Patents

Literature

72results about How to "Applicable manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

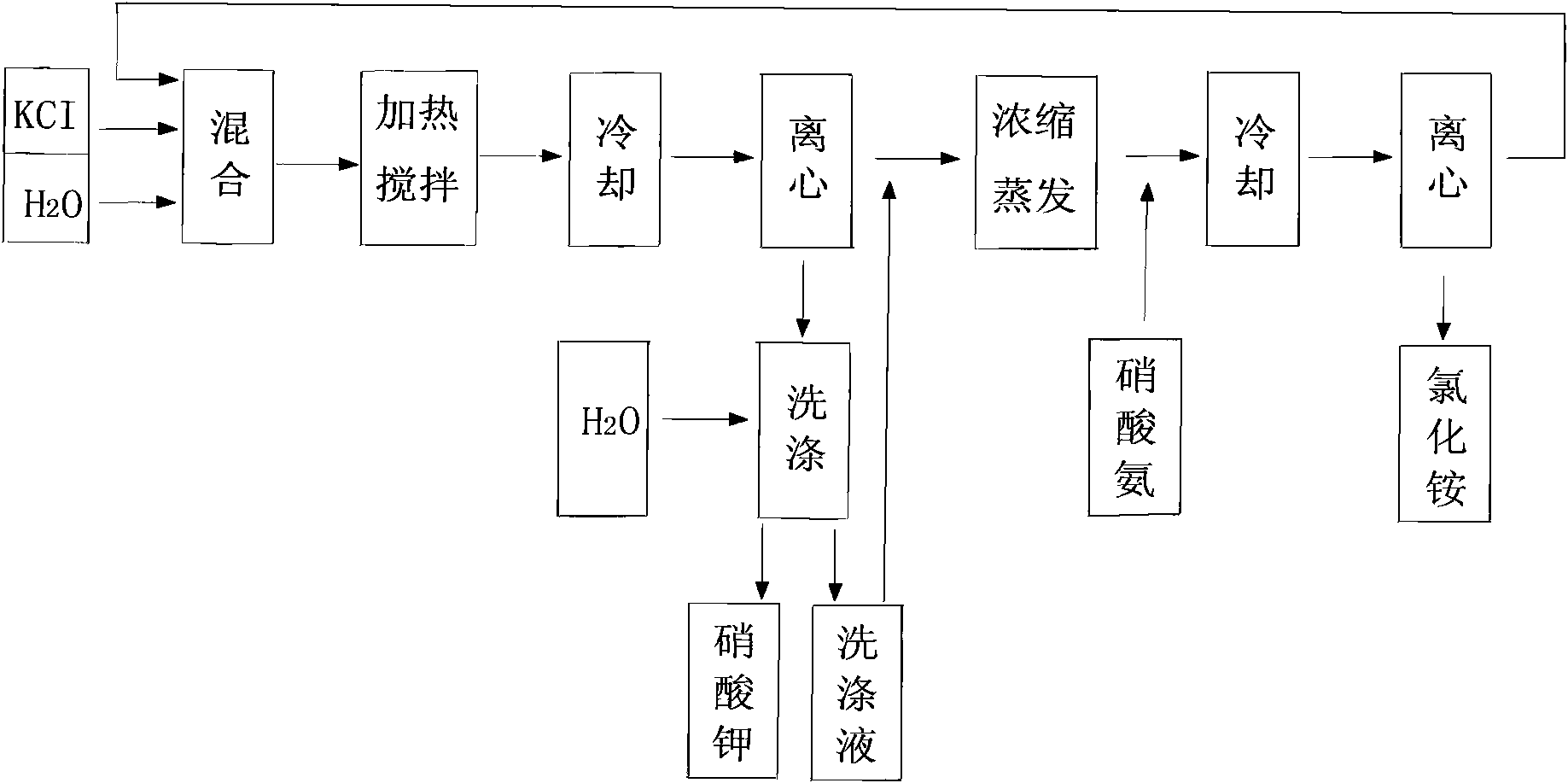

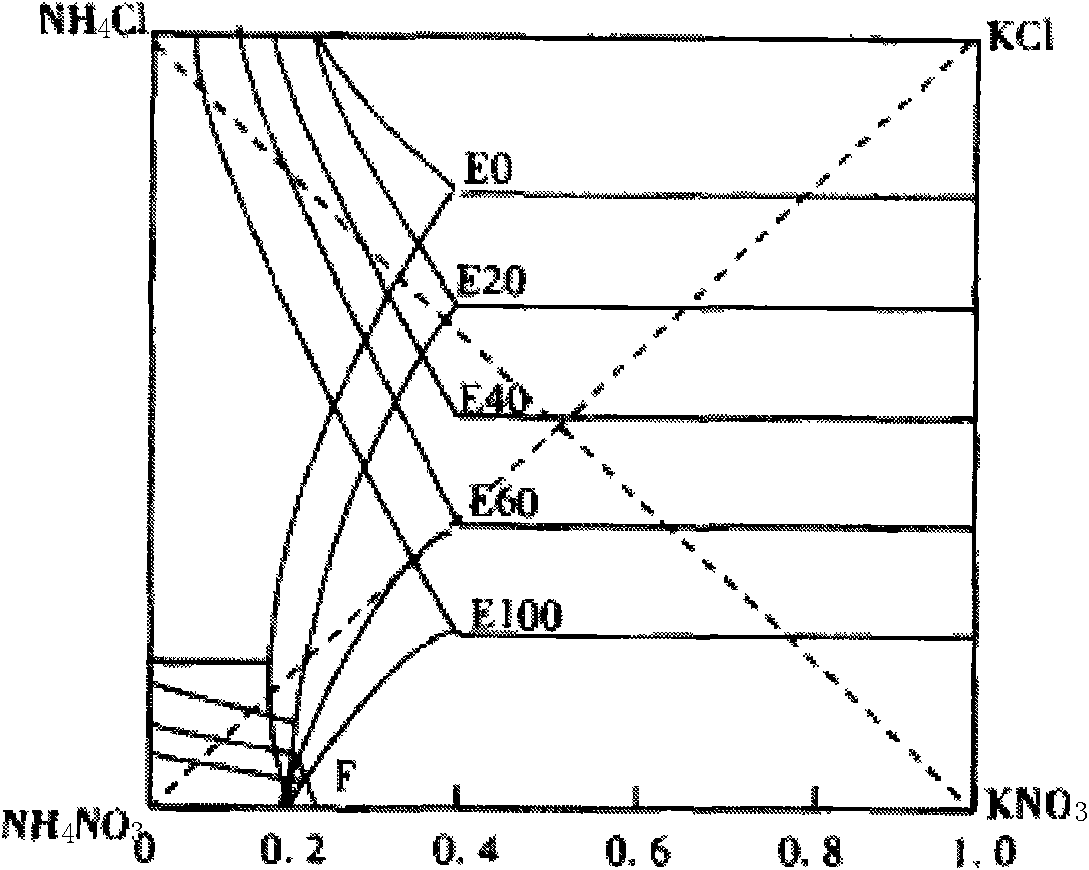

Method for preparing potassium nitrate and ammonium chloride employing double decomposition reaction

InactiveCN101628723ACreate pollutionRealize the concentrated evaporation processAlkali metal nitrate preparationAmmonium halidesDecompositionIon exchange

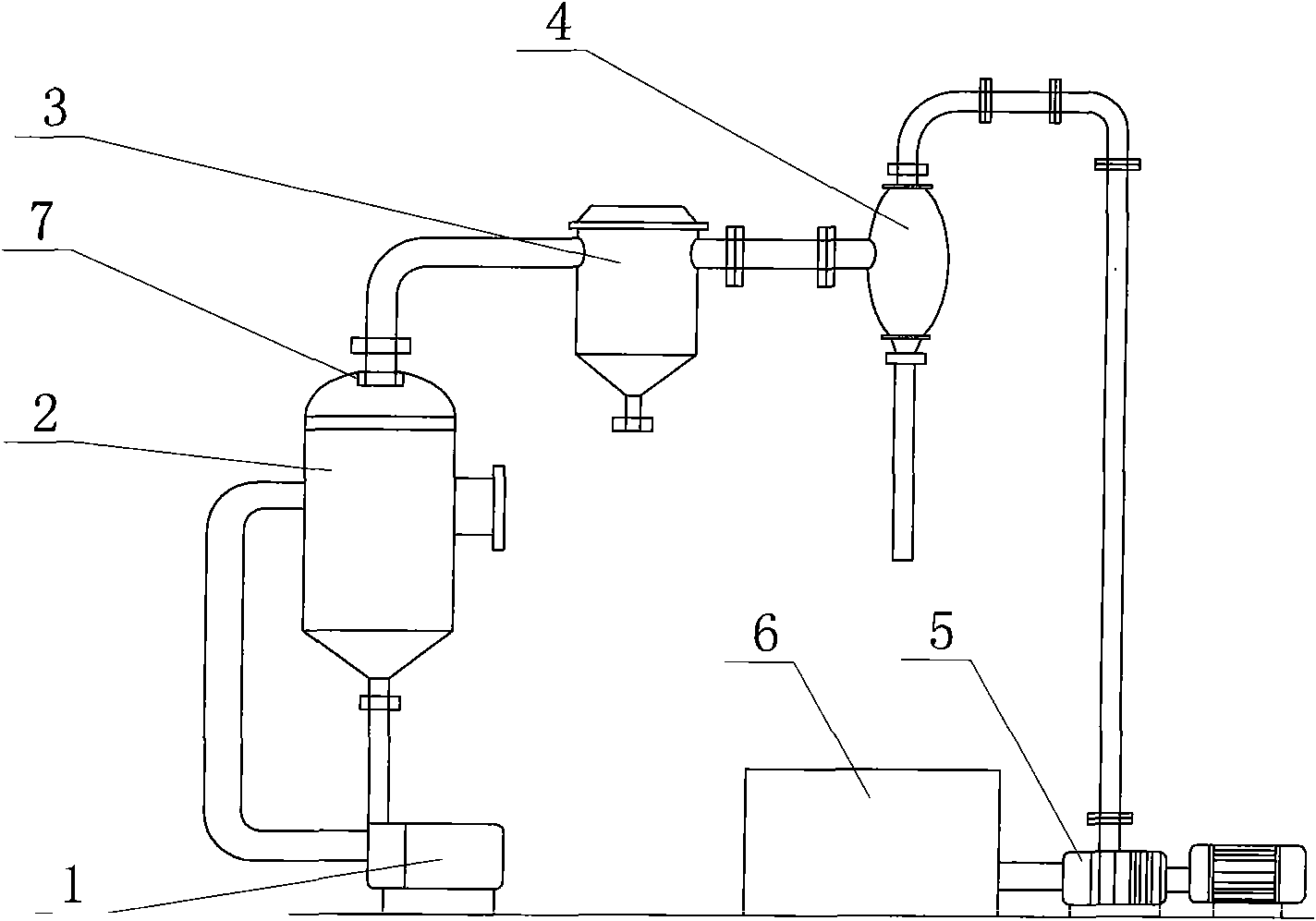

A method for preparing potassium nitrate and ammonium chloride employing double decomposition reaction comprises the following steps: dissolving ammonium nitrate and potassium chloride in water according to a defined ratio at 110 DEG C, continuously adding potassium chloride and water, heating while stirring to ensure that potassium nitrate is in supersaturation state, after stopping heating, cooling the solution in a vacuum cooling crystallizer to 36-40 DEG C to separate potassium nitrate crystal, placing the potassium nitrate crystal in a centrifugal machine with a filter cloth lining to obtain coarse potassium nitrate, then washing the potassium nitrate with cold water, drying to obtain the finished potassium nitrate; in addition, adding ammonium nitrate in mother solution I and cleaning solution to adjust solution concentration so that ammonium chloride can reach supersaturation state, using a vacuum concentration device to perform negative pressure evaporation, separating and precipitating ammonium chloride by centrifuging and obtaining a solid ammonium chloride product, wherein, when dissolving ammonium nitrate and potassium chloride, the ratio of ammonium ion to chlorine ion is 1:2 and when using the centrifugal machine to obtain the coarse potassium nitrate, the separated mother solution is another mother solution I sharing the same saturation point of potassium nitrate and ammonium chloride. The solution of feed liquid circular reaction overcomes the defects of the prior art that the price of potassium nitrate used in reaction is high, the resource of potassium nitrate is in short supply and the cost of devices used in ion-exchange method is high, thus being applicable to the production of potassium nitrate.

Owner:湖南丹化农资有限公司

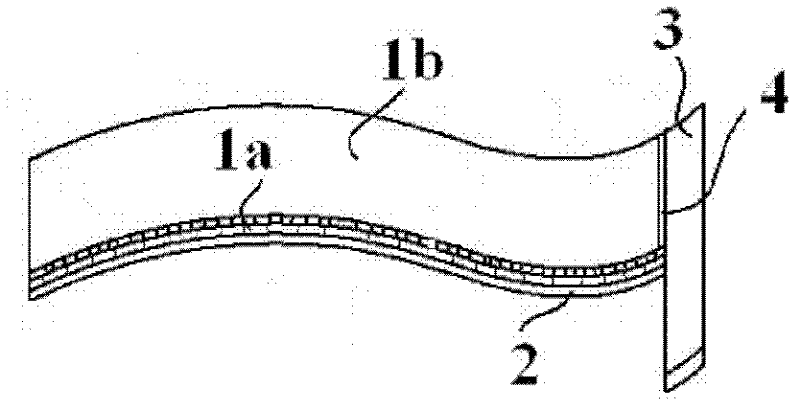

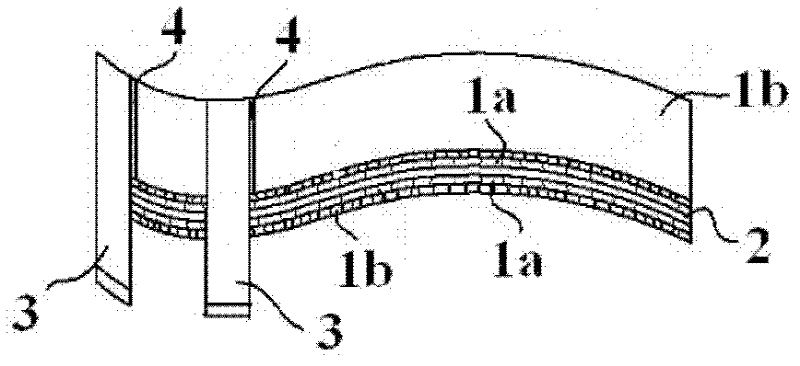

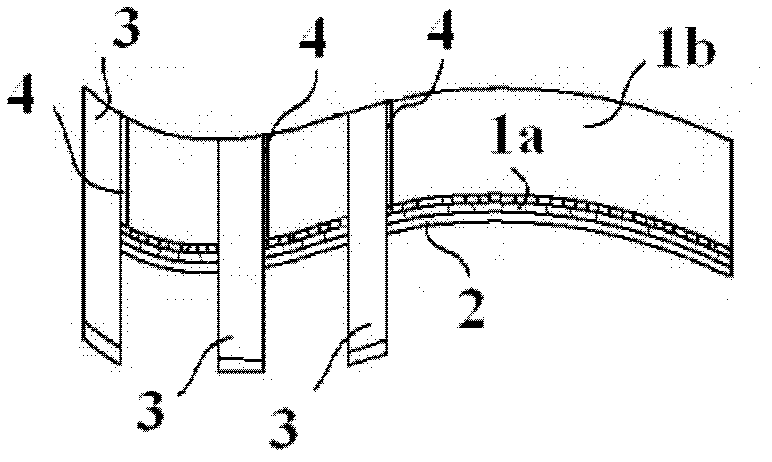

Composite material I-shaped stringer molding process

The invention provides a composite material I-shaped stringer molding process, which comprises: manufacturing a hard mold tool; manufacturing a soft mold process cover plate; manufacturing a lower edge strip soft mold; molding an I-shaped stringer core mold; molding an I-shaped stringer lower edge strip flat plate; molding an I-shaped stringer upper edge strip flat plate; molding a stringer wick strip; combining to obtain an I-shaped stringer tool; preparing a vacuum bag; curing; and demolding. According to the present invention, the part manufactured according to the process has good appearance quality, the generation of internal defects cannot be caused, the molding quality of the thin part can be improved, and the requirements on the manufacture precision and the matching precision of the molding tool are reduced so as to reduce the manufacturing cost of the part.

Owner:COMAC +1

Non-methanal environment-friendly type plant protein modified adhesion agent

InactiveCN101319131AMeet emission testing standardsSolve the hazardProtein adhesivesGlue/gelatin preparationFiberRapeseed

The invention relates to a formaldehyde-free environment-friendly vegetable protein modified adhesive, which aims to solve the problem that the prior urea-formaldehyde adhesive, phenolic aldehyde adhesive and melamine aldehyde adhesive release formaldehyde and cause environmental hazard and pollution, etc. The compositions in portion by weight of the modified adhesive are: 30 to 50 portions of natural plant dregs, 5 to 12 portions of basic material, 5 to 10 portions of calcium hydroxide emulsion, 6 to 15 portions of urea, 4 to 10 portions of alkyl sodium sulfate, 2 to 5 portions of 10 to 20 percent of inorganic acid and 90 to 120 portions of deionized water. The invention takes macromolecular proteins in natural plant soybean dregs, peanut dregs, rapeseed dregs, cottonseed dregs, linseed dregs and sunflower seed dregs as raw materials so as to synthesize a new-generation formaldehyde-free environment-friendly vegetable protein modified adhesive through chemical modification. The formaldehyde-free environment-friendly vegetable protein modified adhesive has the characteristics of uniform and stable product, high adhesion strength, hydrolysis resistance and nontoxicity, etc.; moreover, the performance and the price of the modified adhesive are suitable for wood adhesion and for making artificial fiber boards such as plywood, shaving board and fiber board.

