Top-mounted ball valve and assembling tool and process of top-mounted ball valve

A technology for assembling tools and ball valves, which is used in hand-held tools, manufacturing tools, valve devices, etc., can solve the problems of troublesome installation, damage to the soft sealing surface of the valve seat, and difficult processing, and meets the requirements of convenient assembly and disassembly and matching accuracy. Low, reliable assembly quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

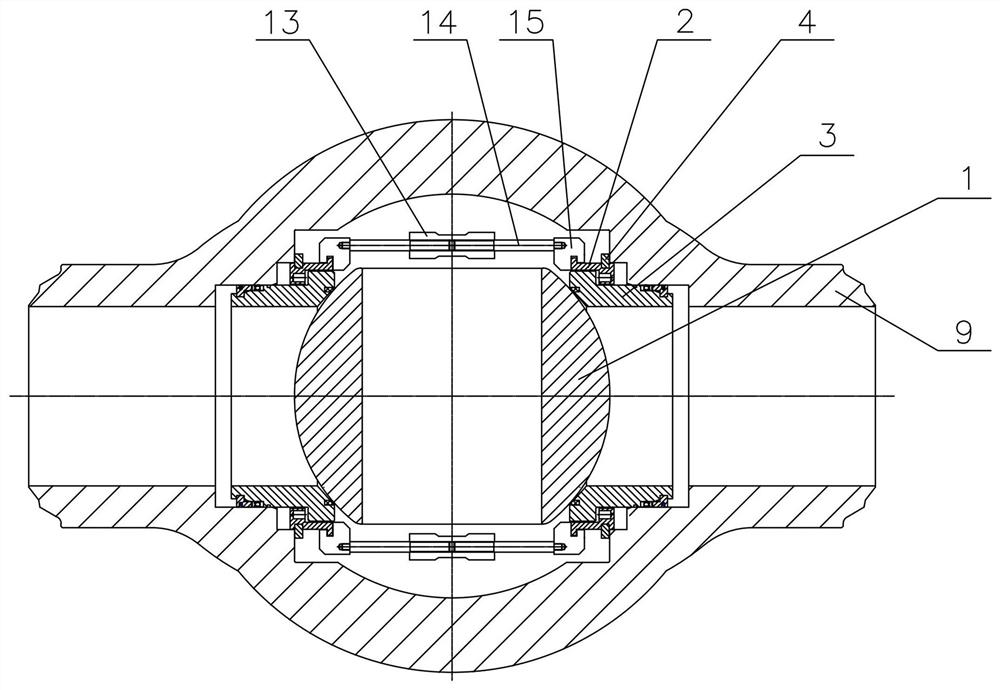

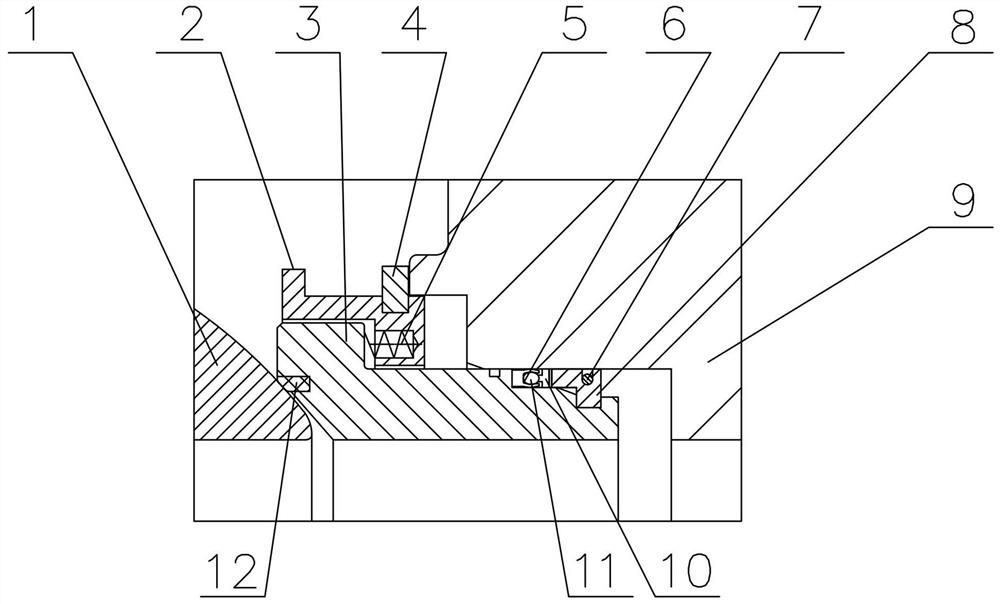

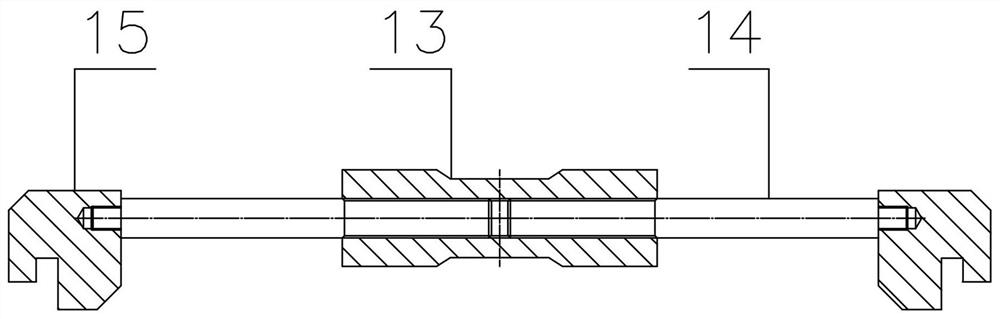

[0022] Such as figure 1 , figure 2 The top entry ball valve shown includes a valve body 9, a ball 1, and a valve seat 3. A rubber sealing ring 12 is embedded in the sealing surface of the valve seat 3 and cooperates with the ball 1 to form a soft seal pair. The valve seat 3 is from the end close to the ball 1 to the The outer circular surface at one end away from the sphere 1 has the first outer cylindrical surface, the second outer cylindrical surface, and the third outer cylindrical surface whose diameter gradually decreases, and the valve body 9 is made in the channel from the side of the valve cavity to the side away from the valve cavity. There are a first cylindrical cavity and a second cylindrical cavity with gradually decreasing inner diameters, and the dynamic sealing fit between the second outer cylindrical surface of the valve seat 3 and the inner wall of the second cylindrical cavity of the valve body 9 makes the second outer cylindrical cavity of the valve seat 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com