Patents

Literature

104results about How to "Applicable productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

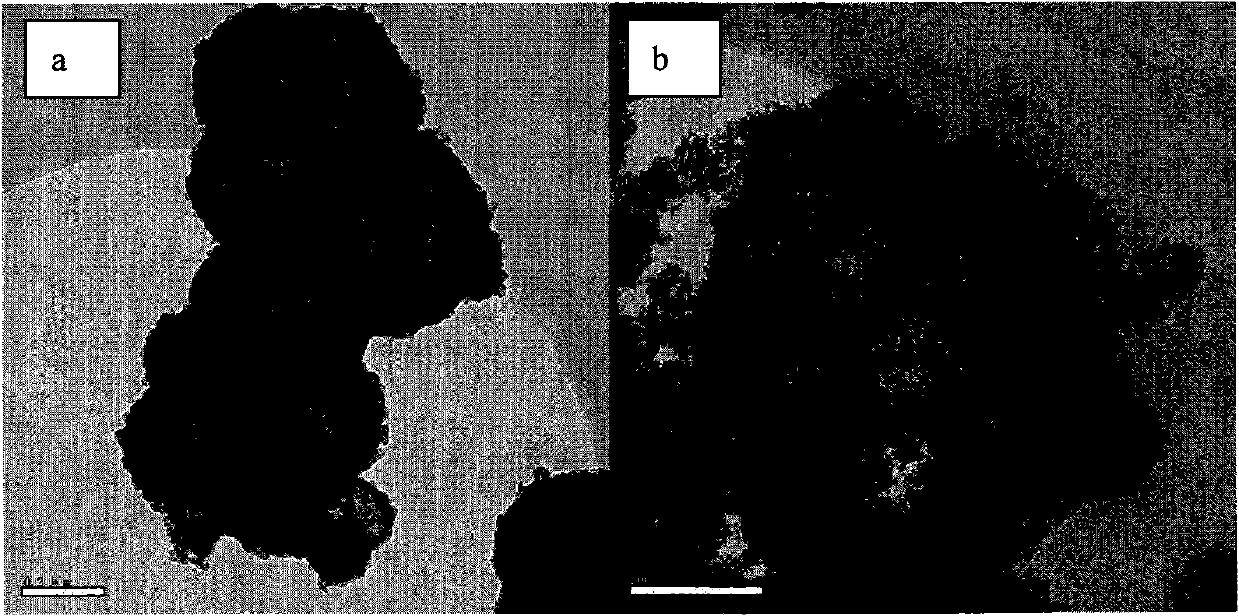

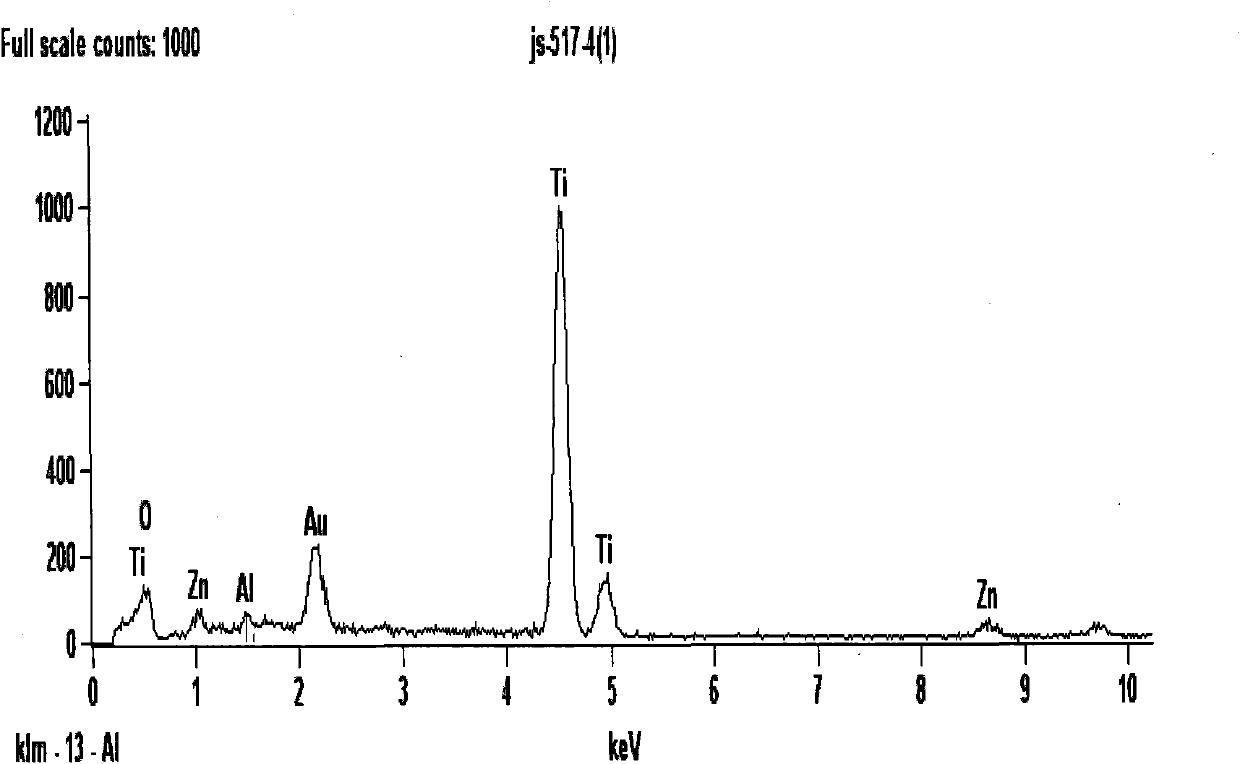

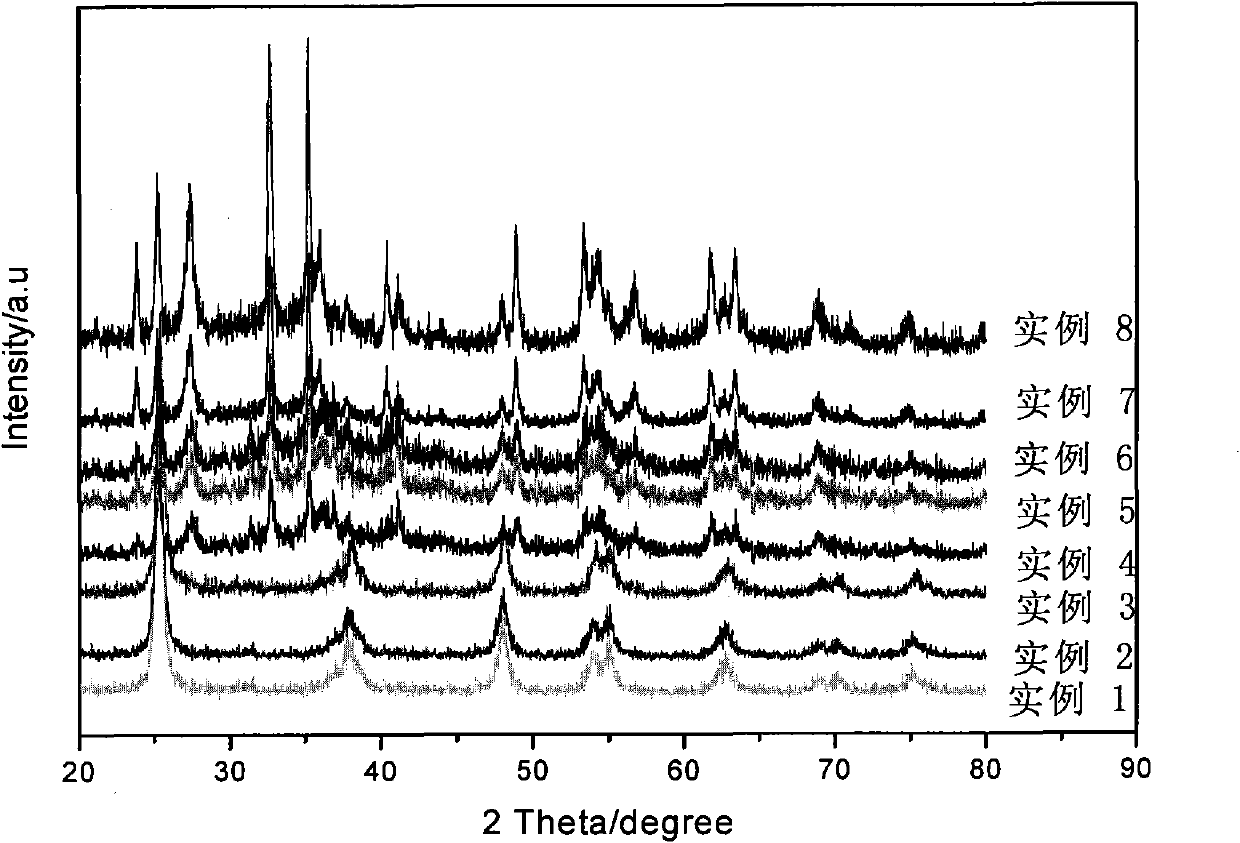

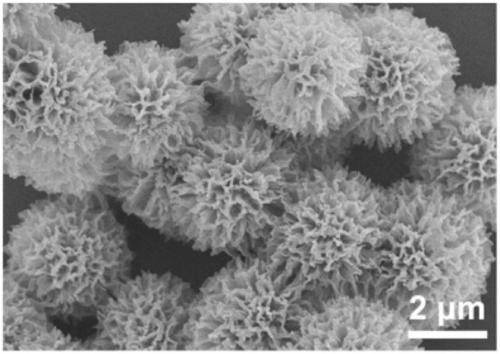

Preparation method and application of ZnO-doped TiO2 composite hollow sphere

InactiveCN101905153ALow costNo pollution in the processWater/sewage treatment by irradiationEnergy based wastewater treatmentSpectral responsePhoton

The invention discloses a preparation method of a ZnO-doped TiO2 hollow sphere composite photocatalyst, comprising the following steps of: preparing Zn<2+> doped carbon / titanium dioxide nuclear-shell particles by adopting a template method and a hydrolytic cladding method, and then calcinating the nuclear-shell particles to obtain the ZnO-doped TiO2 nano hollow sphere composite photocatalyst. The photocatalyst can be used for catalyzing and degrading cationic dyes under ultraviolet or solar visible light. By utilizing low-cost titanium sources, zinc sources and carbon spheres for preparing the ZnO-doped TiO2 nano hollow sphere composite photocatalyst, the preparation method has the advantages of low cost of raw materials, simple process, short preparation period, less energy consumption and belongs to green synthetic technologies. After TiO2 hollow spheres are doped and compounded by utilizing ZnO, absorption spectrums generate red shift by utilizing the interface coupling effect of the TiO2 hollow spheres and the ZnO so that the spectral response range of the photocatalyst is broadened, and the utilization rate of solar energy is improved; and meanwhile, the method can also inhibit the compounding of photon-generated carriers and improve the activity of the photocatalyst by utilizing the high conductivity of ZnO particles.