Owner:上海世鹏聚氨酯科技发展有限公司

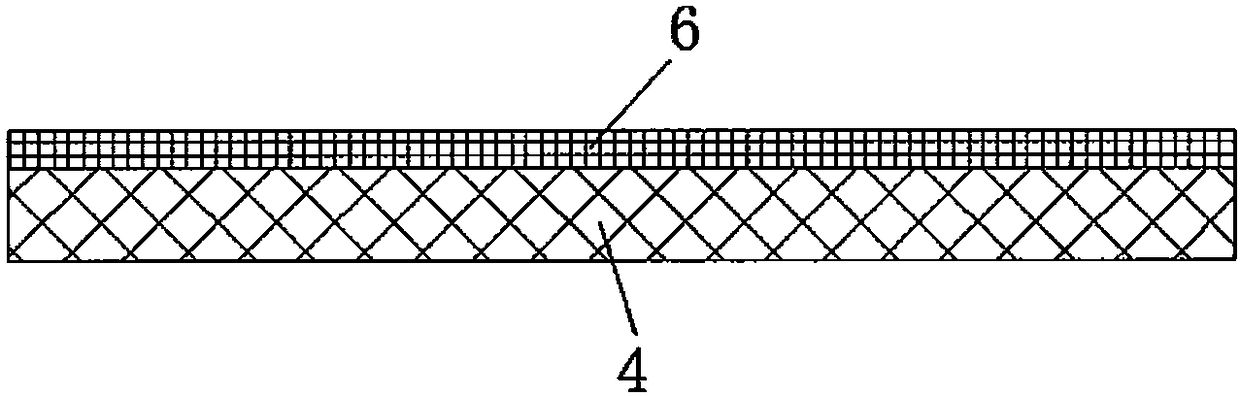

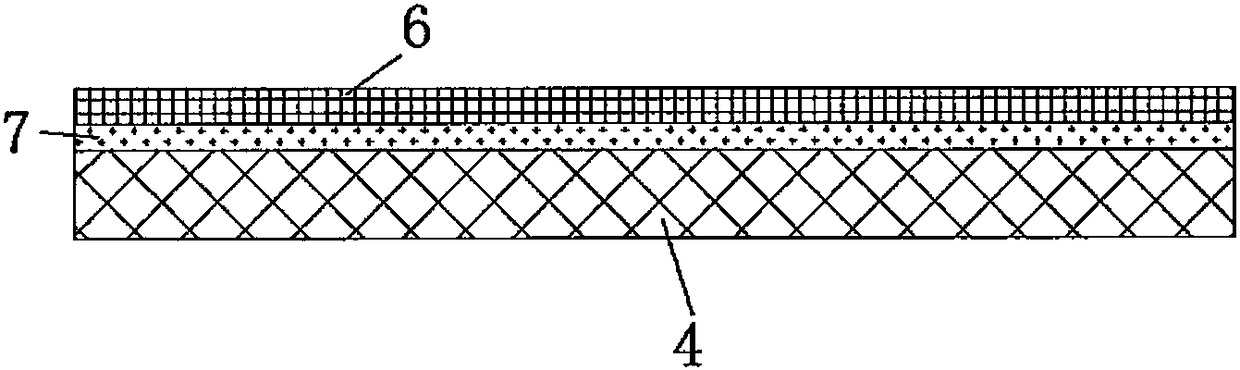

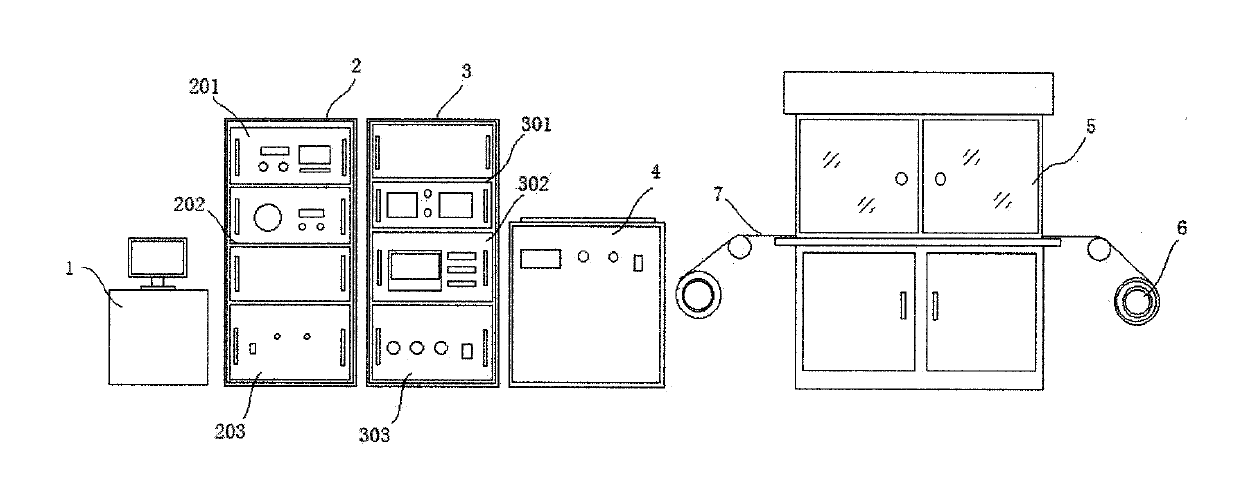

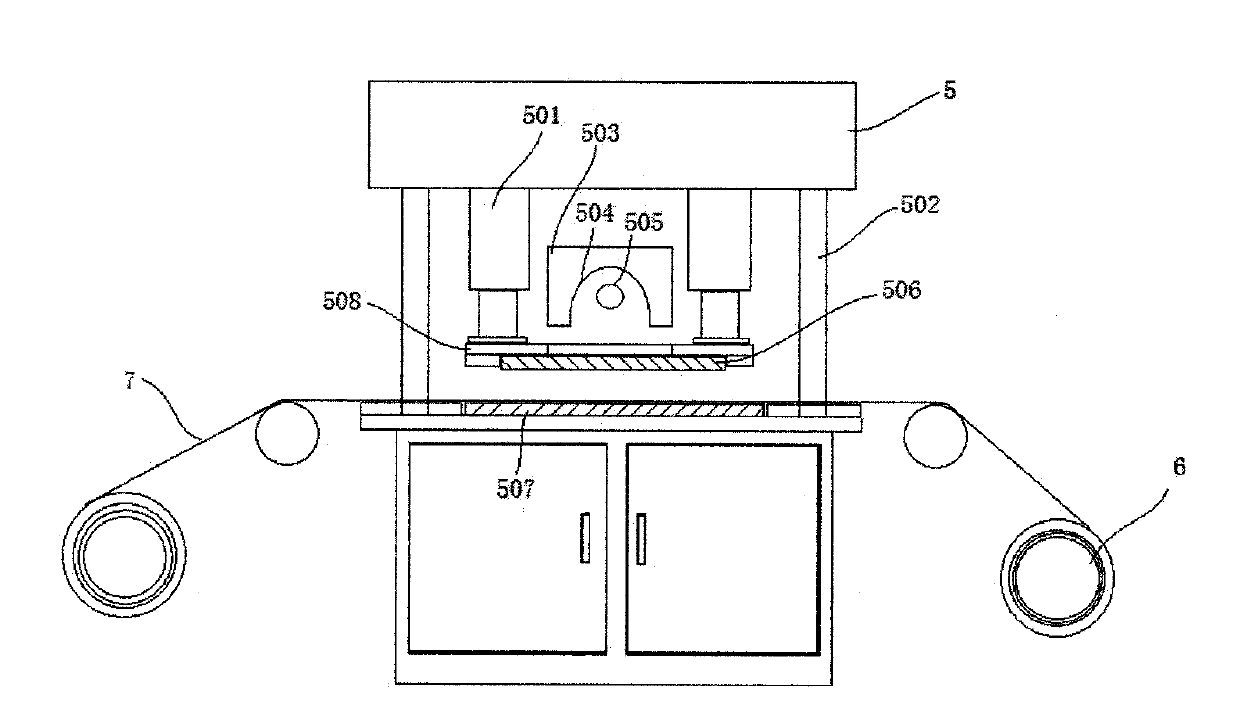

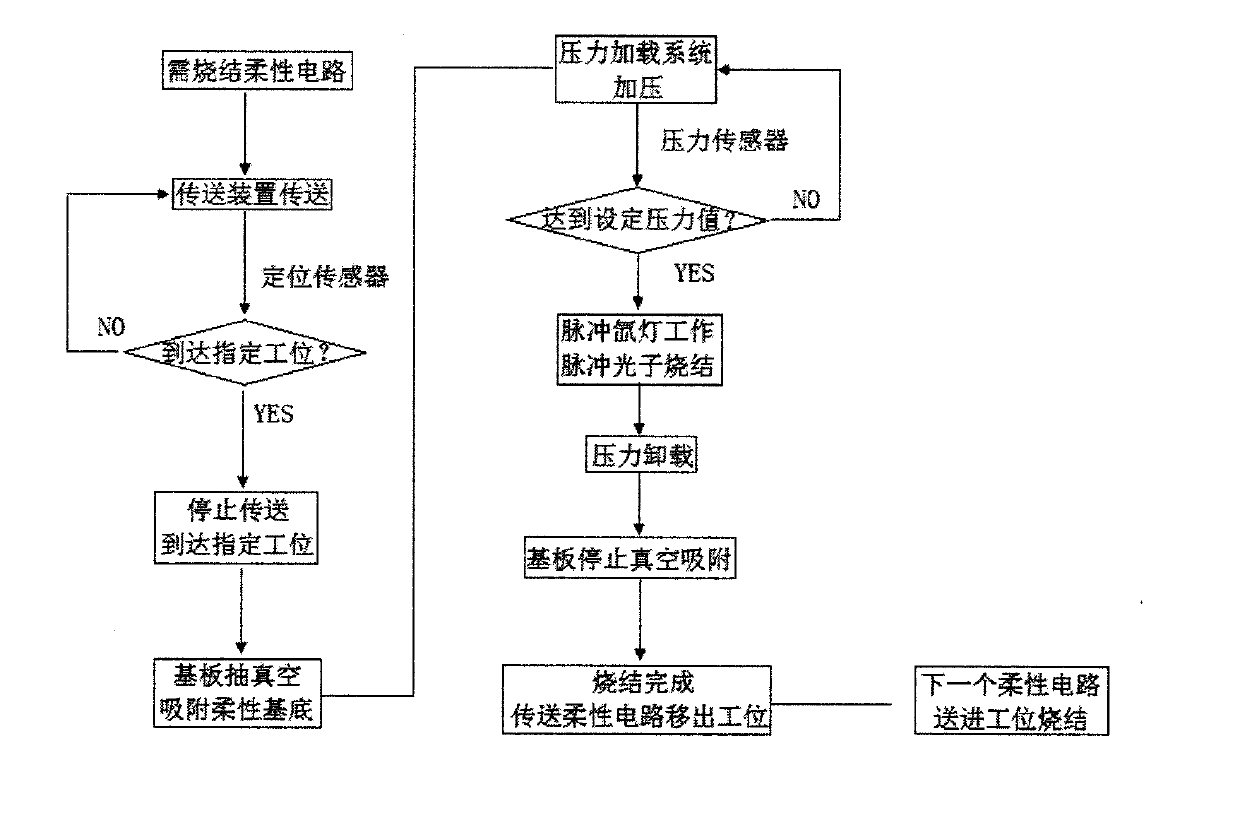

Manufacturing method and manufacturing device of flexible printed circuit

The invention discloses a manufacturing method and a manufacturing device of a flexible printed circuit. The method mainly includes the steps of providing an imaging flexible printed circuit substrate which is coated with nanometer conductive ink or sizing agents; exerting pressure to the flexible printed circuit substrate; and sintering the flexible printed circuit substrate by using xenon lamp sintering technology at the same time when the pressure is exerted and obtaining a target product. By means of the method, a printed circuit can be rapidly manufactured on a low temperature flexible substrate, a metal film which is good in binding force, electrical conductivity and compactness can be obtained, and manufacturing cost is low. The method avoids the processes such as photoetching in the manufacturing process of a traditional flexible printed circuit, rapid and pollution-free flexible printed circuit manufacturing is achieved, and the method is suitable for the production and the manufacture of the flexible printed circuit of the low temperature substrate.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

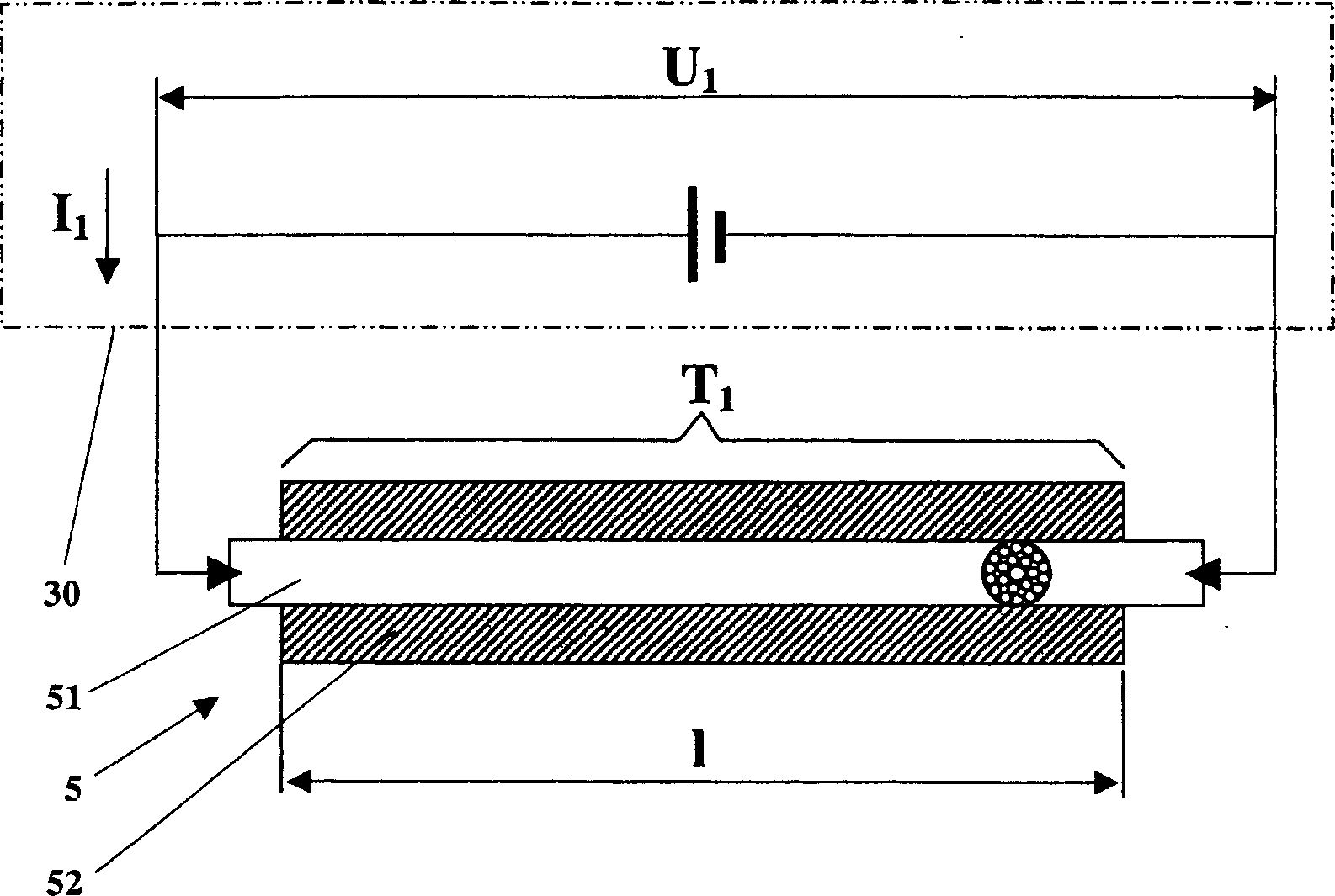

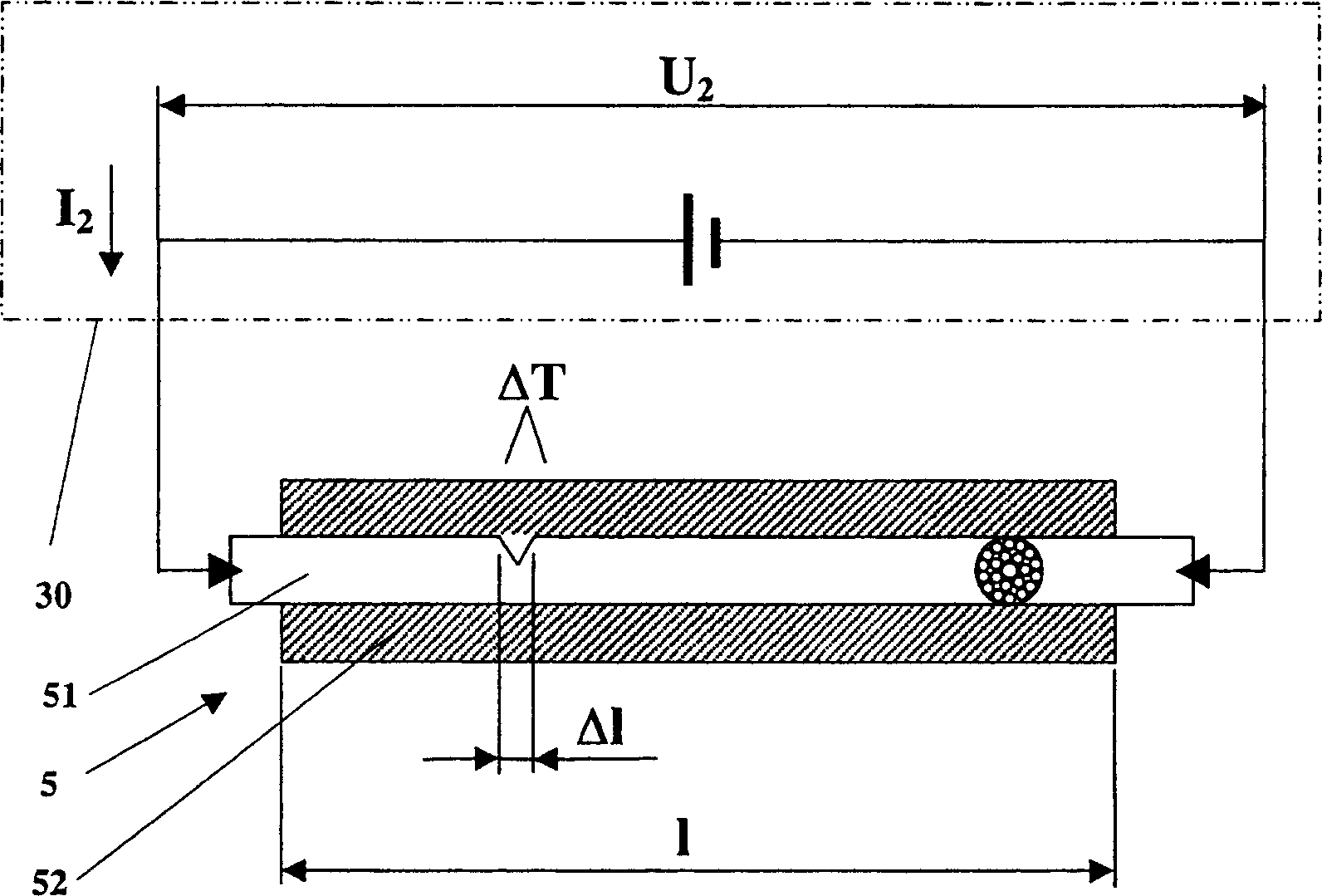

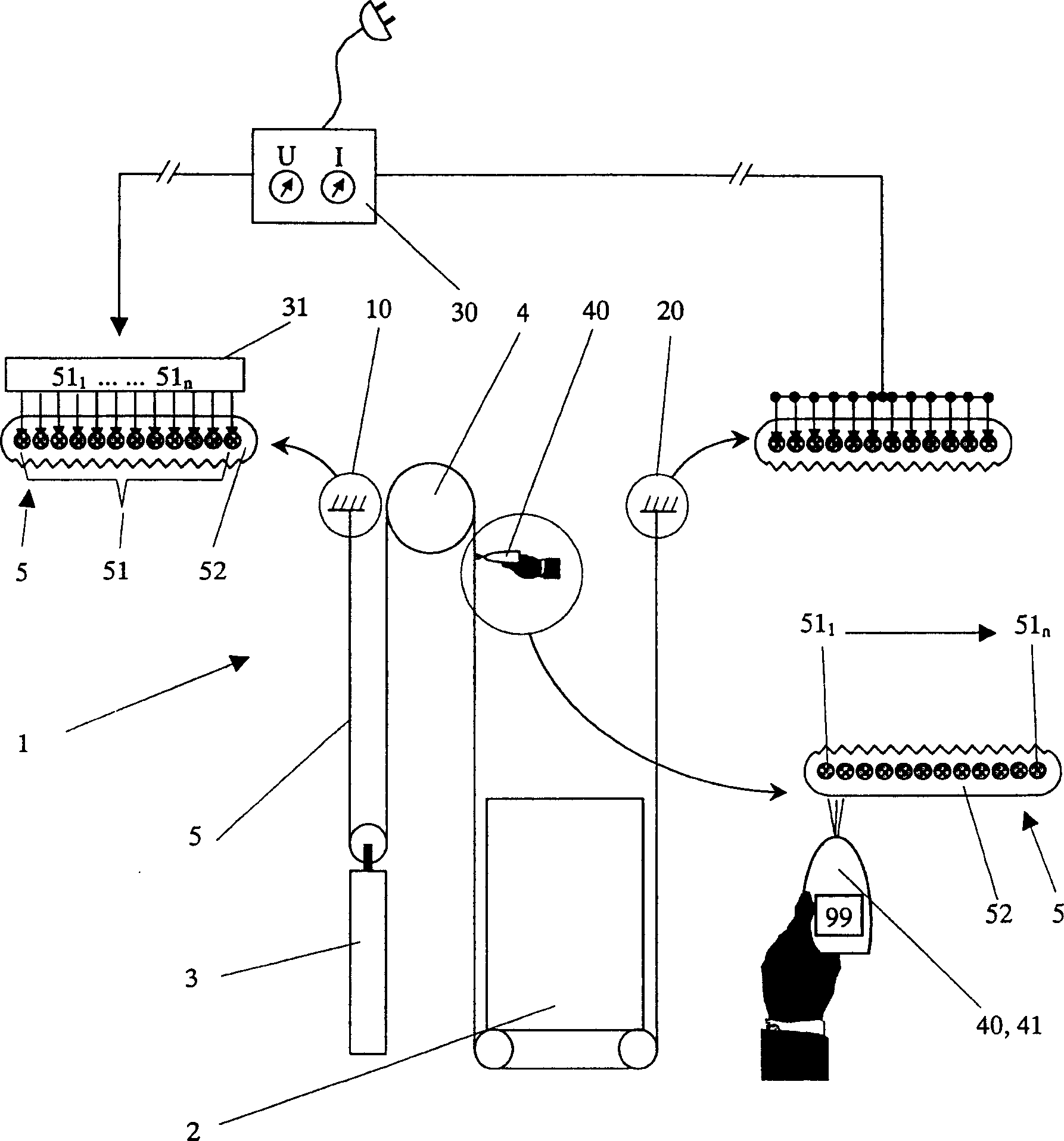

Method and device for checking carrying means

InactiveCN1613740AHigh currentIntense heatingThermometer detailsMaterial flaws investigationElectrical and Electronics engineering

The invention relates to a method for detecting a traction mechanism (5) and a device for detecting the traction mechanism (5). The device (1) is optimally suitable for elevator installations (1). The present invention is to detect the reduction of the cross-section of the loaded tensile carrier (51), wherein the tension carrier (51) is heated and its cross-section is reduced by means of current flow and the sheath surrounding said position (52) will be heated violently, the severe heating is determined by measuring the temperature of the surface of the traction mechanism. A determined temperature increase indicates the extent of damage to the tensile carrier.

