Method and device for checking carrying means

A traction and detection unit technology, applied in the direction of measuring devices, transportation and packaging, elevators, etc., can solve the problems of reducing the bearing section and failure of the traction mechanism, etc., and achieves the effect of low cost and simple application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

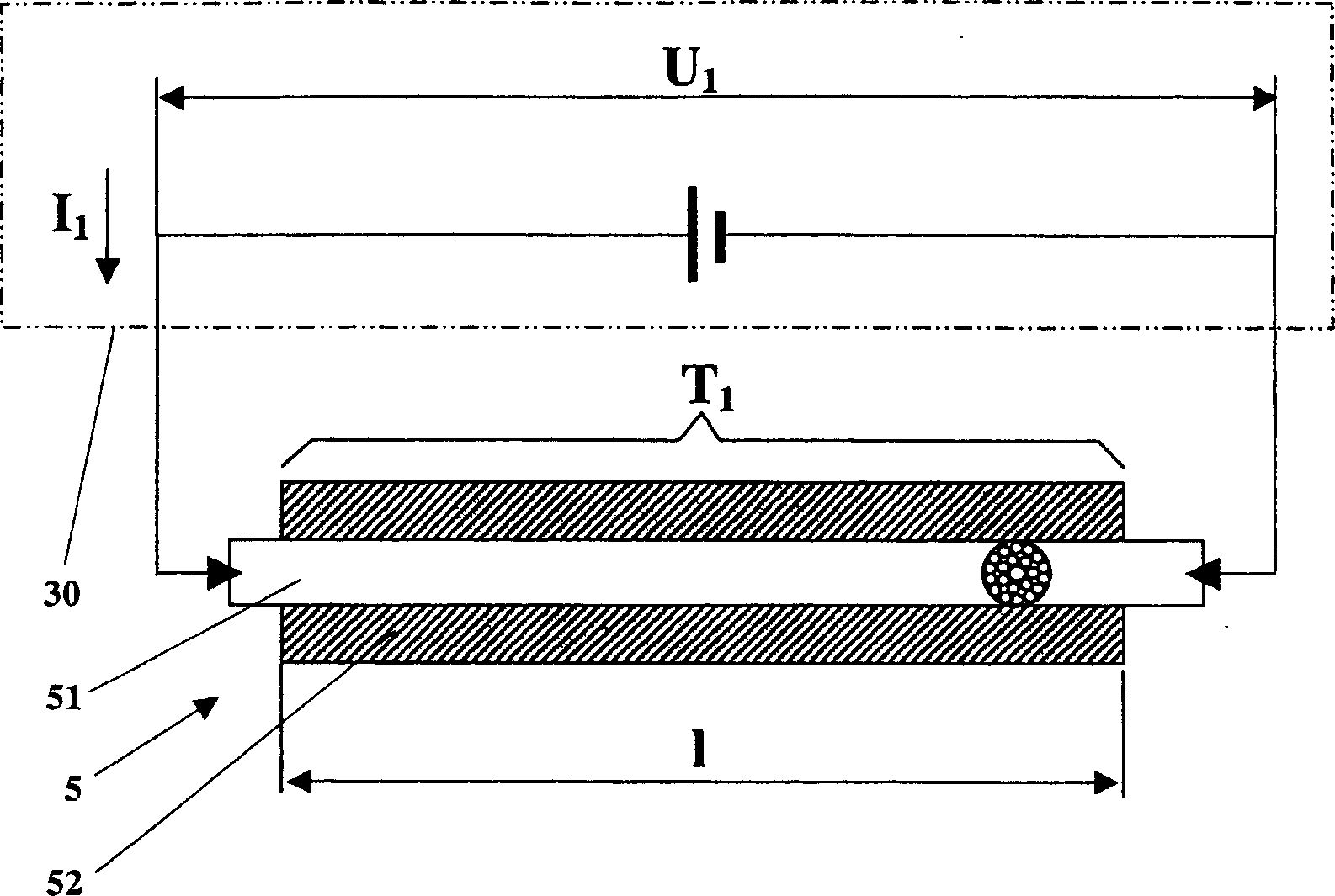

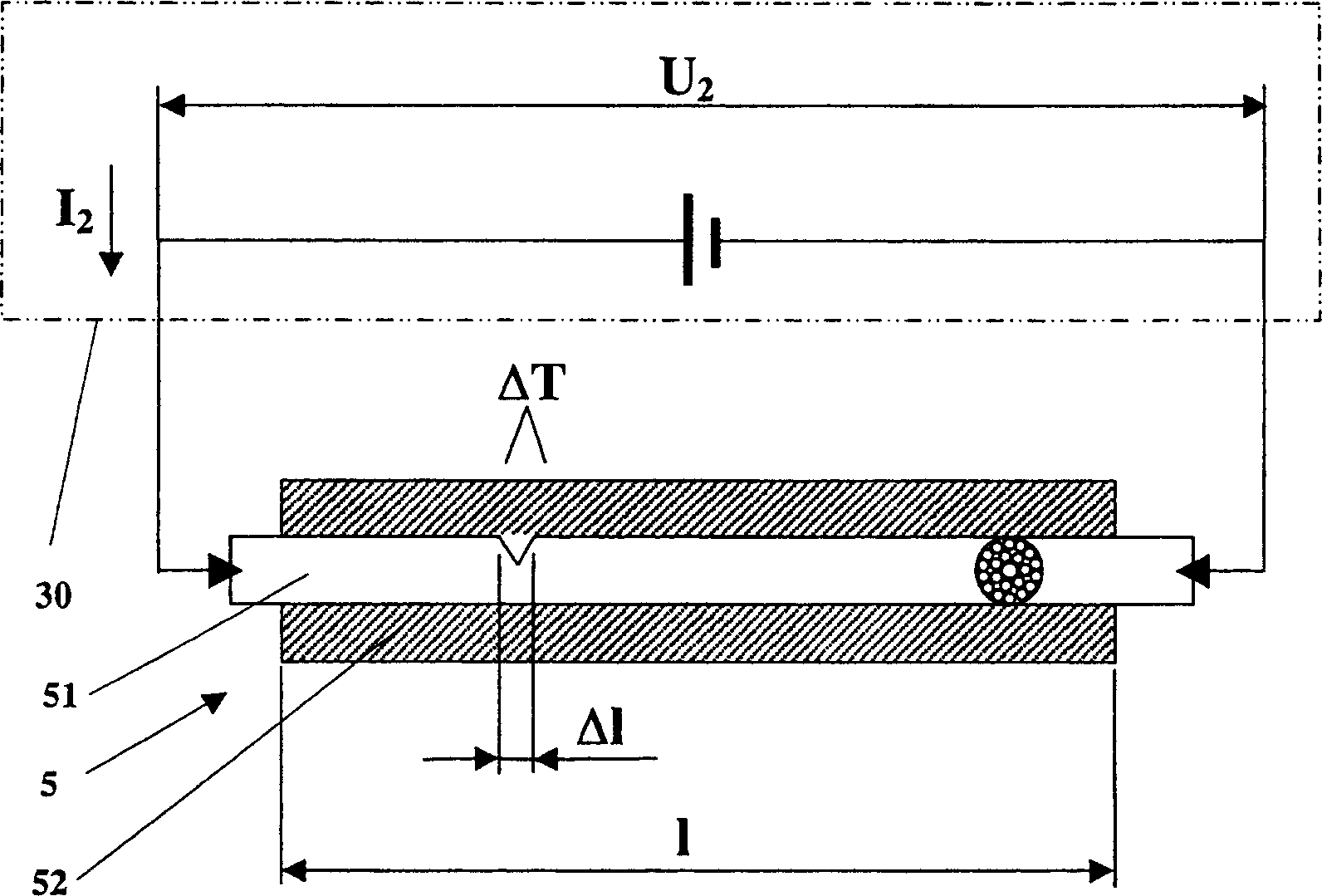

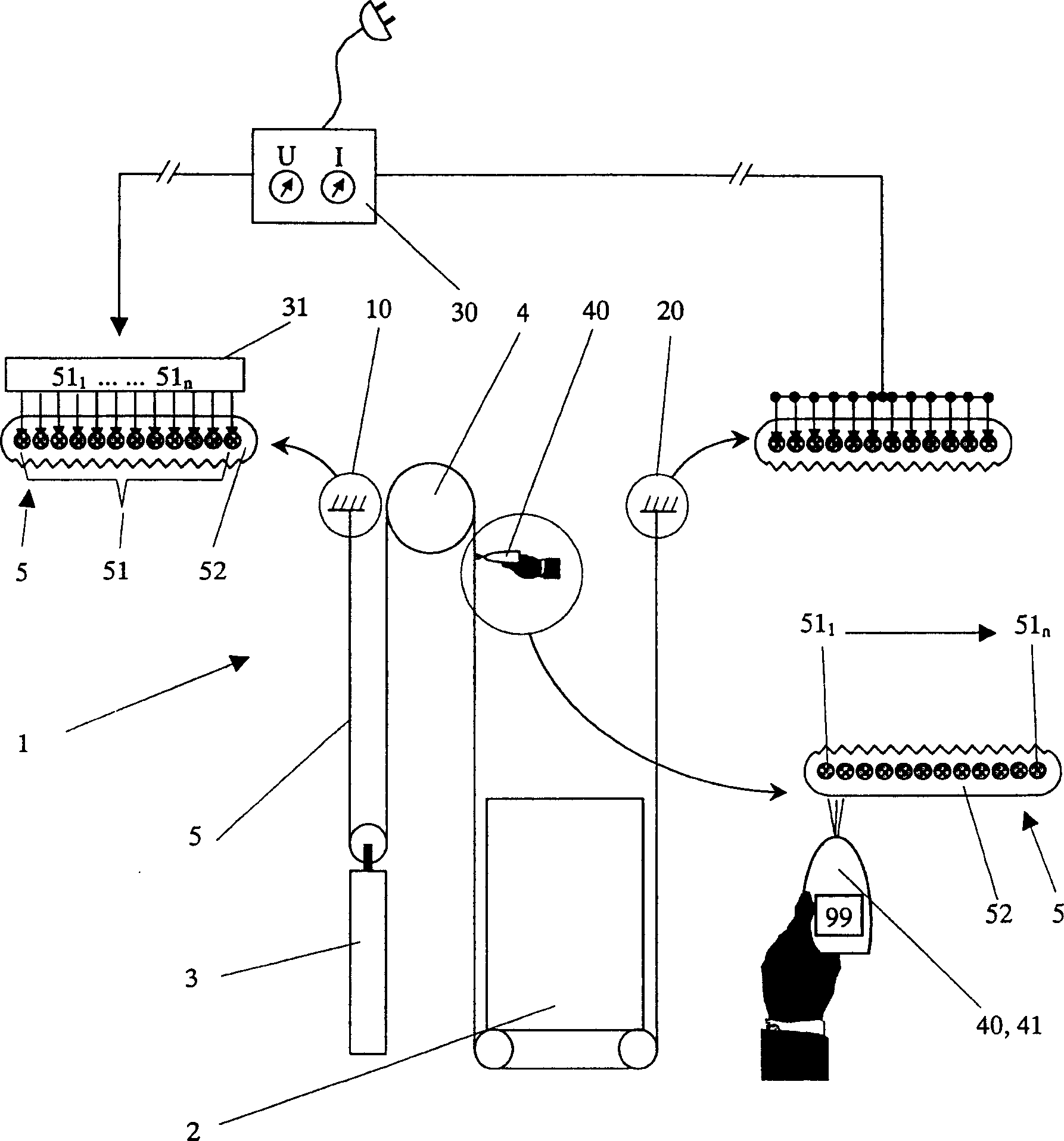

[0040] figure 1 and 2 The physical connections of the present invention are shown. The traction mechanism 5 is composed of a tensile carrier 51 . The tensile carrier 51 is made of conductive material or is conductive as a whole. The tensile carrier 51 is surrounded by a sheath 52 or embedded in said sheath 52 . Sheath 52 is constructed of a substantially insulating material, such as polyamide. The sheath substantially insulates the individual tensile carriers 51 from one another. The traction mechanism 5 has a length 1 which is adapted to the intended application.

[0041] exist image 3 In the example shown in to 7, the traction mechanism 5 consists of 12 tensile carriers 51 twisted from individual steel wires in the form of cable strands. In the example shown, the tensile carrier 51 has a diameter of approximately 1.5 mm to 2.0 mm. The tensile carriers 51 are spaced apart from one another and are entirely surrounded by plastic. The jacket 52 substantially insulates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com