Owner:JIANGSU UNIV

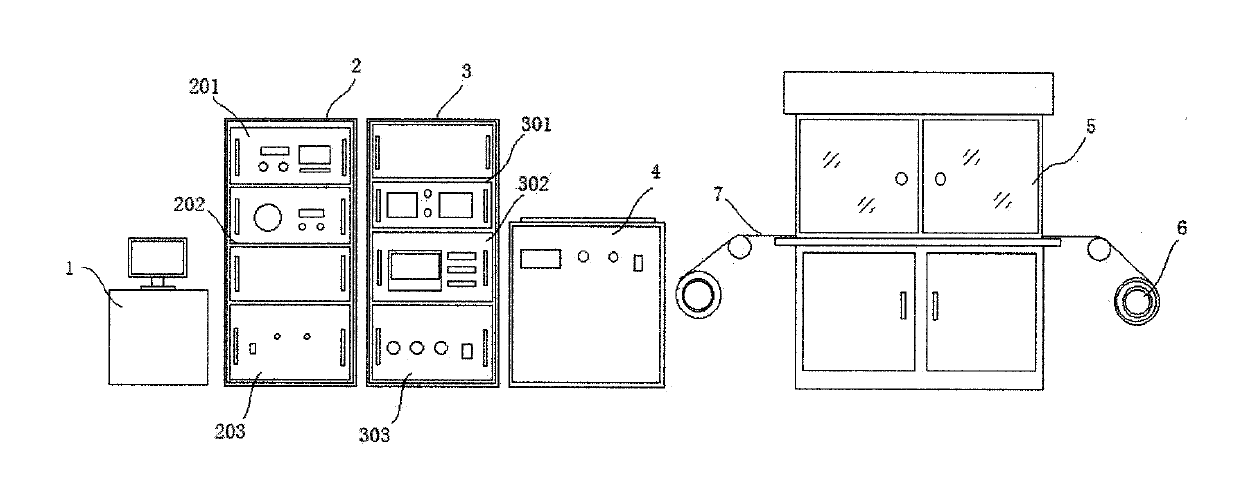

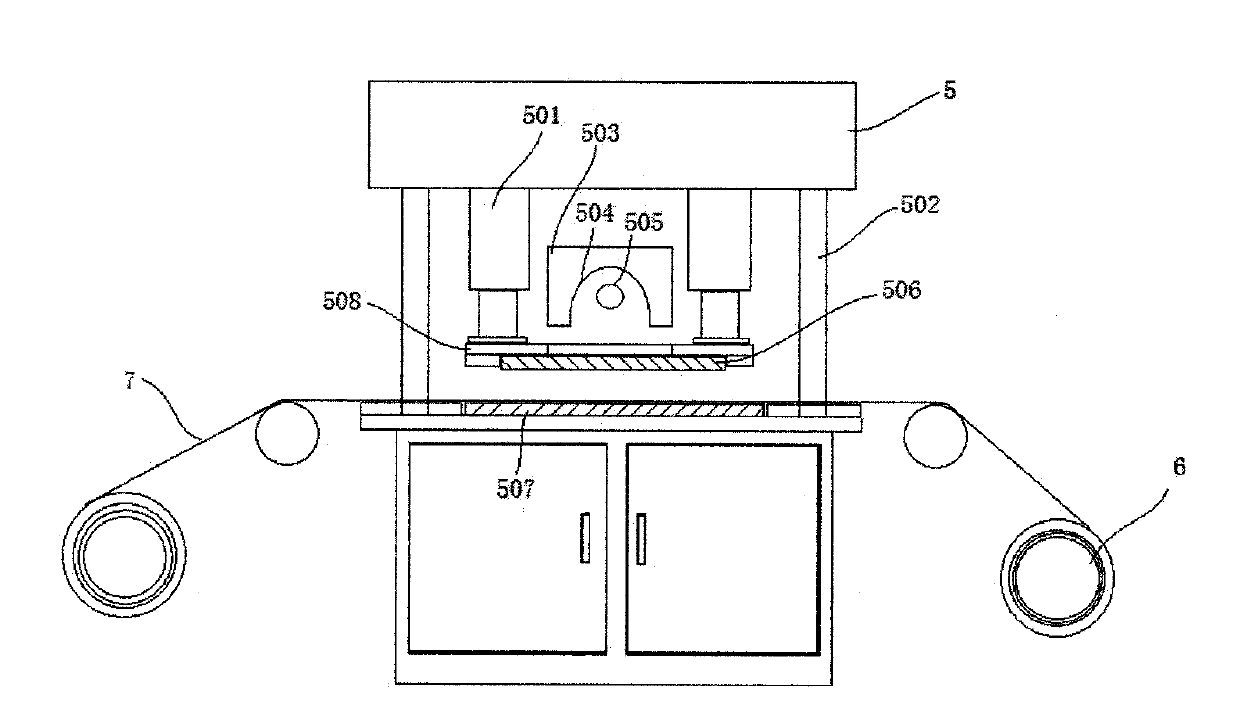

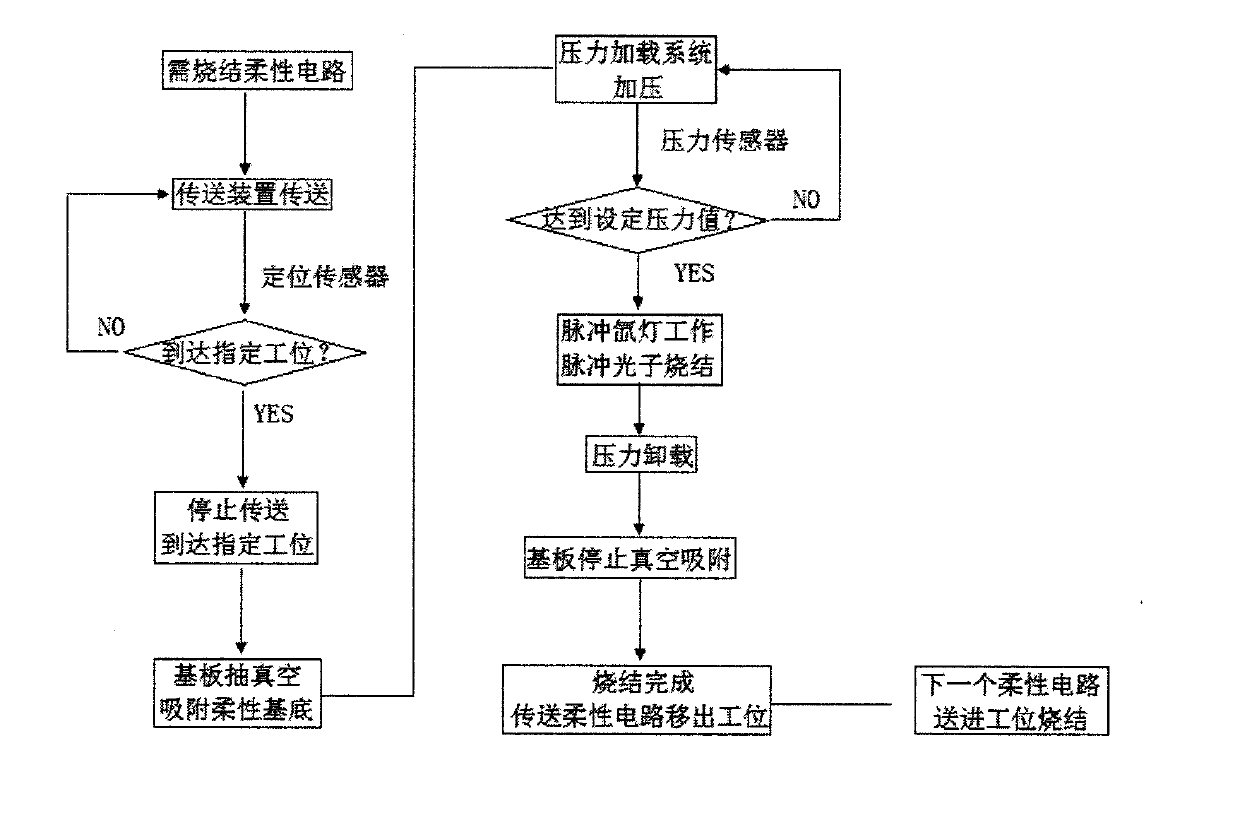

Manufacturing method and manufacturing device of flexible printed circuit

The invention discloses a manufacturing method and a manufacturing device of a flexible printed circuit. The method mainly includes the steps of providing an imaging flexible printed circuit substrate which is coated with nanometer conductive ink or sizing agents; exerting pressure to the flexible printed circuit substrate; and sintering the flexible printed circuit substrate by using xenon lamp sintering technology at the same time when the pressure is exerted and obtaining a target product. By means of the method, a printed circuit can be rapidly manufactured on a low temperature flexible substrate, a metal film which is good in binding force, electrical conductivity and compactness can be obtained, and manufacturing cost is low. The method avoids the processes such as photoetching in the manufacturing process of a traditional flexible printed circuit, rapid and pollution-free flexible printed circuit manufacturing is achieved, and the method is suitable for the production and the manufacture of the flexible printed circuit of the low temperature substrate.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

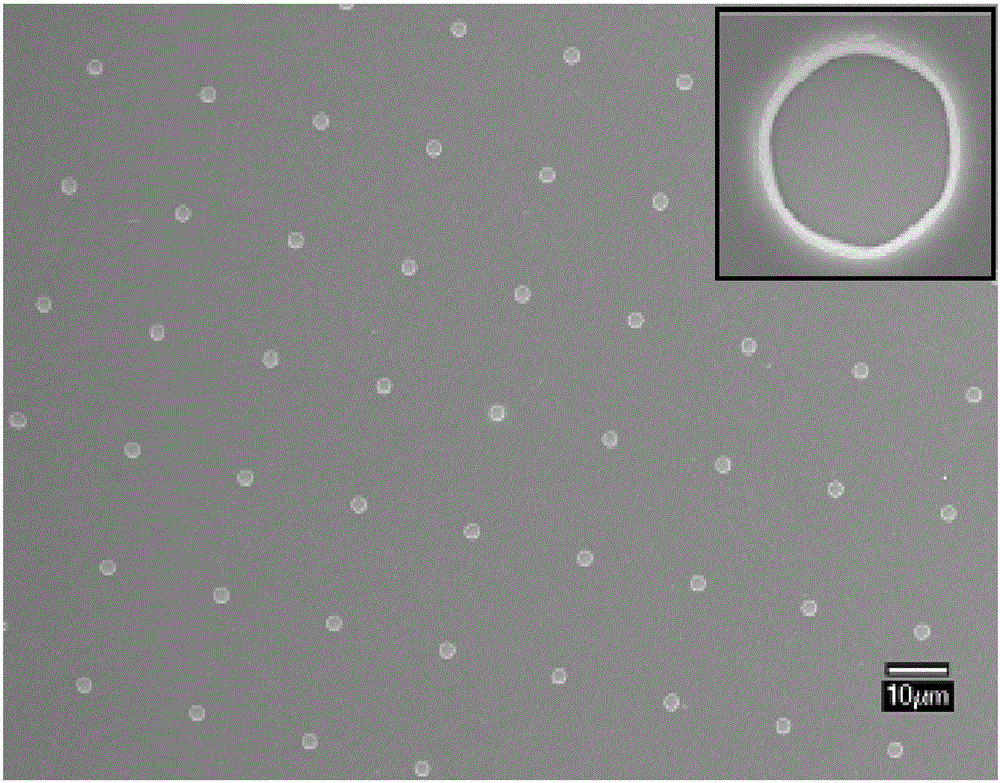

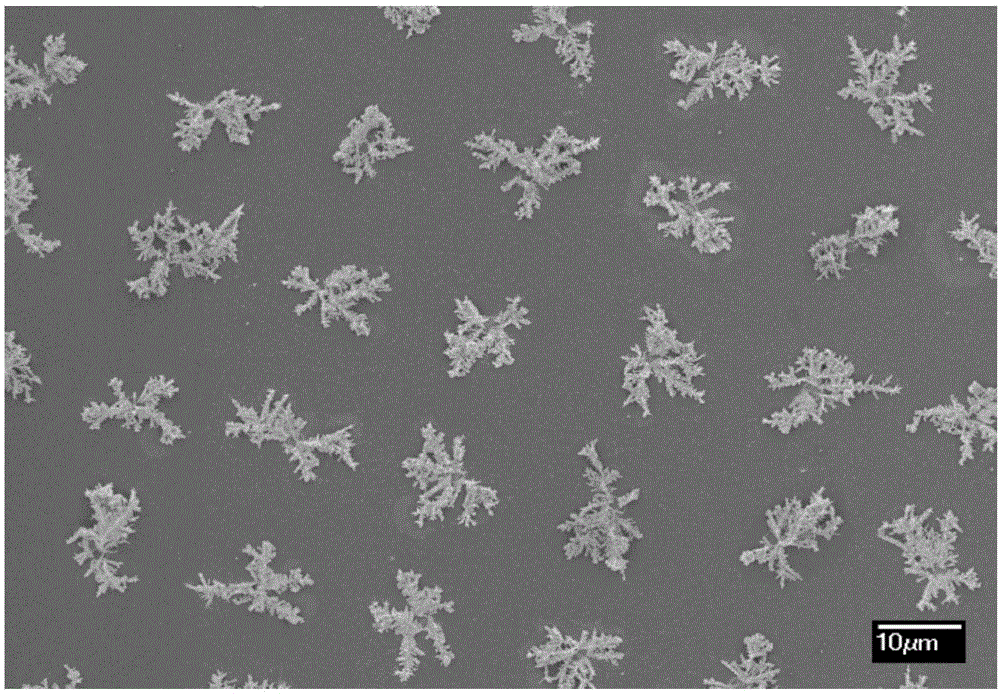

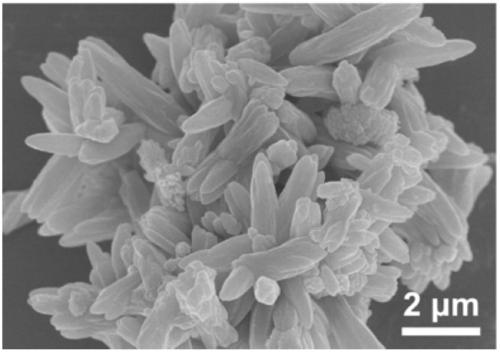

Preparation method for metal nanometer/micrometer dendritic crystal ordered array

InactiveCN106498464AThickness is easy to controlGood size controlNanotechnologyMicrometerSURFACTANT BLEND

The invention discloses a preparation method for a metal nanometer / micrometer dendritic crystal ordered array. A conductive array substrate is used as a working electrode, an electrolyte comprises a metal salt solution and an additive with the dosage being 0-5% of the metal salt solution by molar concentration, and metal nanometer / micrometer dendritic crystals are electrically deposited on the surface of the substrate in a controlled mode through a volt-ampere method, so that the metal nanometer / micrometer dendritic crystal ordered array is obtained. The conductive array substrate is provided with an ordered conductive array, the additive comprises at least one of a complexing agent and a surfactant, and the additive is used for promoting the forming of the metal nanometer / micrometer dendritic crystals and regulating and controlling the morphology. According to the preparation method for the metal nanometer / micrometer dendritic crystal ordered array, the process is simple, operation is easy, the preparation time is short, efficiency is high, and the method is suitable for industrial production and application; and the obtained metal nanometer / micrometer dendritic crystal ordered array is controllable in shape, thickness and size.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