Owner:INVENTIO AG

Manufacturing method of lithium iron phosphate-cobalt acid lithium composite anode plate of lithium ion battery

InactiveCN102386379AImprove high-current discharge performanceShort cycle lifeCell electrodesPole pieceSlurry

The invention discloses a manufacturing method of a lithium iron phosphate-cobalt acid lithium composite anode plate of a lithium ion battery, which comprises the following steps: A, ball-milling and uniformly mixing a nanometer cobalt acid lithium anode active material with a nanometer Super-C conductive agent in proportion to obtain a cobalt acid lithium active material mixture; uniformly mixing the mixture with polyvinylidene fluoride; mixing the mixture with sodium carboxymethylcellulose to obtain anode active material slurry; B, preparing the anode active material slurry: ball-milling and uniformly mixing nanometer lithium iron phosphate with the nanometer Super-C conductive agent in proportion to obtain a lithium iron phosphate active material mixture; mixing the mixture with the sodium carboxymethylcellulose in proportion; adding distilled water into the mixture, ball-milling and mixing uniformly to obtain anode active material slurry B; and C, coating the slurry A on a single surface of an anode current collector, and coating the slurry B on double surfaces of an initial pole piece according to coating process, thus obtaining an anode pole piece. A nickel-metal hydride battery prepared by the invention has high volume, high multiplying power, a good discharging effect, and long circulating service life.

Owner:广州云通锂电池股份有限公司 +1

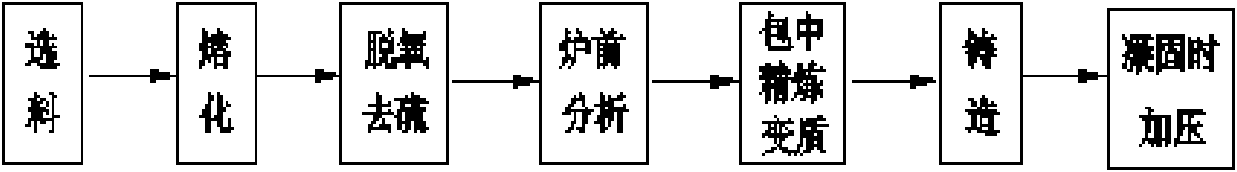

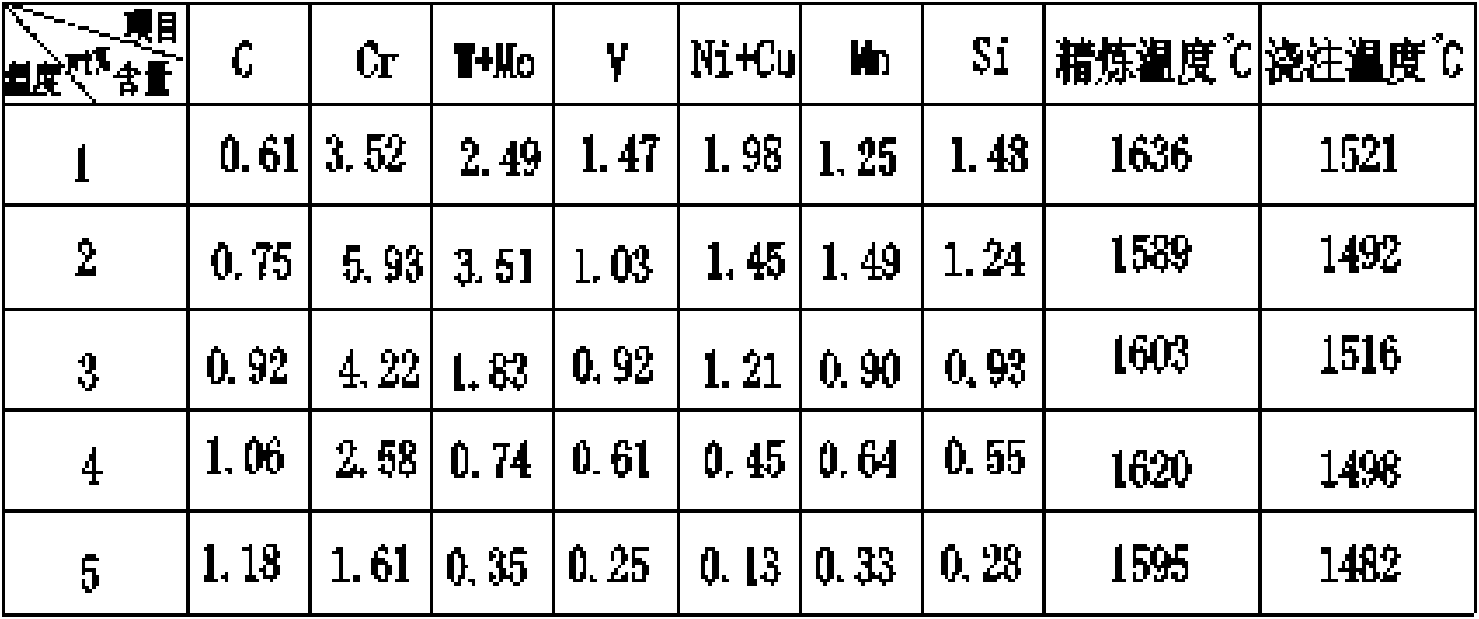

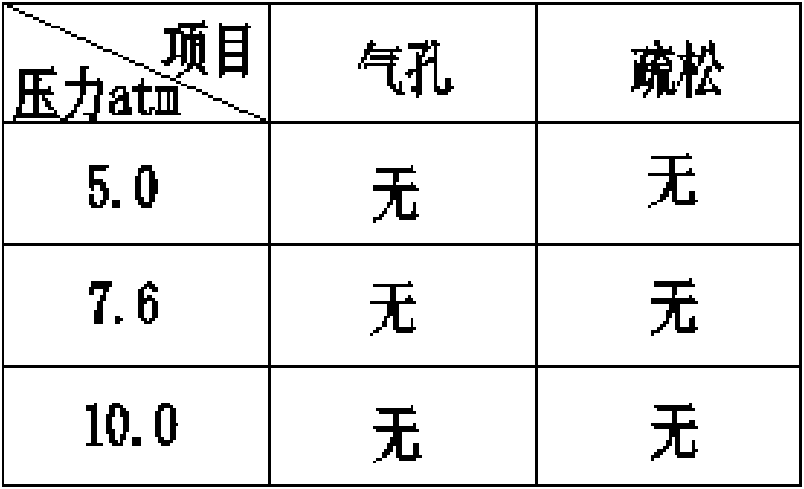

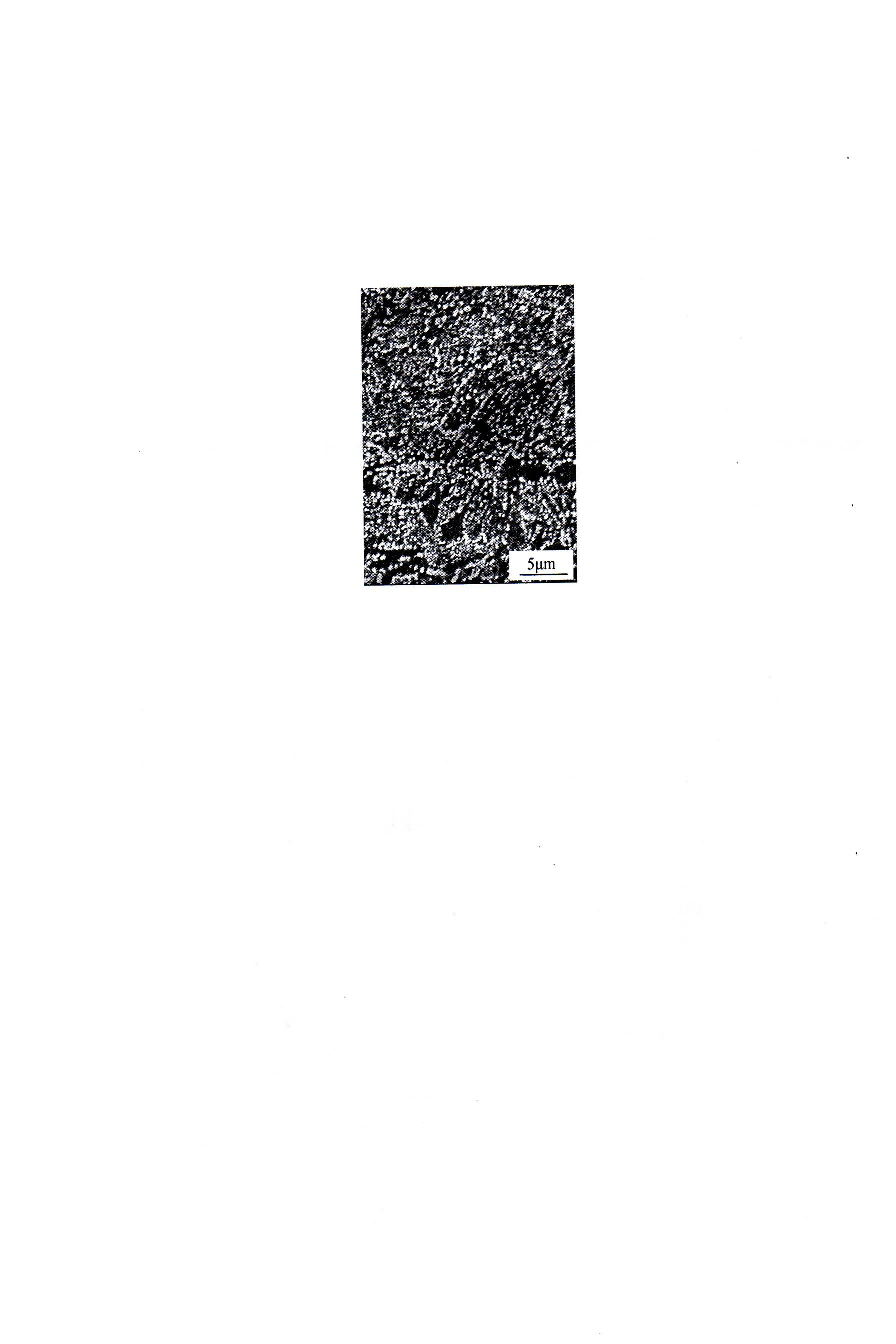

Method for refining, metamorphosing and casting cold roll steel by casting instead of forging

InactiveCN101798660AReasonable alloy contentReasonable carbon contentElectric furnaceProcess efficiency improvementWork rollCarbide

The invention discloses a method for refining, metamorphosing and casting cold roll steel by casting instead of forging. A work roll sleeve or a work layer of the cold roll steel comprises the following chemical components in percentage by weight: 0.6 to 1.2 percent of C, 0.2 to 1.5 percent of Si, 0.3 to 1.5 percent of Mn, 1.6 to 6.0 percent of Cr, less than or equal to 3.5 percent of W and Mo, less than or equal to 1.5 percent of Ni and Cu, less than or equal to 1.5 percent of V, less than or equal to 0.15 percent of Re, less than or equal to 0.10 percent of Ba and Mg, less than or equal to 0.05 percent of K and Na, less than or equal to 0.015 percent of S, less than or equal to 0.002 percent of O and the balance of ferrum, and trace impurities which are difficult to measure; and a work layer of a supporting roll comprises the following chemical components in percentage by weight: 0.4 to 1.0 percent of C, 0.3 to 2.0 percent of Si, 0.6 to 2.5 percent of Mn, 1.0 to 4.5 percent of Cr, less than or equal to 1.5 percent of W and Mo, less than or equal to 1.5 percent of Ni and Cu, less than or equal to 1.0 percent of V, less than or equal to 0.15 percent of Re, less than or equal to 0.10 percent of Ba and Mg, less than or equal to 0.05 percent of K and Na, less than or equal to 0.02 percent of S and less than or equal to 0.003 percent of O. Liquid steel is refined repeatedly and metamorphosed complexly in and out of a furnace to improve the purity of the steel and refine metallographic structures and carbide particles; gas protection and liquid steel filtration are performed in the process of steel taping and casting; and the metallurgical fusion of a metal type blank for making the roll sleeve and a roll core is performed during casting by a CPC method to prepare a composite cold roll, so the method has remarkable energy saving and consumption reduction benefits.

Owner:段岳君

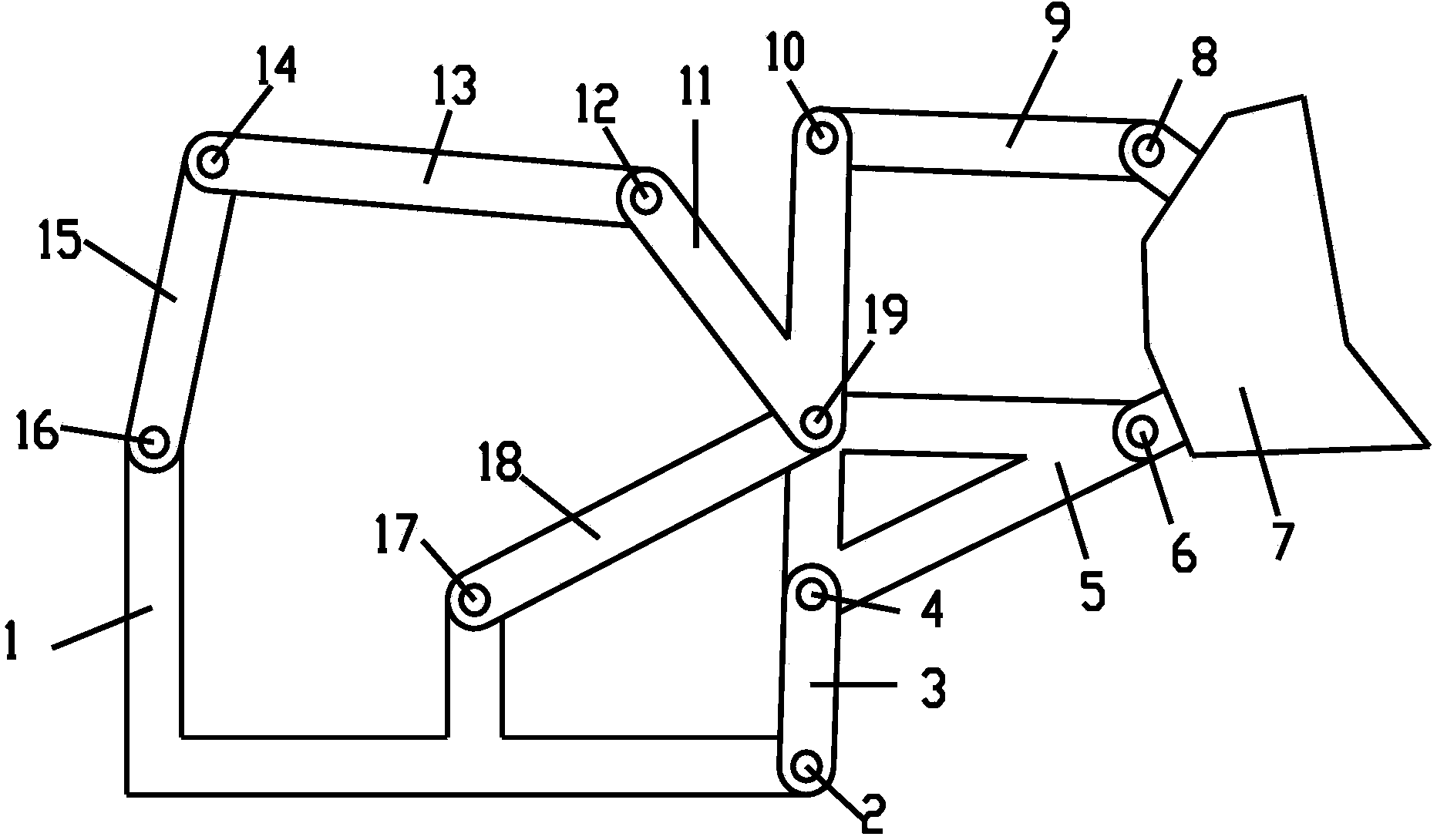

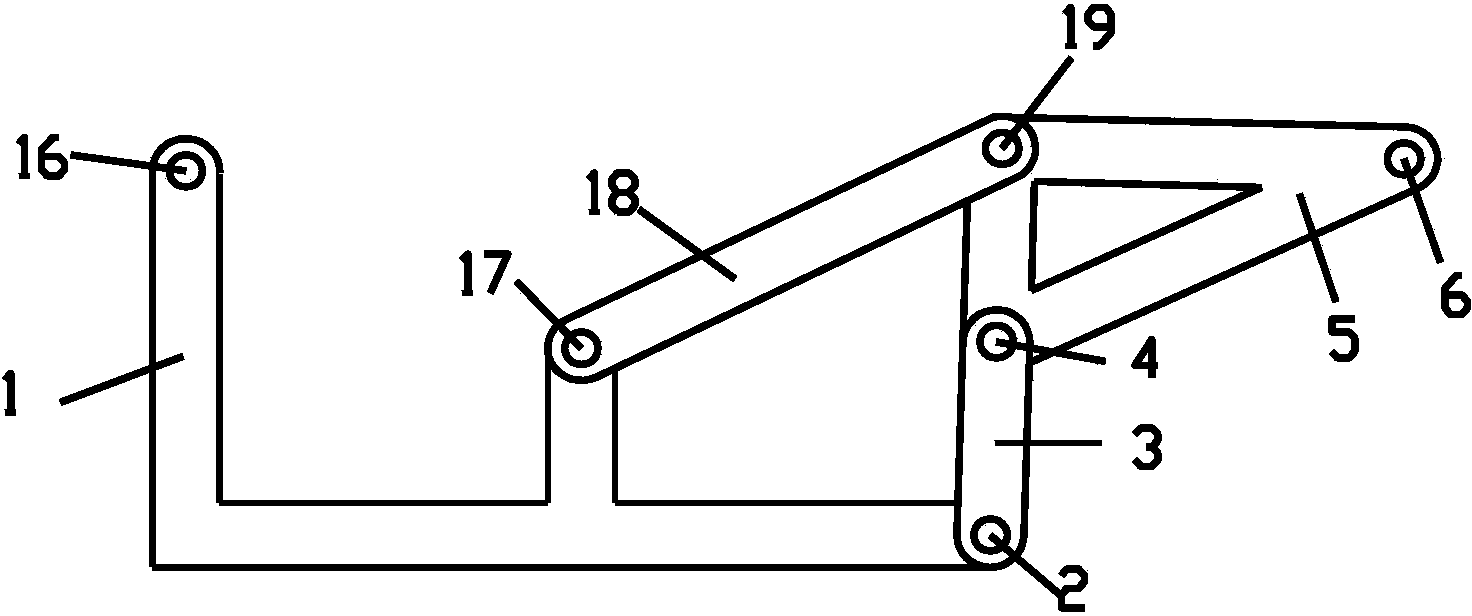

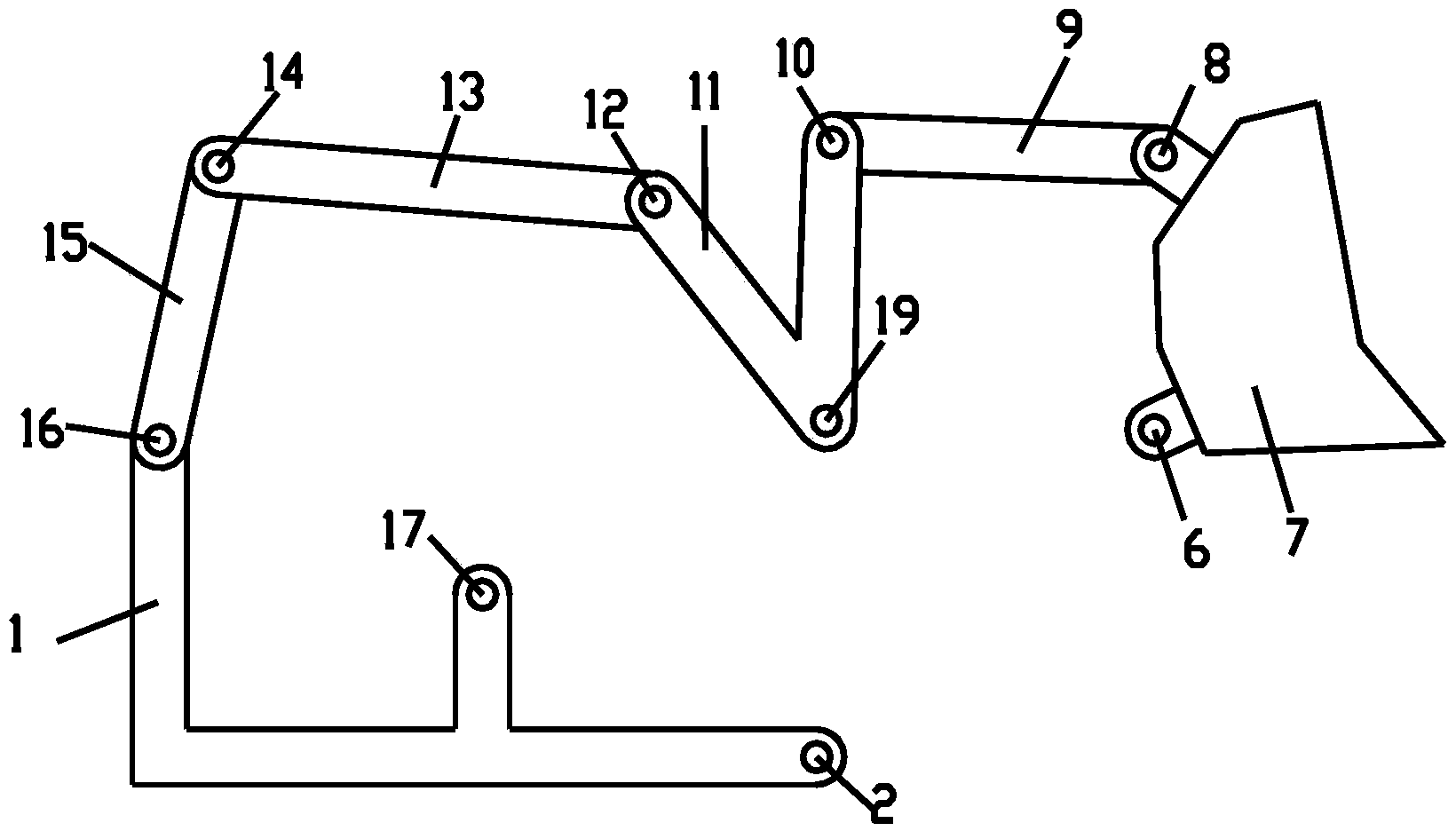

Loading mechanism adopting MDOF (multiple degree of freedom) controllable connecting rods

The invention discloses a loading mechanism adopting MDOF (multiple degree of freedom) controllable connecting rods. Two ends of a second driving lever of a lifting mechanism are connected with a stander and a first end of a first support frame respectively; two ends of a third connecting rod are connected with the stander and a second end of the first support frame, and a third end of the first support frame is connected with a bucket; two ends of a first driving lever of a bucket turnover mechanism are connected with the stander and one end of a first connecting rod respectively, the other end of the first connecting rod is connected with a first end of a second support frame, a second end of the second support frame is connected with one end of the a second connecting rod, a third end of the second support frame is connected with the second driving lever, and the other end of the second connecting rod is connected with the bucket. The loading mechanism can solve the defects that a traditional hydraulic loading machine is complicated in system, easy to leak oil, high in machining precision requirement and the like, and has the advantages of an MDOF controllable mechanism type loading machine, such as flexibility, rapid action and the like; moreover, a connecting rod transmission part is more simple, each rod and each joint bear force batter, and a work space is larger, so that the loading mechanism is more suitable for manufacturing various loading machines and other engineering machinery.

