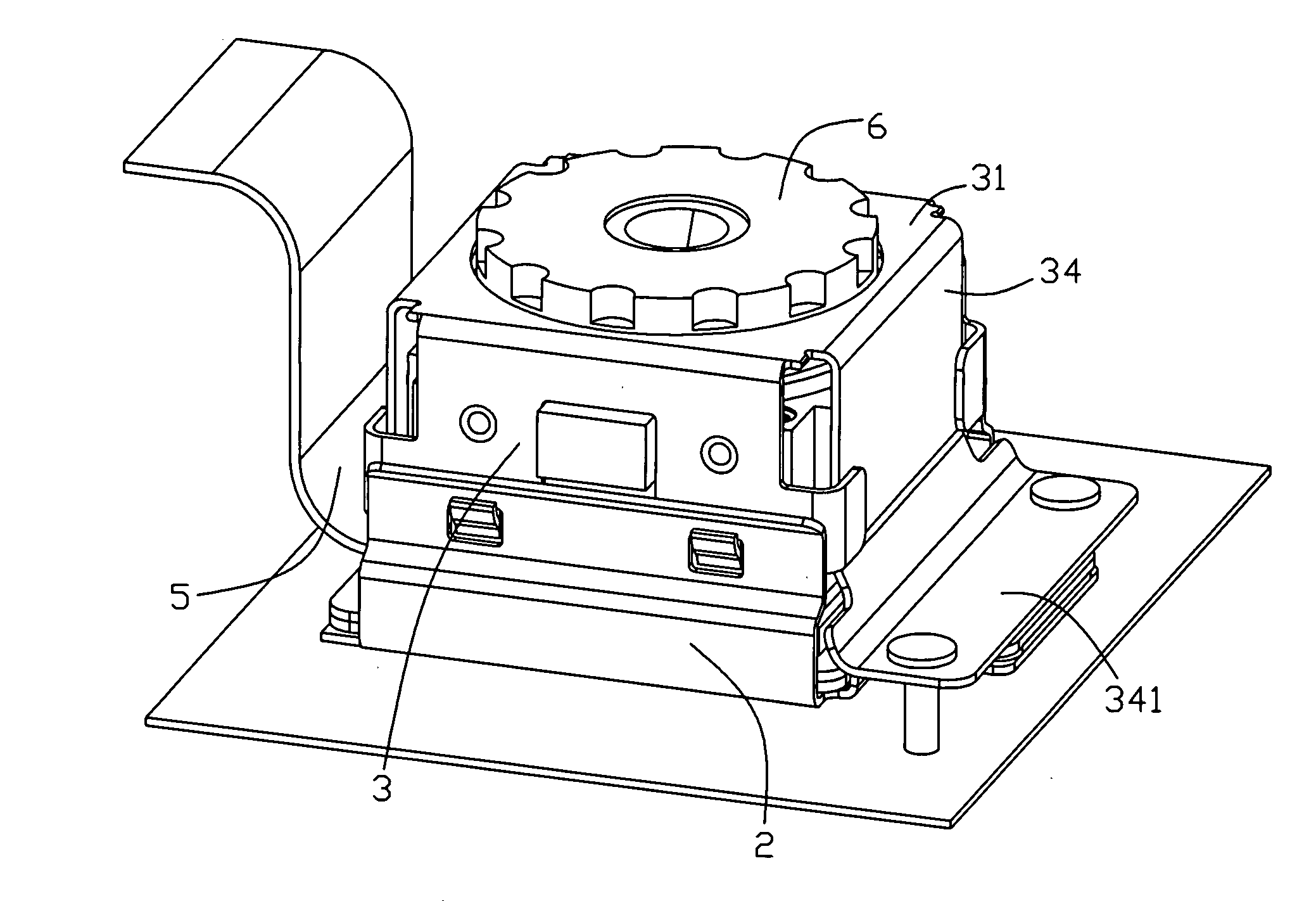

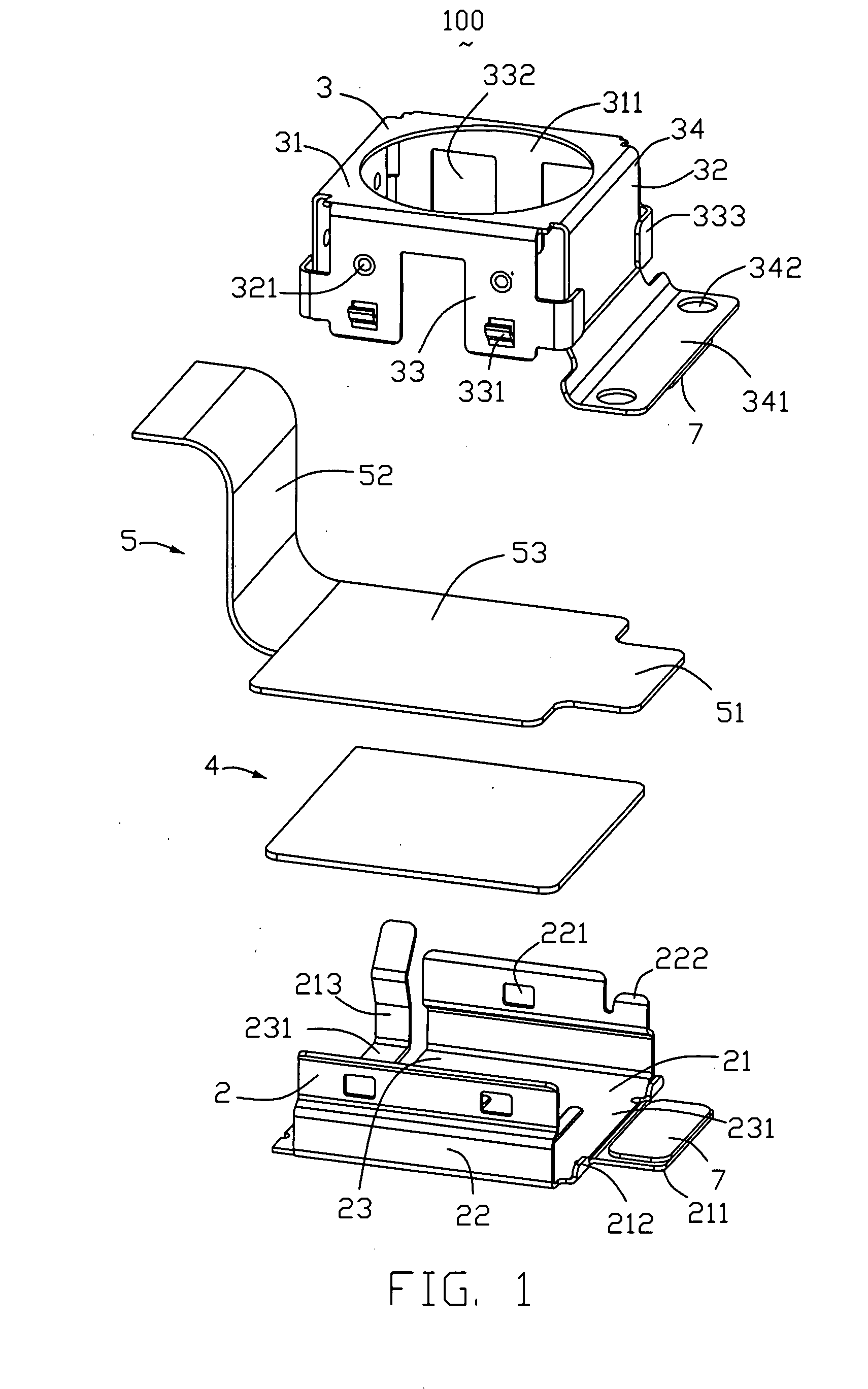

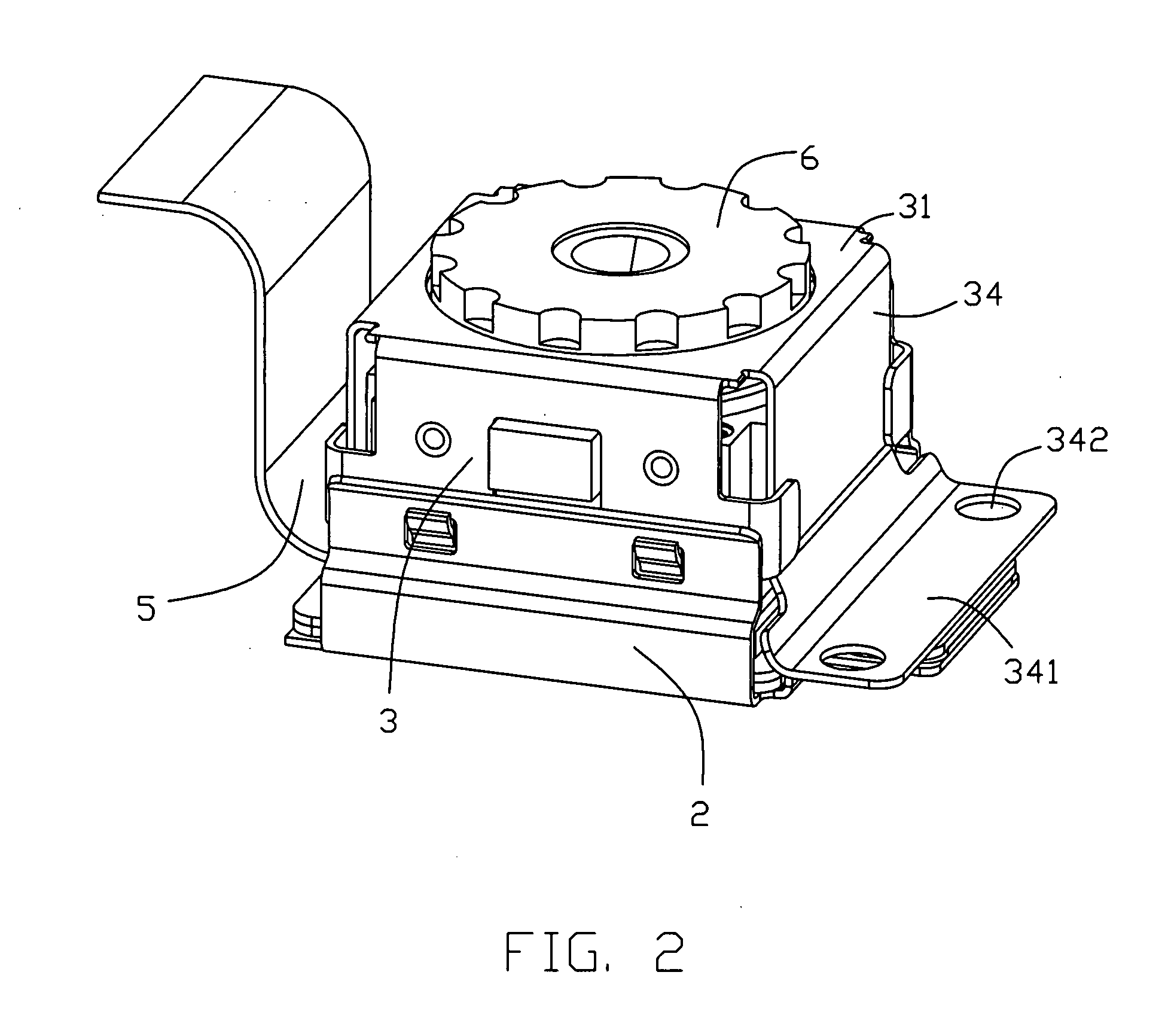

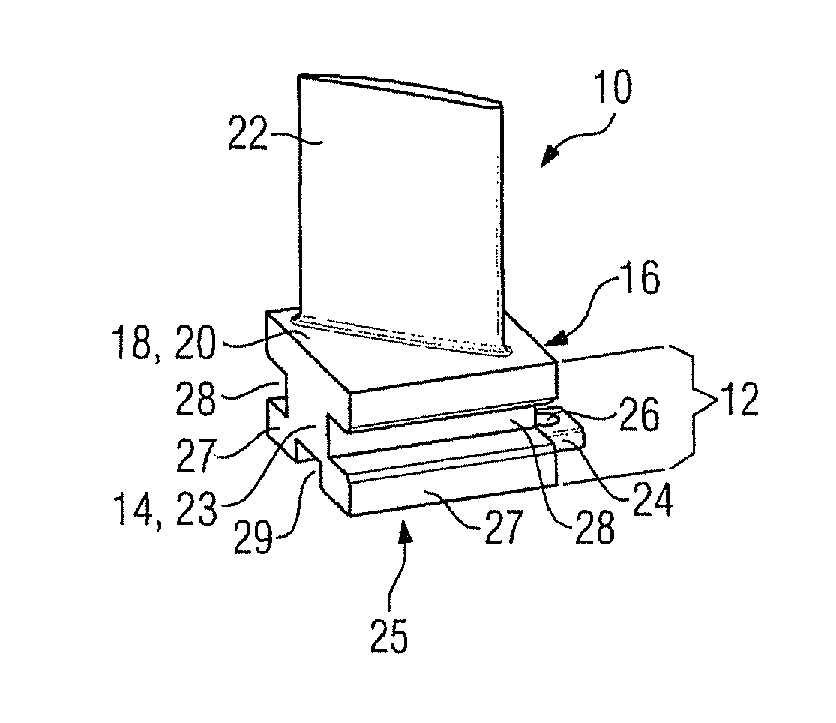

Electrical Connector

InactiveUS20080119070A1Low matching accuracy requirementsLow costCoupling device detailsPrinted circuitsPrinted circuit boardPlate element

An electrical connector adapted for connecting a camera module to a printed circuit board, at least comprising: a lower shield having a bottom wall, a plurality of sidewalls extending from the bottom wall, and a receiving space defined between the bottom wall and the sidewalls, the receiving space has a supporting surface. A flexible printed circuit placed upon the supporting surface for electrically connecting the camera module. An upper shield secured to the lower shield and comprising a top wall, and a plurality of side walls extending from the top wall, said at least one of the side walls defining a second plate element horizontally extending from the bottom end of the side wall, and at least one assembling hole formed in the second plate element for assembling the electrical connector in the printed circuit board.