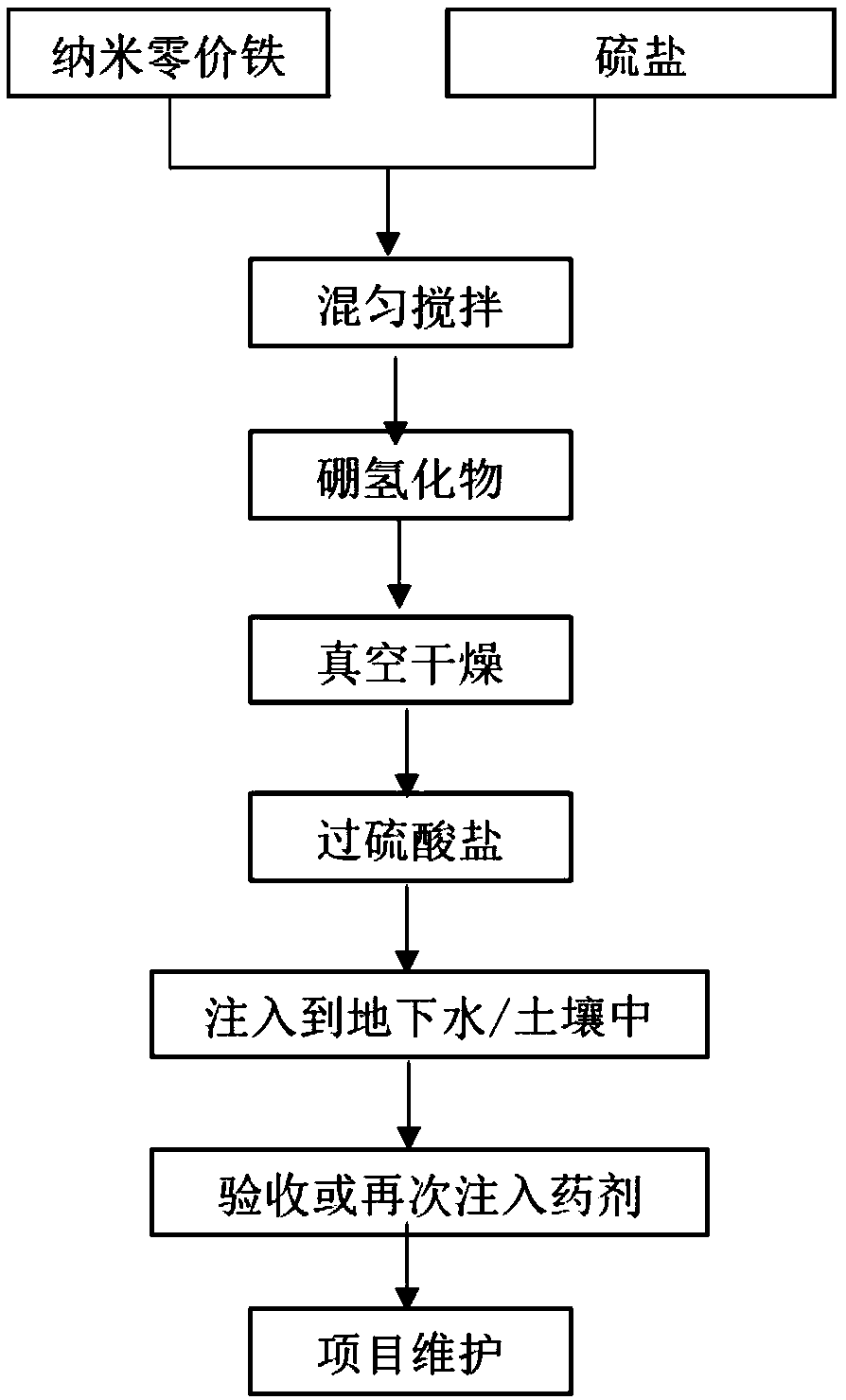

Method for repairing organic pollutants in polluted soil and underground water

InactiveCN108856275ALow cost and readily availableEasy to produceWater contaminantsContaminated soil reclamationPersulfateSulfide

The invention discloses a preparing method for a composite repairing agent and the composite repairing agent prepared through the method. The preparing method comprises the steps that nanometer zero-valent iron is added in a sulfosalt solution, and a sulfosalt and nanometer zero-valent iron mixed solution is obtained; a hydroboron solution is added in the mixed solution to be sufficiently stirred,sulfide is reduced through the reducing capability of hydroboron, supernate is removed, and a vulcanized nanometer iron solid is obtained; and the vulcanized nanometer iron solid and a persulfate solution are mixed, and the composite repairing agent is obtained. A method for repairing organic pollutants in polluted soil and underground water through the composite repairing agent is further disclosed. The method can be widely applied to water treatment and soil repairing and has the beneficial effects that the production technology is simple, and preparing raw materials are easy to obtain; andsynchronous treatment of the organic matter in the polluted soil and the underground water is achieved, and good economic benefits and social benefits are achieved.

Owner:NANJING WONDUX ENVIRONMENTAL PROTECTION TECH CO LTD

Method for extracting cyclic adenosine monophosphate (cAMP) from red jujubes

InactiveCN101525363AThe process consumes less energySimple processSugar derivativesUltrafiltrationFood additiveFiltration membrane

The invention relates to a method for extracting cyclic adenosine monophosphate (cAMP) from red jujubes, which comprises the steps of cleaning of the red jujubes, soaking of the red jujubes at normal temperature, precooking and pulping, zymohydrolysis on pectin mixed enzyme, filter pressing, anion resin combination, formic acid elution, nano-filtration and interception of formic acid with nano-filtration membrane, and purification, thus obtaining a finished product. The method solves the problems of complex current process, long period, low product purity and the like, and has the advantages of rich raw material sources, simple process, large processing amount, high extraction rate, high product purity and the like; the product is a natural non-toxic product; the finished product cAMP can be used for medical raw materials or used as food additive; the extracted byproduct red jujube juice can be continuously and deeply processed to promote the industrial chain of comprehensive development and achieve pollution-free production; the modern nano-filtration technology is applied to industrial production, therefore, not only the cost is reduced, but also a better path for deeply processing the red jujube raw material is provided, and the consumption of energy is greatly reduced; and the method not only has important economic benefit, but also has remarkable social benefits.

Owner:TIANJIN UNIV OF SCI & TECH

Plant protein adhesive as well as preparation method and application thereof

ActiveCN107641495ASolve pollutionReduce manufacturing costProtein adhesivesMacromolecular adhesive additivesAdhesiveRaw material

The invention provides a plant protective adhesive as well as a preparation method and application thereof. The adhesive provided by the invention takes green raw materials as a cross-linking agent, and the prepared raw materials do not contain formaldehyde, so that the formaldehyde release problem of the adhesive is radically and completely solved, and therefore, the adhesive is greener and moreenvironmentally friendly. According to the results of the embodiment, the plant protein adhesive does not contain poisonous and harmful substances such as free formaldehyde and free benzene series compounds, and is completely green, so that a green and environmentally-friendly fine wooden board without harmful substance release can be manufactured. The plant protein adhesive prepared by the preparation method has viscosity of 4520-9860 MPa.s which is obviously greater than viscosity (3490-3610 MPa.s) of the adhesive prepared according to the methods 1-3.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Preparation method of Ni-SiC compound coating on surface of aluminum alloy and electroplating solution thereof

ActiveCN105506526AImprove bindingHigh hardnessHot-dipping/immersion processesElectrolytic coatingsHardnessAmmonium bromide

The invention discloses a preparation method of a Ni-SiC compound coating on the surface of an aluminum alloy. The preparation method adopts an anode type surfactant which is hexadecyl trimethyl ammonium bromide for replacing a cathode type surfactant which is lauryl sodium sulfate adopted by the invention at present. The preparation method is characterized by increasing the concentration of an anode activator NiCl2 while reducing current density and the concentration of silicon carbide in a plating solution, obtaining a fine and dense compound coating at an electroplating rate of 1-2 micron per minute, stirring by using air with volume flow being 4-7L / min and fully dispersing the silicon carbide, simultaneously adding CTAB to improve the wettability of the silicon carbide and obtain a fine and dense compound coating with high content of uniformly-dispersed silicon carbide. Through the preparation method of the Ni-SiC compound coating on the surface of the aluminum alloy, the technical problem of low tensile performance and low abrasion resistance of the aluminum alloy can be solved; the Ni-SiC compound coating with high adhesion strength, high content of uniformly-distributed hard silicon carbide particles, high hardness and high abrasion resistance can be prepared on the surface of the aluminum alloy.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

