Fluoroplastic-metal valve element and molding technological method thereof

A metal valve core and molding process technology, applied in valve devices, engine components, mechanical equipment, etc., can solve the problems of liquid penetration, poor reliability, high fluorine plastic-metal bonding surface, etc., to improve the bonding performance, good The effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

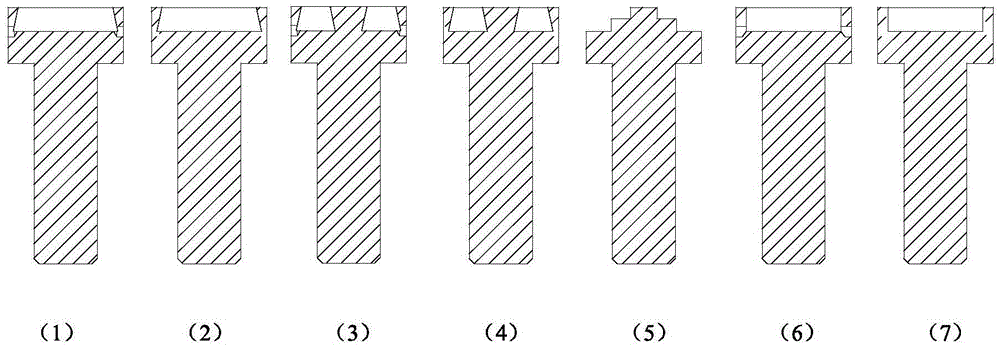

[0024] (1) Cleaning of the metal substrate of the spool: the metal substrate of the spool is cleaned with gasoline and absolute ethanol respectively to remove impurities on the surface of the metal substrate;

[0025] (2) Sandblasting: Use 20-60 mesh quartz sand to sandblast the valve head and the bottom surface, the pressure of the compressed air flow is 0.5MPa, and polish the burrs on the metal edge after sandblasting;

[0026] (3) Clean the sandblasting surface: Soak the metal substrate of the valve core in gasoline for 24 hours after sandblasting, then use a brush dipped in gasoline and alcohol to clean the sandblasting surface twice, dry naturally and store in a desiccator;