Owner:HON HAI PRECISION IND CO LTD

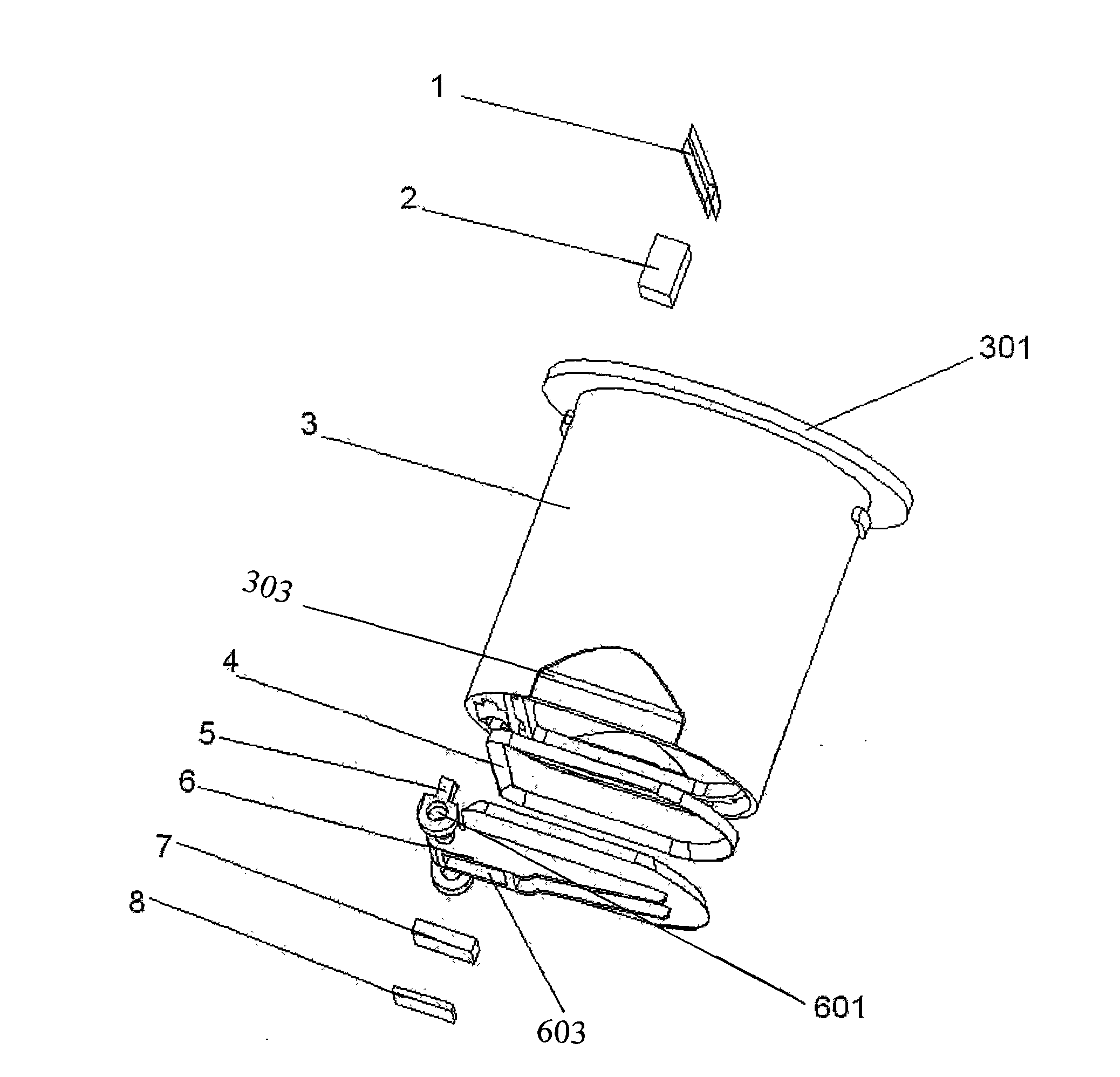

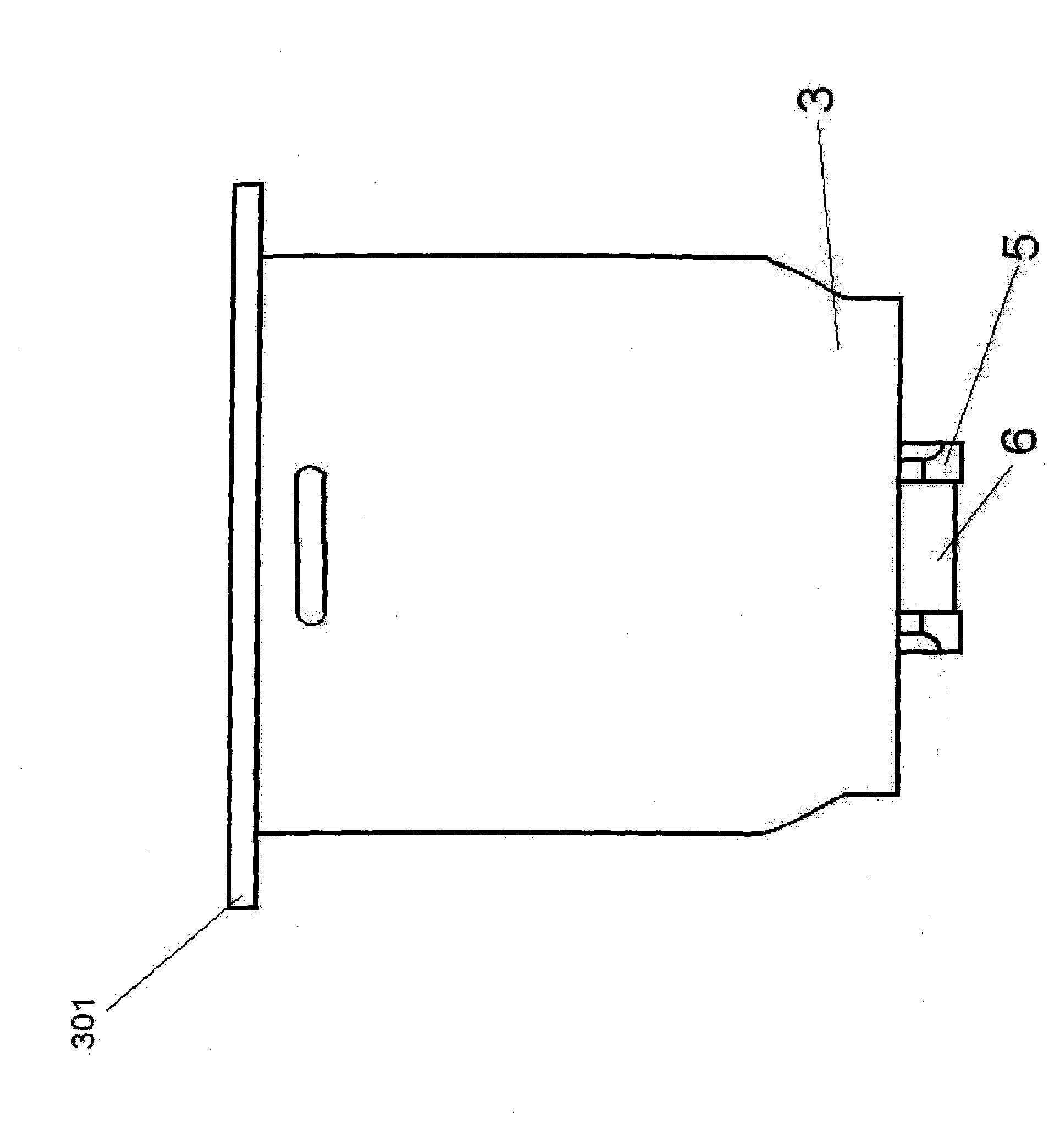

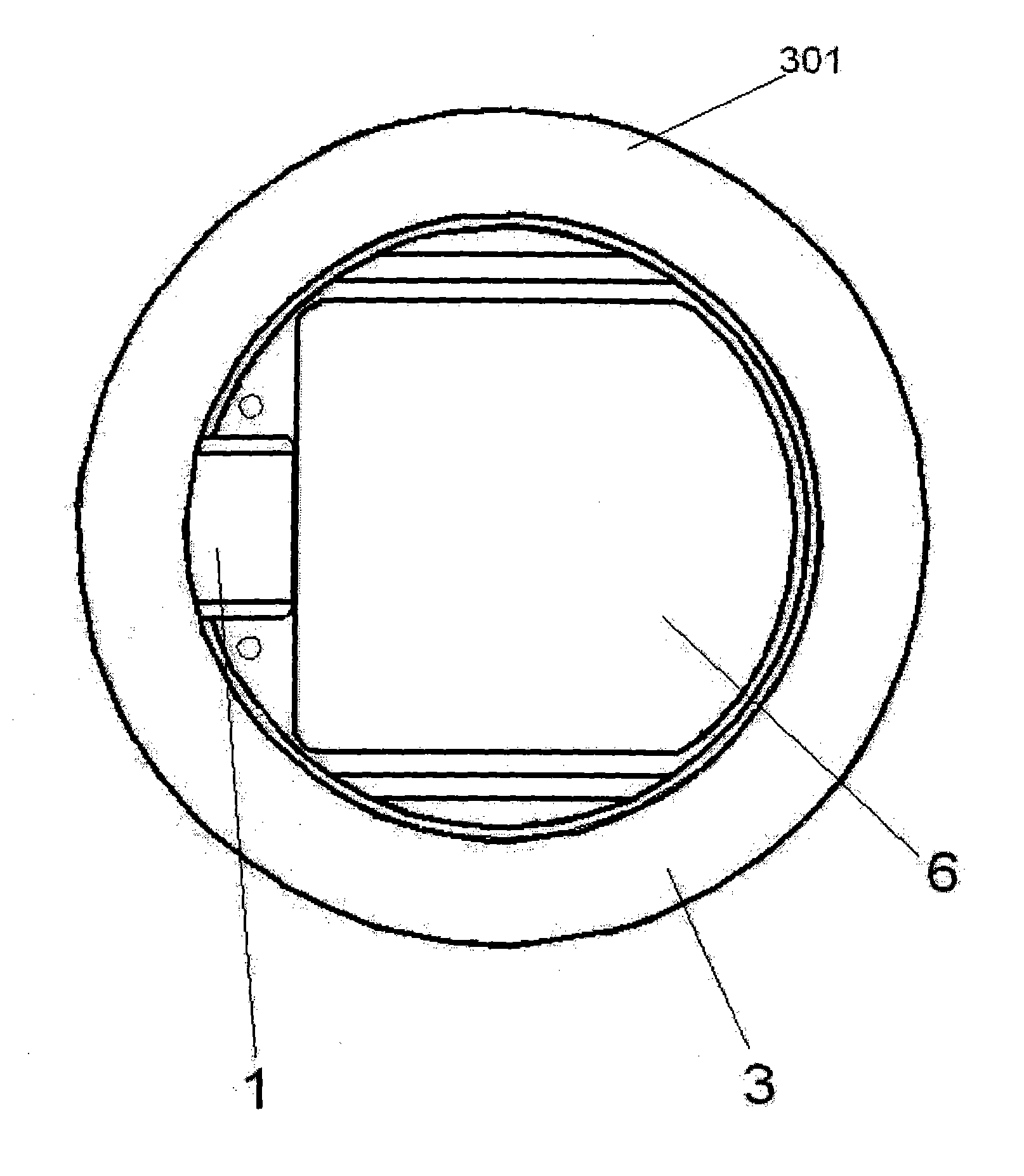

Automatic magnetic check valve

The invention relates to an automatic magnetic check valve, which comprises a cover body, an upper magnet, a valve body, a shaft seat, a valve, a lower magnet and a sealing ring, wherein the shaft seat is arranged on one side of the bottom of the valve body; the valve is hinged on the shaft seat; the upper magnet is arranged on the valve body; the lower magnet is arranged on the valve; the sealing ring is arranged between the valve and the valve body; and the upper magnet and the lower magnet are in a Z-plane asymmetric structure. When asymmetric magnets attract each other, an Fx component force not equal to zero is generated, the consistency of the repeated opening / closing action of the valve is greatly improved under the action of the Fx, and the valve is closed to be accurately attracted and sealed; the valve body has a high flow structure, so that an effective area of fluid flowing through the valve body is greatly improved; the valve body is hardly wound with hair and cotton and is cleaning-free; the valve can realize 90-degree opening in a circular pipeline, the drainage is not hindered and the flow velocity is high; and the overflow of sewage is prevented, polluted air, insects and cockroaches are prevented. The check valve is conveniently arranged at a sewage pipeline to replace the conventional water return bend, is suitable for sewage drainage, and is also suitable for other fluid pipelines with one-way flow requirement.

Owner:张成

Stator blade for a turbomachine which is exposable to axial throughflow, and also stator blade arrangement for it

InactiveUS8622708B2Large toleranceLow matching accuracy requirementsPropellersRotary propellersMechanical engineeringStator

A stator blade and a stator blade arrangement for a turbomachine which is exposable to axial throughflow is provided. Each stator blade is retained via a fixed clamping in a circumferential groove. For the fixed clamping, provision is made on one side of the blade root for a shaped piece with a threaded hole into which a tensioning screw, which is supported on the bottom of the circumferential groove, may be screwed.

Owner:SIEMENS AG

Air condition compressor fixing device and engine and automobile provided with same

The invention discloses an air condition compressor fixing device and an engine and an automobile provided with the same. The air condition compressor fixing device for the engine comprises a stand bar, a support, a fixed bolt for passing through the stand bar and the support, a nut suitable for threaded connection with the fixed bolt, and a mosaic loop which can be arranged in the support only by a way of slipping along the axial direction of the fixed bolt, wherein the mosaic loop is provided with internal threads suitable for threaded connected with a thread part of the fixed bolt. Therefore, the attachment strength of the threaded connection directly extrudes two sides of a protrusion of the support, and no bending stress is generated on the stand bar and the support; in addition, when a large gap exists between the stand bar and the support, the mosaic loop can slip to abut against a protrusion of the stand bar, so the requirement on matching precision is reduced.