High-performance waterborne inorganic paint and preparation method thereof

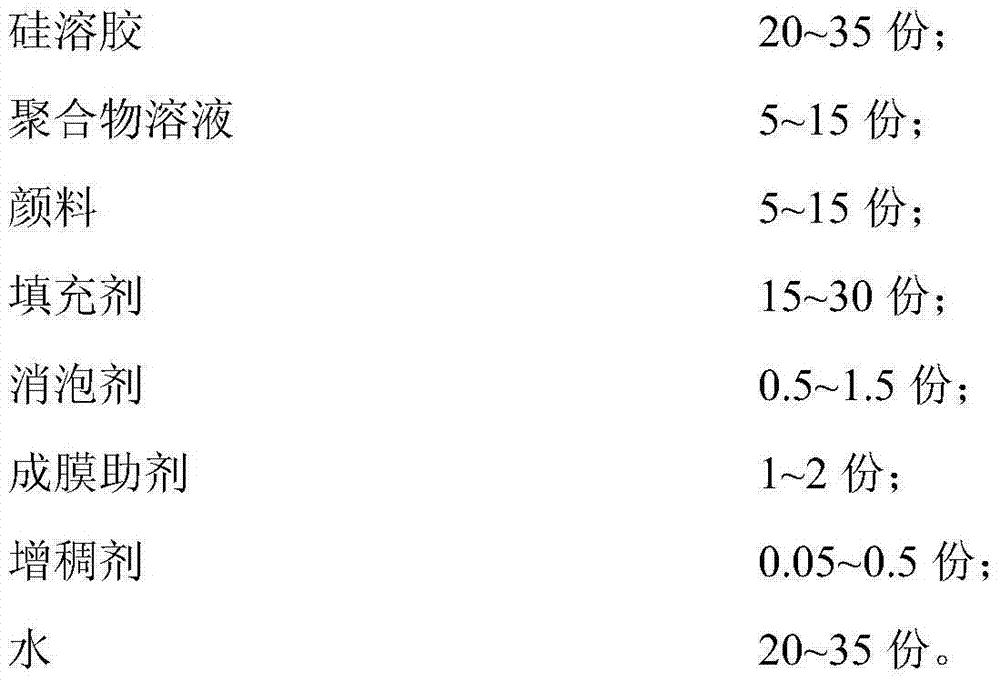

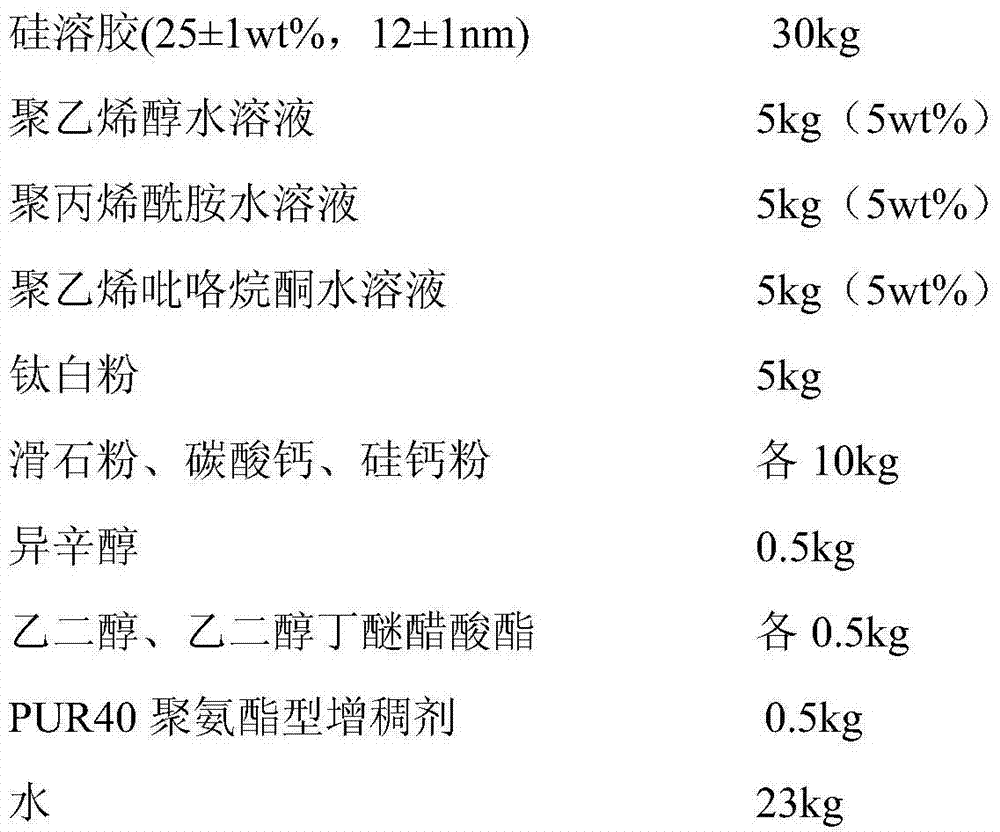

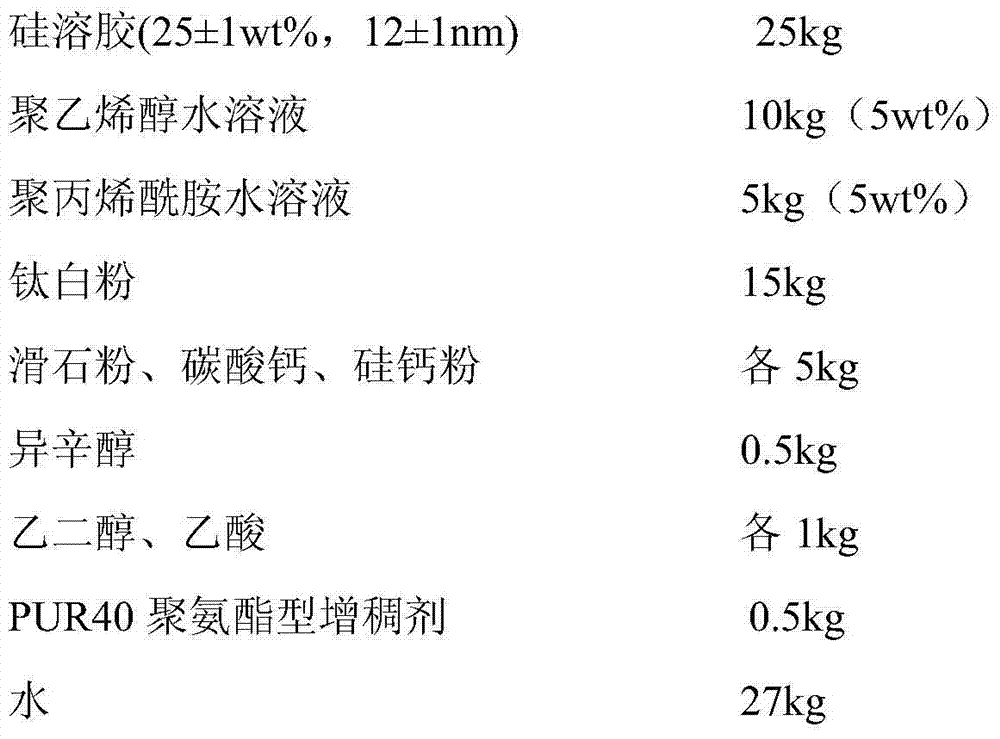

The invention relates to the field of chemical engineering, in particular to a high-performance waterborne inorganic paint and a preparation method thereof. The high-performance waterborne inorganic paint, provided by the invention, comprises the following ingredients in parts by weight: 20-35 parts of silica sol, 5-15 parts of a polymer solution, 5-15 parts of a pigment, 15-30 parts of a filling agent, 0.5-1.5 parts of a foam breaking agent, 1-2 parts of a coalescing agent, 0.05-0.5 part of a thickening agent, and 20-35 parts of water. The waterborne inorganic paint introduces an organic macro molecule solution, so as to optimize the ratio of pigment, the filling material, the foam breaking agent and the coalescing agent, and obtain the high-performance waterborne inorganic paint which is environment-friendly and has remarkably strong adhesion, good leveling property and glossiness property, as well as other characteristics; the preparation method is simple and reliable, and is low in manufacturing cost, thereby being suitable for industrial manufacture and application.

Owner:SHANGHAI XINANNA ELECTRONICS TECH +1

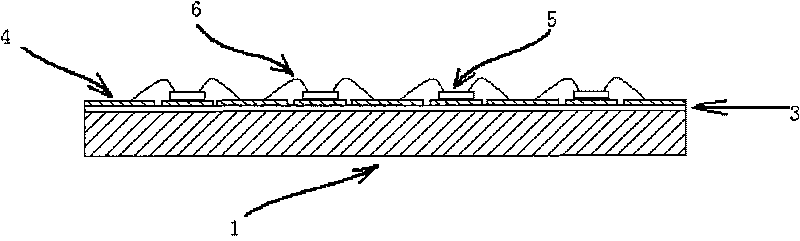

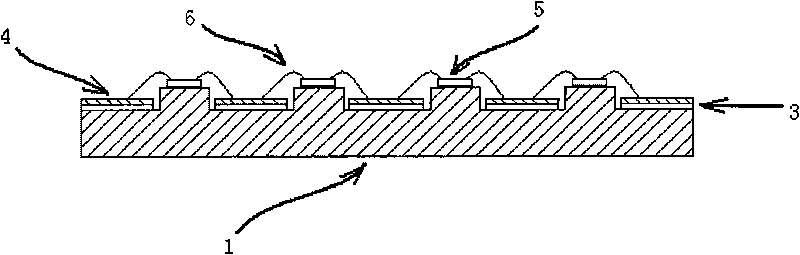

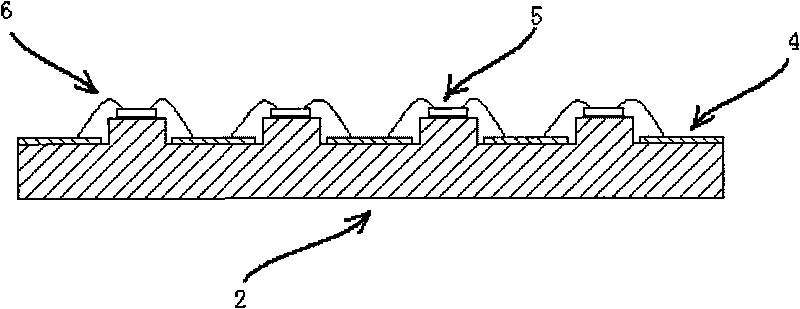

Packaging substrate structure for LED and production method thereof

InactiveCN101752354AEase of lightImprove light color distributionSemiconductor/solid-state device detailsSolid-state devicesHeat conductingEngineering

The invention discloses a packaging substrate structure for an LED and a production method thereof. An LED substrate of the invention is characterized in that a boss with the specific size, shape and height is formed on a die bonding or eutectic position of a common LED substrate; and the boss is directly connected with the substrate. The substrate outside the boss is paved with a circuit connection layer. An LED chip is bonded on the boss in a die bonding or eutectic mode. Compared with the common metal PCB, the LED substrate on the boss position reduces an insulating material layer with bad heat-conducting property so that the heat generated by the high-power LED chip can be better dissipated through the substrate from the bottom. The boss structure increases the utilization of the emitted light on the lateral surface of the LED chip, improves the light-extraction efficiency, reduces the influence of the reflector cup, increases the light emergent angle, and greatly improves the light color distribution of the LED.

Owner:SUN YAT SEN UNIV

Magnesium-aluminium composite material and its preparing method

InactiveCN1821435AOvercome the disadvantages of poor corrosion resistanceImprove shock absorptionSolid state diffusion coatingAl powderElectromagnetic shielding

The present invention is composite Mg-Al material and its preparation process, and belongs to the field of material producing engineering. Specifically, the present invention is the technological prof embedding Mg or Mg alloy in Al powder, Al alloy powder, or the homogeneous mixture of Al powder or Al alloy powder, Al2O3 and NaF; and maintaining at 350-500 deg.c for 30-120min under vacuum or reducing gas protection condition to form compact aluminizing layer on the surface of Mg or Mg alloy. The composite Mg-Al material with Mg or Mg alloy base and surface aluminizing layer is superior to Mg and Mg alloy, which has poor corrosion resistance, excellent shock eliminating performance, electromagnetic shielding performance, etc. similar to that of Mg and Mg alloy, and excellent surface modification performance.

Owner:TAIYUAN UNIV OF TECH

Method of forming nanostructure on friction surface of metal friction pair and special composition thereof

ActiveCN102230063AImprove performanceApplicable to industrialization promotionAdditivesContact pressureRelative motion

The invention provides a method of forming nanostructure on the friction surfaces of metal friction pairs and a special composition thereof. The method is characterized by that: the special composition is added in a lubricant medium that the metal friction pairs used with the weight ratio of 0.01-2%, under the working condition of the metal friction pairs, the special composition particles are brought to the friction surfaces of the metal friction pairs by the lubricant medium, under the high contact pressure generated from the friction surfaces of the metal friction pairs and the repeated actions of the composite forces composed of extrusion and rolling generated by relative motions between the friction surfaces, the open grain structures on the friction surfaces are allowed to generate strong microscopic plastic deformation repeatedly by the special composition particles, the metal friction pairs run for 1-100 cumulative working hours, so that the nano-structured crystal layer on the respective friction surface of the metal friction pair is online realized respectively, with the particle size of less than 100 nanometer, and the thickness of the nano-structured crystal layer of 2-10 micrometer. The invention has the advantages of extremely simple processing, extremely high production efficiency, low processing cost, no processing energy consumption and the like, is very suitable for large range industrialization and large scale production, having a far-reaching influence on machinery equipment manufacturing industry and mechanical parts processing industry.

Owner:孙静

Device used for welding copper tube and aluminum tube in refrigeration equipment and welding method thereof

ActiveCN104191081ANo consumptionNice appearanceHigh frequency current welding apparatusWelding/soldering/cutting articlesMagnetic tension forceTransformer

The invention discloses a device used for welding a copper tube and an aluminum tube in refrigeration equipment and a welding method of the device. The device comprises a main device body and a working table, wherein the main device body comprises a main box, an alternating-current power source, a transformer, a high-voltage rectifier, a capacitor set, vacuum switches and a triggering device; the working table comprises a rack and a welding head, the welding head comprises an electric conducting coil and a magnetic flux concentrator, and the electric conduction coil is connected with all the vacuum switches through coaxial cables. The welding method includes the following steps that (1), one end of an outer tube is inserted in the magnetic flux concentrator, and one end of an inner tube is inserted into the magnetic flux concentrator; (2), a pulser is started, when a charging voltage reaches a set value, the system control triggering device turns on a discharging switch, and the outer tube and the inner tube are welded through magnetic force in the magnetic flux concentrator. The device used for welding the copper tube and the aluminum tube in the refrigeration equipment achieves normal-temperature welding, and is more convenient and faster to use, more environmentally friendly and lower in welding cost.

Owner:CHONGQING PULSAR TECH

High-gloss scratch-resistant flame-retardant polypropylene material and preparation method thereof

The invention belongs to the technical field of polymer materials and relates to a modified polypropylene material and a preparation method thereof. The modified polypropylene material is prepared from the following components in parts by weight: 74-81.2 parts of polypropylene resin, 12-15 parts of a fire retardant, 4-5 parts of a flame retardant synergist, 0.3-1 part of a compatilizer, 0.2-0.5 part of an antioxidant, 0.3-0.5 part of a lubricant and 2-4 parts of a scratch-resistant agent. According to the high-gloss scratch-resistant V-0 flame-retardant polypropylene material, the bromine flame retardant with low melting point and the flame retardant synergist are reasonably proportioned, so that high glossiness of the material is guaranteed while the flame retardant grade V-0 of the material is reached; in addition, the material has the advantages of excellent scratch resistance, low cost, easiness for large-scale industrialization production and the like.

Owner:HEFEI GENIUS NEW MATERIALS

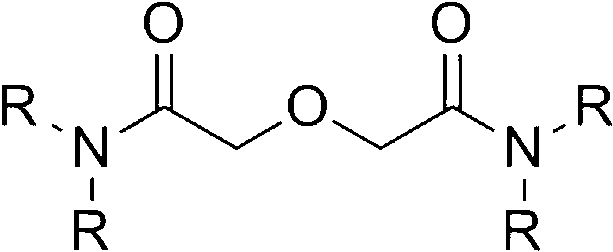

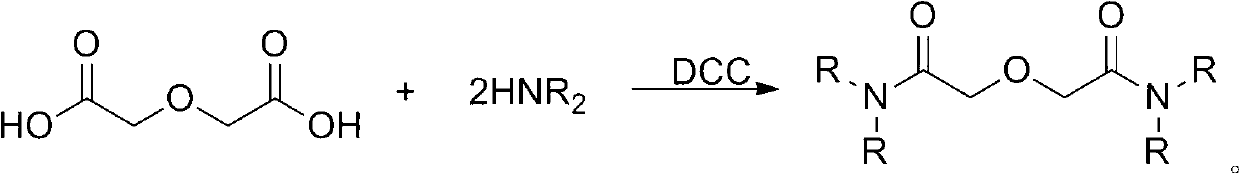

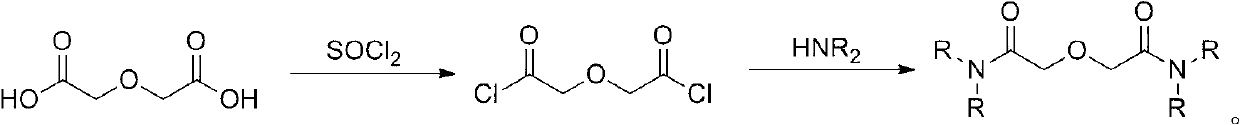

Method for synthesizing diamide podand extraction agent

ActiveCN102993042AEasy to purifyMild reaction conditionsOrganic compound preparationCarboxylic acid amides preparationLiquid wasteFuel reprocessing

The invention discloses a method for synthesizing diamide podand extraction agent, wherein chloro-carbonic ester and diglycolic anhydride react to generate mixed anhydride under the action of tertiary amine, and then the reaction is performed with amine to generate the diamide podand extraction agent. The method has mild reaction condition, can be performed at a low temperature, and has high reaction speed and short consumed time; the product purification operation is simple and easy; the obtained diamide podand extraction agent can meet the extraction purity requirement, and is beneficial to establishing flow that the diamide podand is used for treating high-level liquid waste in spent fuel reprocessing plant; the used chloro-carbonic ester is easy to prepare and has a low price, therefore, the cost for preparation of a great amount of extraction agent is greatly reduced; and besides, the yield of the extraction agent is high, so that the method is very suitable for industrial production and application.

