Manufacturing method and manufacturing device of flexible printed circuit

A flexible printed circuit and manufacturing device technology, applied in the direction of conductive pattern formation, etc., to achieve the effect of increasing density, high-quality flexible circuit manufacturing, and avoiding porous and loose structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

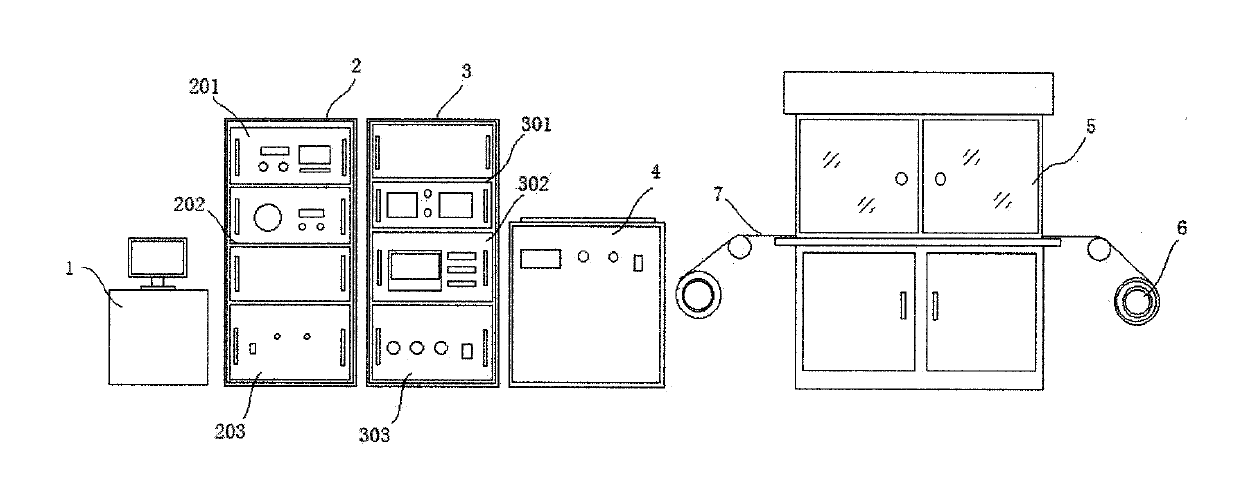

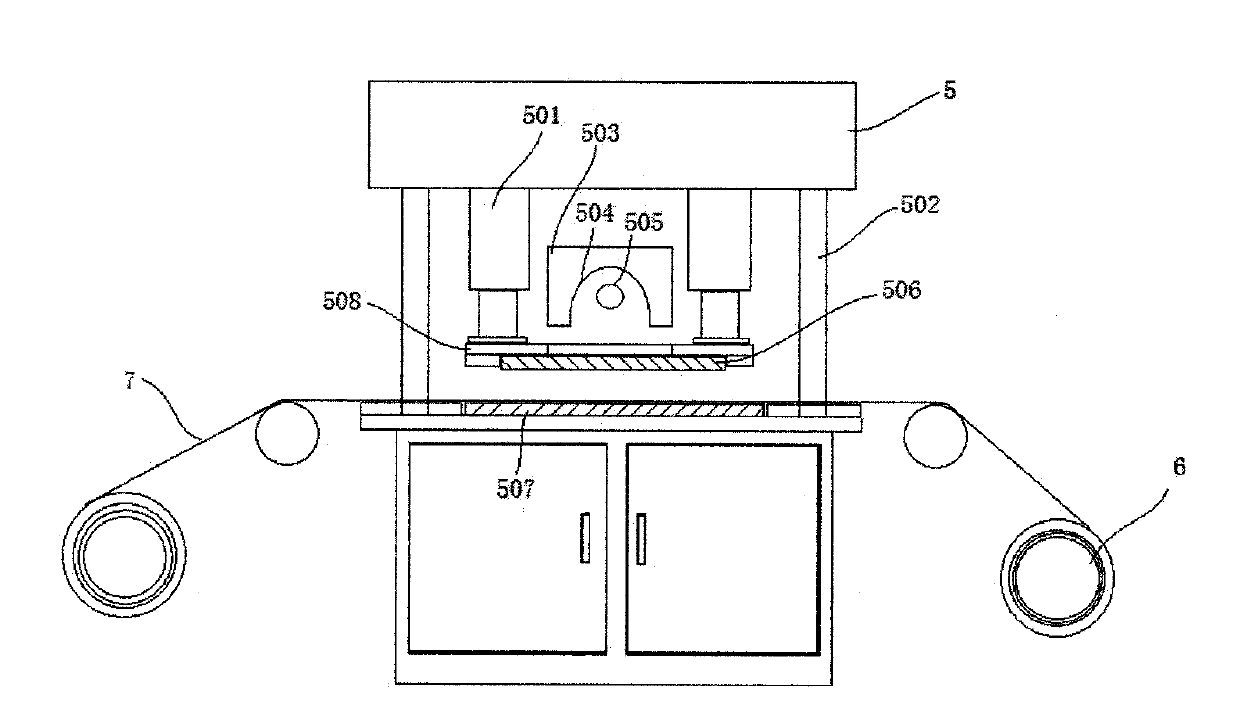

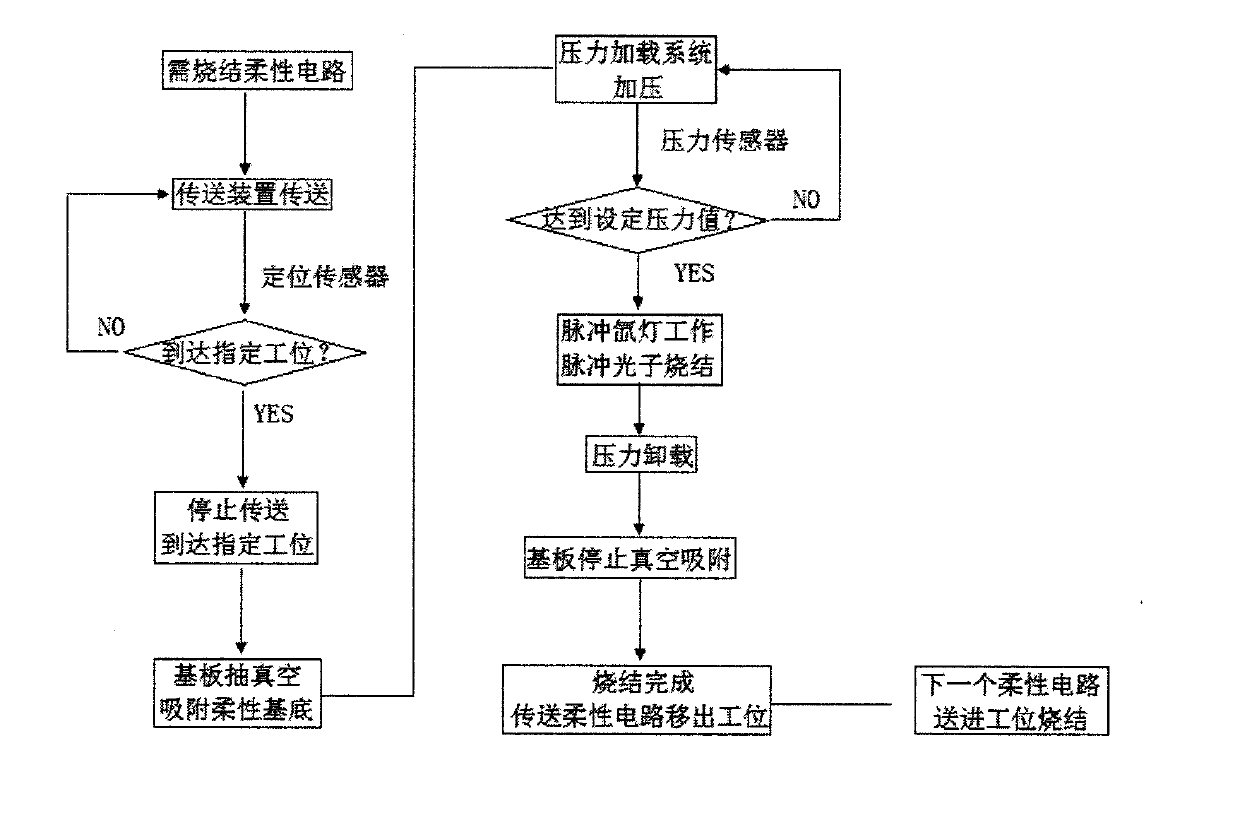

[0032] As mentioned above, in the existing manufacturing process of flexible printed circuit, there are still many deficiencies in the nanoparticle conductive ink sintering technology. technology, a method for manufacturing a flexible printed circuit is proposed, which includes the following steps: providing a patterned flexible printed circuit substrate coated with nano-conductive ink; applying pressure to the upper surface of the flexible printed circuit substrate; The flexible printed circuit substrate is sintered by a xenon lamp sintering process while under pressure to obtain a flexible printed circuit.

[0033] Wherein, according to different choices of materials of the flexible printed circuit substrate, the method of applying pressure to the flexible printed circuit substrate can be a constant pressure method or a variable pressure method; the applied pressure can be selected within the range of 0-40MPa.

[0034] Wherein, the nano-particles in the nano-conductive ink o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com