Owner:BEIQI FOTON MOTOR CO LTD

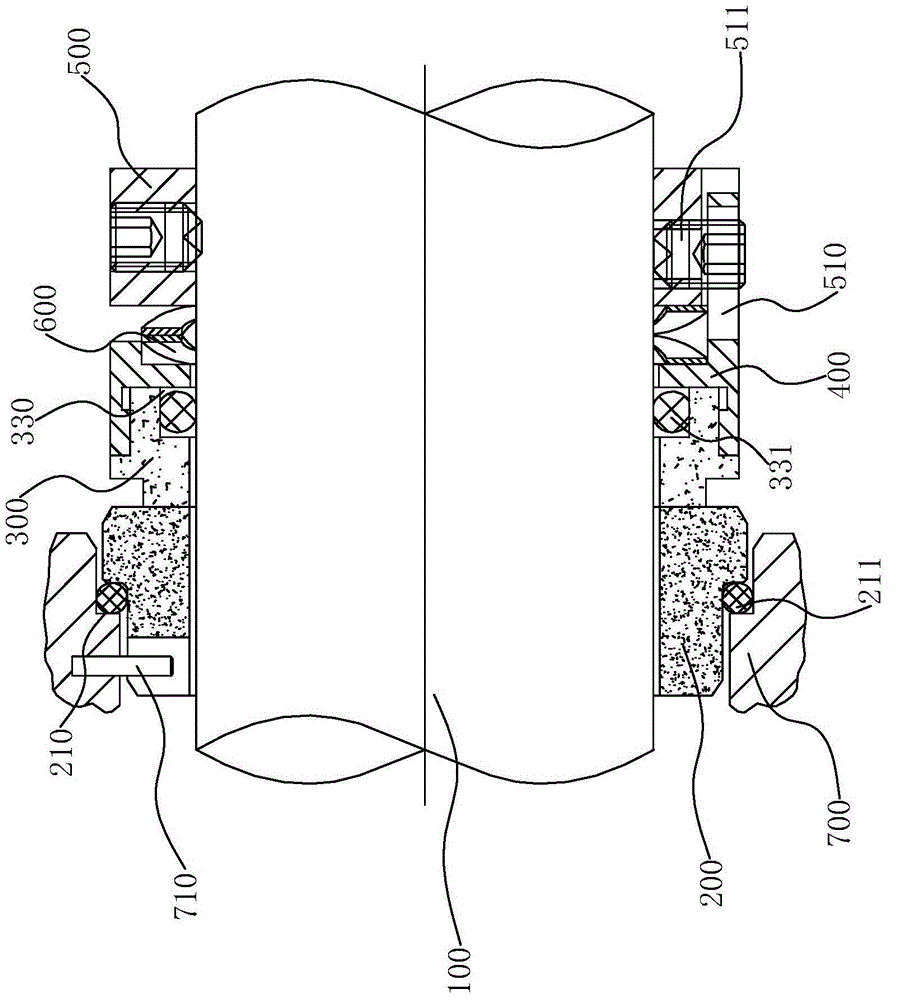

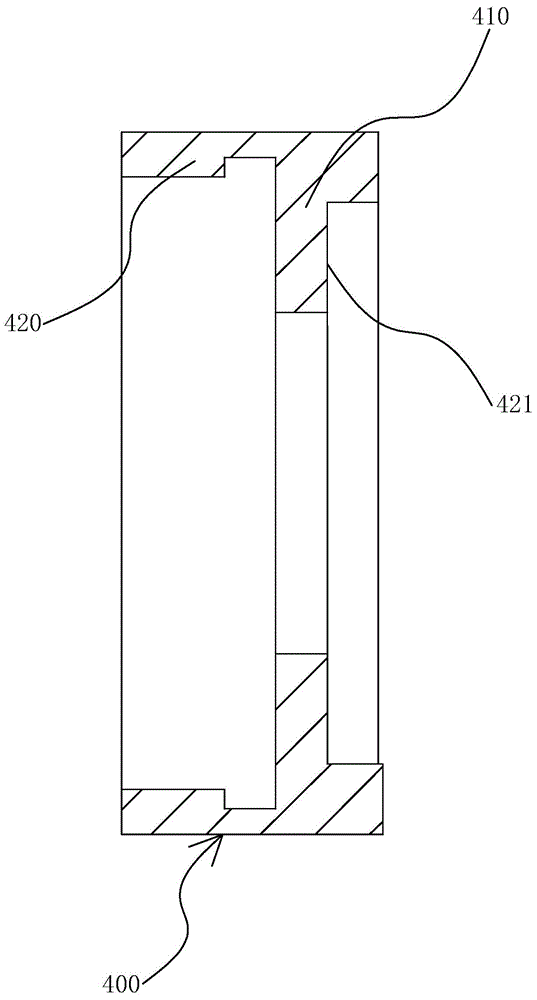

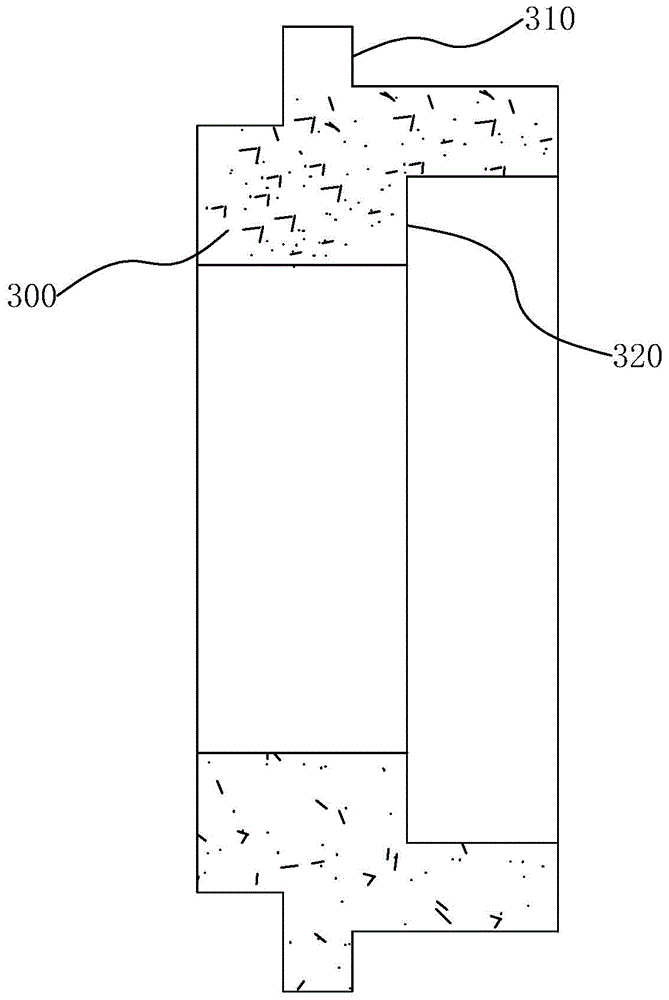

Mechanical sealing device for pump

InactiveCN104989827ASimple structureFit closelyEngine sealsPositive displacement pump componentsSet screwEngineering

The invention provides a mechanical sealing device for a pump. The mechanical sealing device comprises a rotary shaft, wherein a static ring and a dynamic ring are arranged on the rotary shaft; one end of the dynamic ring is resisted against the static ring; a dynamic ring base and a transmission ring are further arranged on the rotary shaft; the transmission ring is fixedly connected with the rotary shaft; the front end of the dynamic ring base is connected with the dynamic ring; a first ring-shaped pit is formed in the rear end of the dynamic ring base; a spring is arranged on the outer surface of the rotary shaft is a surrounding mode; the spring is positioned in the first ring-shaped pit; one end of the spring is resisted against the first ring-shaped pit; the other end of the spring is resisted against the transmission ring; a tightening plate is axially arranged at one side of the transmission ring; the tightening plate is resisted against the dynamic ring base; a tightening bolt is arranged on the tightening plate; and the tightening bolt penetrates through the tightening plate and the transmission ring and then is resisted against the rotary shaft. The mechanical sealing device is optimized in structure, relatively convenient to dismount due to reduction of parts, and low in processing precision requirement. Moreover, the dynamic ring is made of a hard material and the static ring is made of a hard or soft material, so that fitting-up effect between the dynamic ring and the static ring is improved, the sealing reliability is guaranteed, and the service lives of the dynamic ring and the static ring are prolonged.

Owner:NINGBO DONGLIAN MECHANICAL SEAL

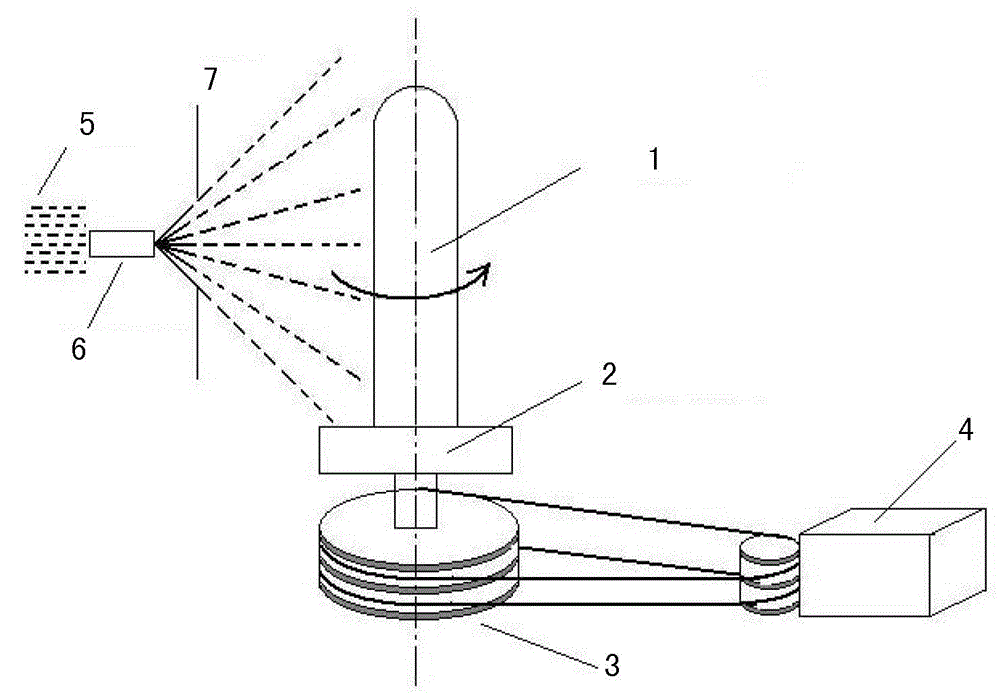

Method for preparing beta-Al2O3 ceramic electrolyte separator for sodium battery

ActiveCN104556980ALow matching accuracy requirementsReduce usageCeramic shaping apparatusCell component detailsSlurrySolvent

The invention provides a method for preparing a beta-Al2O3 ceramic electrolyte separator for a sodium battery. The method comprises steps as follows: Step (1), Na-Z powder and Li-Z powder which are used as precursor powder are synthesized respectively on the basis of an Al source and a Na source as well as on the basis of the Al source and an Li source; Step (2), the Na-Z powder and the Li-Z powder are mixed in the specified mole ratio and mixed with a binder and a solvent, and then slurry is prepared; Step (3), the slurry is atomized and then sprayed onto a rotating mandrel to be condensed and molded into a base body; Step (4), the condensed and molded base body is sleeved with a plastic film, and a beta-Al2O3 biscuit is obtained through demolding after isostatic pressing machining; Step (5), the beta-Al2O3 biscuit is subjected to plastic removal and then high-temperature sintering, and the beta-Al2O3 ceramic electrolyte separator is obtained.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