Owner:GUANGXI UNIV

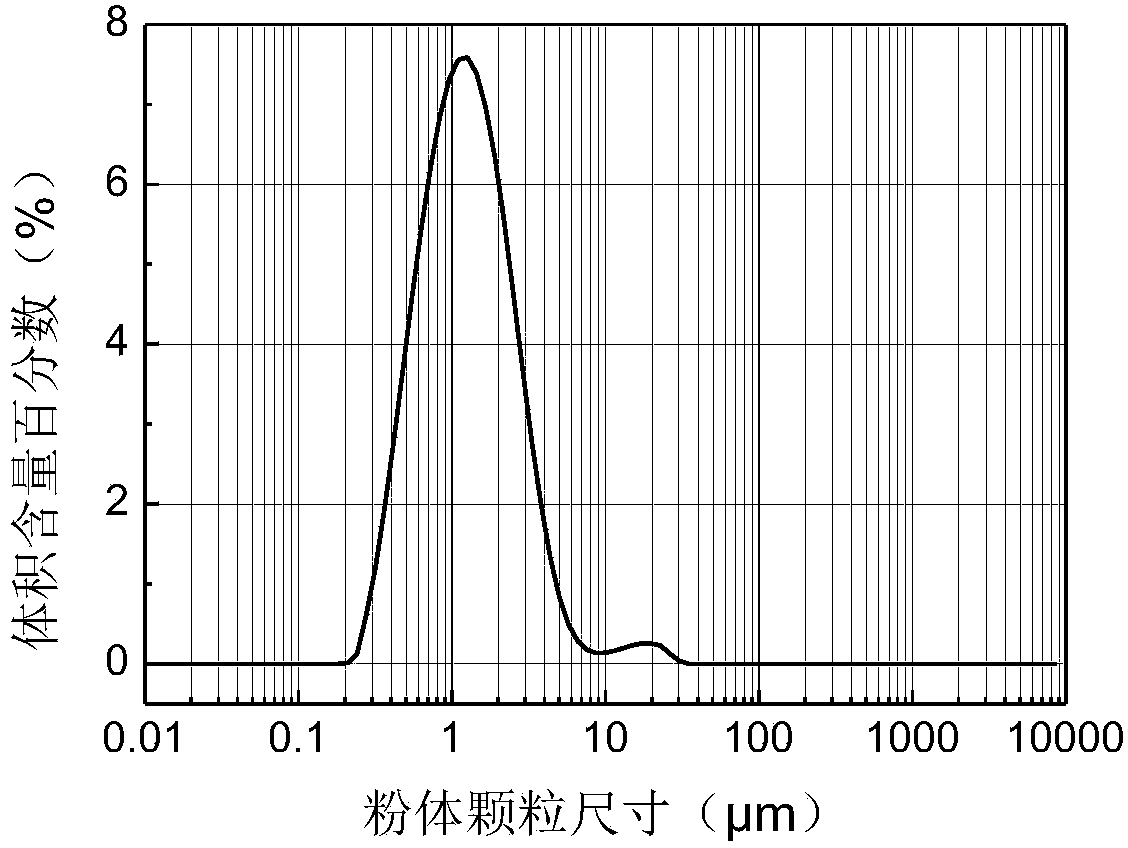

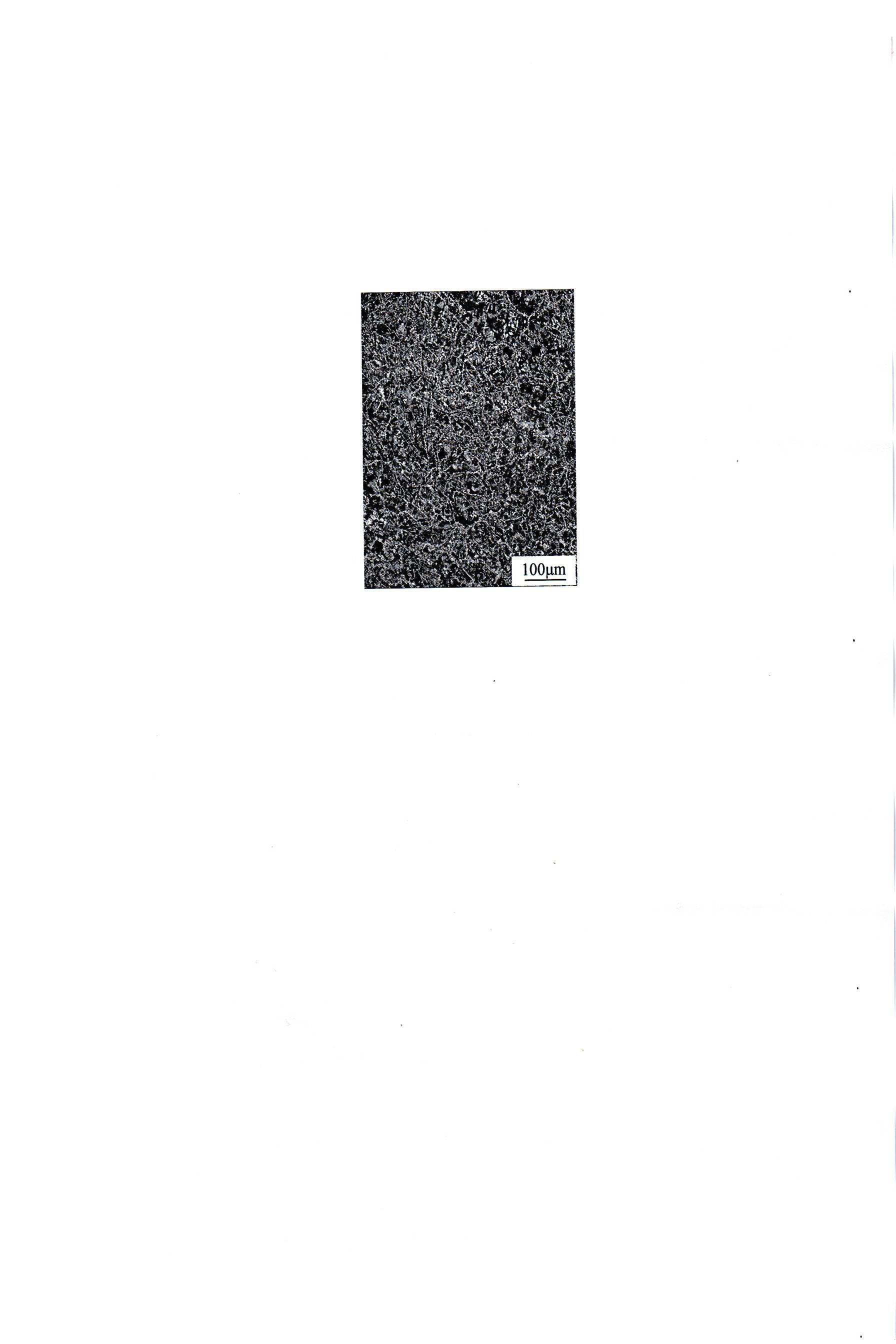

Selected region laser sintering and molding method of ultrahigh molecular weight polyethylene

ActiveCN105172154AImprove mechanical propertiesHigh dimensional accuracyAdditive manufacturing apparatusCeramic shaping apparatusSelective laser sinteringLaser scanning

The invention discloses a selected region laser sintering and molding method of ultrahigh molecular weight polyethylene. The selected region laser sintering and molding method comprises the following steps: (1) heating ultrahigh molecular weight polyethylene powder in selected region laser sintering and molding equipment to a pre-heated temperature; (2) molding the ultrahigh molecular weight polyethylene powder in the selected region laser sintering and molding equipment by adopting pre-set laser scanning speed and output power to obtain a molded piece; and (3) taking out the molded piece and keeping the heat at a temprature of 110-130 DEG C for 8-12 hours, and then cooling to obtain a molded part of the ultrahigh molecular weight polyethylene. The molded part of the ultrahigh molecular weight polyethylene, molded by the method disclosed by the invention, has relatively high mechanical property and size precision, has small transformation shrinkage and is particularly suitable for manufacturing medical auxiliary tools.

Owner:安徽隆源成型科技有限公司

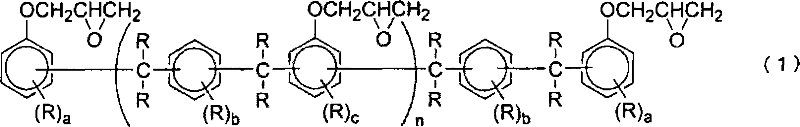

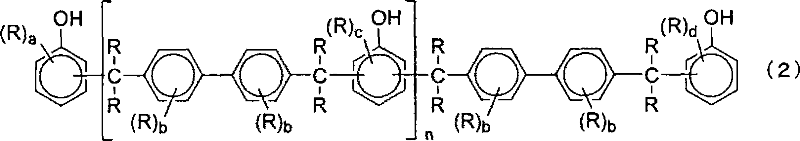

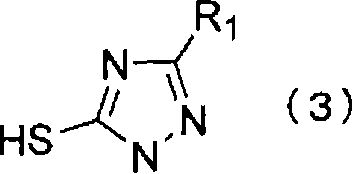

Epoxy resin composition and semiconductor device

ActiveCN101039984AGood adhesionExcellent resistance to solder reflowSemiconductor/solid-state device detailsSolid-state devicesEpoxyInorganic filler

Disclosed is an epoxy resin composition for semiconductor encapsulation which exhibits high flame retardance without using a flame retardance-imparting agent, while having excellent solder reflow resistance. Also disclosed is a semiconductor device obtained by sealing a semiconductor element using such an epoxy resin composition. The epoxy resin compositions for semiconductor encapsulation of first, second and third aspects are characterized by containing (A) a phenolaralkyl-type epoxy resin having a phenylene skeleton, (B) a phenolaralkyl-type phenol resin having a biphenylene skeleton, and (D) an inorganic filler as the common essential components. The epoxy resin compositions are further characterized in that the inorganic filler (D) is contained in an amount of 84-92% by weight of the total epoxy resin composition.

Owner:SUMITOMO BAKELITE CO LTD

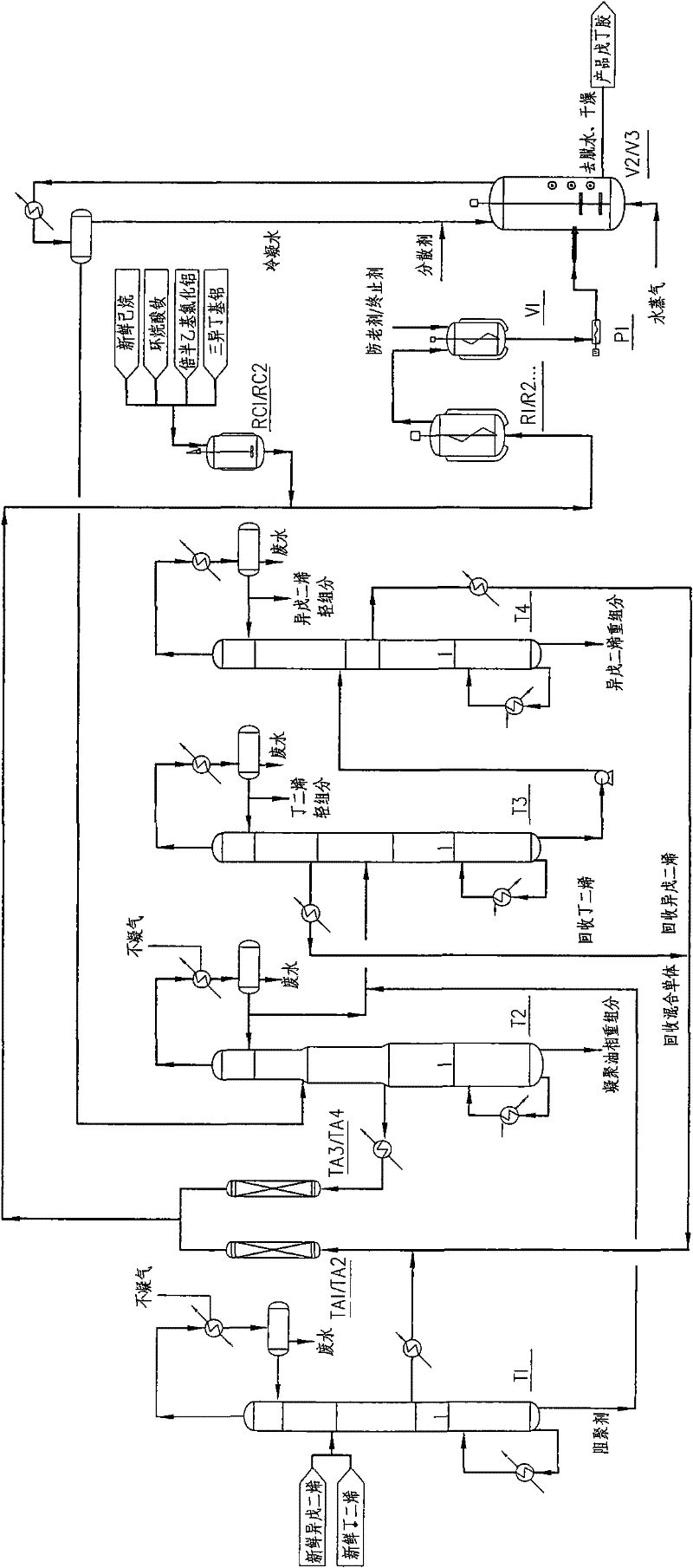

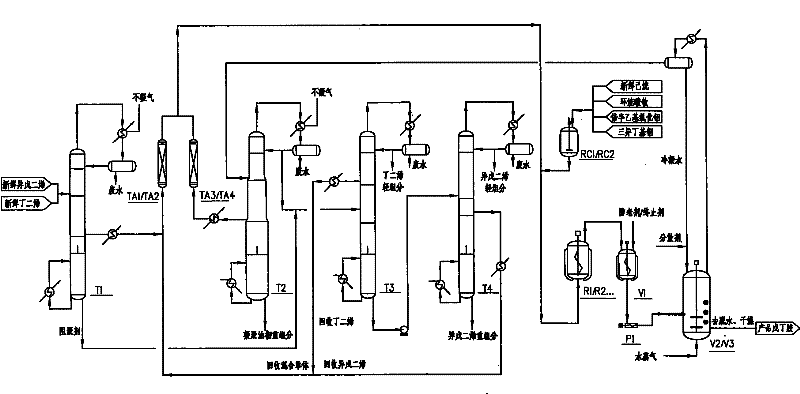

Method for producing rare-earth isoprene butadiene rubber

ActiveCN102234356AIncrease production energy consumptionReduce production energy consumptionSpecial tyresPolymer scienceRare earth

The invention discloses a method for producing rare-earth isoprene butadiene rubber. Two refined monomers, namely isoprene and 1, 3-butadiene are proportioned and mixed, and subjected to polymerization reaction in the presence of a rare earth catalyst to form random copolymer rubber. A multi-tower circular preparation process flow is adopted, and the problem of low purity of recovered monomers and solvents caused by crossed boiling points of various monomers and impurities thereof is solved, so that the production efficiency and molecular weight of the rare-earth isoprene butadiene rubber areimproved and the whole production cost is reduced. In the rare-earth isoprene butadiene rubber, the molar content of polyisoprene units is 40 to 90 percent, the cis-content in the polyisoprene units is more than 95 percent, the cis-content in polybutadiene units is more than 99 percent, the weight-average molecular weight is 2,000,000 to 3,000,000, the molecular weight distribution is 3 to 7, andthe anti-ageing agent content is 1 to 2 percent. The rare-earth isoprene butadiene rubber copolymer can replace a binary blend of natural rubber (or high cis-isoprene rubber) and butadiene rubber, and has the characteristics of capacity of being easily mixed, low themogenesis, wear resistance, crack growth resistance and the like.

Owner:FUSHUN YIKESI NEW MATERIAL

Potassium niobate sodium-based multi-layer piezoelectric ceramic element and preparing method thereof

ActiveCN104051606AImprove piezoelectric performanceGuaranteed performanceMagnetostrictive device manufacture/assemblyElectromechanical coupling coefficientDielectric permittivity

The invention provides a potassium niobate sodium-based multi-layer piezoelectric ceramic element. A chemometry general form of a formula of potassium niobate sodium-based leadless piezoelectric ceramics is that [(Na0.52K0.44)1-xLix] (Nb0.93-ySb0.07Tay)O3, wherein 0.02<=x<=0.06, 0.02<=y<=0.06, a piezoelectric constant ranges from 300 pC / N to 350 pC / N and even higher, a dielectric constant ranges from 1700 to 2000, and an electromechanical coupling coefficient ranges from 0.40 to 0.45.

Owner:PAIHE SCI & TECH HLDG CO LTD BEIJING +1

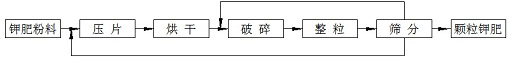

Manufacture method of particle potash fertilizer

InactiveCN102249766AExtended service lifeIncrease surface tensionPotassium fertilisersFertilizer mixturesTemperature controlCrusher

The invention provides a manufacture method of a particle potash fertilizer. A potash fertilizer qualified finished product with a particle size of 2-5.6mm is prepared by tabletting, drying, fragmentation, granulation and screening, with powdered potash fertilizer produced by a water-salt method as the raw material. The raw material powdered potash fertilizer has a water content less than 4.0%. A pressure roller gap of a tablet machine needs to be adjusted to control a tabletting thickness during tabletting and granulation; a depth of a roller skin pattern groove of a pressure roller is 5-8mm; a long shaft is 45-50mm; a short shaft is 35-45mm; and a pressure of a pressure roller wire is no less than 5KN / cm. A turn-over type of dryer is employed for drying with a temperature controlled lower than 220 DEG C and a water content lower than 1.5%. A roller gap of a crusher is adjusted to 3-8mm during fragmentation. After granulation, particles need to be graded; particles with a particle size less than 2mm are recovered to the tabletting step for further treatment, and particles with a particle size larger than 5.6mm are recovered to the fragmentation step for further treatment until having a qualified particle size. During screening, a first screen has a mesh count of 3-5 mesh, and a second screen has a mesh count of 17-19 mesh. Fragmented particles are granulated by a granulator to have smooth edges, so as to reduce powder generated during transportation.