Owner:SICHUAN UNIV

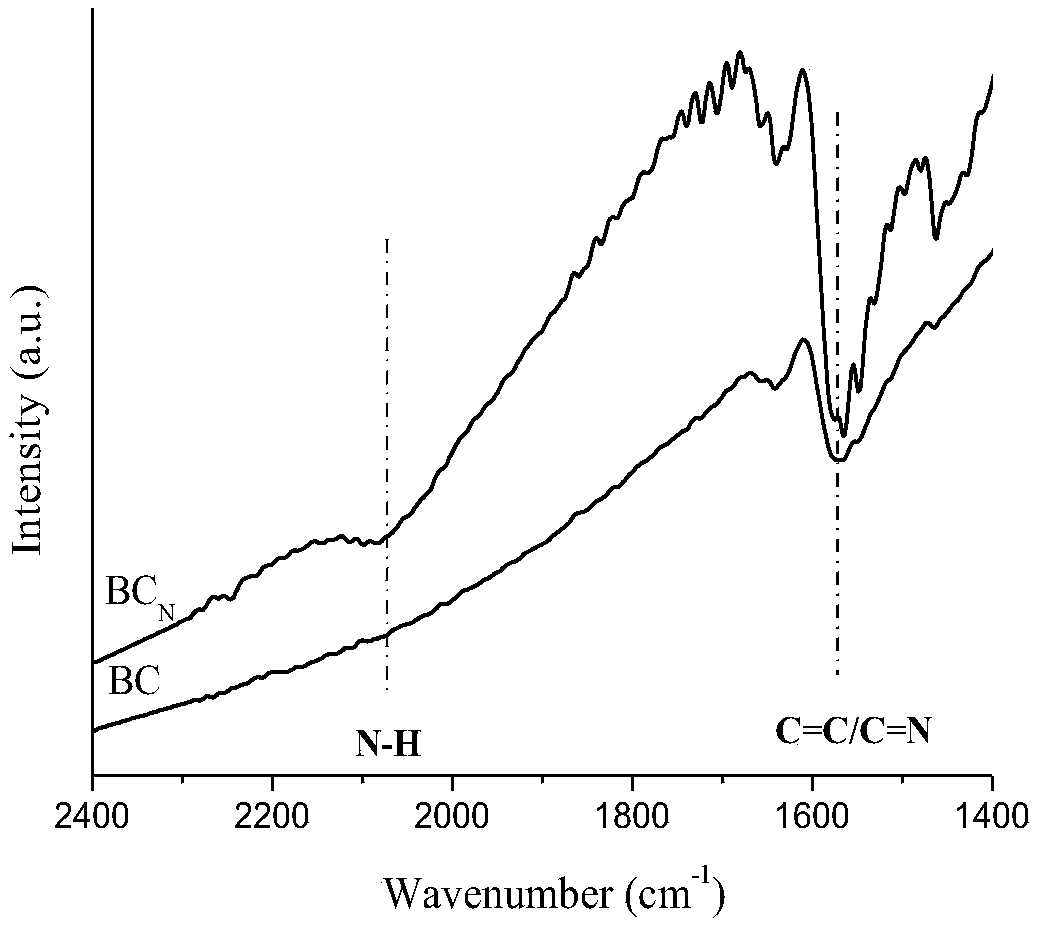

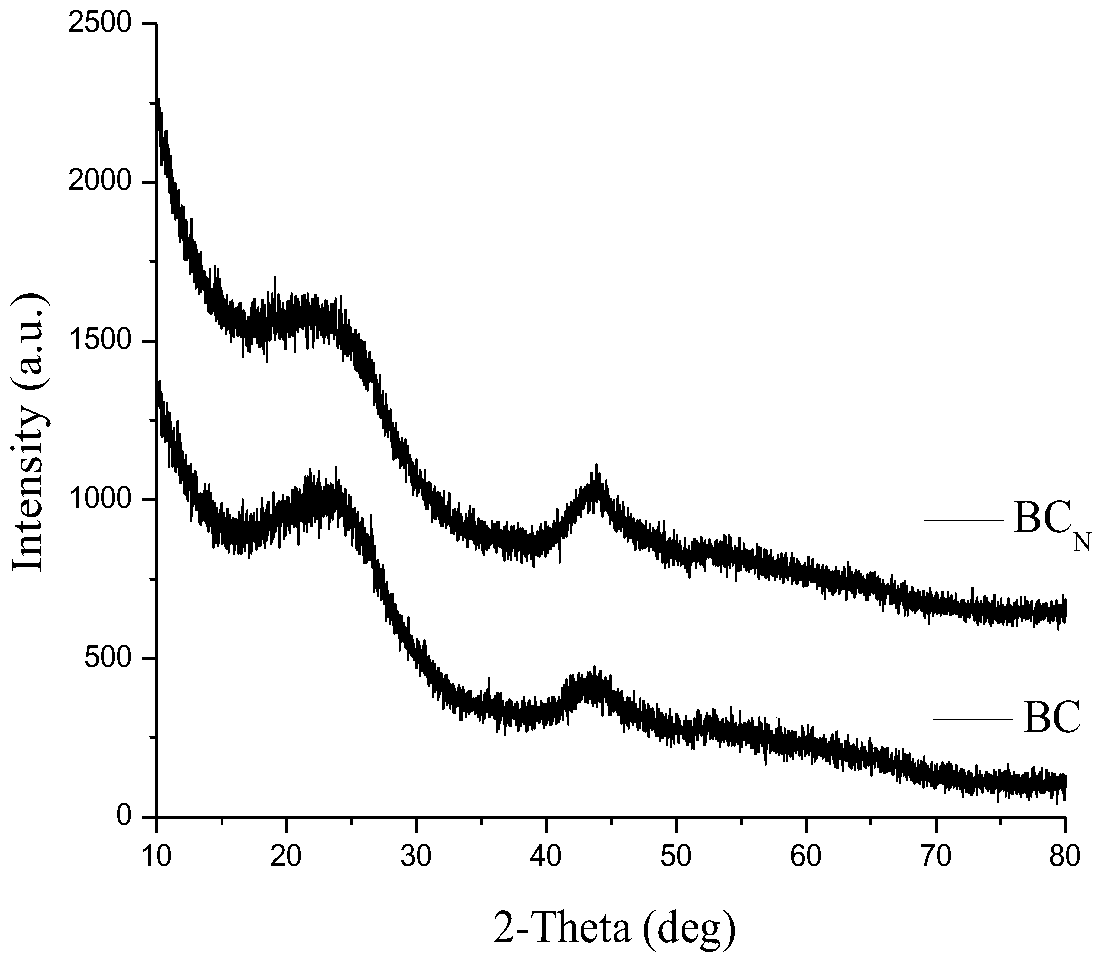

Nitrogen-doped carbon material, and preparation method and application thereof

ActiveCN109647474AHigh reactivityImprove removal efficiencyPhysical/chemical process catalystsWater contaminantsD-GlucoseNitrogen source

The invention belongs to the field of carbon materials, and concretely relates to a nitrogen-doped carbon material, and a preparation method and an application thereof. The prearatio method comprisesthe following steps: calcining glucose used as a raw material in an inert atmosphere using melamine used as a nitrogen source to a certain temperature to obtain a carbon substrate, mixing the carbon substrate with melamine in an aqueous solution according to a certain ratio, performing heating and stirring, drying the obtained material, and calcining the dried material in the inert atmosphere at alow temperature in order to obtain the nitrogen-doped carbon material. The preparation method has the advantages of simplicity, low energy consumption and low cost, and the nitrogen-doped carbon material has a very high reactivity, and can selectively degrade a plurality of organic pollutants, so the technical problems of complexity and high cost of preparation methods of the nitrogen-doped carbon material in the prior art and the technical problem of limited ability to degrade the organic pollutants in the environment are solved.