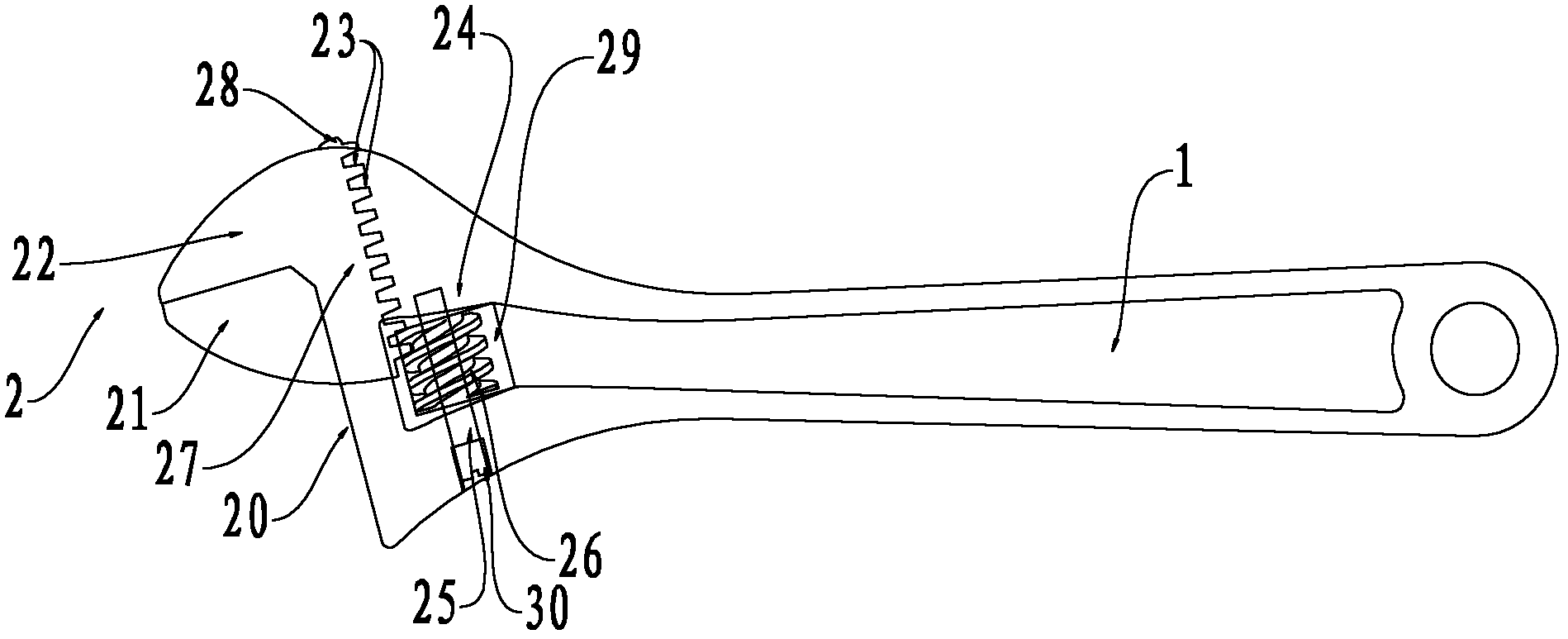

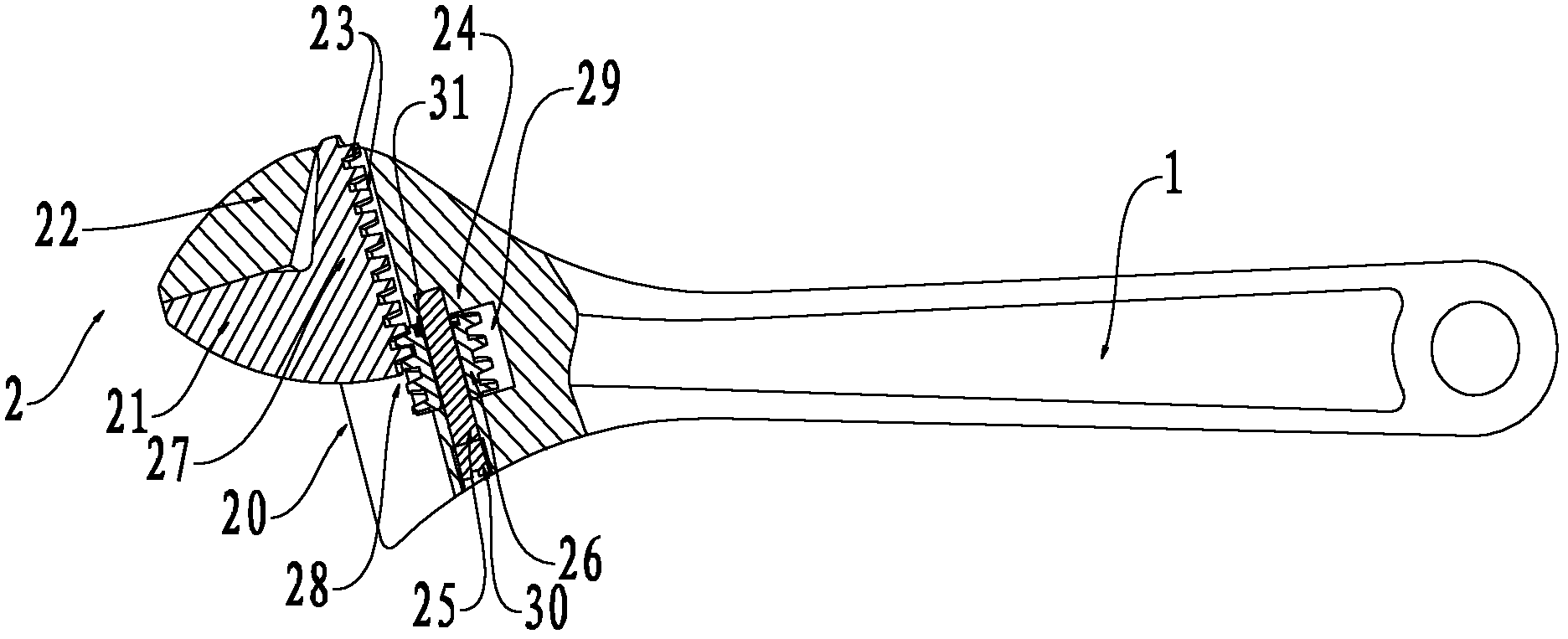

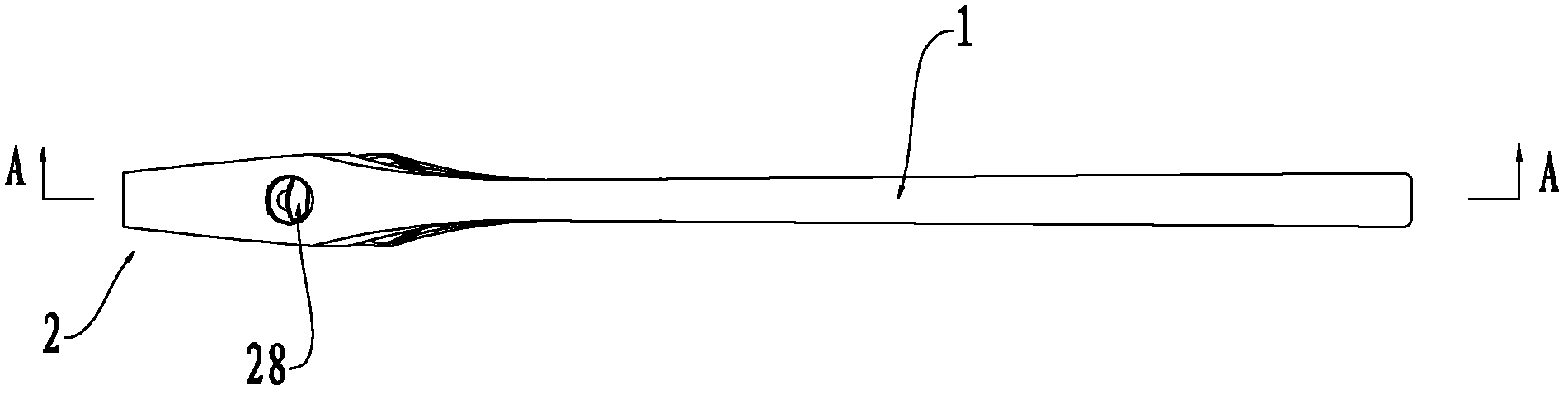

Monkey wrench

ActiveCN103203703AIncrease forceRequirements for lower fit accuracySpannersWrenchesWrenchMoving parts

The invention discloses a monkey wrench, which comprises a wrench body and a worm wheel, wherein the wrench body comprises a handle and a working part; the working part comprises a fixed part, a moving part and a chute; the lower end of the moving part is arranged in the chute; the bottom edge of the lower end of the moving part is provided with a tooth part; the working part comprises a through hole; the worm wheel is arranged in the through hole and meshed with the tooth part; when the worm wheel is rotated, the worm wheel and the tooth part function to drive the moving part to move towards or away from the fixed part; and threads of the worm wheel have at least two spiral lines. The monkey wrench can quickly adjust the distance between the moving part and the fixed part, and increase the torque borne by the worm wheel.