Owner:SDIC XINJIANG LUOBUPO POTASH CO LTD

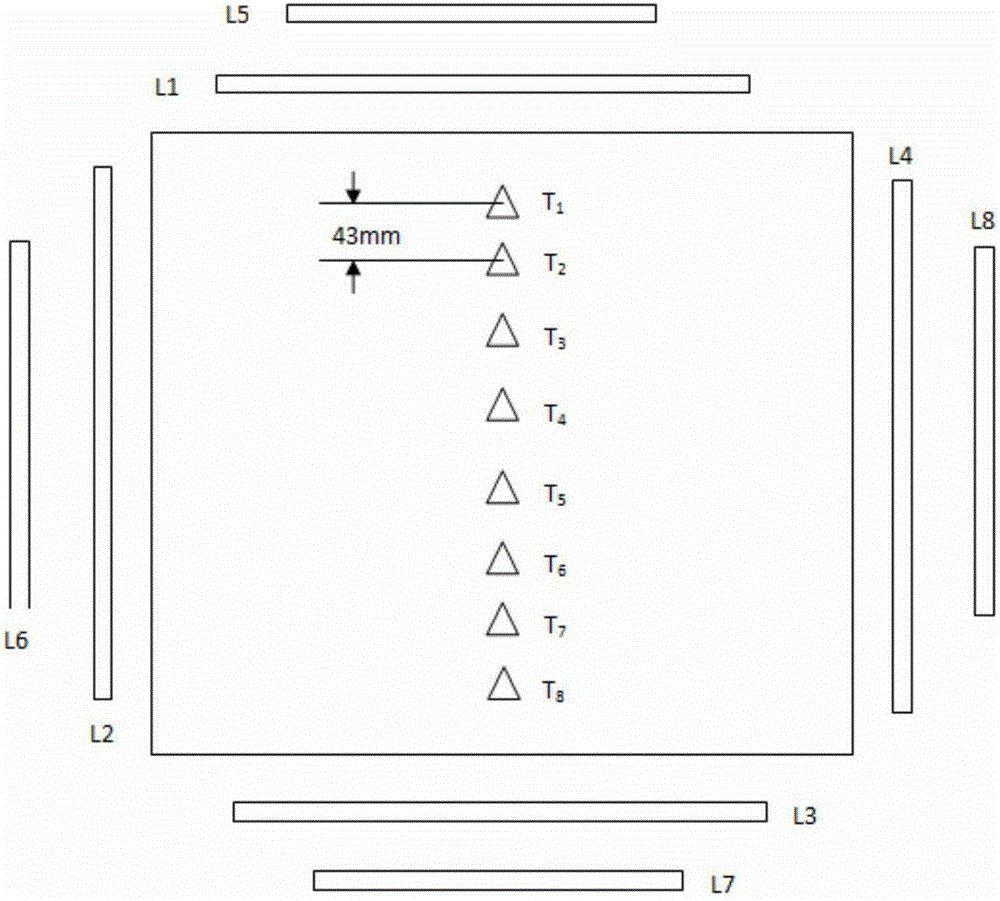

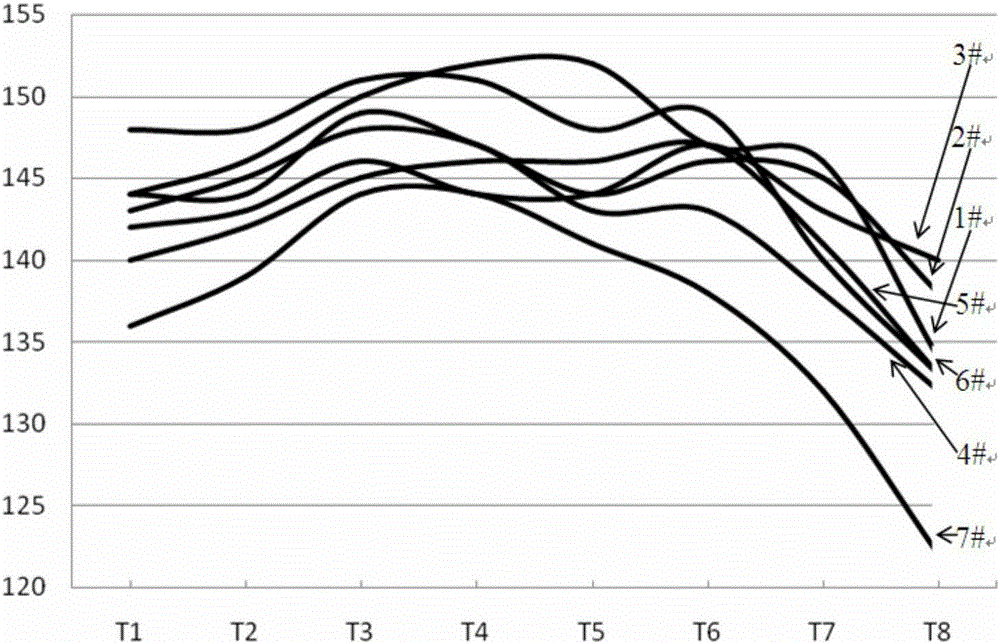

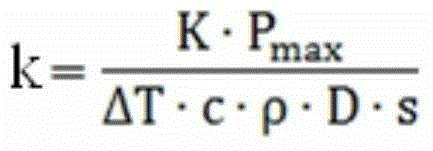

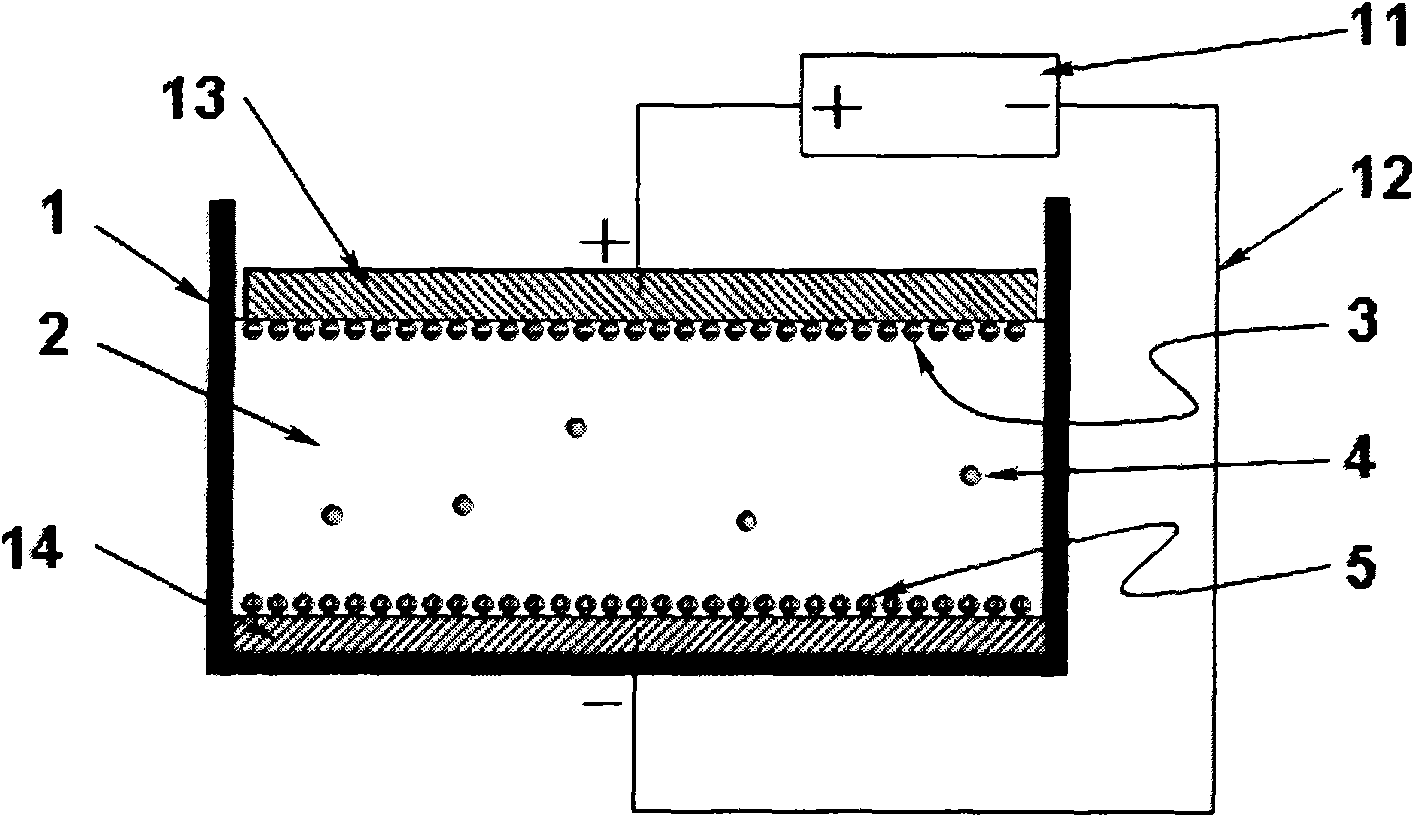

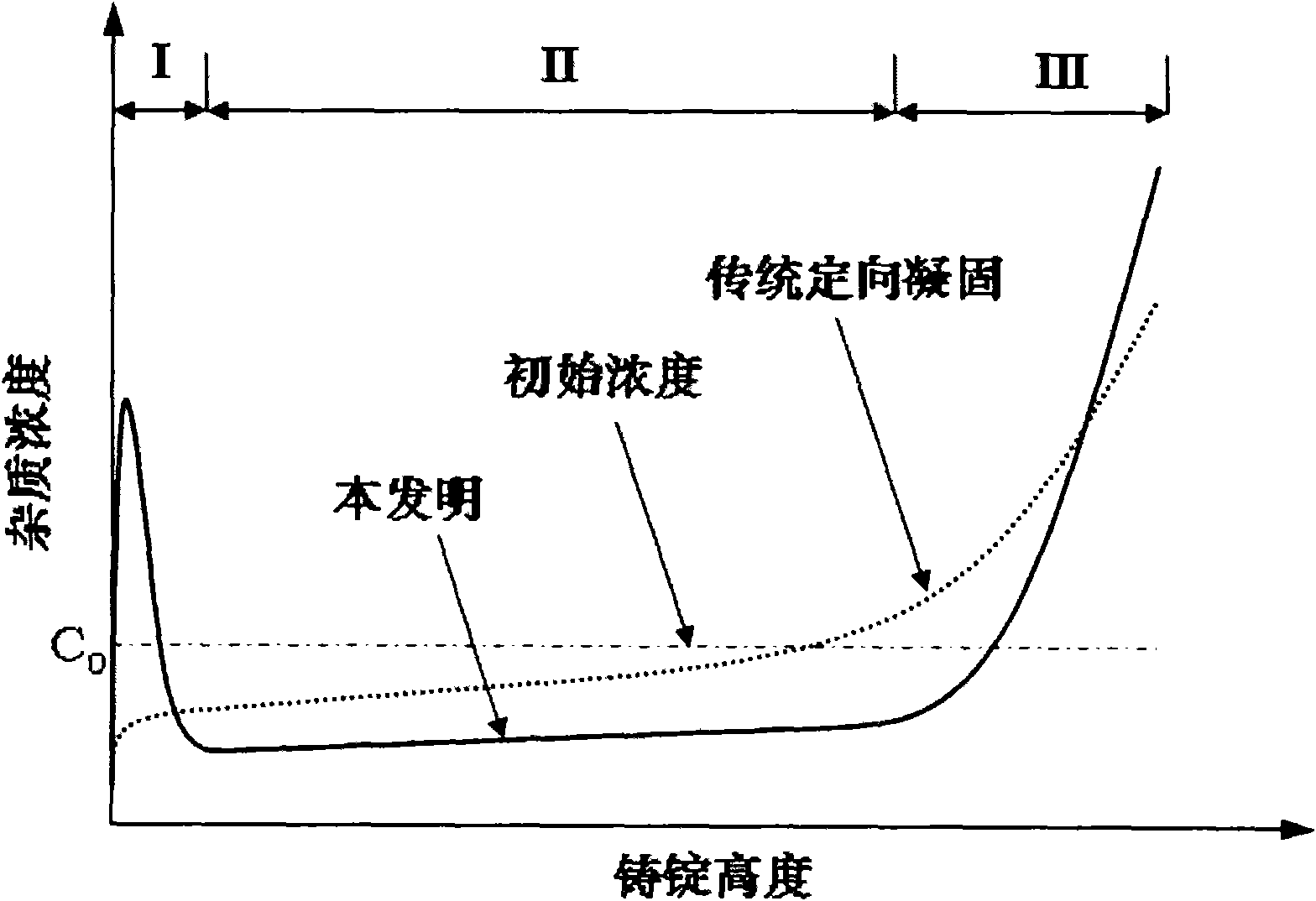

Method for directionally solidifying and purifying polycrystalline silicon under DC electric field

InactiveCN101812727AApplicable manufacturingPolycrystalline material growthSingle crystal growth detailsIngotDirectional solidification

The invention discloses a method for directionally solidifying and purifying polycrystalline silicon under the action of a DC electric field. In the method, the DC electric field which is parallel to the crystal growth direction is applied to fused silicon solution in the growth process of the polycrystalline silicon directional solidification crystal, so that the impurities rapidly move to the electrode direction under the action of the electric field, namely the cation impurities move to the cathode direction, and the anion impurities move to the anode direction. Therefore, the impurity concentration in the crystal growth terminal liquid phase is effectively reduced and the crystal impurity content of subsequent growth is lowered, and polycrystalline silicon ingots of which the directional solidification purity is higher than that of the traditional method for directionally solidifying and purifying the polycrystalline silicon are obtained.

Owner:上海太阳能电池研究与发展中心

Disposable noodles and method for producing same

ActiveCN1853501AEasy to stretchExcellent SlipperyDough treatmentMixing/kneading with horizontally-mounted toolsInstant noodleViscoelasticity

To provide a method for producing instant noodles comprising non-fried instant noodles with no wave, having slimy smoothness and viscoelasticity similar to those in boiled raw noodle but unavailable in conventional noodles such as wheat noodles or buchwheat noodles, causing no blister when steaming noodle strips, generating no longitudinal porosity or short noodles when cooked and taken, and favorably raveled out. The method for producing instant noodles comprises at least one of the following processes after changing an ordinary production process taken in a method for producing such kinds of noodles, namely a method of steaming noodle strips to pregelatinize them and cutting out the steamed noodle strips to make them noodle ribbons: a kneading process under reduced pressure; a process of using powdery oil and fat and / or lecithin as submaterial for making noodles; a process of using gluten as the submaterial for making noodles; and a process of spraying water, emulsified oil and fat solution and lecithin solution on the surface of the noodle strips just before the process of steaming the noodle strips.

Owner:NISSHIN FLOUR MILLING CO LTD

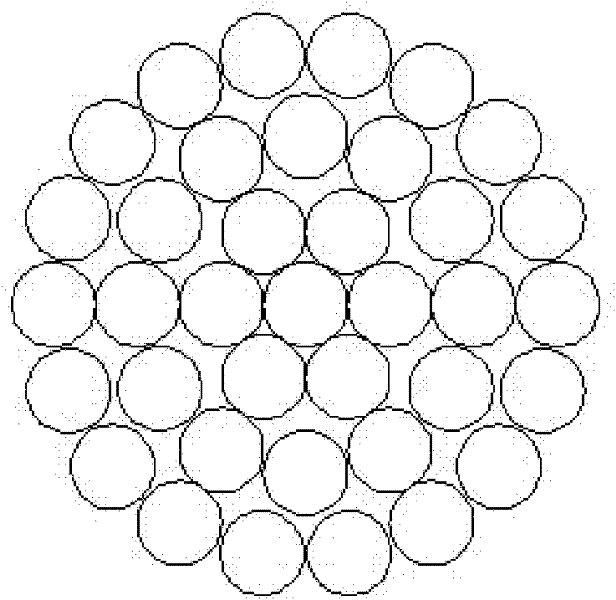

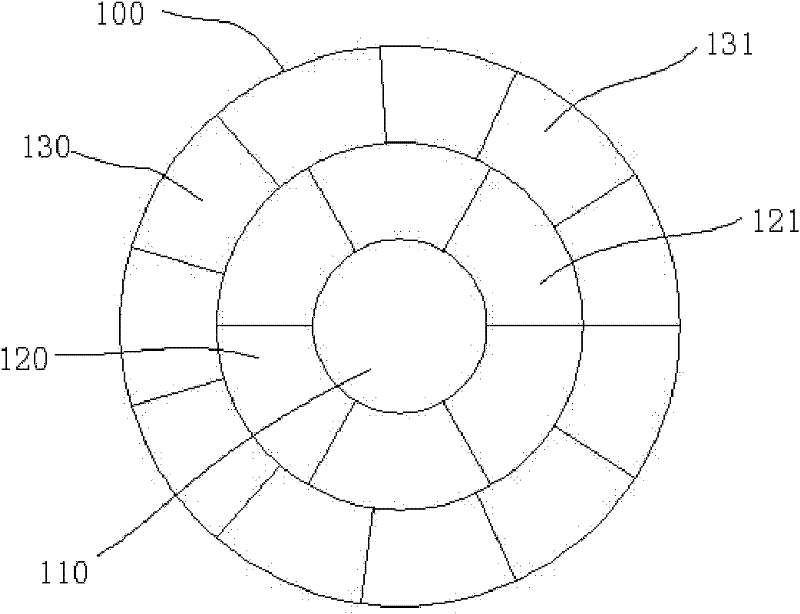

Aluminum alloy cable conductor and manufacturing method thereof

InactiveCN102543276ASolve the century-old problem of low compression coefficient in the stranding processStranded denseNon-insulated conductorsFlexible cablesElectrical conductorMechanical property

The invention discloses an aluminum alloy cable conductor and a manufacturing method thereof. The aluminum alloy cable conductor comprises a conductor main body with circular section, and the conductor main body comprises a central part and a peripheral part, wherein the peripheral part is sheathed outside the central part, and the inner wall of the peripheral part is adapted to the outer wall of the central part; and the peripheral part is formed by splicing a plurality of unit components along the peripheral direction. The machining method comprises the following steps of: firstly, machining raw materials into the central part and the unit components of the peripheral part; and then, stranding and splicing the central part and the unit components of the peripheral part obtained in the step (A) according to the concentric stranding rule. The seamless splicing of blocks in the aluminum alloy cable conductor is realized, and the outer surface of the aluminum alloy cable conductor forms a smooth cylinder. The mechanical properties of the aluminum alloy cable conductor are greatly improved, the corrosion resistance is also enhanced, the creep resistance is effectively improved, and the aluminum alloy cable conductor has wide applicability.

Owner:SHANGHAI MORN ELECTRIC EQUIPMENT CO LTD

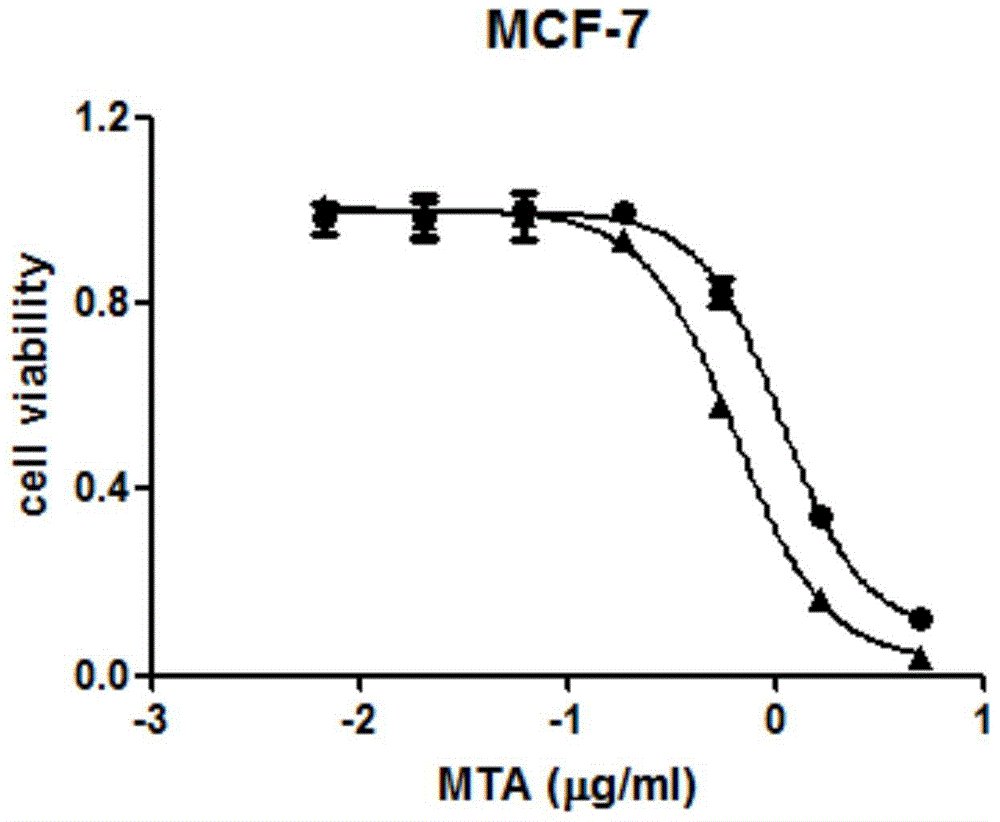

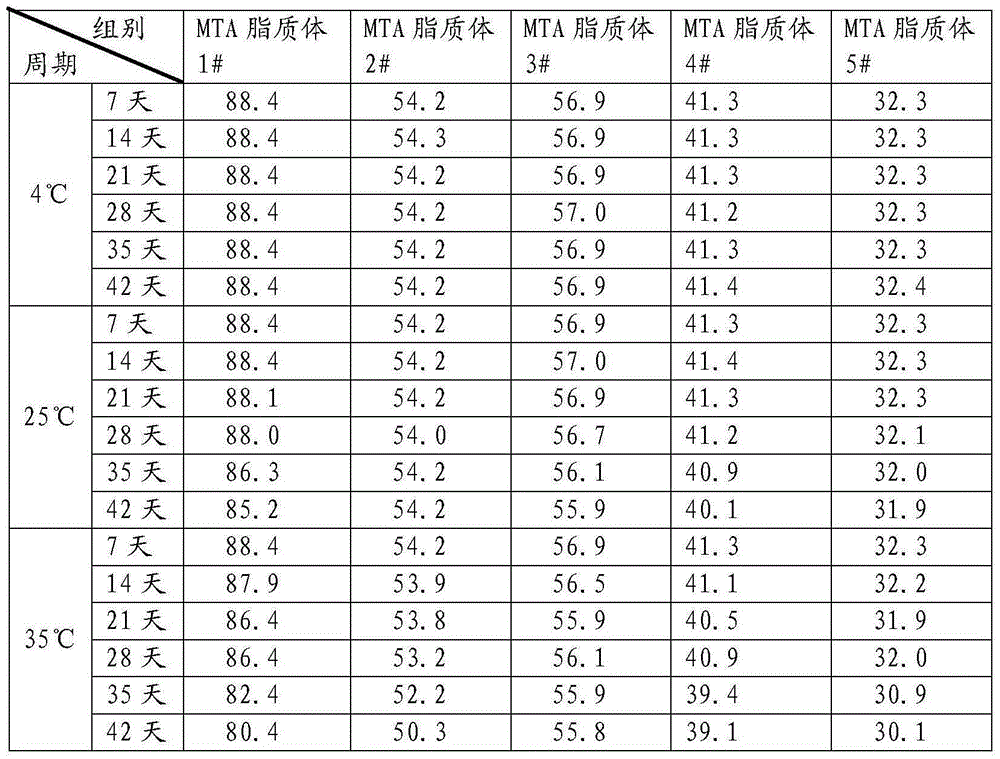

Pemetrexed liposome and preparation method thereof

InactiveCN104546723AImprove stabilitySimple processOrganic active ingredientsPharmaceutical non-active ingredientsMedicineTrial drug

The invention provides a pemetrexed liposome, which is characterized by being prepared from a pemetrexed and a liposome mixture, wherein the mass ratio of the pemetrexed and the liposome mixture is 1:(0.1-10); through the prepared pemetrexed liposome, the drug resistance can be reduced by more than 60% of non-liposome pemetrexed. Known from stability test, the liposome is favorable in stability. Known from clinical trials, the efficacy of the liposome can be improved by more than 80% compared with the common preparation, the in-vivo retention time can be prolonged by more than 65%, and the targeting effect is obvious.