Owner:HUAZHONG UNIV OF SCI & TECH

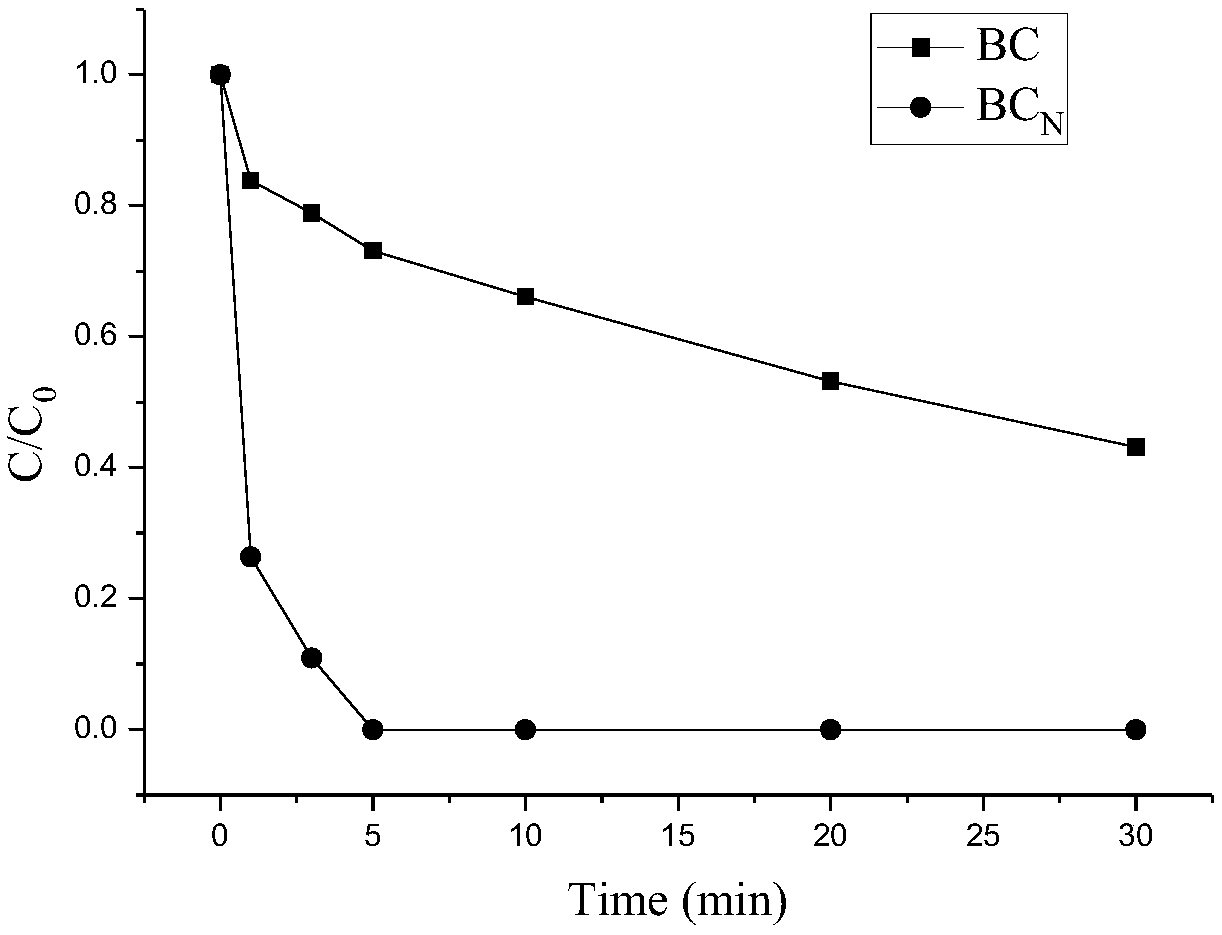

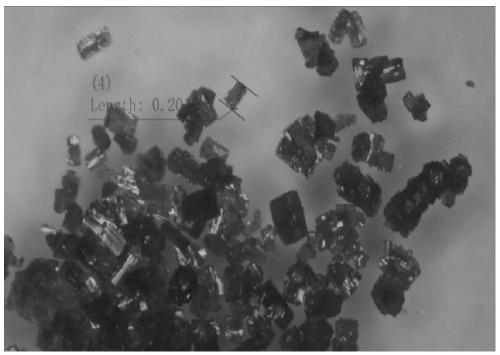

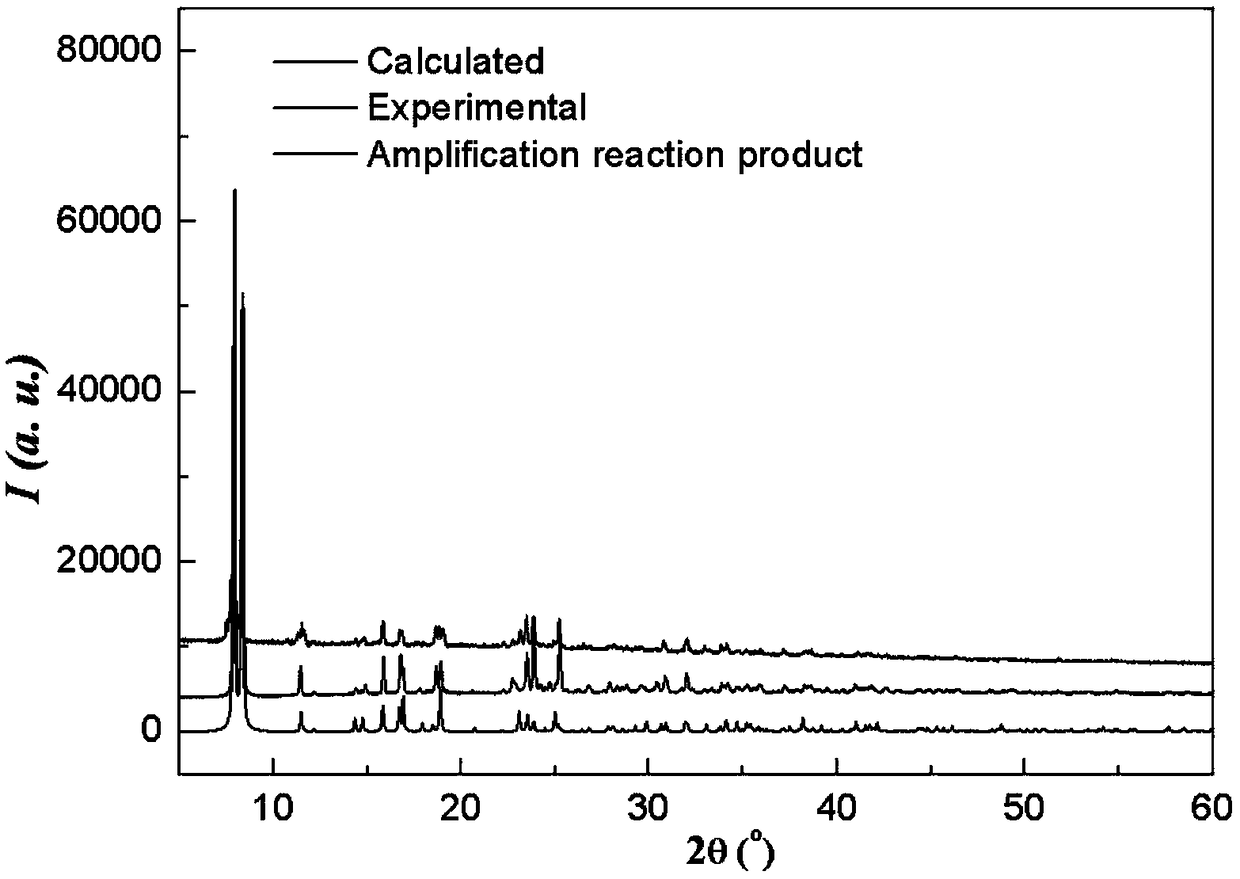

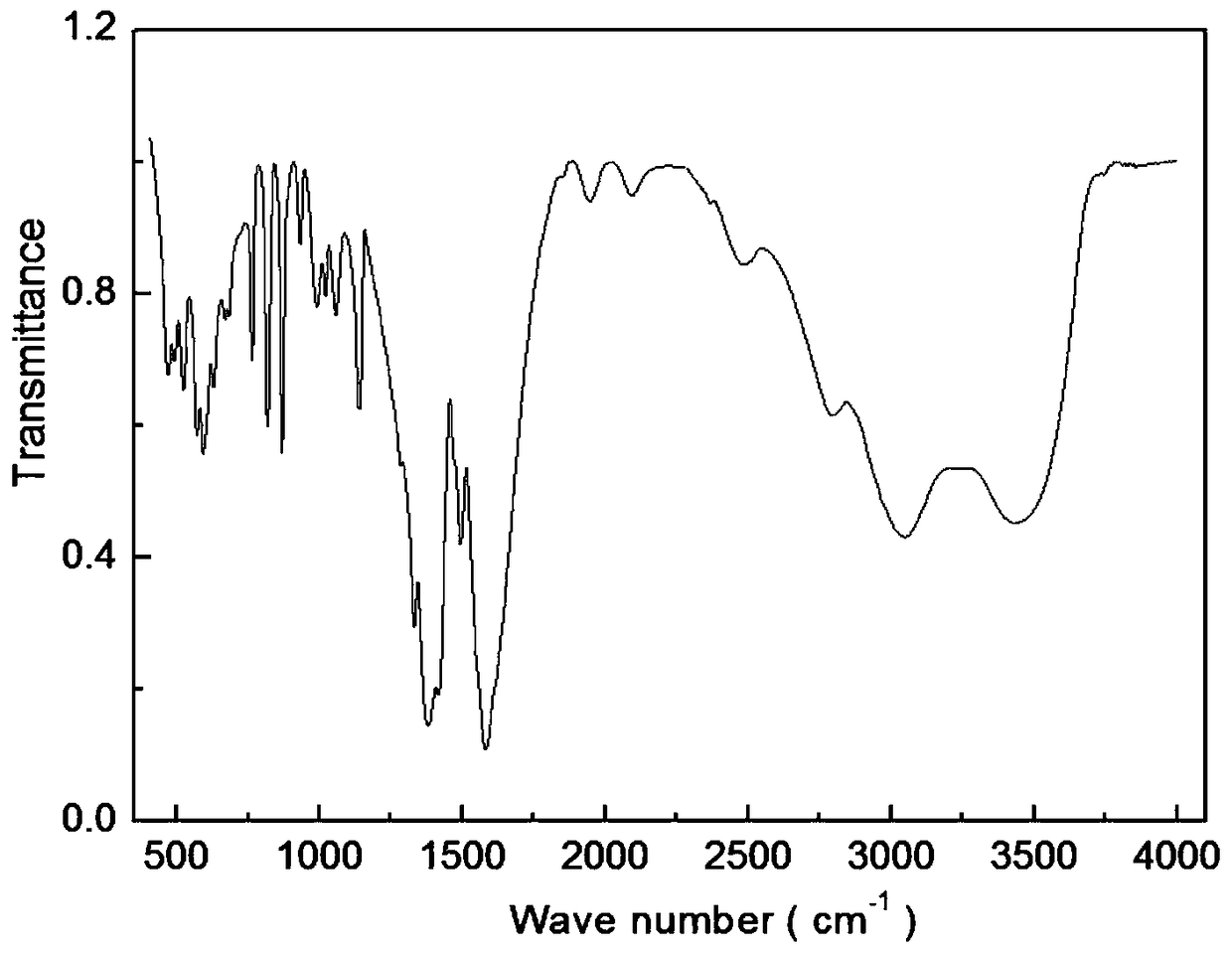

Metal organic framework material, synthetic method and application thereof

ActiveCN109180953AHigh porosityImprove water stabilityOrganic-compounds/hydrides/coordination-complexes catalystsPorosityUltraviolet

The invention relates to the technical field of materials, in particular to a metal organic framework material, a synthetic method and an application thereof. The X-ray diffraction peak positions of power of the framework material are as follows: 7.95+ / -0.5, 11.43+ / -0.5, 15.80+ / -0.5, 16.77+ / -0.5 and 18.89+ / -0.5; the 2theta angle range is between 5 degrees to 60 degrees. The material has the beneficial effects that the invention provides a novel metal organic framework material which has relatively high porosity, excellent water stability and heat stability and has a wide application prospect in the fields of photo-catalysis, hydrogen storage and ultraviolet resistance. Meanwhile, the synthetic material is low in price and easily available in raw material. The synthetic method is simple andlow in cost, can carry out amplified production on the premise of not affecting the product performance, and is suitable for industrial production and application.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

Method for preparing TiC-reinforced copper-based electric contact composite material

The invention discloses a method for preparing a TiC-reinforced copper-based electric contact composite material. The preparing method includes the steps of raw material preparation, carbon source manufacturing, powder briquetting and sintering, TiC self-forming reaction synthesis and the like. The method for preparing the TiC-reinforced copper-based electric contact composite material has the characteristics that the preparation technology is simple and stable, cost is low, efficiency is high and the method is suitable for industrial production and application. The carbon source used in the preparing method refers to Cu-graphite coated TiC mixed powder obtained by ball milling, the grain size of synthesized TiC is 0.5-2.0m, and TiC grains are evenly distributed on a copper substrate. Theprepared TiC-reinforced copper-based electric contact composite material is high in compactness, good combination of the strength, hardness, electrical conductivity and thermal conductivity of the composite material can be realized by adjusting the content of the TiC, and the high-strength and high-conductivity characters are achieved.

Owner:STATE GRID HEBEI ENERGY TECH SERVICE CO LTD +2

Double-functional amorphous FeMn-MOF-74 (ferromanganese-metal organic framework-74) nanoflower material and preparation method and application

InactiveCN109320736AEasy to operateNo secondary pollutionWater contaminantsWater/sewage treatment by sorptionMetal-organic frameworkChloride

The invention relates to a double-functional amorphous FeMn-MOF-74 (ferromanganese-metal organic framework-74) nanoflower material and a preparation method and application, and relates to a nanometermaterial and a preparation method and application, which aim at solving the problem of low adsorption capacity of existing MOF-based adsorbent to As(III). The double-functional amorphous FeMn-MOF-74 nanoflower material is prepared by taking 2,5-dihydroxy terephthalic acid as an organic ligand, anhydrous manganese chloride and anhydrous ferrous chloride as metal salt ligands, and N,N-dimethyl formamide and anhydrous ethanol as solvents through a solvothermal method. The preparation method comprises the following steps of 1, preparation of a mixed solution; 2, solvothermal reaction; 3, cleaningand drying. The double-functional amorphous FeMn-MOF-74 nanoflower material is used for removing poisonous metals in water, and oxidizing the poisonous metals in the water. The preparation method canbe used for preparing the double-functional amorphous FeMn-MOF-74 nanoflower material.