Owner:HANGZHOU GREAT STAR TOOLS

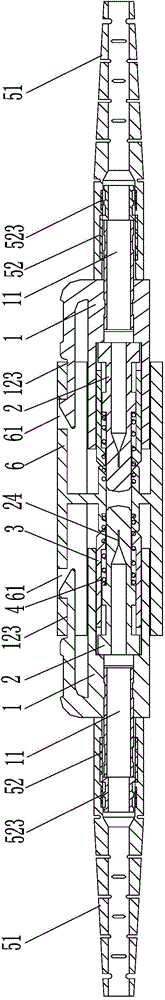

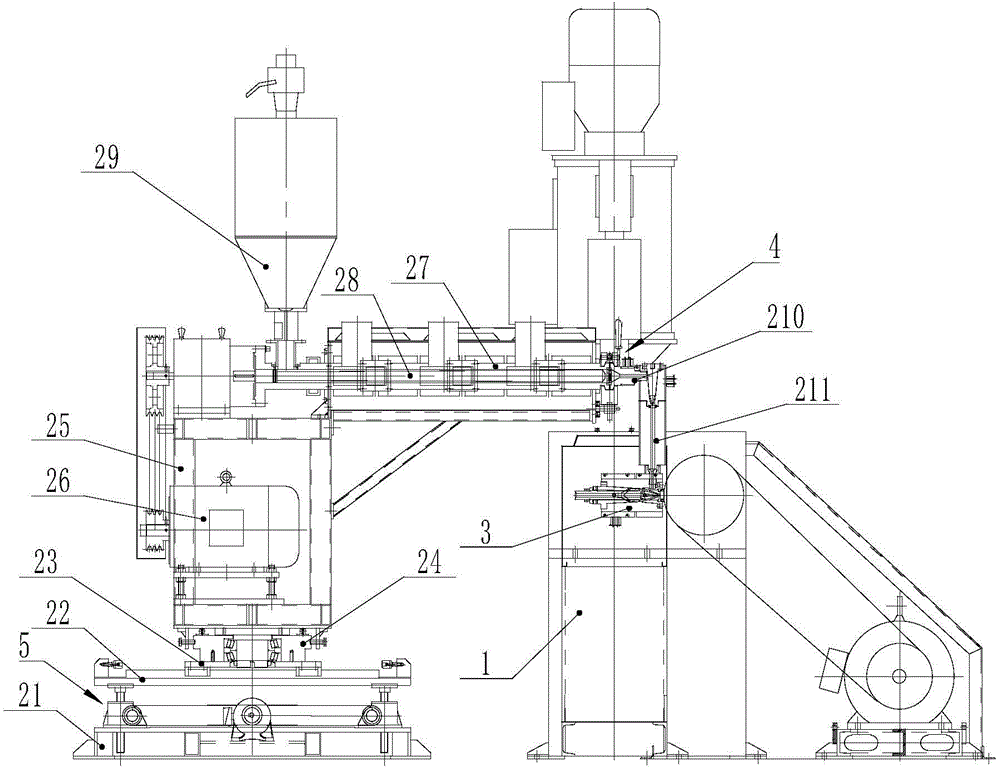

Electric cable line extruder

Owner:JIANGSU JIACHENG TECH

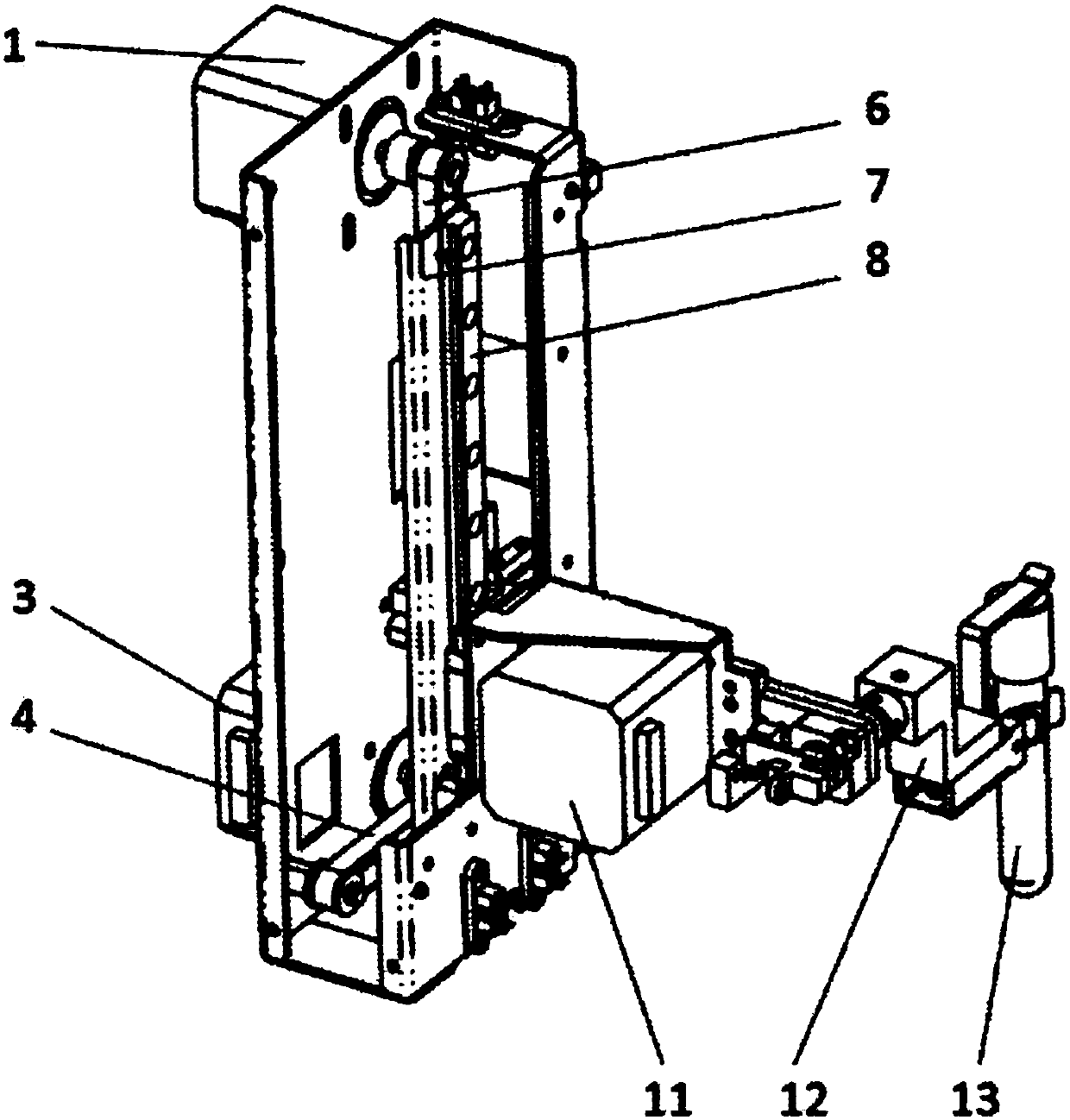

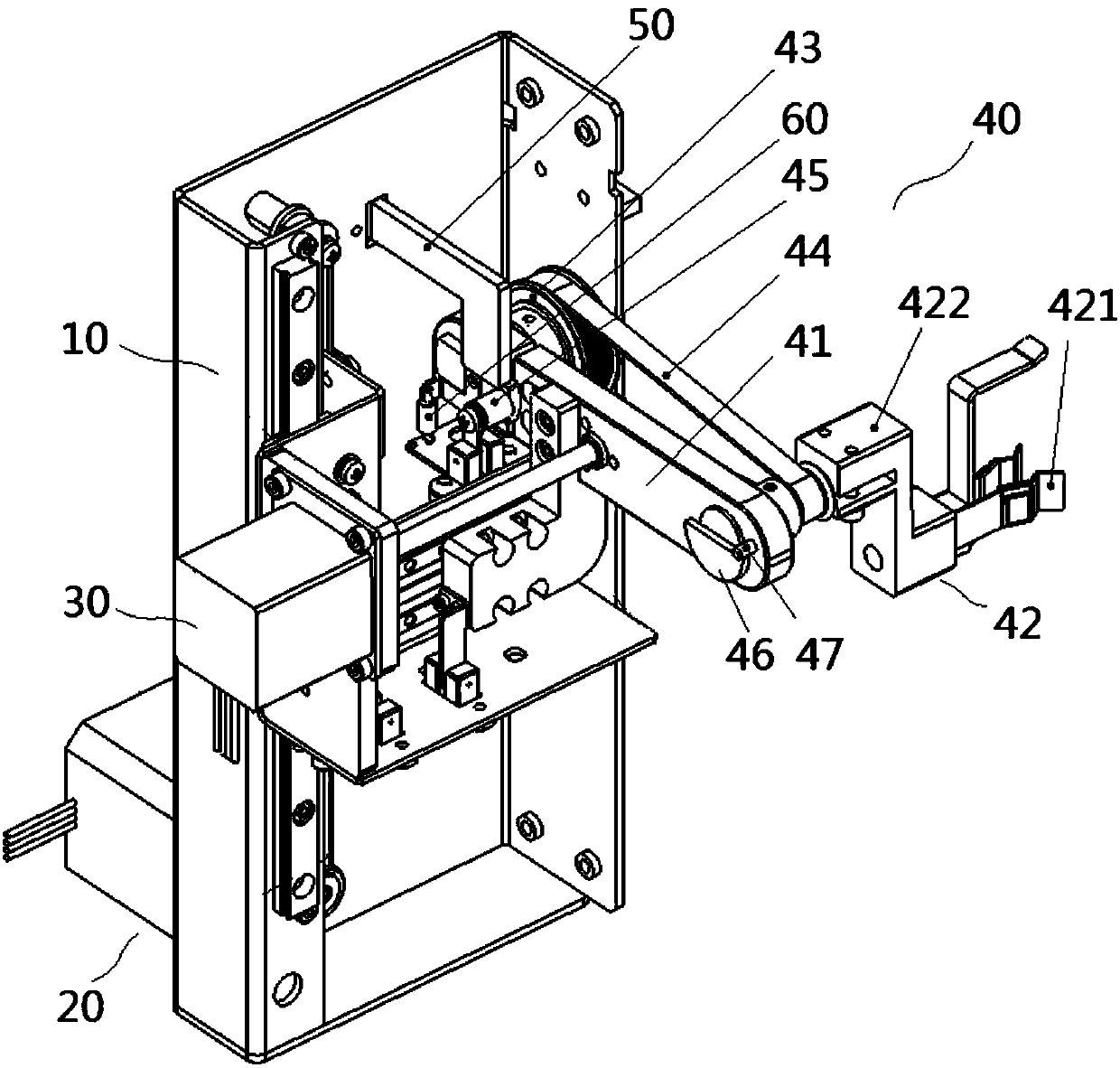

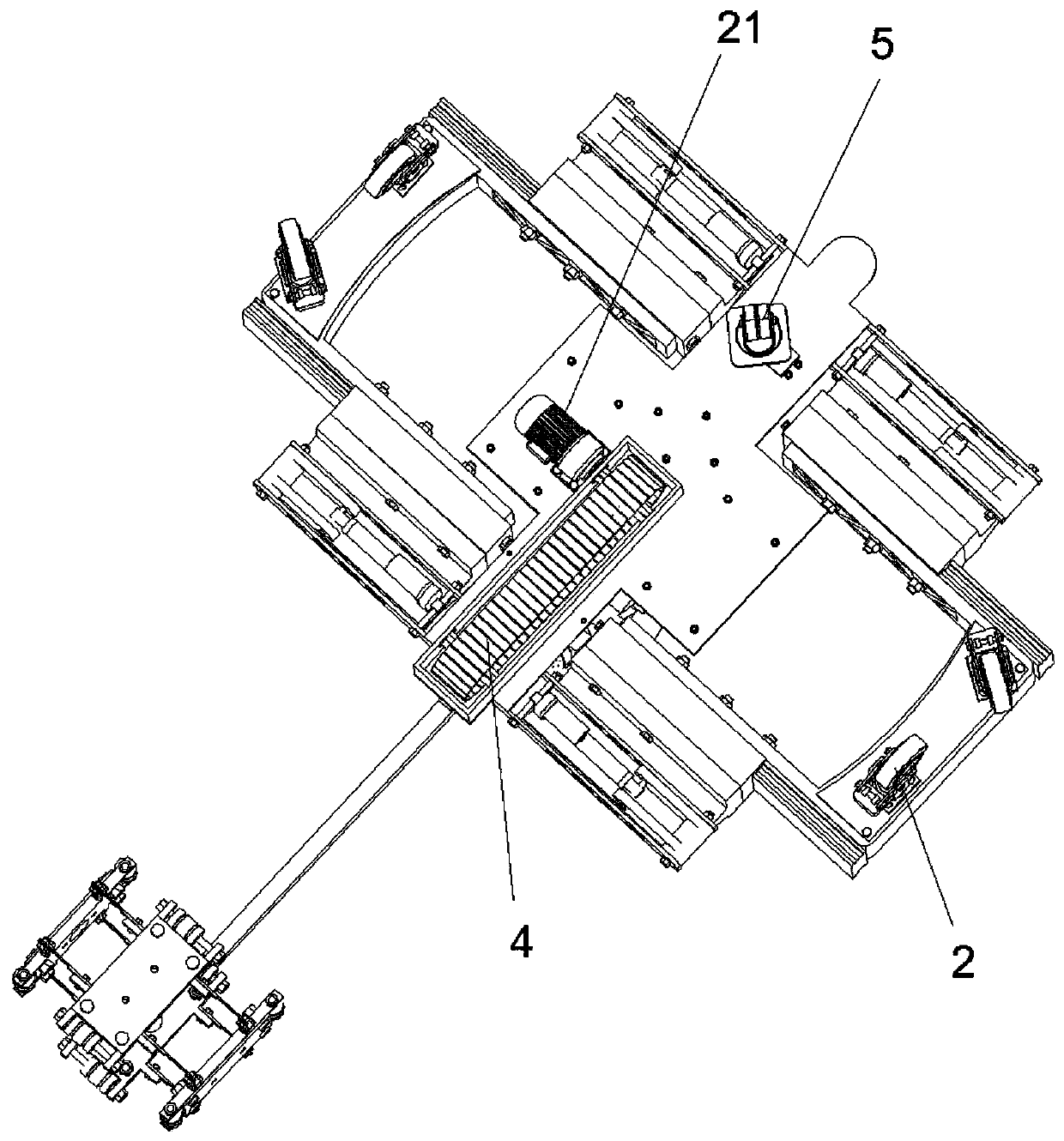

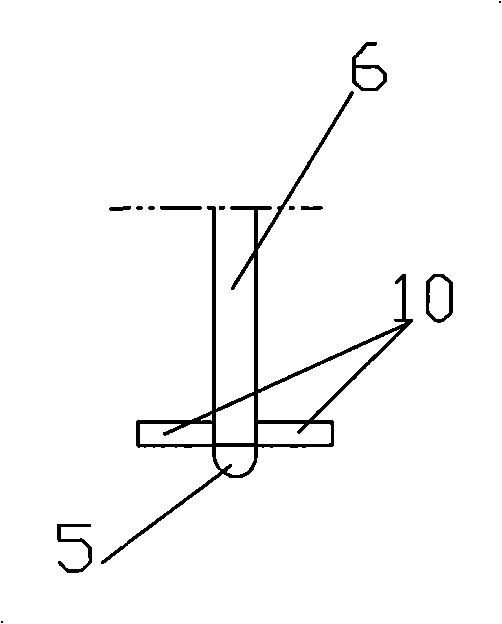

Test tube mixing device

ActiveCN108014700AImprove stabilityLow matching accuracy requirementsShaking/oscillating/vibrating mixersTransportation and packagingEngineeringTest tube

The invention provides a test tube mixing device. The test tube mixing device comprises a shell, a vertical moving mechanism, a horizontal moving mechanism, a test tube pick and place assembly and a driving rod, wherein the vertical moving mechanism is arranged on the shell, the horizontal moving mechanism is arranged on the vertical moving mechanism, and the test tube pick and place assembly is rotatably mounted on the horizontal moving mechanism. The drive rod is fixedly arranged on the shell and is positioned on the vertical moving track of the test tube pick and place assembly. When the test tube pick and place assembly moves towards the driving rod in the vertical direction, the test tube pick and place assembly press against the driving rod and is stirred by the driving rod to rotate. According to the technical scheme provided by the invention, power driving parts are reduced, so that the requirement of overall matching precision and overall control precision of the whole test tube mixing device is reduced, and the stability of the use of the test tube mixing device is improved.

Owner:SHANDONG EXCELLENCE BIOTECHNOLOGY CO LTD

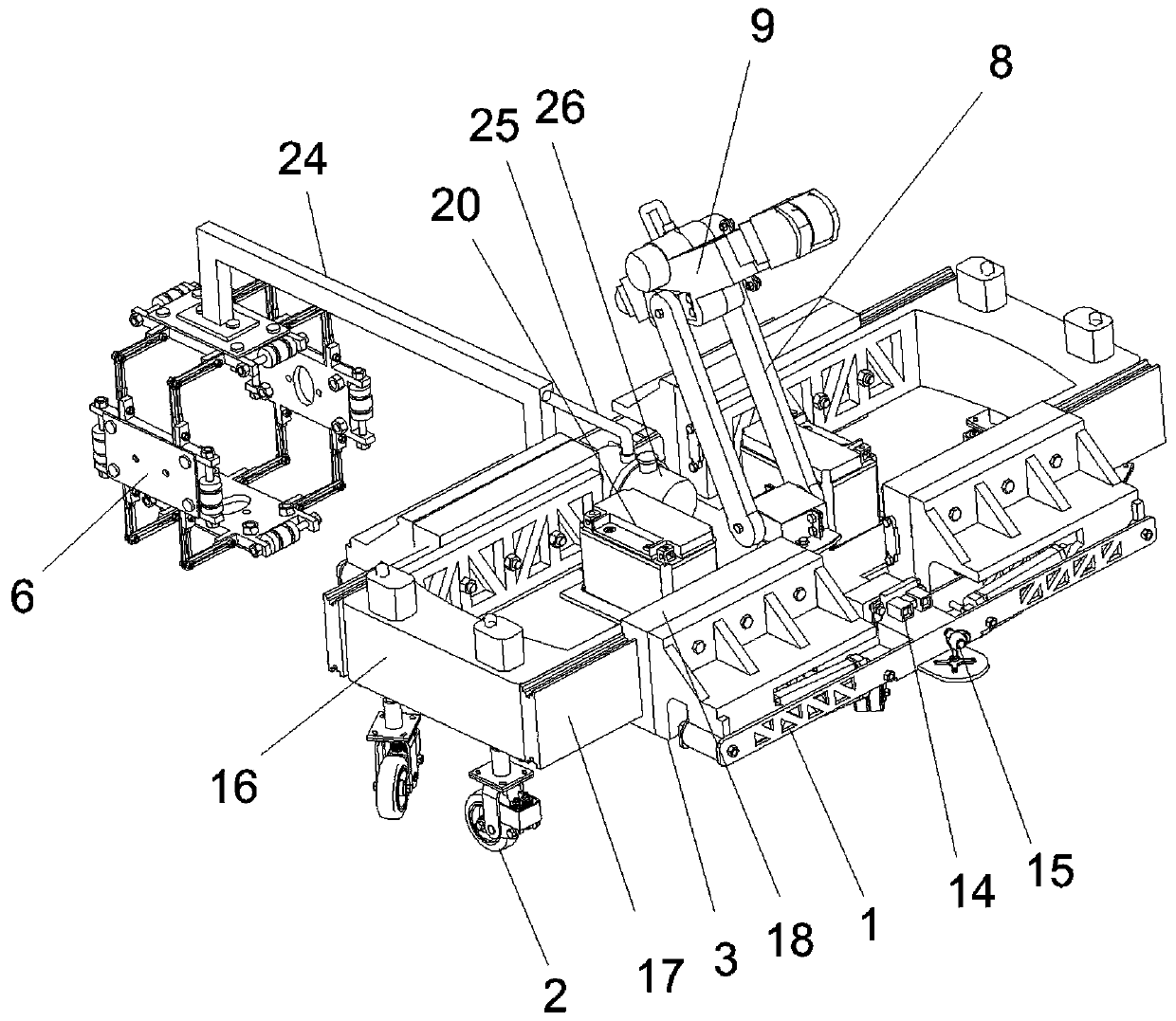

Climbing robot capable of automatically detecting and maintaining

InactiveCN110000758AImprove detection efficiencyAvoid safety hazardsProgramme-controlled manipulatorVehiclesVehicle frameCable stayed

The invention discloses a climbing robot capable of automatically detecting and maintaining. The climbing robot comprises a car frame, a climbing assembly mounted at the bottom of the car frame and used for climbing components, a detecting assembly arranged on a rack for detecting the surface quality of the components and a maintaining assembly for maintaining the surfaces of the components. According to the climbing robot capable of automatically detecting and maintaining, the robot is driven by the climbing assembly to walk along the wall surfaces of the components, for example,the robot walks along the wall surface of an oil storage tank, the wall surface of a ship or a cable-stayed bridge inhaul cable, meanwhile the surface quality of the components is detected by the detecting assembly, and thus corresponding maintenance is conducted by the maintaining assembly, the robot can replace people to operate in high-altitude, the hidden safety hazards caused by the high-altitude operation of inspectors are avoided, the detection efficiency of the robot is high, maintaining operation can be conducted simultaneously, and an integrated detection and maintenance technology for the components can be formed.

Owner:CHONGQING UNIV OF ARTS & SCI

Pressure cooking appliance

The present invention provides a pressure cooking appliance. The pressure cooking appliance comprises a pot body, a pot cover, a pressure limiting valve, a first transmission piece, a second transmission piece, a driving mechanism and a magnetic mechanism, wherein the pot body is used for accommodating cooked food; the pot cover is arranged on the pot body, and an exhaust passage is formed in thepot cover; the pressure limiting valve is matched with the exhaust passage, and comprises a pressure limiting valve body and a counterweight block; the first transmission piece and the second transmission piece are matched with each other, and the second transmission piece is pivotably arranged on the pot cover; the driving mechanism drives the first transmission piece to rotate, and the second transmission piece has a first position corresponding to the pressure limiting valve and a second position away from the pressure limiting valve under the transmission of the first transmission piece; and the magnetic mechanism is arranged on the second transmission piece and / or the counterweight block, when the second transmission piece is located at the first position, the counterweight block is separated from the pressure limiting valve body under the action of magnetic attraction force, and when the first transmission piece is located at the second position, the counterweight block is pressed on the pressure limiting valve body under the action of gravity. Through the application of the technical scheme of the invention, the problem of high processing difficulty of the pressure cooking appliance in the prior art can be effectively solved.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