Owner:XIN HUA HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

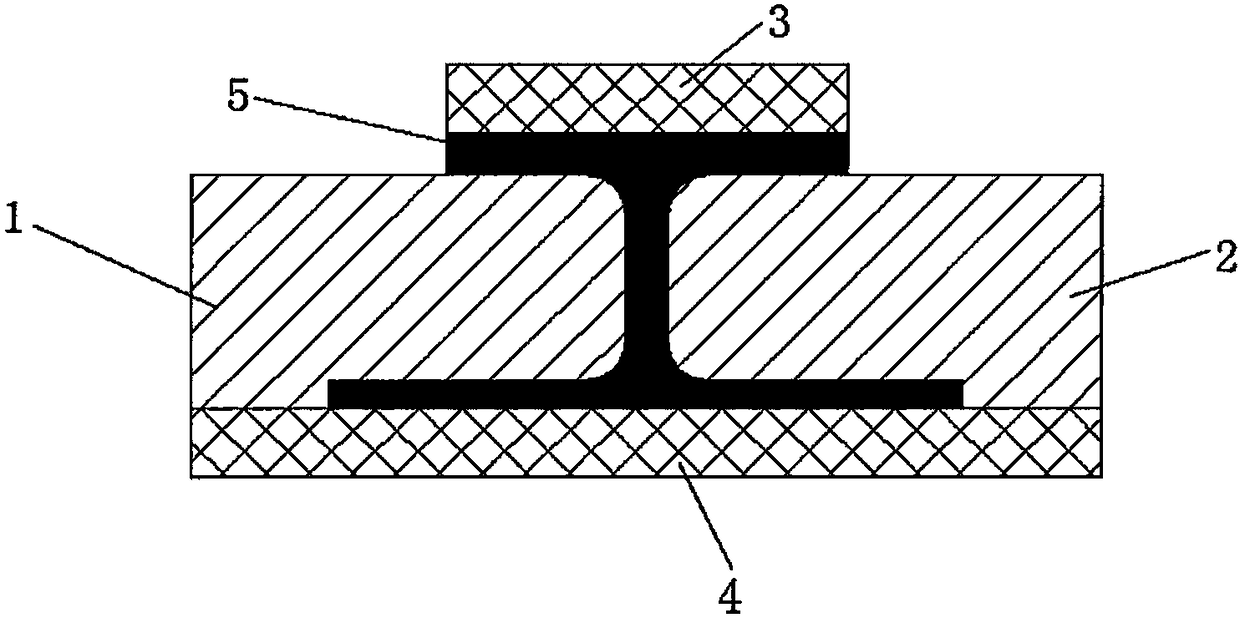

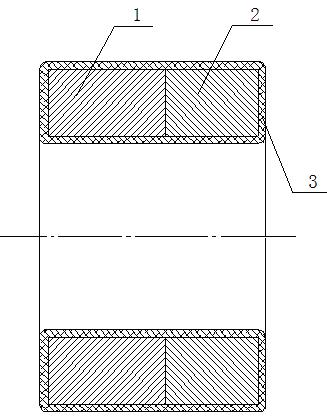

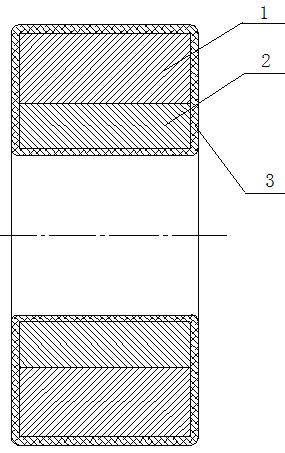

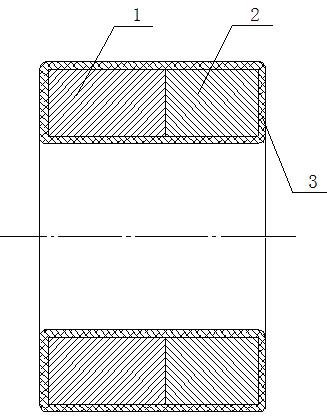

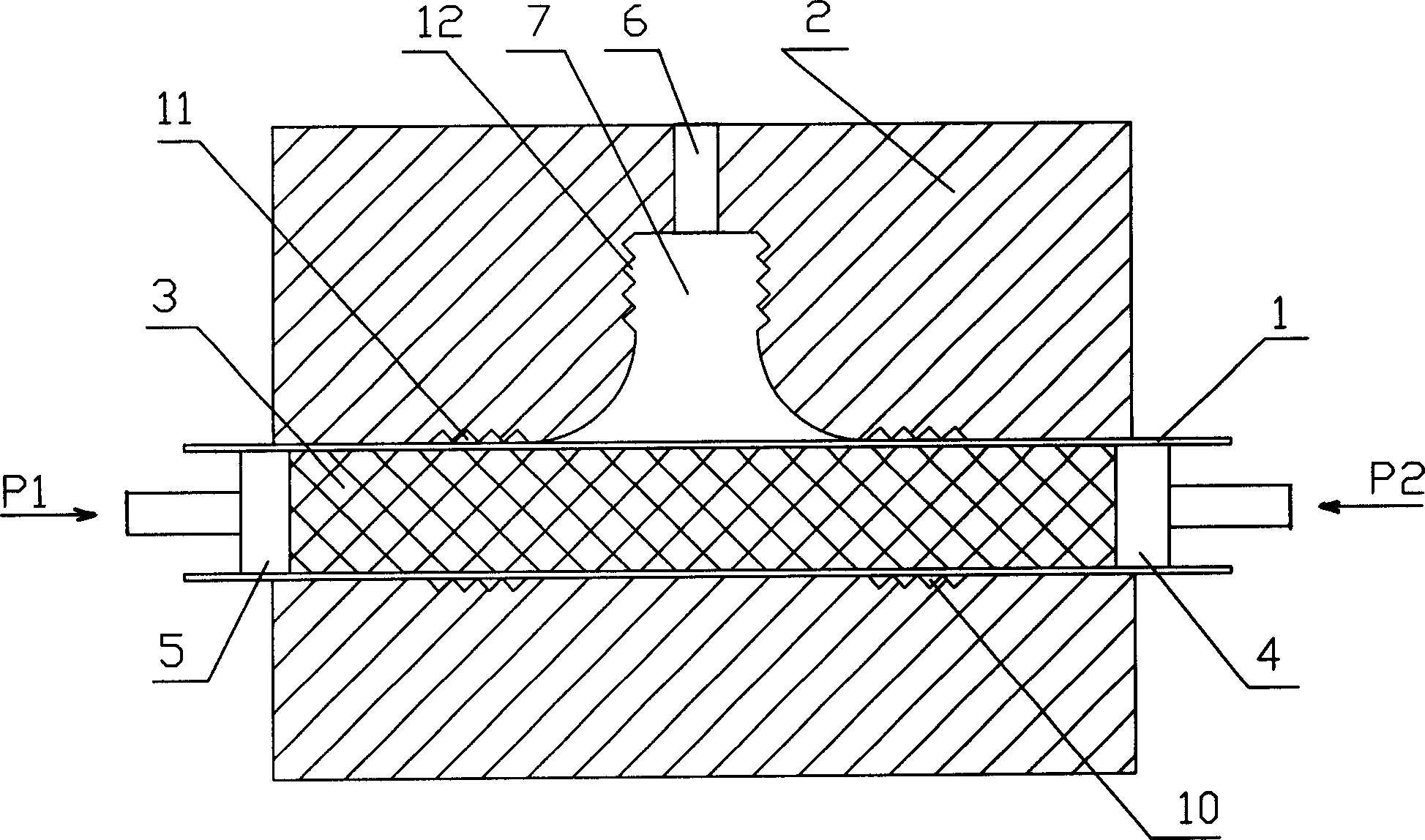

Direct current resisting transformer based on composite magnetic core and manufacturing method thereof

InactiveCN102426909AMake up for major technical defects that cannot be measured correctlyAccurate measurementTransformersTransformers/inductances magnetic coresDc currentProcess engineering

The invention discloses a direct current resisting transformer based on a composite magnetic core and a manufacturing method thereof. The manufacturing method is based on the error theory of the transformer and the characteristics that an iron-based amorphous material has the magnetic inductivity slighter inferior to that of an ultra-crystallite magnetic core but has a large saturated magnetic induction coefficient. When the detected current contains a direct current component, a saturated principle is not easily generated; the ultra-crystallite magnetic core (1) of a traditional current transformer is superposed with an iron-based amorphous magnetic core (2) according to the proportion, so that an electric energy in a semi-wave direct current load state can be accurately metered and the error rate is less than 1 percent; and meanwhile, technical requirements of related rules are met. The direct current resisting transformer disclosed by the invention has strong operability; and the ultra-crystallite magnetic core of the traditional current transformer is superposed with the iron-based amorphous magnetic core to form the composite magnetic core. The direct current resisting transformer has the advantages of no change of a winding technology, a pouring technology and a mounting mode of the traditional current transformer, convenience in replacement, and the like, and is suitable for designing and manufacturing the direct current resisting transformer.

Owner:ELECTRIC POWER RES INST STATE GRID JIANGXI ELECTRIC POWER CO +1

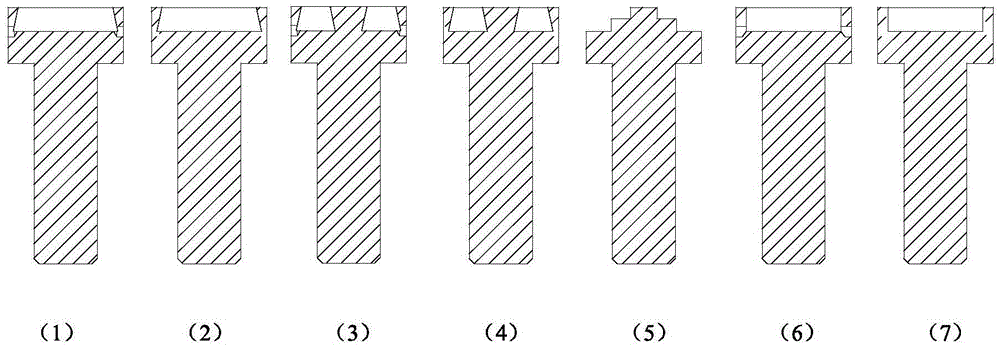

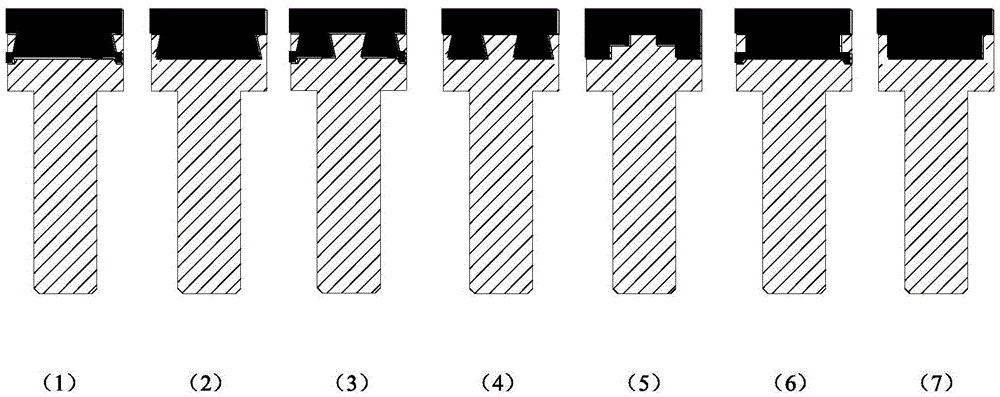

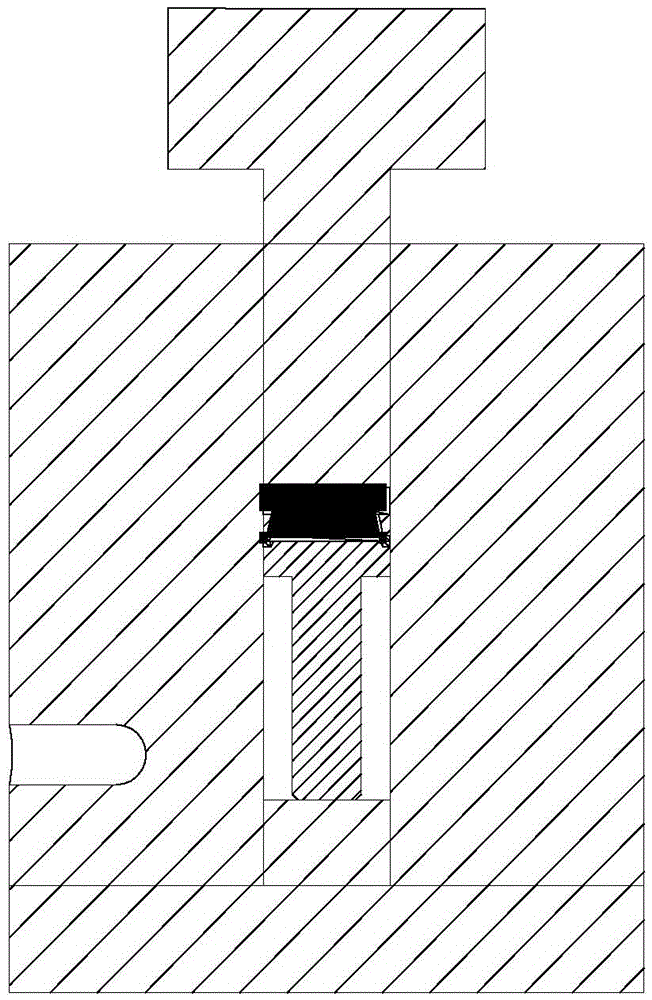

Fluoroplastic-metal valve element and molding technological method thereof

The invention discloses a fluoroplastic-metal valve element and a molding technological method thereof. The fluoroplastic-metal valve element comprises a valve element metal base body and fluoroplastic attached to the top of the valve element metal base body. The valve element metal base body comprises a valve head and a valve rod. By the adoption of the molding technological method, the valve head is filled with melted fluoroplastic. After a fluoroplastic transitional layer tightly fastened to the metal base body is manufactured between the fluoroplastic and the metal base body, the hot-press molding technological method is adopted, the adhesion strength between the fluoroplastic and the fluoroplastic transitional layer and between the fluoroplastic transitional layer and the metal base body is guaranteed and reaches over 17 MPa, and the sealing performance is reliable.

Owner:XIAN AEROSPACE PROPULSION INST

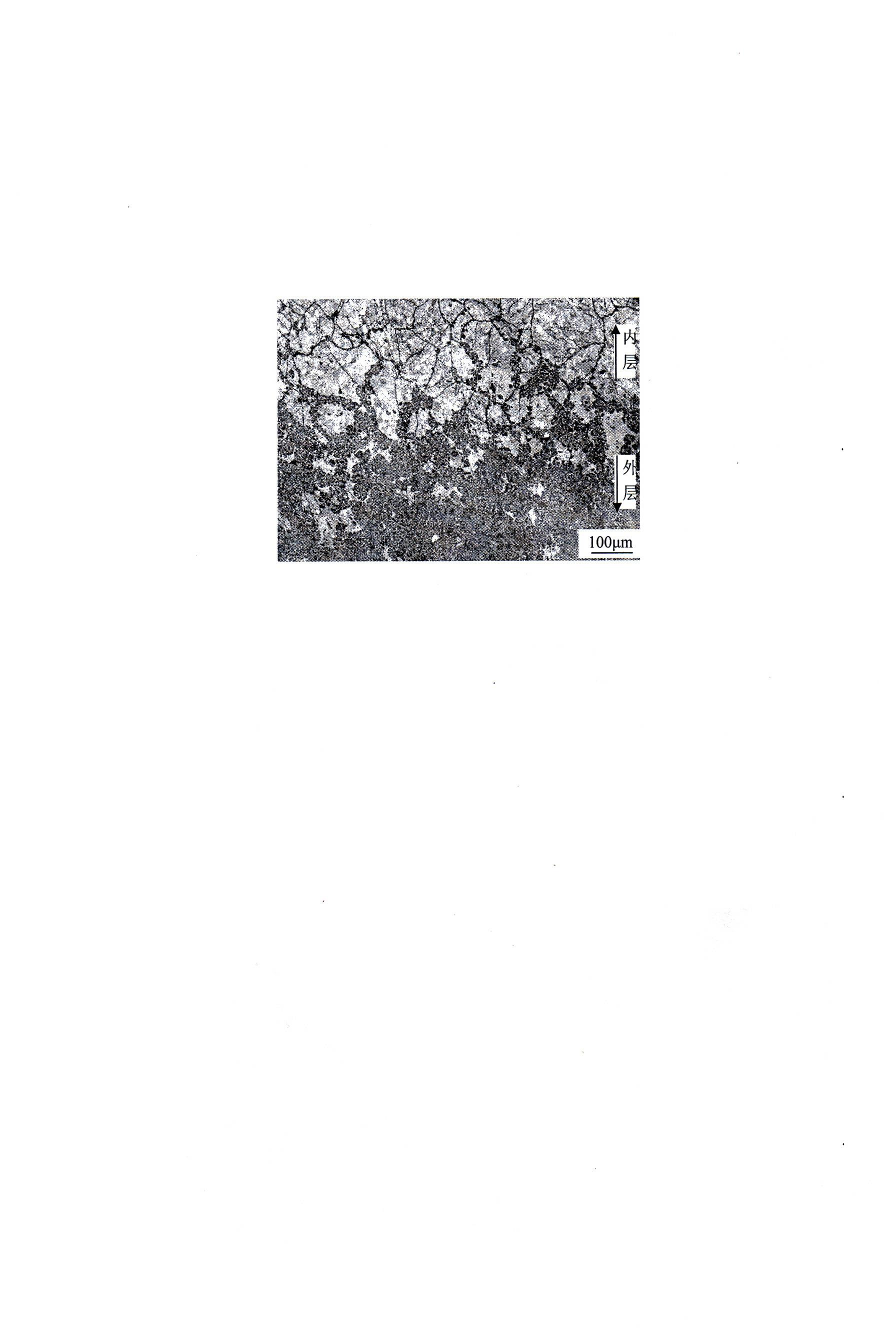

Layered composite tissue shaft parts material and its preparation method

ActiveCN102425595AHigh strengthHigh hardnessTemperature control deviceShaftsOne passChemical composition

The invention relates to a layered composite tissue shaft parts material and its preparation method, which is characterized in that the material is a medium-high carbon low-alloy steel which contains 0.40-1.5wt% of C and the sum of other alloy content less than 5wt% in the chemical composition; the material has more than two layers of composite tissue, the external layer enables high strength andhardness, the internal layer has good shock resistance. The preparation method comprises the following steps that a blank material is heated to the rolling temperature, and treated to a rolling blankmaterial with low temperature of the external layer and high temperature of the core part, wherein the rolling blank surface layer temperature is required at the 300 DEG C below the A1 temperature, the temperature of the core part is still the rolling temperature, one-pass skew rolling or cross wedge rolling is carried out. The invention has the advantages that the shaft parts material has layered composite tissue, the certain performance difference is existed between the external layer and the internal layer, the external layer has high strength and hardness, the internal layer has good shock resistance, heat treatment and a lot of cutting processes are not required after the material is shaped, the shaft parts material of the invention is adapted to production of shaft parts and motor shaft parts of automobile, engine and mechanical structure.