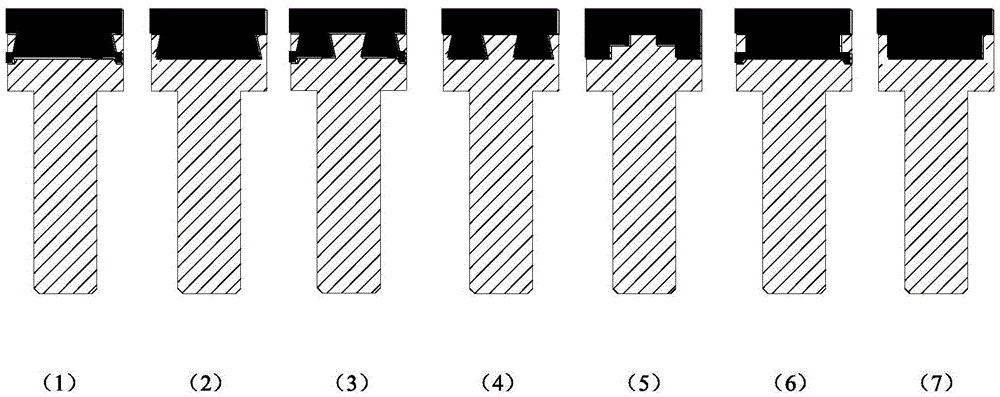

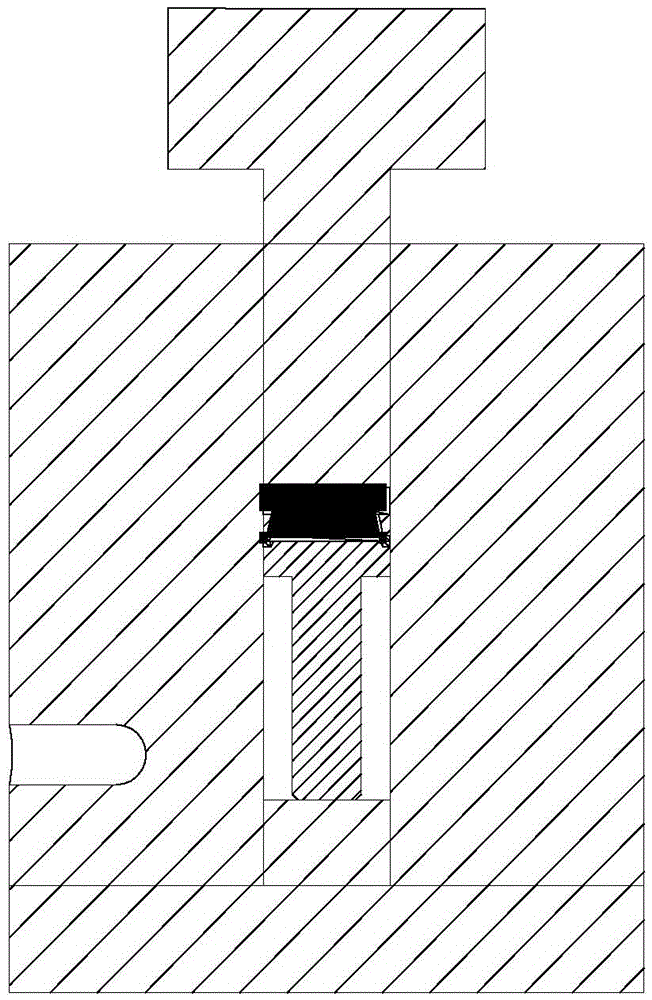

[0027] (4) FEP transition layer spraying: place the metal substrate of the valve core with the sandblasted side upward, place it on the substrate fixing tool and transfer it to the sintering furnace. After the sintering furnace is heated to 310 ° C, the sintered valve core Take out the metal substrat...

Embodiment 2

[0033] (1) Cleaning of the metal substrate of the spool: the metal substrate of the spool is cleaned with gasoline and absolute ethanol respectively to remove impurities on the surface of the metal substrate;

[0034] (2) Sandblasting: use 20-60 mesh quartz sand to sandblast the valve head and the bottom surface, the pressure of the compressed air flow is 0.75MPa, and polish the burrs on the metal edge after sandblasting;

[0035] (3) Clean the sandblasting surface: Soak the metal substrate of the valve core in gasoline for 24 hours after sandblasting, then use a brush dipped in gasoline and alcohol to clean the sandblasting surface for 3 times, dry naturally and store in a desiccator;

[0036] (4) Spraying of polytrifluorochloroethylene transition layer: place the metal substrate of the valve core with the sandblasted side upward, place it on the substrate fixing tooling and transfer it to the sintering furnace. After the sintering furnace is heated to 210 ° C, the sintered va...

Embodiment 3

[0042] (1) Cleaning of the metal substrate of the spool: the metal substrate of the spool is cleaned with gasoline and absolute ethanol respectively to remove impurities on the surface of the metal substrate;

[0043] (2) Sandblasting: Use 20-60 mesh quartz sand to sandblast the valve head and the bottom surface, the pressure of the compressed air flow is 0.6MPa, and polish the burrs on the metal edge after sandblasting;

[0044] (3) Clean the sandblasting surface: Soak the metal substrate of the valve core in gasoline for 24 hours after sandblasting, then use a brush dipped in gasoline and alcohol to clean the sandblasting surface for 3 times, dry naturally and store in a desiccator;

[0045] (4) Spraying of polyvinylidene fluoride transition layer: Put the sandblasted surface of the valve core metal substrate upwards, place it on the substrate fixing tooling and transfer it to the sintering furnace. After the sintering furnace is heated to 210 ° C, the sintered valve core met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com