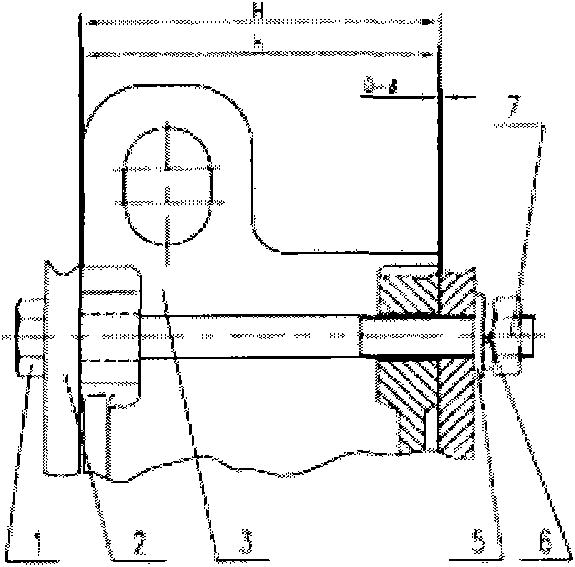

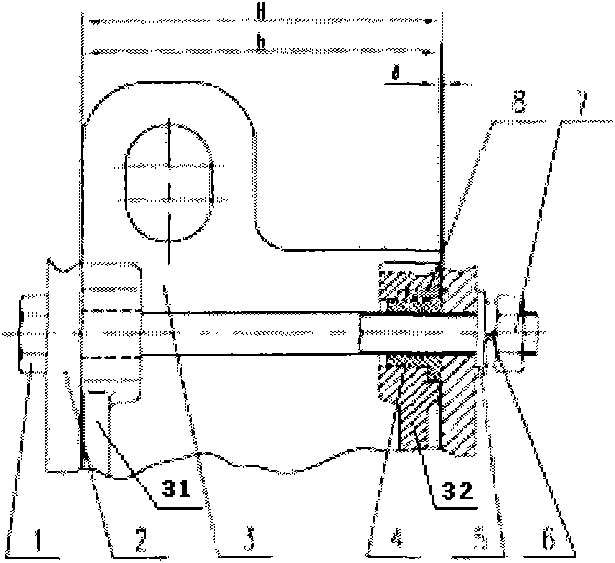

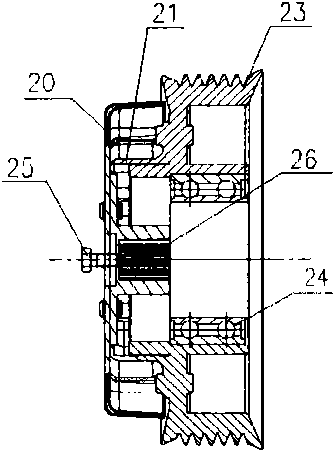

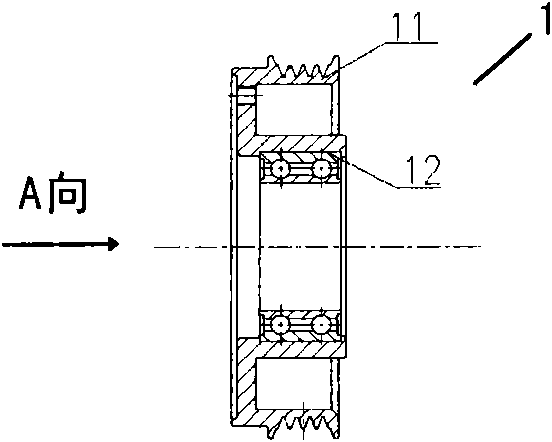

Clutch used for variable displacement rotary swash plate compressor of vehicle air conditioner

InactiveCN101876352AEasy to processLow matching accuracy requirementsAir-treating devicesVehicle heating/cooling devicesDrive wheelAutomobile air conditioning

The invention discloses a clutch used for a variable displacement rotary swash plate compressor of a vehicle air conditioner. The clutch comprises a belt wheel assembly (1) and a driven wheel assembly (2), wherein the axial central hole of a belt wheel (11) is matched with a bearing (12); the belt wheel (11) is provided with a plurality of connecting holes (13); the driven wheel (2) comprises a drive plate (21) which comprises an inner ring (211) with an inward extending part and an outer ring (212) with an outward expanding part; the inward extending ring of the inner ring is provided with a plurality of discontinuous grooves (214); neighboring grooves form a connecting rib (215); the outward expanding part of the outer ring is provided with a plurality of connecting holes (216); the outer ring is connected with a locking screw (3) through the belt wheel; a coupling body (4) and the inward extending part thereof are connected coaxially by using a radial outward expanding part (41) thereof; and the connecting point between the coupling body and the inner ring is closer to the axial centre of the drive plate than the plurality of grooves on the inner ring. The clutch has the characteristics of simple structure, reduced machining process, reduced machining cost and uniform stress; and an overload protection effect is ensured.

Owner:SUZHOU ZHONGCHENG NEW ENERGY TECH CO LTD

Top-mounted ball valve and assembling tool and process of top-mounted ball valve

PendingCN113007379ALow matching accuracy requirementsEasy to processPlug valvesMetal-working hand toolsEngineeringMachine

The invention relates to a top-mounted ball valve and an assembling tool and process of the top-mounted ball valve. The top-mounted ball valve structurally comprises a valve body, a ball body and a valve seat. The valve seat is installed in an inlet and outlet channel of the valve body through a spring seat and a clamping spring by means of the special assembling tool, and the problem that threads are prone to being damaged due to the fact that the valve seat is driven through the threads in the prior art is solved. The requirement for the matching precision between the valve seat and the spring seat is low, parts are easy to machine, assembling and disassembling are convenient, and the assembling quality is reliable.

Owner:ZHEJIANG BETHEL TECH CO LTD

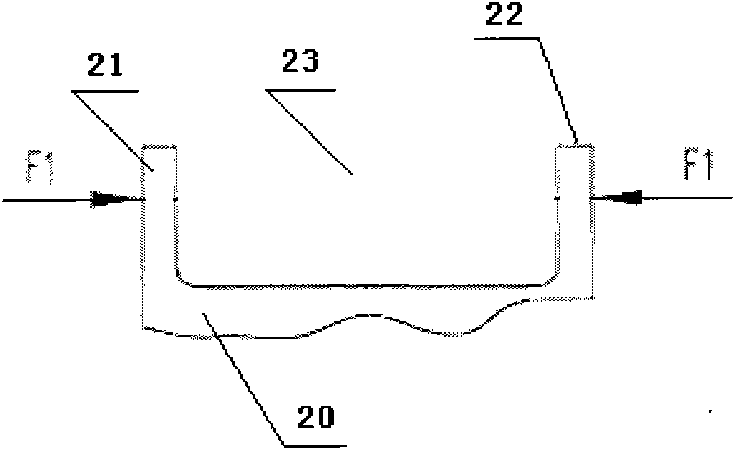

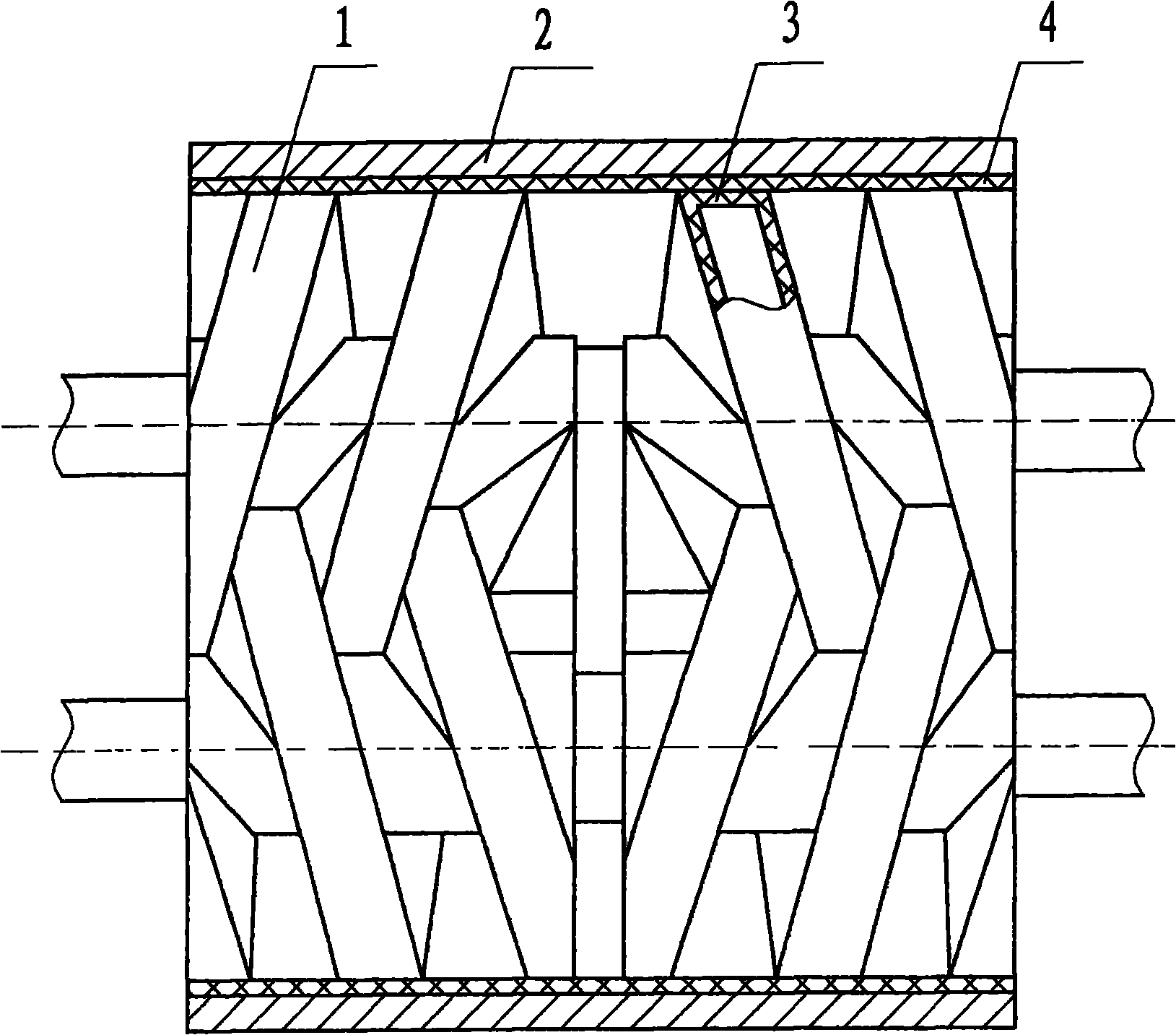

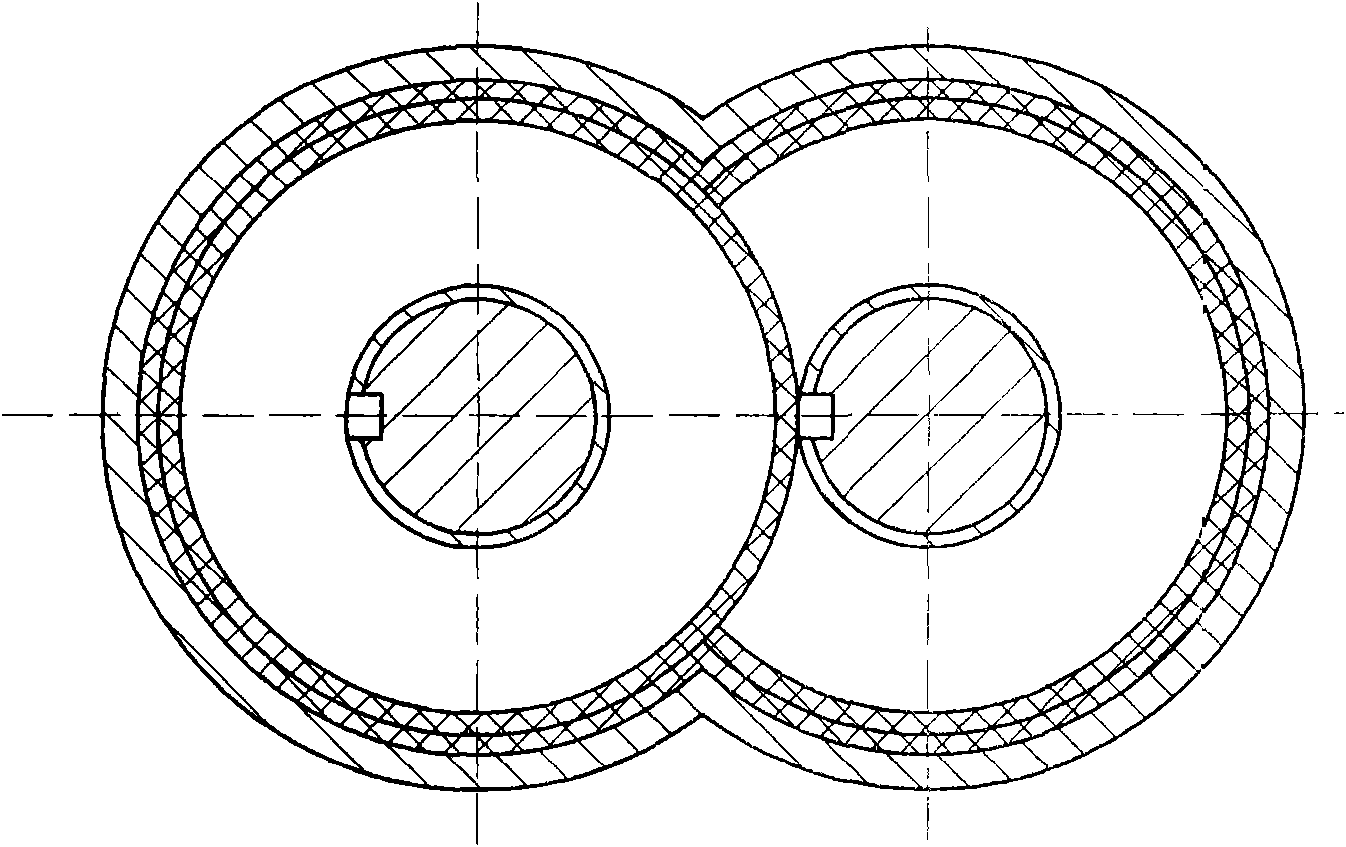

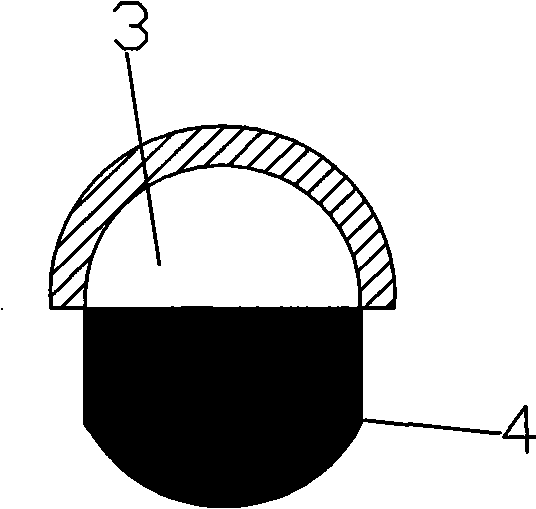

Double-screw pump provided with elastic lining layer

InactiveCN102062087AImprove mechanical propertiesImprove volumetric efficiencyRotary piston pumpsRotary piston liquid enginesElastomerSurface layer

The invention relates to a double-screw pump provided with an elastic lining layer, which is characterized by comprising a screw 1 and a pump sleeve 2, wherein a surface layer lining of the screw 1 is provided with a screw surface layer elastic body 3 or / and an inner surface lining of the pump sleeve 2 is provided with an inner pump sleeve surface elastic body 4. With the arrangement of a layer of the elastic body at the screw surface layer or the pump inner lining, the meshing performance between the screw and the pump sleeve is improved, the processing precision of the screw or the pump sleeve is reduced, the processing cost of a key element of the pump is lowered, the comprehensive mechanical properties of the double-screw pump is enhanced, the volumetric efficiency of the pump and the pump efficiency are improved, the adaptability of the double-screw pump on mediums is increased, and the application field is broadened.