Owner:江苏信众企业管理有限公司

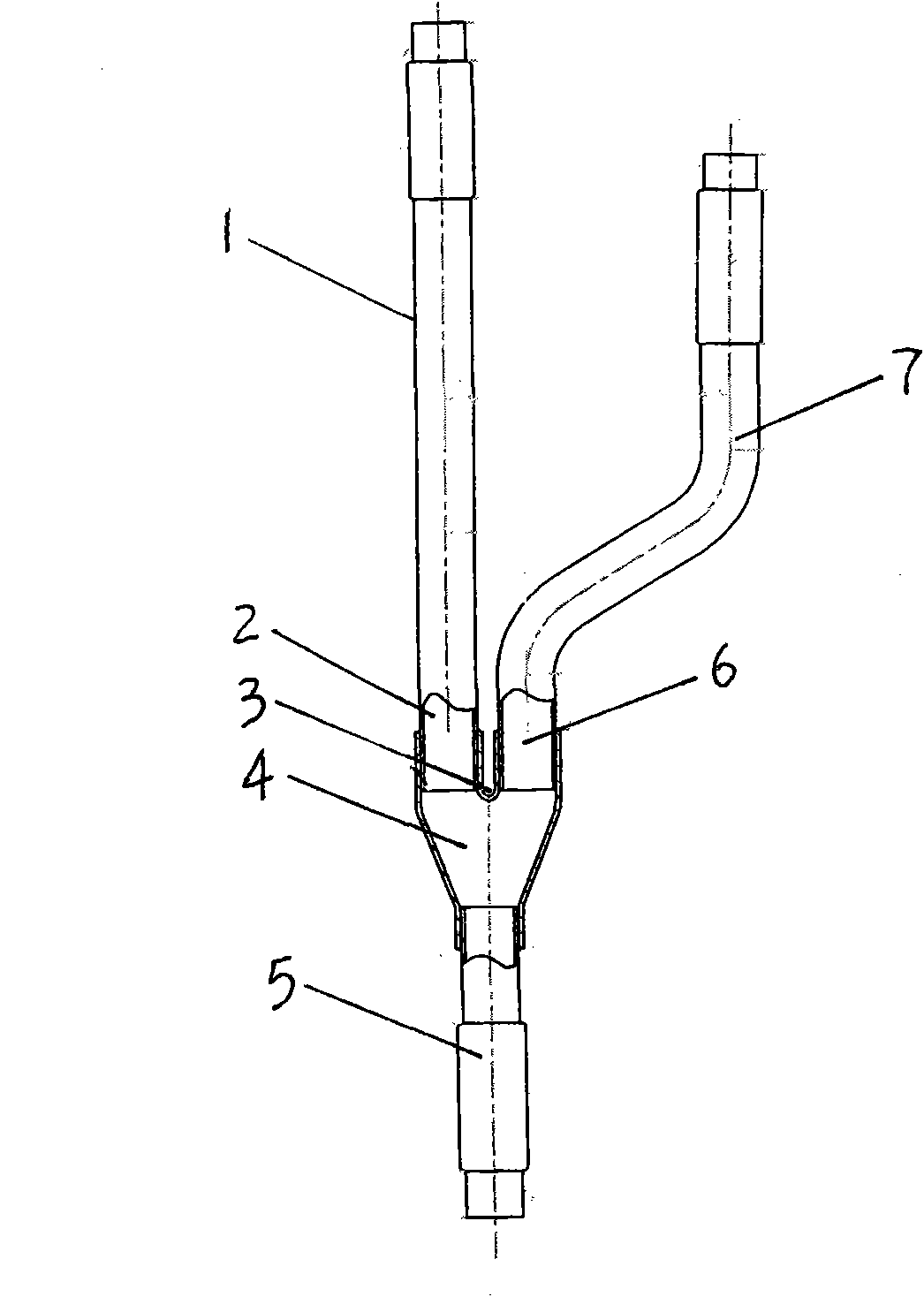

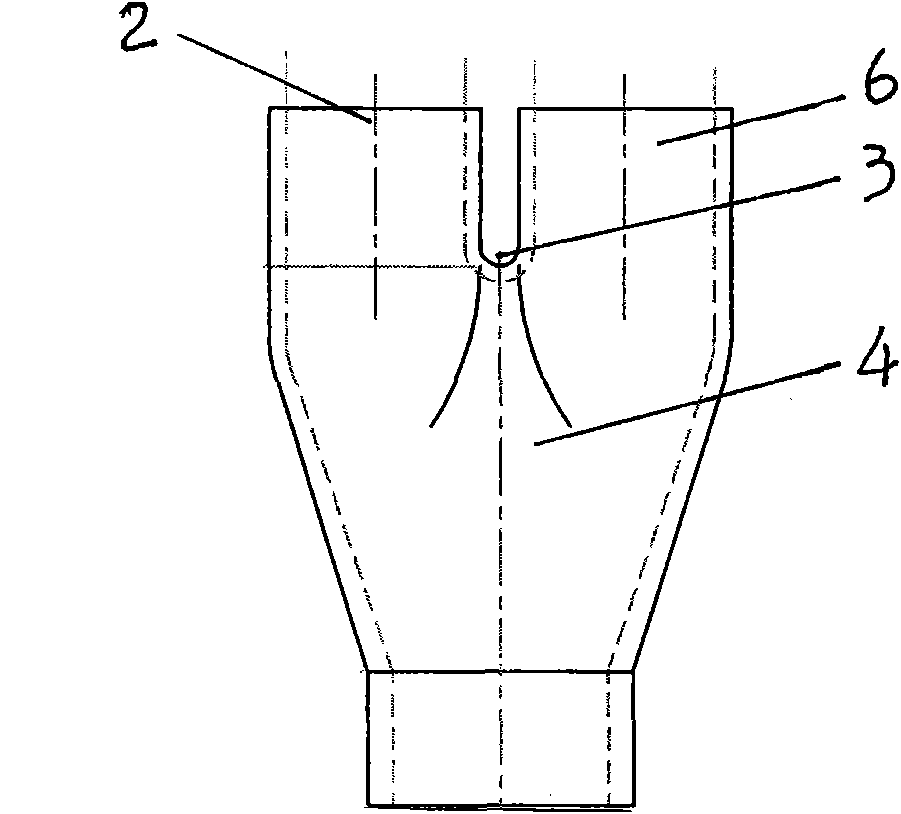

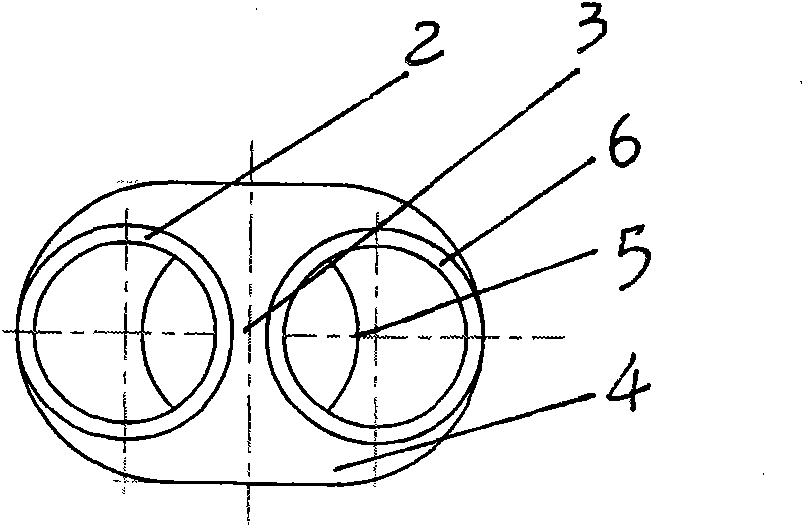

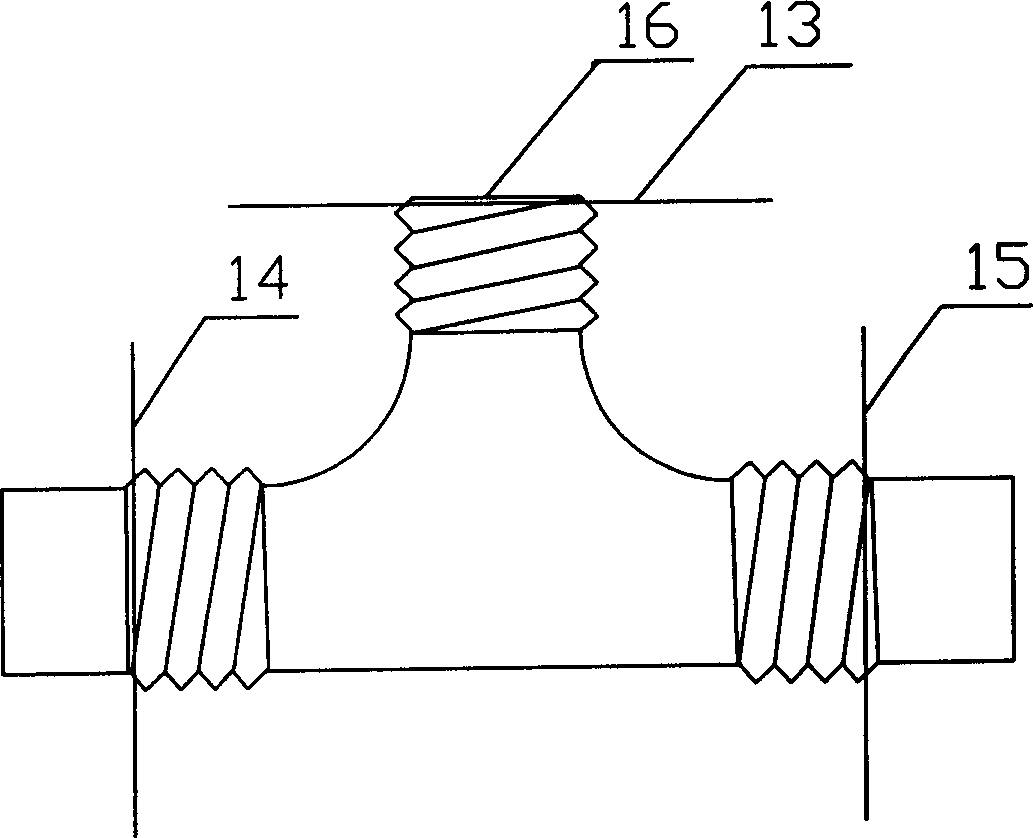

Manifold and manufacturing process thereof

InactiveCN101839383AImprove roundnessImprove sealingExtrusion diesFluid circulation arrangementEngineeringCopper tubing

The invention discloses a manifold and a manufacturing process thereof. The manifold is a pants tee comprising a straight pipe and branched welding bellmouths of a long straight pipe and a bent pipe which are arranged at the ends of the straight pipe, wherein the branched welding bellmouths are independent seamless pipe mouths, branched mouths in a circular-arc shape are arranged on the pants tee, and the two branched welding bellmouths and the central line of the straight line are parallel and are on the same plane. In the manufacturing process of the manifold, by adopting a hydraulic extrusion process, a copper pipe is extruded into a pants tee comprising welding bellmouths of a long straight pipe and a bent pipe, wherein the welding bellmouths are independent seamless pipe mouths. The invention is suitable for manufacturing the manifold of an air conditioner.

Owner:何永水

Production method of suede elastic fabric

The invention discloses a production method of suede elastic fabric. The method comprises steps such as preparation of fabric raw material fibers, spinning and weaving, after-finishing and the like. According to the method, core-spun yarn made of elastic fiber core filaments and sorona staple fiber surface yarn is adopted as half of weft, characteristics of good rebound resilience, permanent pollution resistance, softness and good skin friendliness, static electricity resistance and pilling resistance of sorona staple fibers are utilized, the obtained fabric has a uniform and fluffy suede surface and an obvious drooping property, and compared with suede elastic fabric in the prior art, the fabric obtained with the method has the advantages that the hand feeling, the style and the wearability are further improved.

Owner:JIANGSU SUNSHINE GRP CO LTD

Method for manufacturing plastic forming thin wall three-way pipe with threaded couplings

InactiveCN1669692ALower requirementLow power required for moldingExtrusion diesThin walledEngineering

This invention discloses a method for making plastic-shaping light-wall tee pipe with shoulder interface, belonging to common accessories-making technology field for pipe joint, which bears disadvantages of convenient process, less need of equipments and power, and can one-shot form tee pipe and triple screw thread and lower cost. It is characterized in inserting pliofilm in light-wall pipe blank with bipetalous mold, exerting axial force to pliofirm by two side jack-posts, forcing the blank to generate plastic deformation, and forming as the shape of shaping chamber and triple screw thread. The invention is mainly applied in making light-wall tee steel pipe, especially stainless steel pipe, and also in non-metal material pipes.

Owner:王文辉

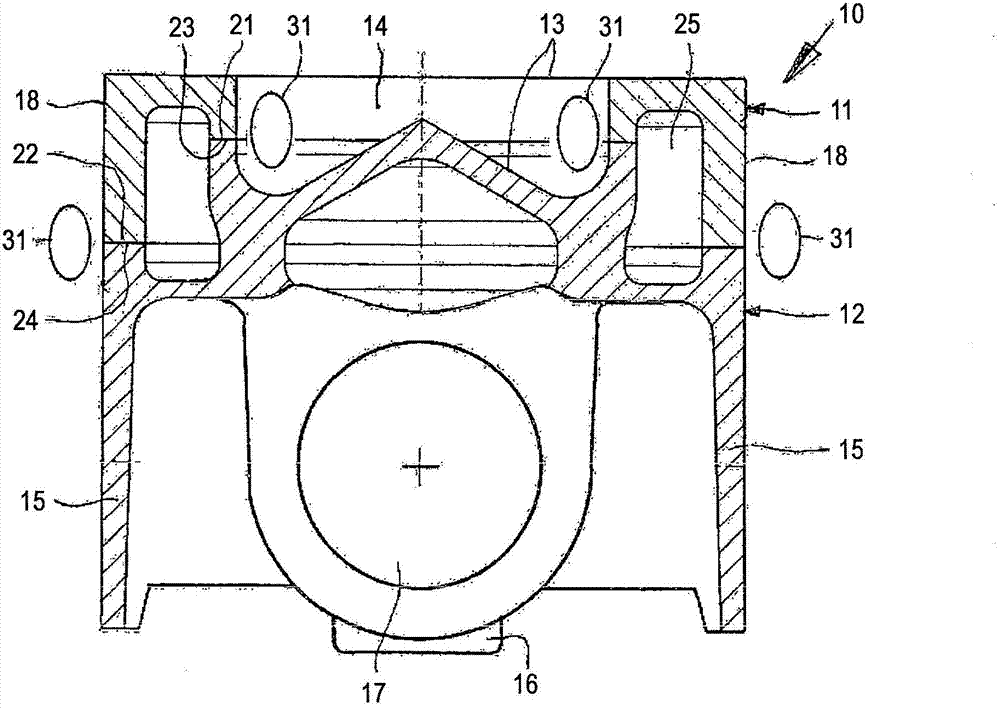

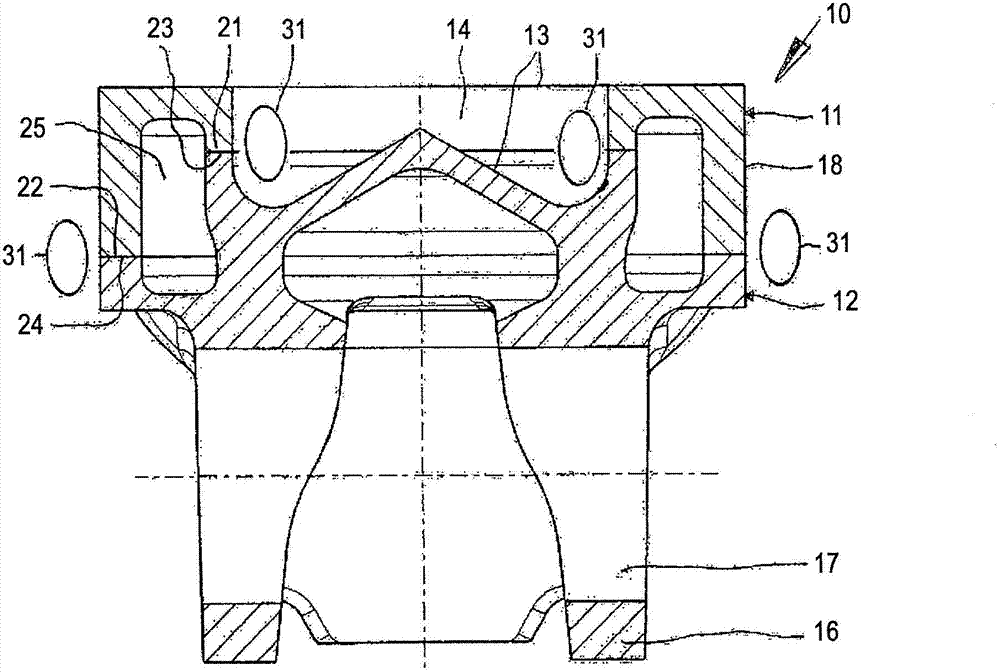

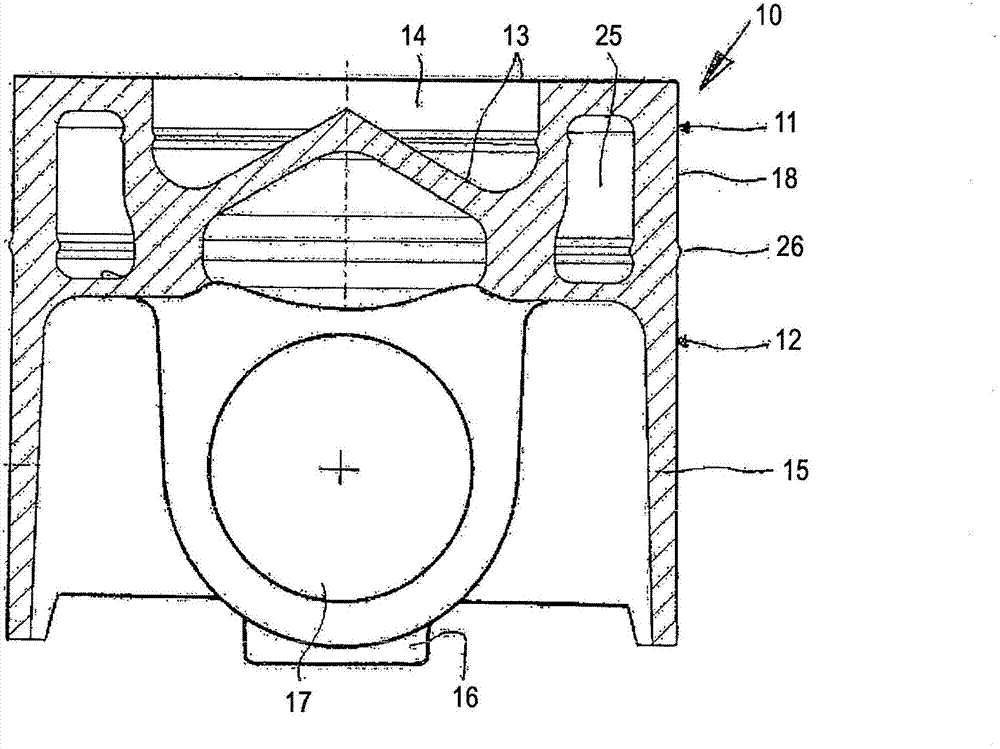

Method for producing a piston for an internal combustion engine and piston for an internal combustion engine

InactiveCN103118831AAvoid cooling downEasy solder connectionMachines/enginesPistonsEngineeringInternal combustion engine

The invention relates to a method for producing a piston (10, 110, 210) for an internal combustion engine, characterized by the following steps: a) producing an upper piston part (11, 111, 211) having at least one joining surface (21, 22; 121, 122), b) producing a lower piston part (12, 112, 212) having at least one joining surface (23, 24; 123, 124), c) establishing a direct contact between the at least one joining surface (21, 22; 121, 122) of the upper piston part (11, 111, 211) and the at least one joining surface (23, 24; 123, 124) of the lower piston part (12, 112, 212), d) heating the upper piston part (11, 111, 211) and the lower piston part (12, 112, 212) in the region of the joining surfaces (21, 23; 22, 24; 121, 123; 122, 124) brought in direct contact by induction or by a direct current flow through the joining surfaces (21, 23; 22, 24; 121, 123; 122, 124), and (e) connecting the upper piston part (11, 111, 211) and the lower piston part (12, 112, 212) to form a piston (10, 110, 210) by means of a pressing process and optionally finishing the piston (10, 110, 210).

Owner:MAHLE INT GMBH

Method for reinforcing fast-growing floor board

ActiveCN102198679BLow densityHigh elastic propertiesWood treatment detailsCarbonizationEconomic benefits

The invention belongs to the field of wood processing, and discloses a method for reinforcing a fast-growing floor board. The method comprises the steps of orderly performing densification, carbonization and nitridation on the fast-growing board. The fast-growing floor board processed by the method has the advantages of high surface hardness, excellent wear resistance and the like, and the fast-growing floor board is elastic, can absorb sound and provides comfortable feet experience; and simultaneously, wood is effectively saved, and optimal economic benefit is implemented.