Owner:NORTHWEST A & F UNIV

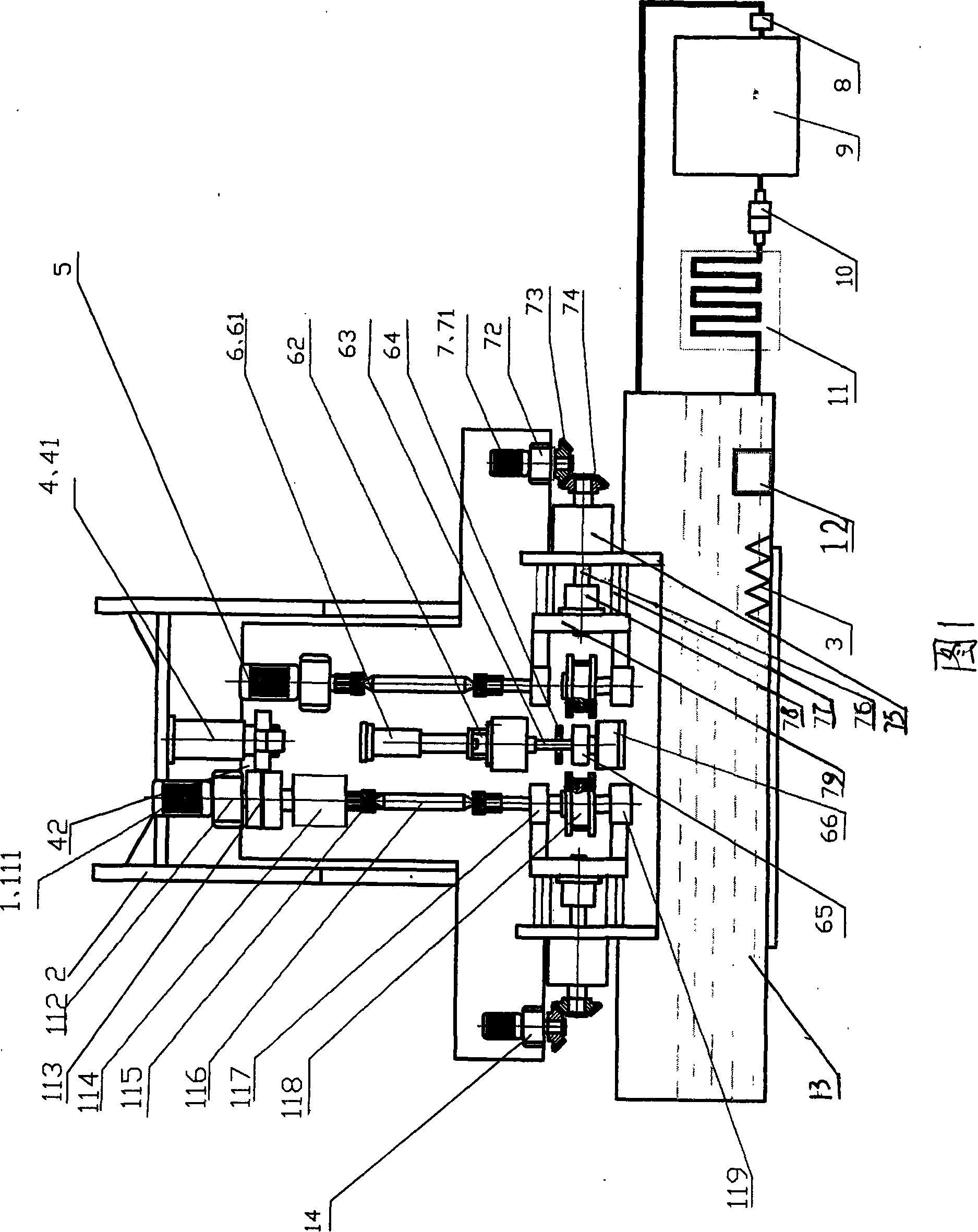

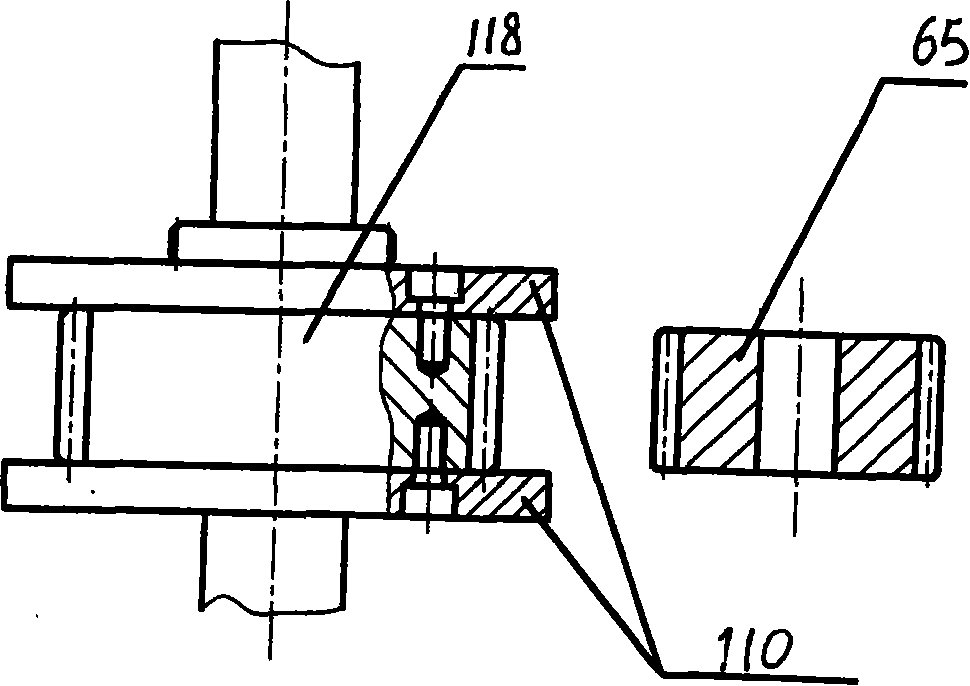

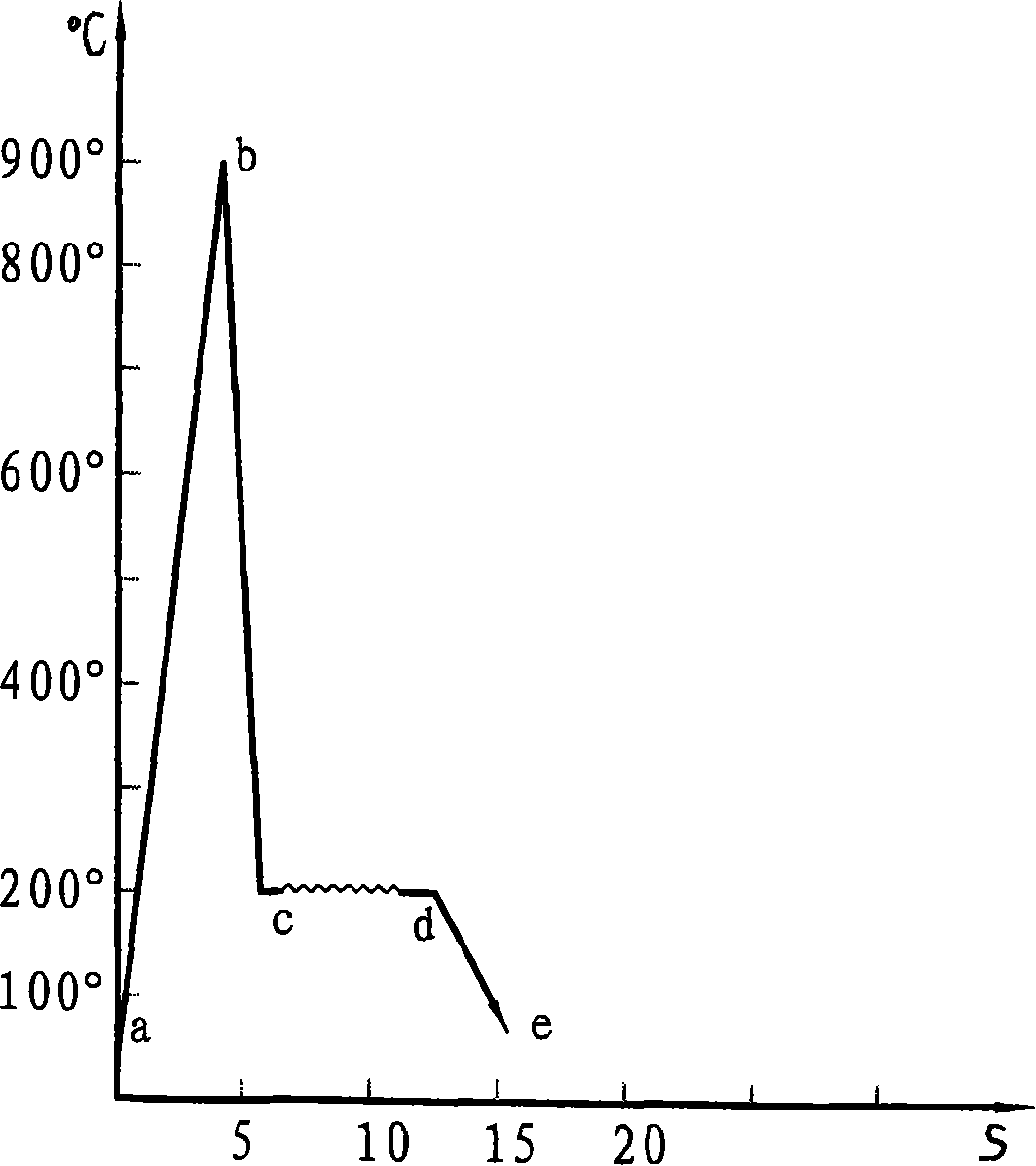

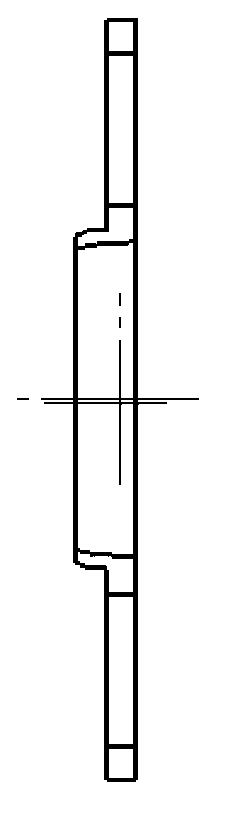

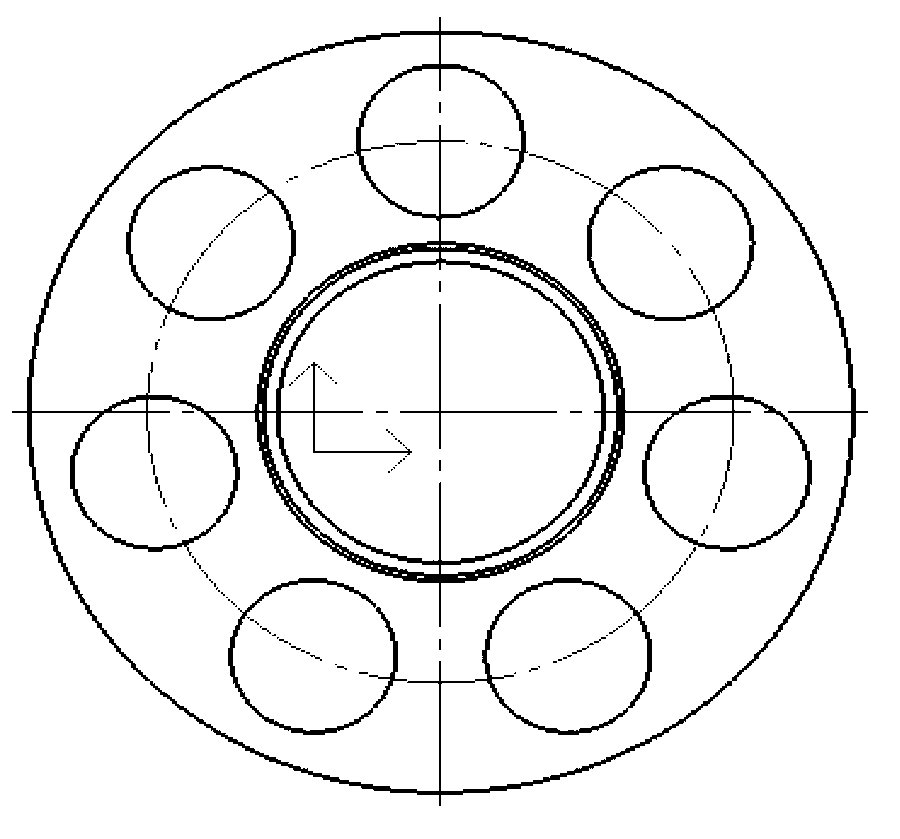

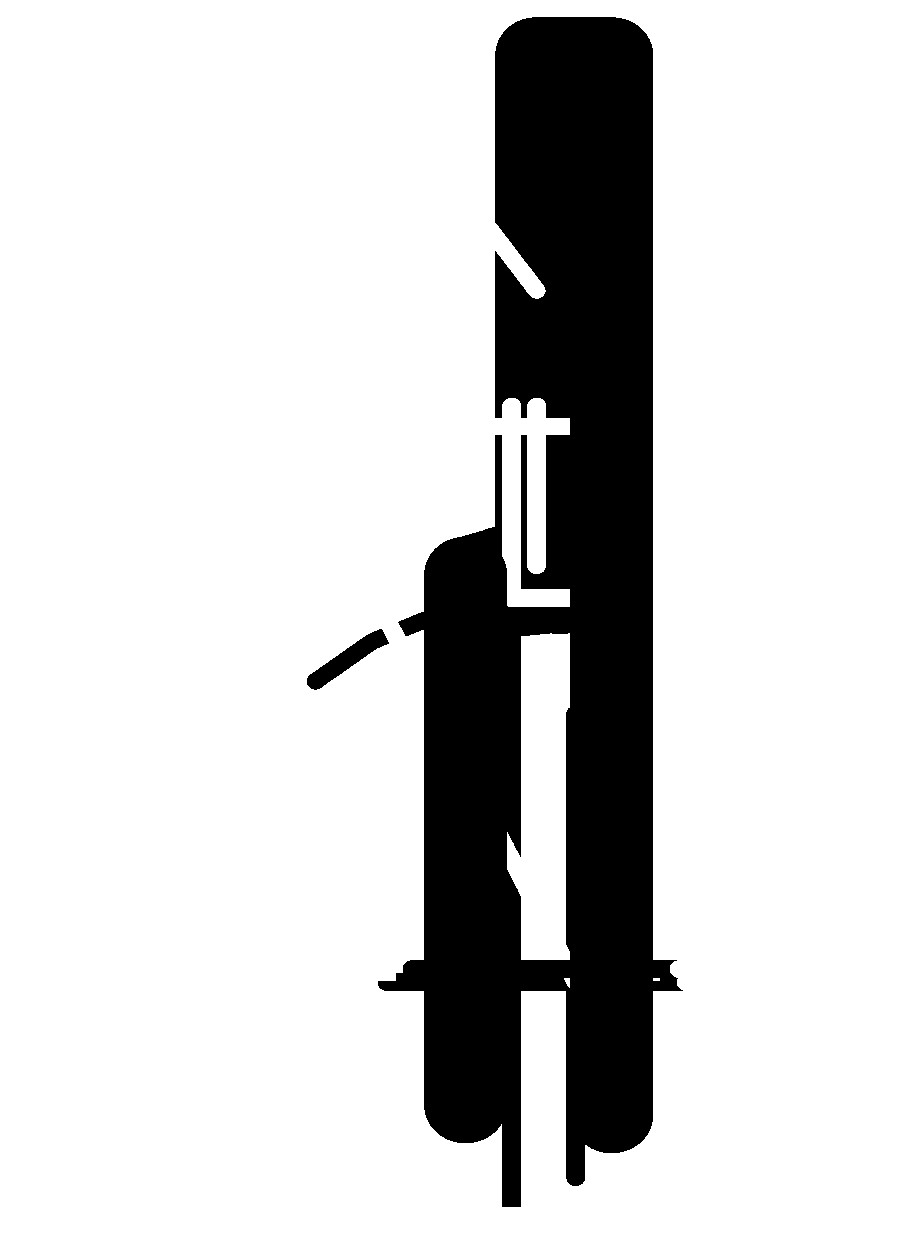

Gear wheel precision hot rolling extruding and grinding machine and processing method thereof

ActiveCN101168183AReduce the impact of stabilizationReduce in quantityGear wheelsHigh volume manufacturingHobbing

A pinion precision hot rolled squeezing and milling device and a method for processing belong to the field of precision-machined machinery devices and craft technology. The purpose of the invention is to provide the pinion precision hot rolled squeezing and milling device, and the method for processing which are economical, practical and have low inaccuracy and high accuracy and are applicable to be in mass production. The technical points are that a framework is straddled and arranged on the two lateral sides of an oil tank, and a slider controlled by a hydraulic oil tank is arranged on the framework, wherein a first gear hobbing die actuating mechanism, a work-piece handing hold-down mechanism, and a second gear hobbing die actuating mechanism are hung vertically and consecutively from left to right, the two lateral sides of the lower portion are correspondingly arranged with pushing shelves of a first screw mandrel pushing mechanism and a second screw mandrel pushing mechanism which are respectively connected with an upper bearing block and a lower bearing block of the first gear hobbing die actuating mechanism and the second gear hobbing die actuating mechanism. Compared with prior crafts and devices, the invention is a finishing tooth processing device and craft which is more advanced, reasonable and scientific, economical, practical, lowly inaccurate, and further has the advantages of high efficiency and high accuracy, and is adaptable for mass production without cutting.

