Selected region laser sintering and molding method of ultrahigh molecular weight polyethylene

A selective laser sintering and ultra-high molecular weight technology, which is applied in ceramic molding machines, manufacturing tools, additive processing, etc., to achieve the effect of high dimensional accuracy and small deformation and shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

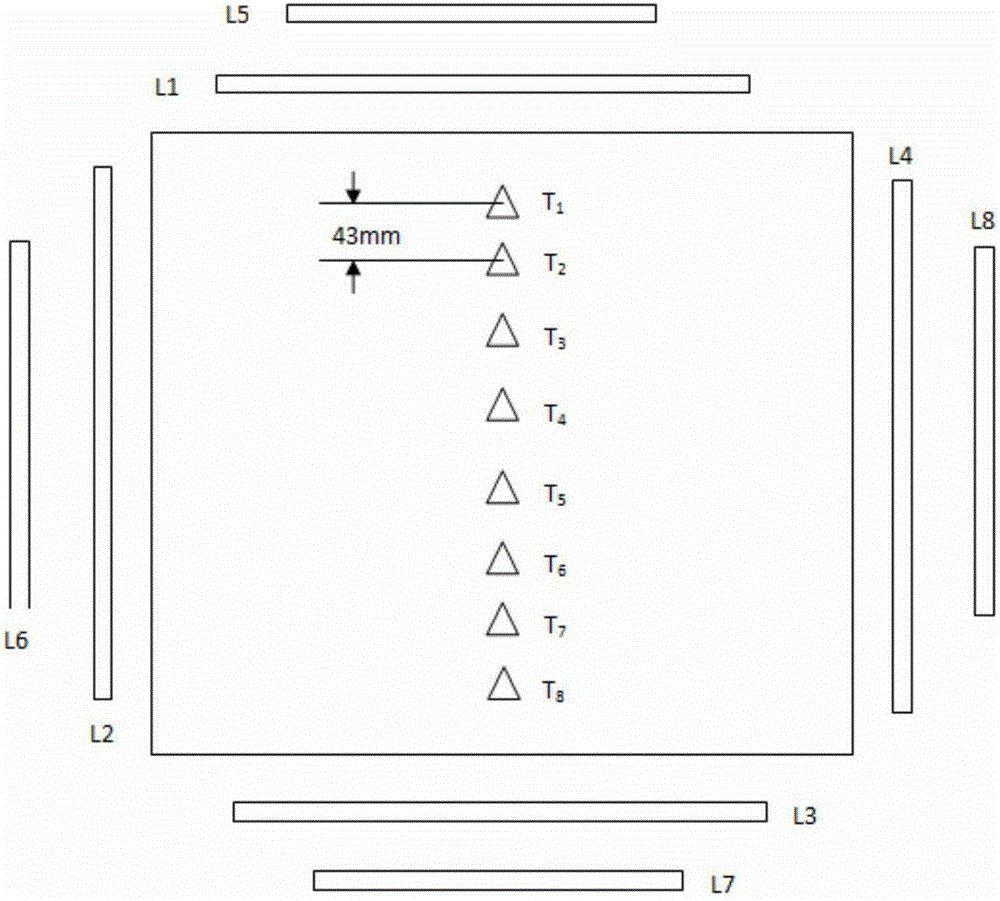

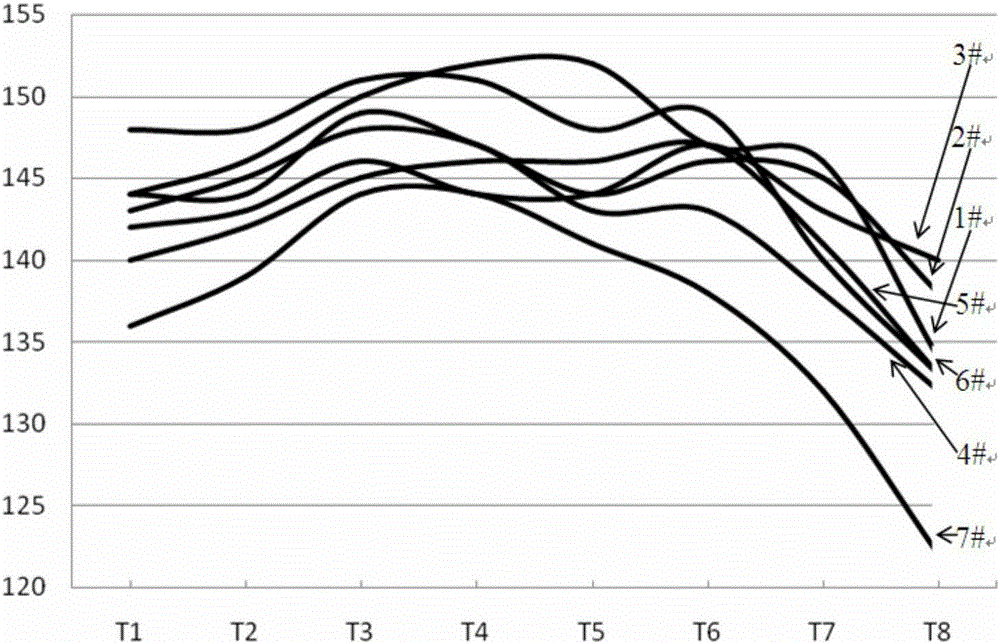

[0031] The present invention will be further described below with reference to the accompanying drawings and in combination with preferred embodiments.

[0032] UHMWPE is a crystalline polymer material with a molecular weight of more than one million, poor fluidity of processed melt, high viscosity, and large shrinkage and deformation after molding. These all limit the application of SLS molding of UHMWPE. The inventor analyzed the factors that affect UHMWPE. After many factors of SLS molding, the following technical solutions are obtained. In a specific embodiment, a selective laser sintering molding method of ultra-high molecular weight polyethylene includes the following steps:

[0033] (1) heating the ultra-high molecular weight polyethylene powder to the preheating temperature in the selective laser sintering molding equipment;

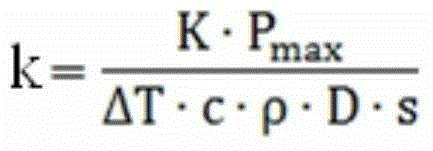

[0034] (2) Using a predetermined laser scanning speed and output power to form the ultra-high molecular weight polyethylene powder in a selectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com