Owner:徐州欧美国林人造板有限公司

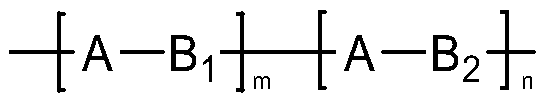

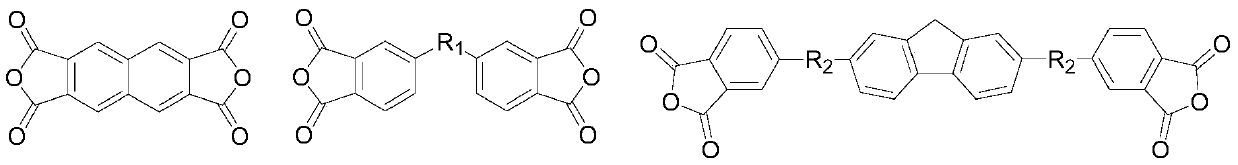

Polyimide precursor, precursor composition, polyimide, high-temperature-resistant transaprent polyimide film and preparation method of high-temperature-resistant transaprent polyimide film

The invention discloses a polyimide precursor, a precursor composition, polyimide, high-temperature-resistant transaprent polyimide film and a preparation method of the high-temperature-resistant transaprent polyimide film. The polyimide precursor is polyamide acid having a general formula which is shown in the description, wherein A is a structural unit derived from a diamine, B1 is a structuralunit derived from a main dianhydride, B2 is a structural unit derived from a control dianhydride, and the control dianhydride is from one or more than two of the structures which are shown in the description; the high-temperature-resistant transaprent polyimide film is prepared with the precursor composition by means of a thermal imidization process or a chemical imidization process. The high-heat-resistant colorless transparent polyimide herein has light transmittance of up to 88% and above, for example, 88-90%, has glass transition temperature of 336 DEG C and above, for instance, 336-360 DEG C, and further 350-360 DEG C, and has coefficient of linear expansion of 15-21 ppm / K, tensile strength of 109-120 MPa and elongation at break of 20-26%.

Owner:株洲时代华昇新材料技术有限公司

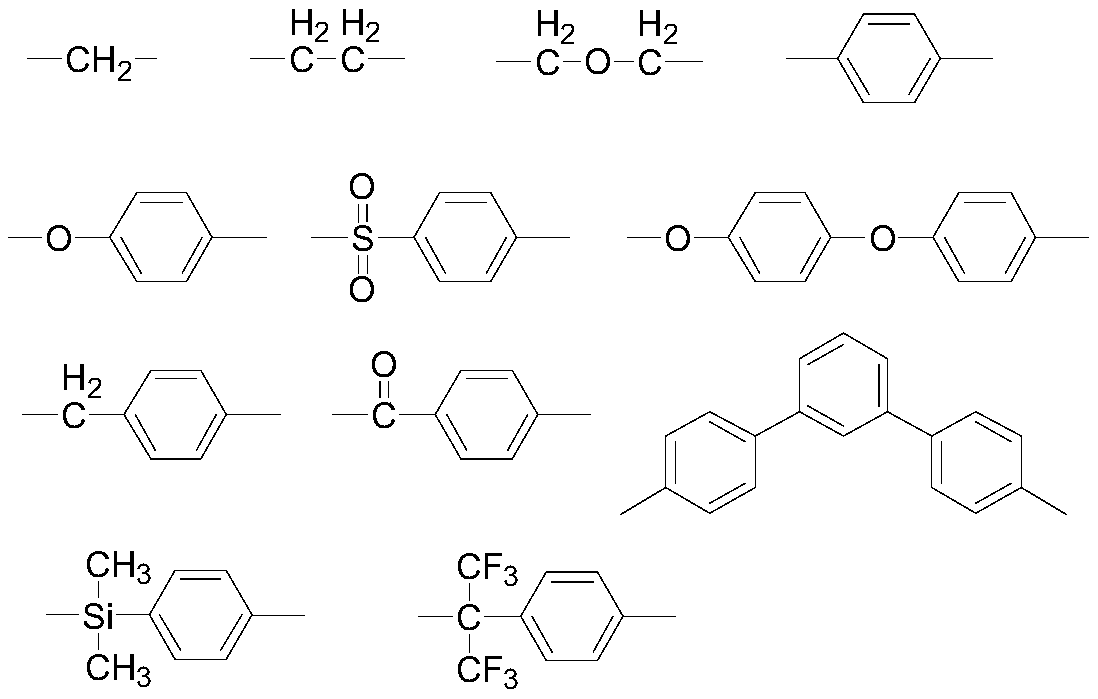

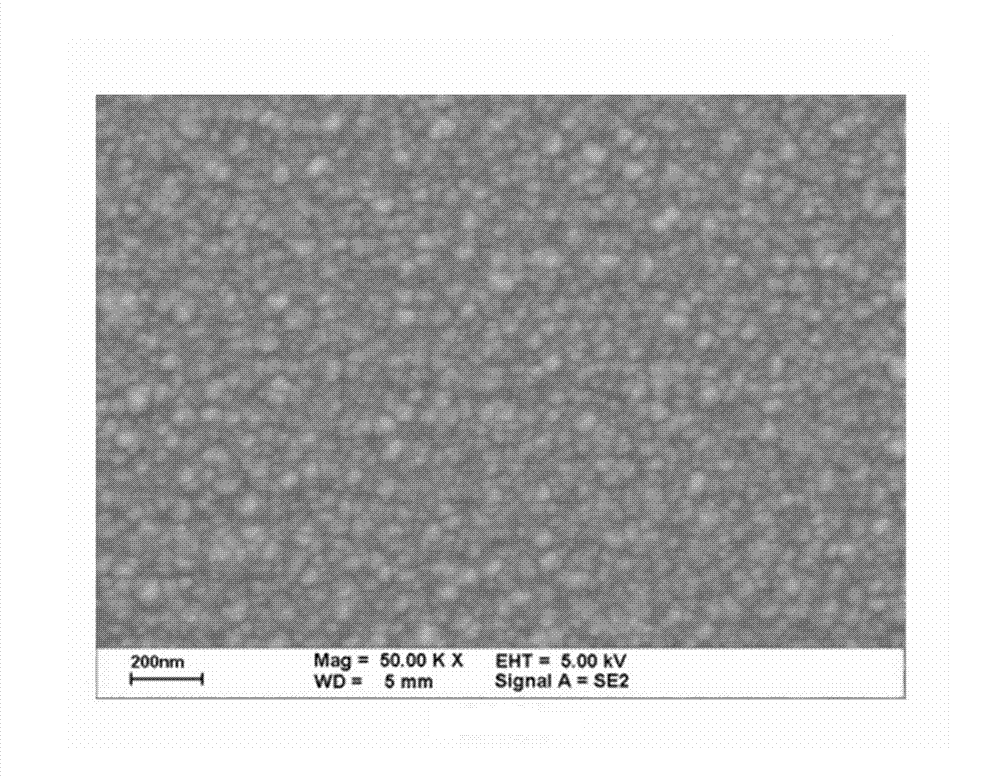

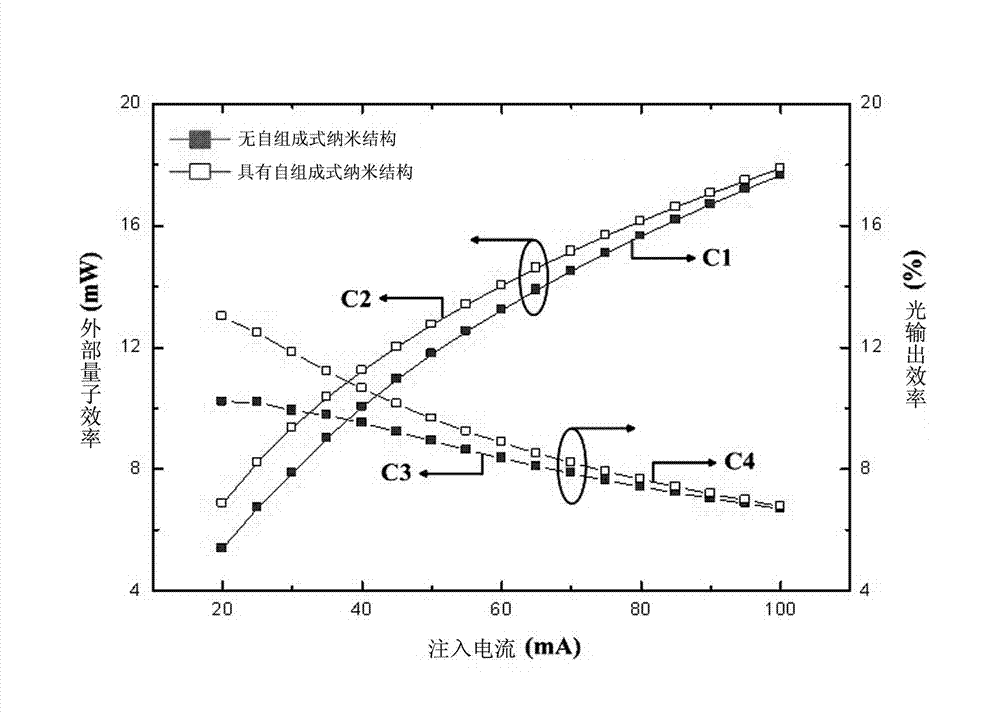

White-light LED (light-emitting diode) chip structure with self-assembly nano structure

InactiveCN102738347AWith refractive index differenceWith surface roughening effectSemiconductor devicesNano structuringIndium zinc oxide

The invention relates to an LED (light-emitting diode) assembly, and in particular relates to a white-light LED chip structure with a self-assembly nano structure, solving the problem that the chip structure of the existing white-light LED easily causes the reduction of the light taking out efficiency of the LED. The white-light LED chip structure with the self-assembly nano structure comprises a sapphire substrate, an N-type gallium nitride epitaxial layer, a multilayer quantum well indium gallium nitride active layer, a P-type gallium nitride epitaxial layer, a negative electrode metal layer and a positive electrode metal layer as well as an indium zinc oxide transparent conductive layer with the self-assembly nano structure, wherein the N-type gallium nitride epitaxial layer is stacked on the sapphire substrate; and the multilayer quantum well indium gallium nitride active layer is stacked on the N-type gallium nitride epitaxial layer. Based on the brandnew structure, the problem that the chip structure of the existing white-light LED easily causes the reduction of the light taking out efficiency of the LED can be solved, and the white-light LED chip structure is applicable to production of LEDs.

Owner:SHANXI FEIHONG MICRO NANO PHOTOELECTRONICS SCI & TECH

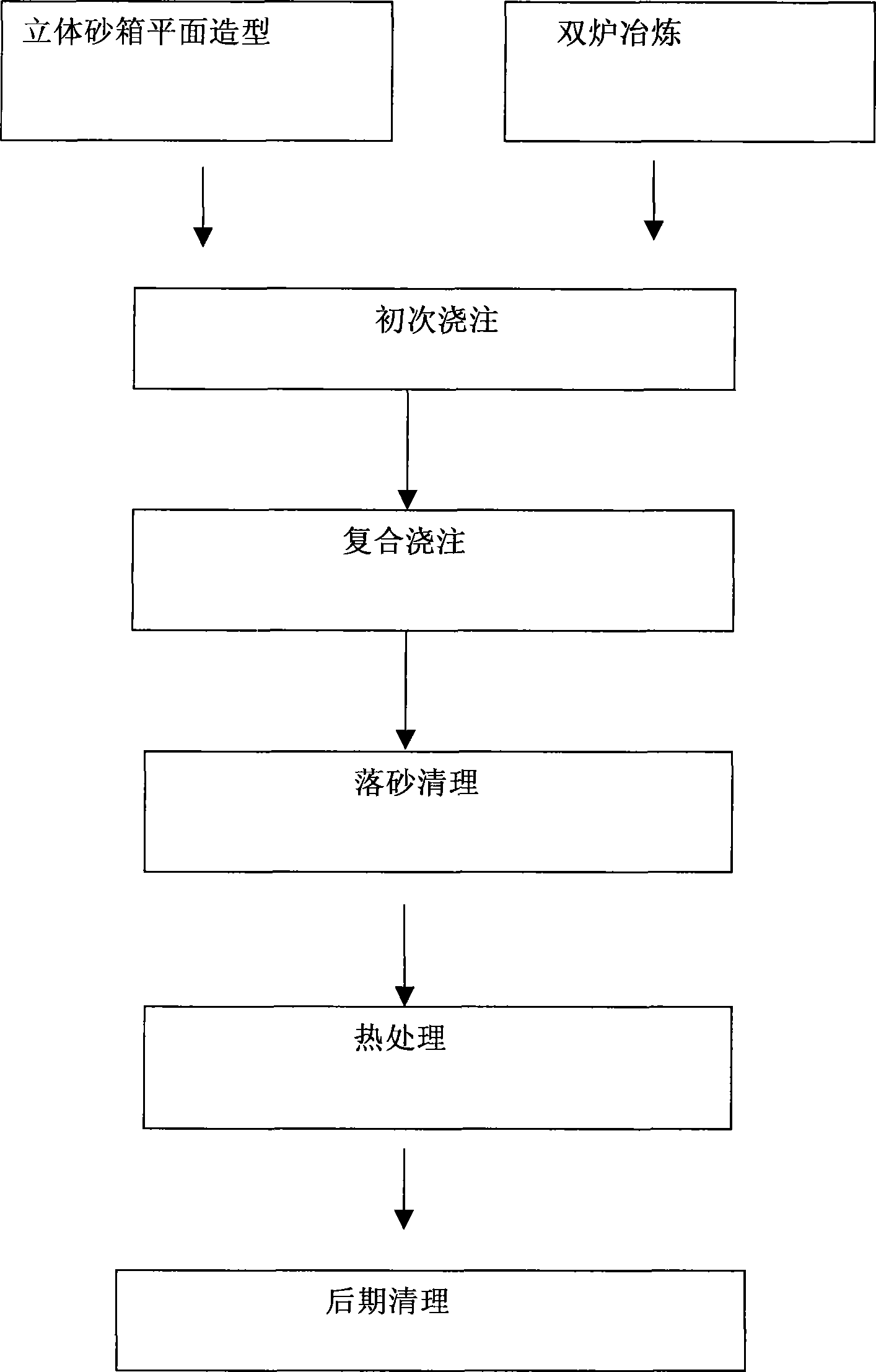

Composite wear-resistant casting parts and non-medium double-liquid three-dimensional compound casting technique thereof

The invention discloses a composite abrasion-resistant casting and medium-free biliquid solid composite casting technology thereof. The technology adopts molten steels with two different performances and efficacies of strong-toughness materials and high-hardness materials, and performs casting and composition in turn to form a structure according to the sequence. The technology can adjust the specific gravity of the two types of molten steels in workpieces and the dimension proportion of the structure according to the requirements of different workpieces, can adjust the casting sequence of the two types of molten steels according to different structures of the workpieces, and can also design and adjust the physico-chemical indexes of the two materials according to the industrial and mining conditions of the workpieces. Moreover, the technology makes finished pieces not only have high toughness but also have strong abrasion resistance, and effectively solves the problems of single material and incapability of having both strong toughness and strong abrasion resistance in the prior finished pieces; and the products are suitable for abrasion-resistant spare part products in grinding equipment in the fields of cement, electric power, mining, and the like.

Owner:王大伟

Method for preparing cerium-added neodymium-iron-boron magnet by 3D printing technology

InactiveCN105405636AShorten the production cycleIncrease productivityAdditive manufacturing apparatusTransportation and packagingProcedure AgentsCerium

The invention discloses a method for preparing a cerium-added neodymium-iron-boron magnet by a 3D printing technology. The method comprises the steps of smelting metal neodymium, cerium, ferroboron, iron, zinc, and nickel into an alloy; preparing into irregular magnetic powder after performing melt-spinning and air flow milling; performing plasmas gas atomization on the irregular magnetic powder to prepare spherical magnetic powder body; uniformly mixing the spherical magnetic powder body with a binder and a processing aid; feeding the mixed powder into 3D printing equipment, performing three-dimensional modeling according to sizes and shapes of a product based on computer software, and performing a hierarchical slicing treatment on the product models; leading the three-dimensional models into the 3D printing equipment, spraying the mixed powder to a heating model workbench, enabling the binder and the processing aid in the mixed powder to be dissolved, and enabling the cerium neodymium-iron-boron powder to be glued together, and performing magnetizing in the printing process until the product is printed completely. The product is good in cost performance and high in processing property, and the production period and cost of the bonded magnets are reduced.

Owner:LONGYAN ZIJIN INNOVATION RES INST

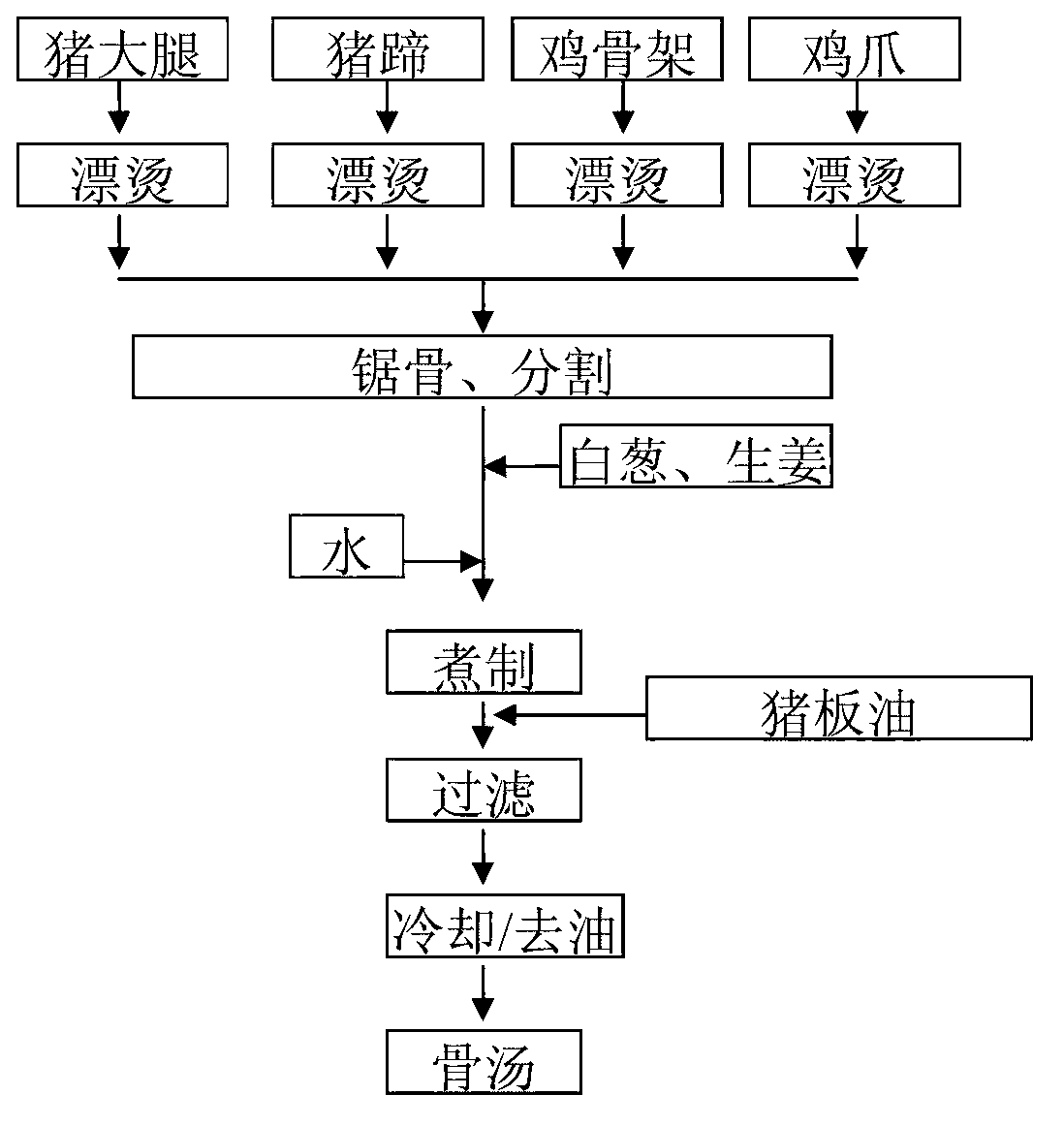

Japanese pulled noodle soup base

The invention discloses Japanese pulled noodle soup base. The Japanese pulled noodle soup base comprises the materials by weight parts: 400-600 parts of bone soup, 400-650 parts of water, 10-15 parts of salt, 15-25 parts of soy sauce, 12-20 parts of Maggi delicate flavour juice, 15-25 parts of oyster cocktail, 50-70 parts of leaf lard, 5-10 parts of gourmet powder, 5-10 parts of seafood white, and 0.2-0.5 part of fish gravy. The Japanese pulled noodle soup base provided by the invention has the advantages that the taste is pure, and the nutrition is rich.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com