Direct current resisting transformer based on composite magnetic core and manufacturing method thereof

A current transformer and anti-DC technology, which is applied in the direction of inductors, inductors/transformers/magnets, transformers/inductor cores, etc., to achieve the effect of strong operability and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

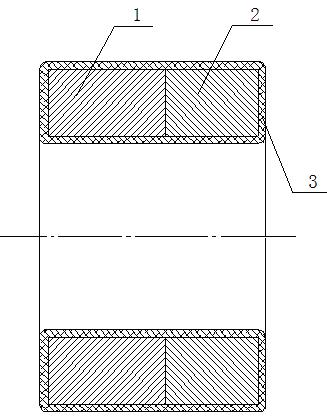

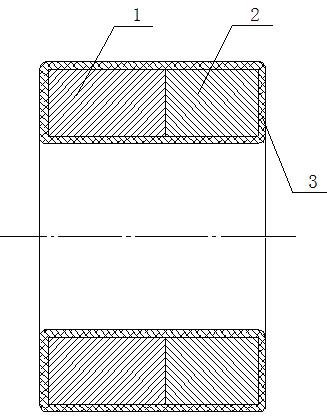

Embodiment 1

[0026] The iron-based amorphous magnetic core 2 has an outer diameter of 70 mm, an inner diameter of 42 mm, and a thickness of 20 mm.

[0027] After the two kinds of magnetic cores are combined side by side, the high voltage resistant insulating plastic 3 is hot-pressed outside the magnetic core to form a side-by-side composite magnetic core.

[0028] Example 2:

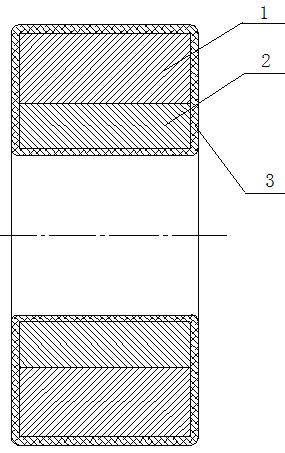

[0029] This embodiment is a nested composite magnetic core, such as figure 2 shown.

[0030] The ultramicrocrystalline magnetic core and the iron-based amorphous magnetic core that make up the composite magnetic core of this embodiment are both annular; the outer diameter of the ultramicrocrystalline magnetic core 1 is 74mm, the inner diameter is 56mm, and the thickness is 40mm; The outer diameter of the base amorphous magnetic core 2 is 56mm, the inner diameter is 42mm, and the thickness is 40mm; the iron-based amorphous magnetic core 2 is nested in the ultramicrocrystalline magnetic core. After the two kinds of...

Embodiment 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com