Owner:重庆明珠机电有限公司

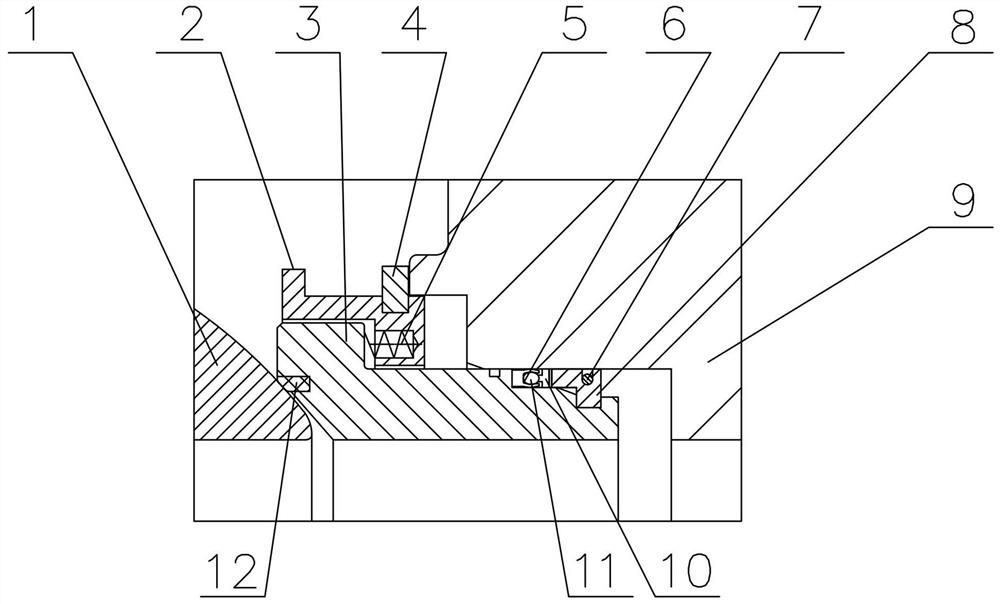

Whole-type bearing high-speed spinning spindle with detachable and washable spindle feet

InactiveCN103789888AExtended service lifeLow matching accuracy requirementsTextiles and paperBolsterEngineering

The invention relates to a whole-type bearing high-speed spinning spindle with detachable and washable spindle feet. The whole-type bearing high-speed spinning spindle comprises a spindle base and a rod disc, the spindle base is composed of the spindle feet and a bolster, abrasive particles can be removed by directly disassembling and washing oil storage cups in the spindle feet, vibration is transmitted to spindle foot tubes through a vibration attenuation sleeve and lubricating oil in a two-time mode, the vibration energy consumption can be effectively reduced, and the service life of the spindle is prolonged. The inner wall of a bearing base, the upper end face of an elastic pipe and the lower end of an oil proofing cap in the bolster serve as an outer ring, a lower bearing plate and an upper bearing plate of a roller respectively, a whole-type bearing structure is combined, a spinning spindle bearing, the upper bearing plate and the lower bearing plate are removed, the requirement for the fit accuracy between parts is lowered, the concentricity of bearing holes is guaranteed, and stress of the holes in the radial direction is even. Meanwhile, as the outer diameter of the bearing base is reduced, the diameter of a spindle disc of the spindle is accordingly reduced, high-speed operation of the smaller spindle disc can be adapted, and the operation speed ranges from 25000 r / min to 30000 r / min.

Owner:HENGYANG TEXTILE MACHINERY MANUFACTORY +1

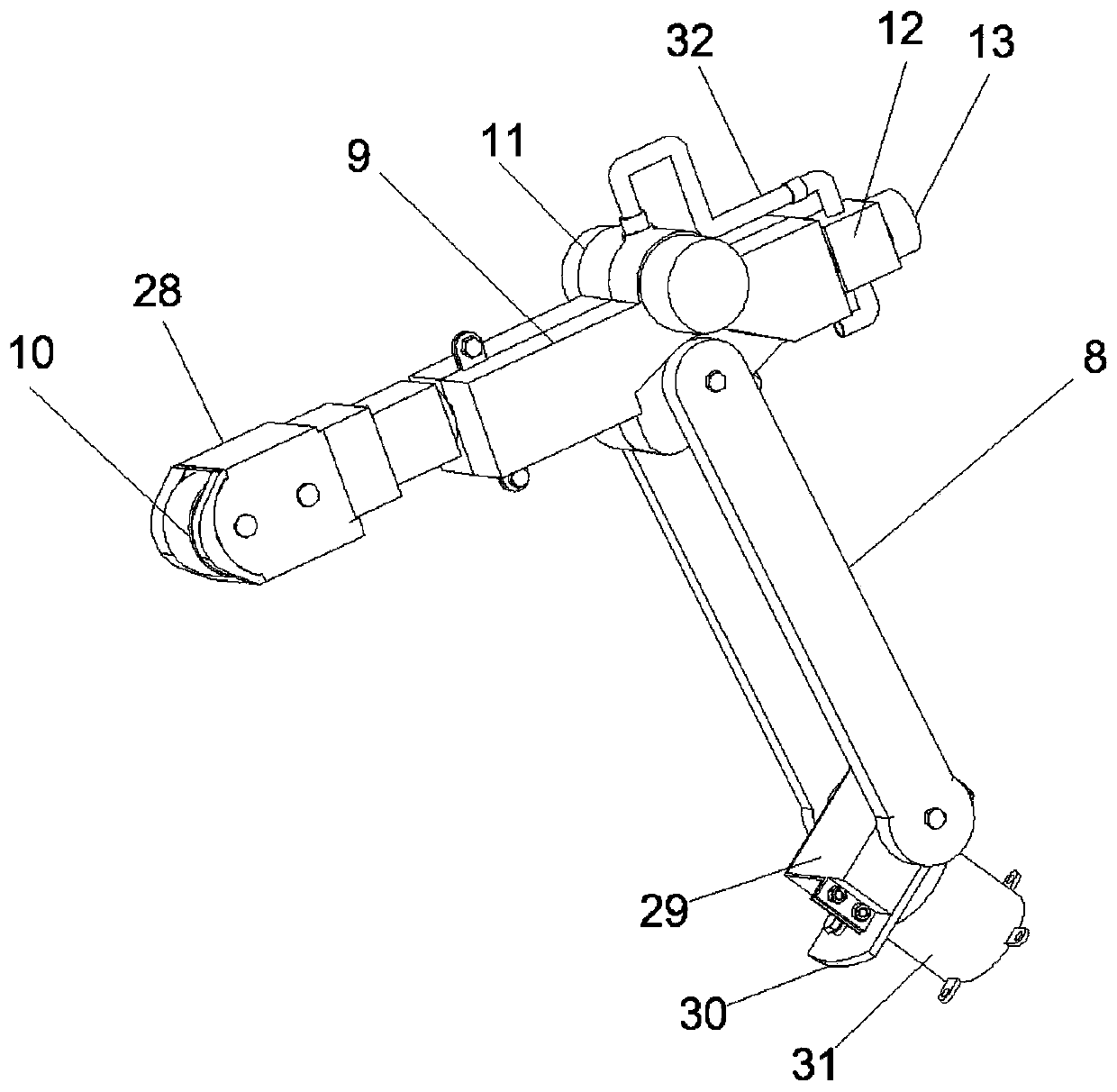

Breaker

ActiveCN103871762ALow matching accuracy requirementsLow costProtective switch detailsElectric switchesEngineeringCam

This invention discloses a breaker, comprising a housing and a handle. A first accommodating space and a second accommodating space are arranged within the housing; the handle is installed in the first accommodating space and at least partially projects out of the housing; the breaker also comprises a locking device; the locking device comprises a lock head and a sliding member; the lock head is installed on the housing and possesses a cam member; the sliding member is arranged within the second accommodating space in a sliding manner; the sliding member comprises a first side plate, a second side plate, an opening and a first pin; the first side plate is connected to the second side plate; the opening is formed between the first side plate and the second side plate; the cam member extends to the portion between the first side plate and the second side plate through the opening; and the first pin is selectively installed on the first side plate and the second side plate in order to lock the circuit.

