Japanese pulled noodle soup base

A soup and ramen technology, applied in food preparation, food extraction, food science, etc., can solve the problems of poor nutrition and taste, and achieve the effect of delicious and pure taste, simple production and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The raw material mass ratio of bone broth is:

[0024] 1) Pork thigh bone 1200g, trotter 360g, chicken skeleton 1800g, chicken feet 400g, ginger 400g, white onion 720g and pork suet 600g.

[0025] 2) Pork thigh bone 2000g, trotter 200g, chicken skeleton 1000g, chicken feet 200g, ginger 200g, white onion 360g and pork suet 320g.

[0026] 3) Pork thigh bone 1600g, trotter 280g, chicken skeleton 1400g, chicken feet 280g, ginger 280g, white onion 480g and pork suet 480g.

Embodiment 2

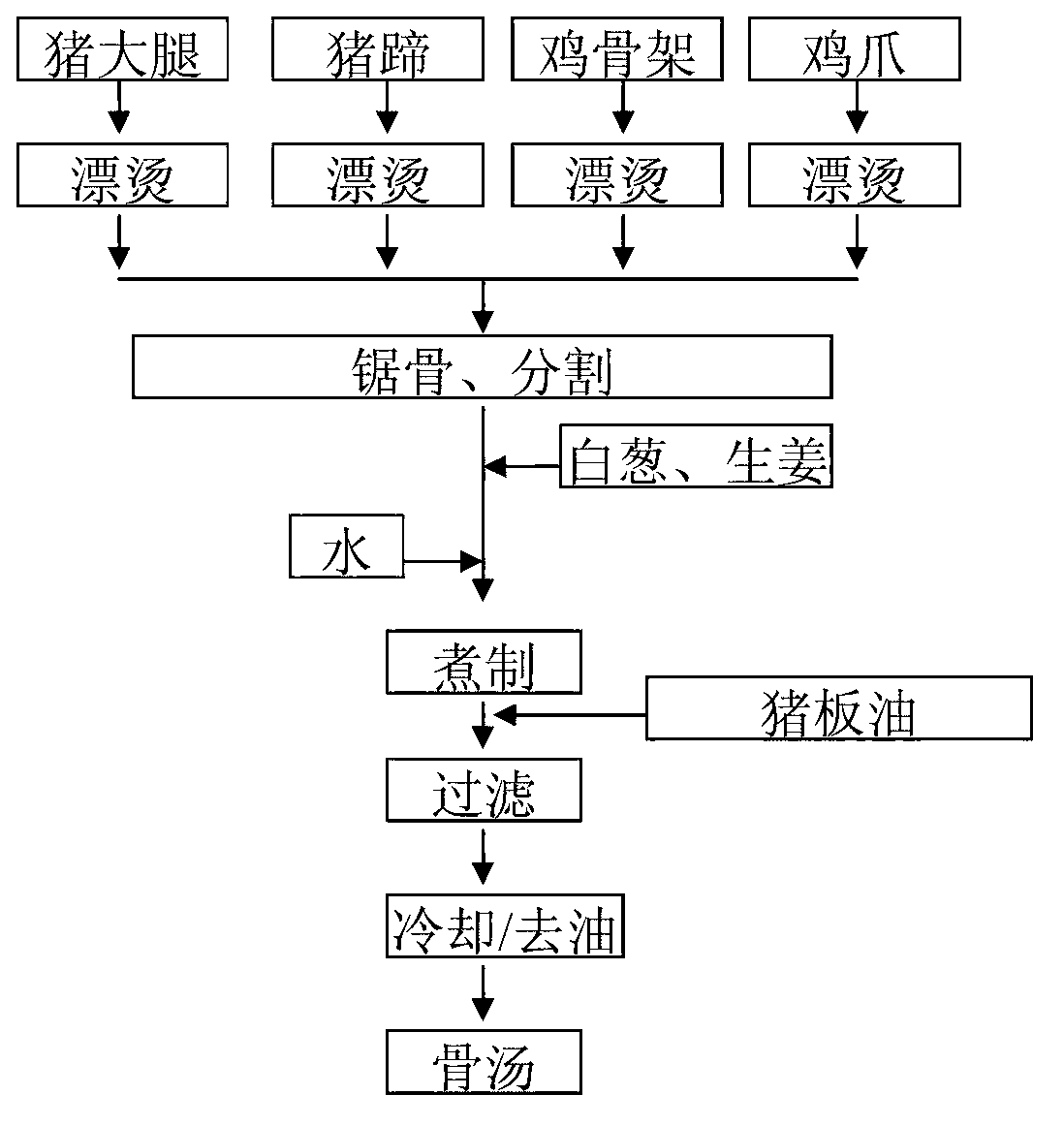

[0028] Such as figure 1 Shown, the raw material mass ratio of 1), 2) and 3) described in embodiment 1 is boiled into bone broth according to the following steps.

[0029] Step 1. Pig thigh bones, trotters, chicken skeletons and chicken feet are at room temperature;

[0030] Step 2, blanching: Put the pork thigh bones, trotters, chicken skeleton and chicken feet into boiling water. When the water boils again, quickly take out the pork thigh bones, pig feet, chicken skeleton and chicken feet, and wash them with cold water. Remove the foam and blood coagulation attached to the surface of pig thigh bones, trotters, chicken skeletons and chicken feet;

[0031] Step 3. Bone sawing and segmentation: Saw the pig thigh bones, trotters, chicken skeletons and chicken feet into blocks;

[0032] Step 4, cooking: Put the pork thigh bones, trotters, chicken frame bones, chicken feet, white onions and ginger prepared in step 1 into a straight stainless steel bucket, add cold water to the st...

Embodiment 3

[0035] Japanese Ramen Soup Recipe:

[0036] Recipe 1

[0037] Choose according to the mass ratio of raw materials in 1) in Example 1 and 800g of bone broth, 1300g of water, 30g of salt, 50g of soy sauce, 40g of Maggi fresh juice, 50g of oyster sauce and 140g of lard suet prepared according to the method of Example 2 .

[0038] Recipe 2

[0039] Choose according to the mass ratio of raw materials in 2) in Example 1 and boil 1200g of bone broth, 800g of water, 20g of salt, 30g of soy sauce, 24g of Maggi fresh juice, 30g of oyster sauce and 100g of lard suet prepared according to the method of Example 2 .

[0040] Recipe 3

[0041] Choose according to 3) raw material mass portion ratio among the embodiment 1 and the bone broth 1000g that boils according to the method for embodiment 2, water 1000g, salt 24g, soy sauce 40g, Maggi umami juice 32g, oyster sauce 40g, lard suet 120g and MSG 14g.

[0042] Recipe 4

[0043] Select according to the mass ratio of raw materials in 3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com