Owner:SIEMENS AG

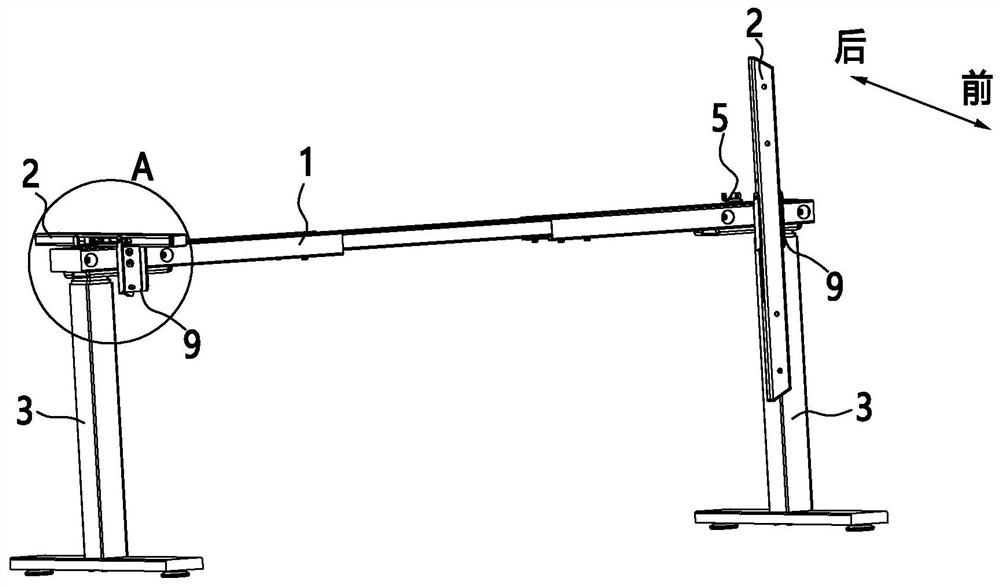

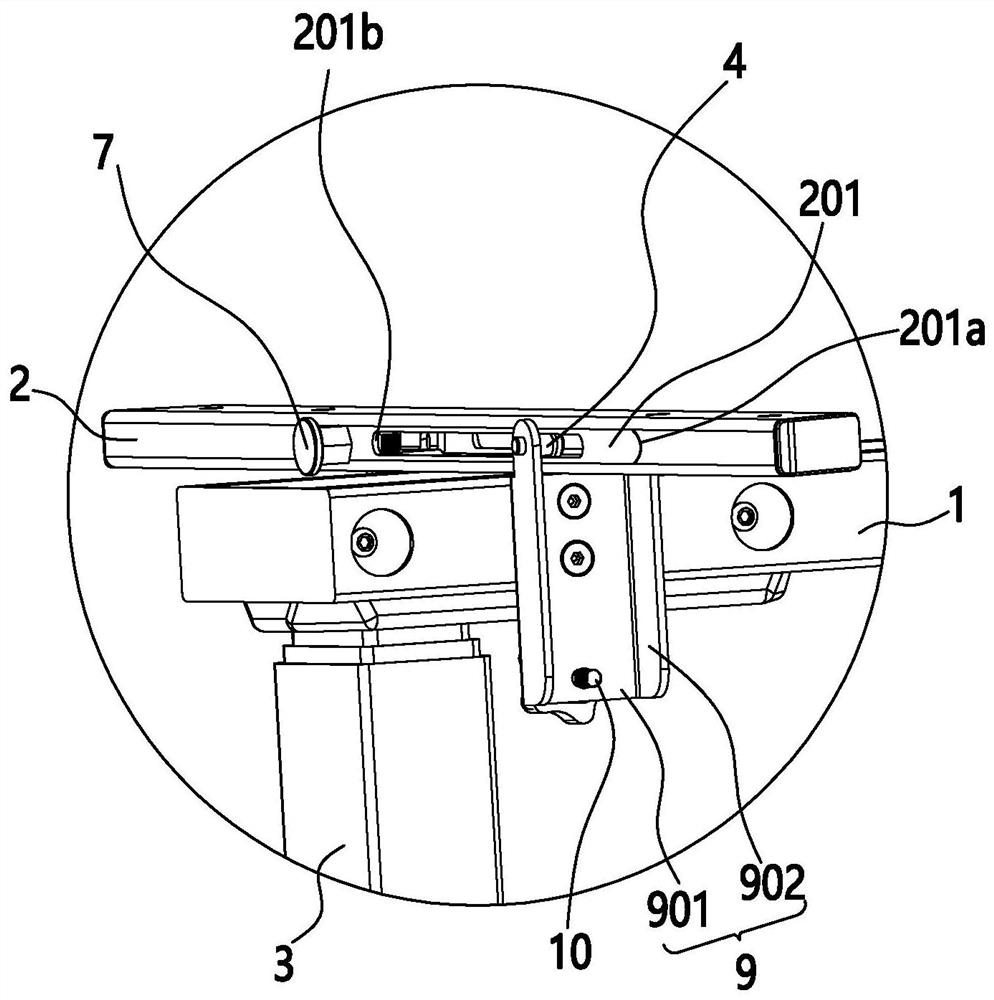

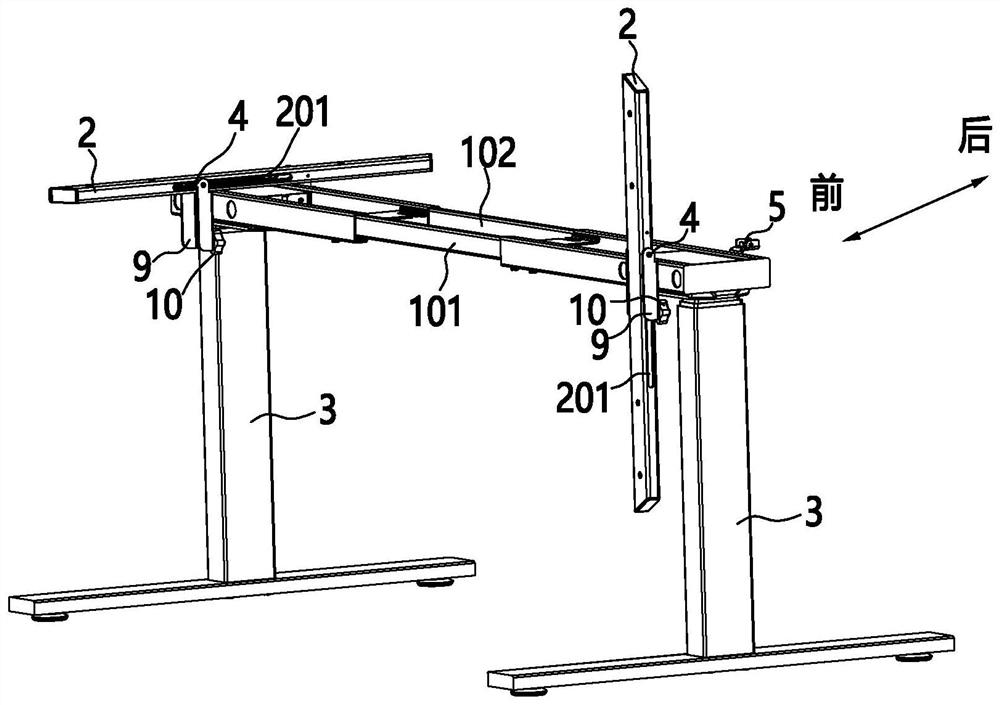

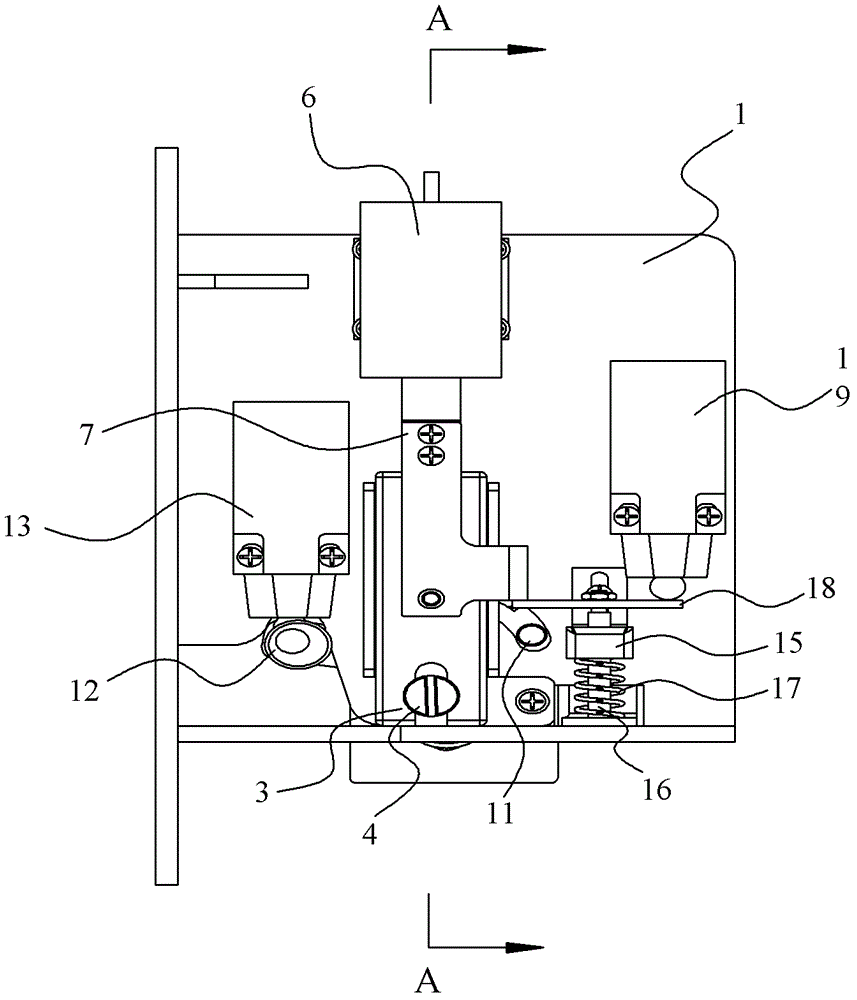

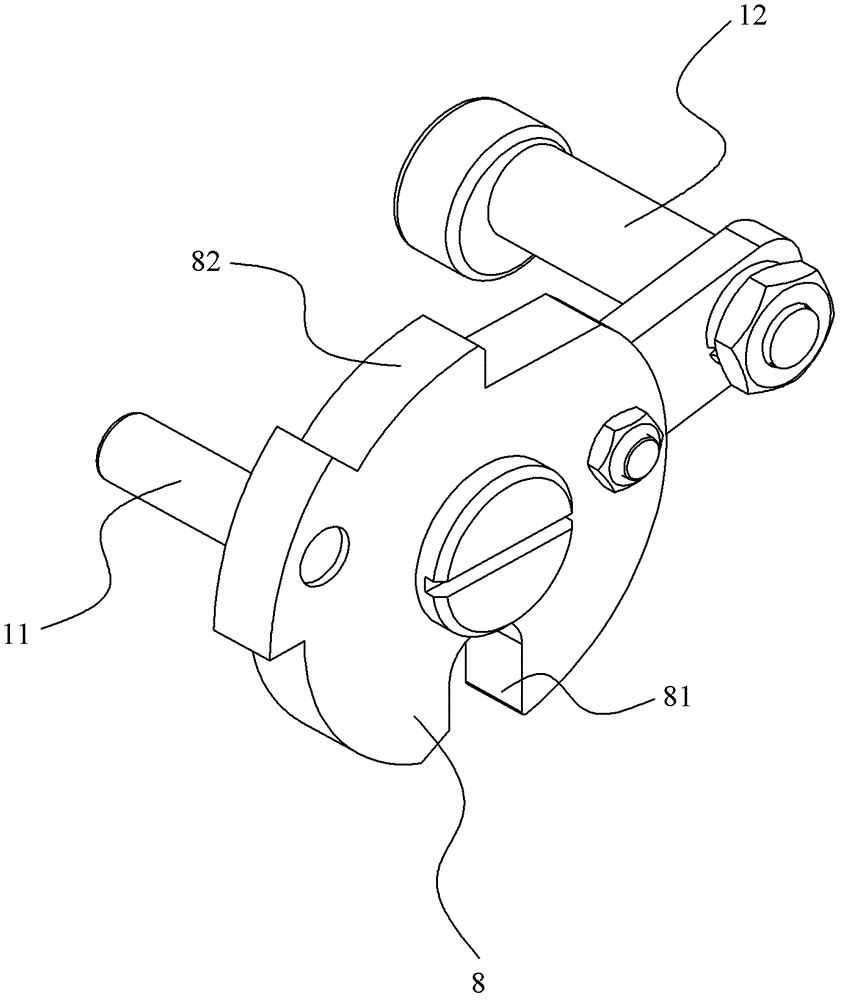

Self-locking overturning and lifting table frame and table

PendingCN112869349AImprove stabilityAvoid vertical liftingVariable height tablesFeetEngineeringCavity wall

The invention discloses a self-locking overturning and lifting table frame and a table, and belongs to the technical field of overturning tables, the overturning and lifting table frame comprises a cross beam, a longitudinal beam and a lifting stand column, the cross beam is provided with a hinge piece and a locking piece, the longitudinal beam is hinged to the cross beam through the hinge piece and can overturn relative to the cross beam, the overturning and lifting table frame comprises a use mode and a storage mode, the conversion between the use mode and the storage mode is achieved through the turnover of the longitudinal beam on the cross beam, when the overturning and lifting table frame is in the storage mode, the longitudinal beam is laterally arranged beside the cross beam, when the overturning and lifting table frame is in the use mode, the longitudinal beam is horizontally arranged on the cross beam and locked through the locking piece, and the longitudinal beam comprises an inner cavity. The longitudinal beam is provided with a notch enabling the locking piece to vertically enter the inner cavity, the locking piece is slidably inserted in parallel on the cavity wall of the inner cavity and automatically locked, the longitudinal beam is limited in the radial direction in the mode that the locking piece is arranged in the inner cavity and slidably inserted in parallel with the cavity wall, the stability of the longitudinal beam in the vertical direction is enhanced, and the safety during use is guaranteed.

Owner:NINGBO HAISHIKAI DRIVER TECH CO LTD

Safety door locking device and safety door adopting same

The invention discloses a safety door locking device and a safety door. The safety door locking device includes a main support, an auxiliary support and a unlocking slideway sliding block mounted on the main support through a slideway, a locking wheel mounted on the main support through a torsional spring and including a guide groove and a plurality of teeth-shaped objects, a lock pin fixed on the auxiliary support and accommodated in the guide groove, a stop pin matched with the teeth-shaped objects to limit the rotation of the locking wheel and fixedly connected with the unlocking slideway sliding block, and a first unlocking mechanism arranged on the main support and fixedly connected with the stop pin through a connecting plate. The safety door locking device and the safety door can be used in low-temperature environment and are free from the influence of the environment change; the machining is rather simple, and the matching precision requirement is low; and the door opening / closing status signal feedback structure is simple, the reliability is high, and the device is convenient to mount and adjust.

Owner:JIANGSU SUBURBAN RAILWAY ELECTRICAL EQUIP

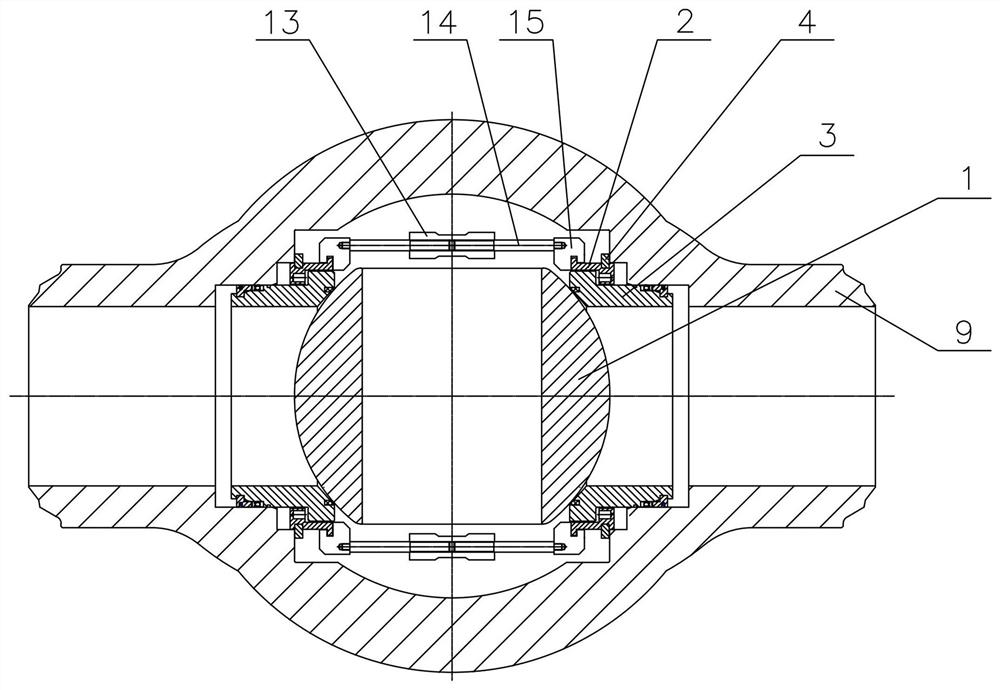

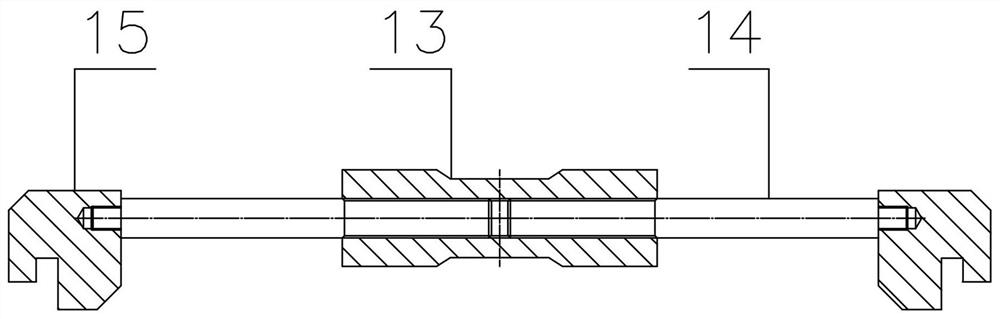

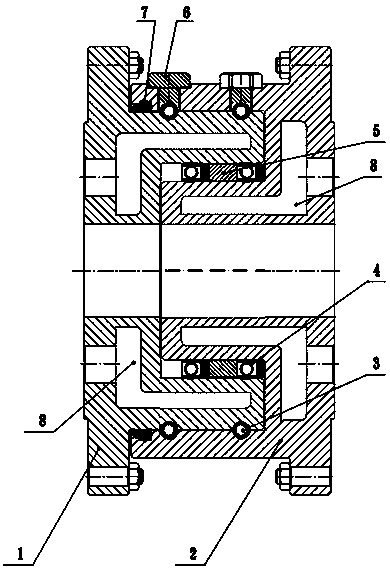

Axially sealed vacuum insulation ultralow-temperature rotating joint

InactiveCN103629459AReduce processing difficultyReduce cold conductionThermal insulationAdjustable jointsNitrogenEngineering

The invention relates to an axially sealed vacuum insulation ultralow-temperature rotating joint, comprising an inner ring, an outer ring, rolling bodies, axial sealing rings, retainers and dustproof sealing rings, wherein the inner ring and the outer ring are in rotating connection trough the rolling bodies, two axial sealing rings and the retainers for axial sealing are arranged between the inner ring and the outer ring, the end, connected with the outer ring, of the inner ring is provided with the dustproof sealing rings, the retainers are arranged between the two axial sealing rings, and annular vacuum cavities are formed in the inner ring and the outer ring. By adopting axial sealing, the difficulty in machining the inner ring and the outer ring and fit precision requirement of relative rotation are reduced; the annular vacuum cavities are is formed in the inner ring and the outer ring of the rotating joint by adopting the vacuum insulation technology, and the cold conduction between the overflow channel surface and the roller path rotating bearing surface is reduced. The cold loss caused by the frosting and freezing of an original loading arm is solved, the leakage caused by the low-temperature deformation of a rotating component is overcome, the nitrogen protection is unnecessary, and the operation cost is reduced.

Owner:YANGCHEN MACHINERY SHANGHAI

Tile pointing device

InactiveCN101514585ABeautiful appearanceNo pollutionBuilding constructionsPointing deviceMechanical engineering

The present invention discloses a tile pointing device which comprises a material cylinder and a feeding piston that is installed in the material cylinder. The material cylinder is installed with a pointing agent outlet. The back side of pointing agent outlet is installed with a pointing blade which has an elongated structure. The invention adopts the material cylinder and piston structure, and is combined with a material outlet and elongated pointing blade satisfying the dimension of tile gap. The tile pointing device has the advantages of material saving in using, no pollution to the surface of tile, beautiful appearance of tile, elongated structure of pointing blade, alternated structure of prior pointing blade, ensured pointing quality, strengthened pointing strength and prevention to falling-off of pointing agent. The invention adopts manual driving for driving the feeding piston and has no high requirement to the fitting precision between the feeding piston and material cylinder thereby furthermore the tile pointing device of the invention has the advantages of easy operation, high operating efficiency, long service lifetime, simple structure and low manufacturing cost.

Owner:冉鹏程

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com