Owner:安徽省小小科技股份有限公司

Preparation method for TiC/Ti5Si3 composite enhanced copper-based electrical contact material

The invention discloses a preparation method for a TiC / Ti5Si3 composite enhanced copper-based electrical contact material. The preparation method comprises the following steps of preparation of raw materials, preparation of graphite-coated Sic mixed powder, preparation of Cu-graphite-coated Sic prefabricated body, reaction synthesis of TiC / Ti5Si3 and the like. The preparation method has the advantages of being simple in preparation process, low in cost and high in efficiency, and the prepared TiC / Ti5Si3 composite reinforced copper-based electrical contact material has high hardness, high wearresistance and high conductivity, and is suitable for industrial production and application; and Tic is obtained through self-generation reaction of Ti, graphite and Sic in a copper melt, the Tic is near-stoichiometric, the stability is good, the particle size is in the range of 0.5-3.5 micrometers, the Tic is uniformly distributed on a copper substrate, and prepared Ti5Si3 is rod-shaped or plate-shaped.

Owner:STATE GRID HEBEI ENERGY TECH SERVICE CO LTD +2

Diameter measuring tool of inner spherical section circle and measuring method

InactiveCN103017638AReduce repetitive positioning errorsApplicable siteMechanical diameter measurementsPhysicsSeries production

The invention discloses a diameter measuring tool of an inner spherical section circle and a measuring method. The measuring tool comprises a base, a first movable measurement unit, a first data reading device and a fixed measurement unit, wherein the fixed measurement unit comprises two contoured fixed bulbs; the two fixed bulbs are fixedly arranged on the base; a movement center of the first movable measurement unit and the two fixed bulbs form an isosceles triangle on the same plane; one end of a first movable measurement unit is connected with a second movable measurement unit through a spring; the other end of the first movable measurement unit contacts a reading meter measuring head of the first data reading device; the second data reading device stops at one end of the second movable measurement unit; and the first movable measurement unit and the second movable measurement unit are arranged on the base and can carry out axial slot clearance sliding along the axis on which a connecting line of the second movable measurement unit and the first movable measurement unit is. The diameter measuring tool can meet detection of the diameter of the inner spherical section circle with fixed distance; and the measuring method is reliable and suitable for field and volume production.

Owner:XIAN AERO ENGINE CONTROLS

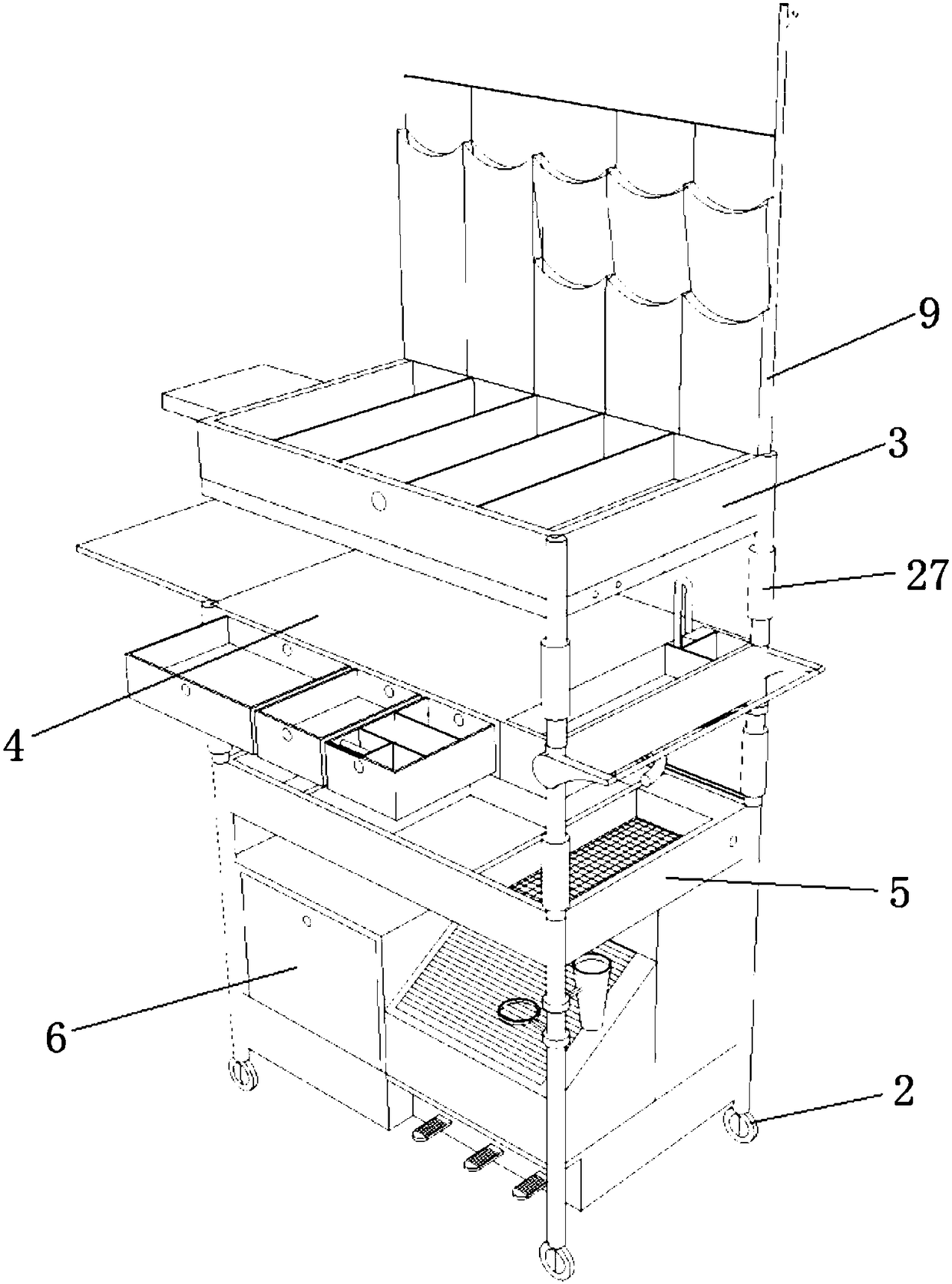

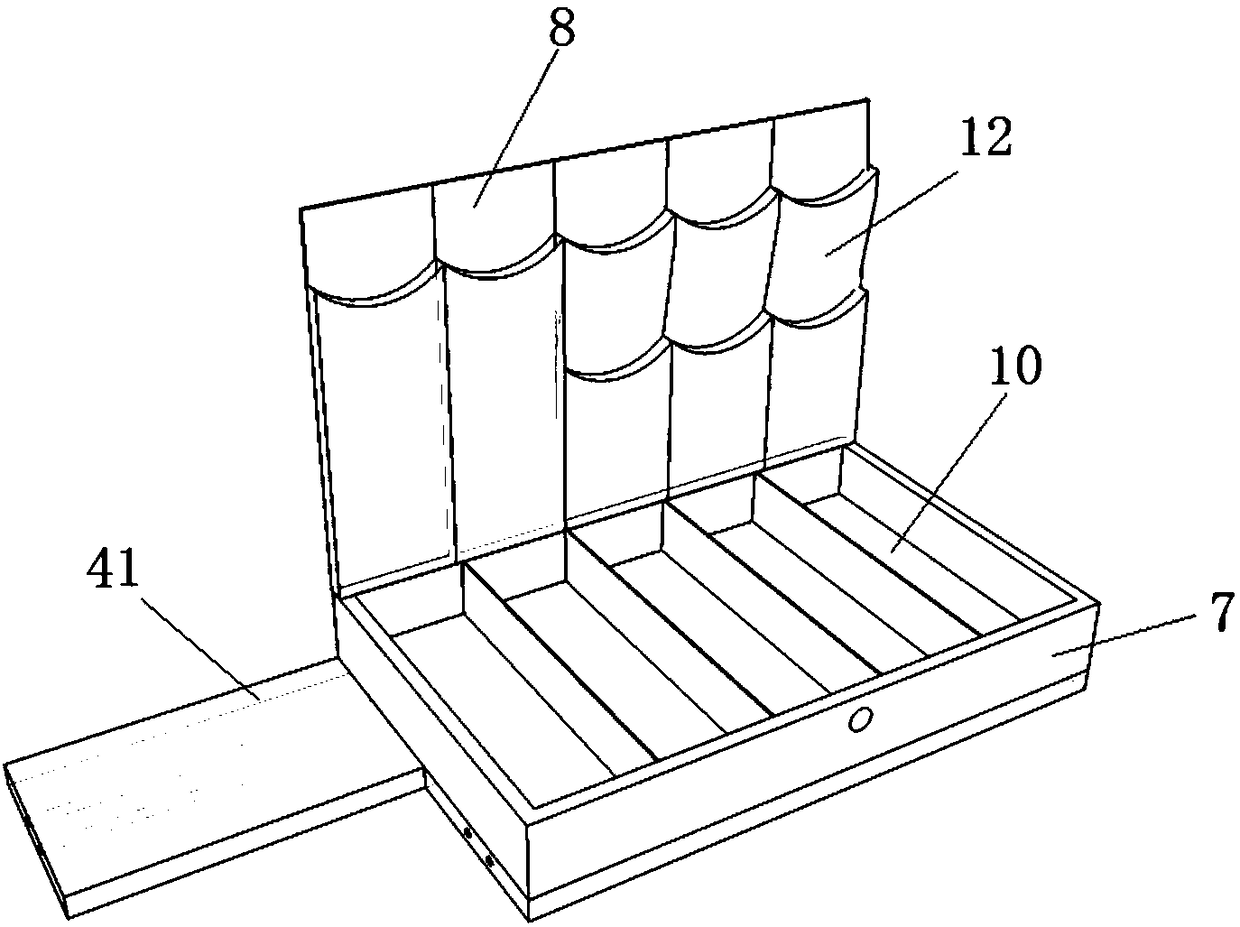

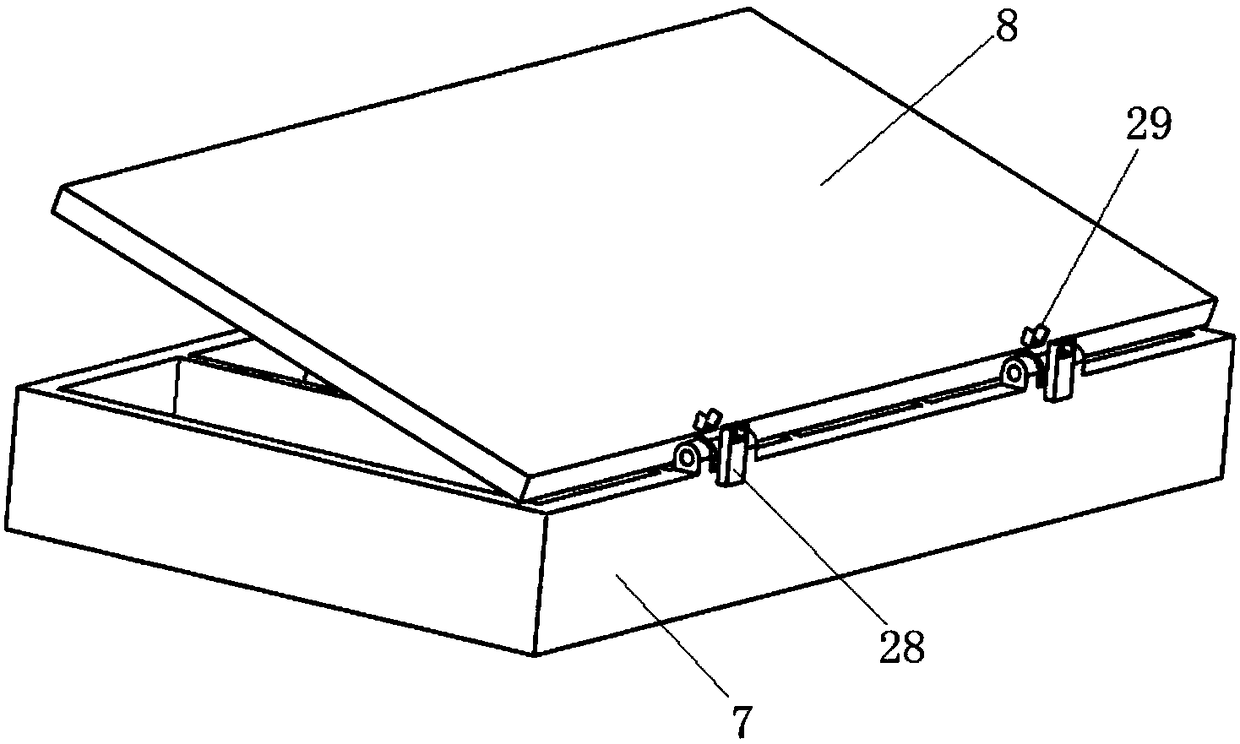

Multifunctional chronic wound nursing and dressing dolly

PendingCN108379015AAddressing Healing DelaysReasonable structureNursing accommodationInjury mouthChronic wound

The invention discloses a multifunctional chronic wound nursing and dressing dolly. The dolly comprises a body and wheels. The body sequentially comprises a material dressing layer, an operation layer, a cleaning layer and a collecting layer from top to bottom, the layers are connected with each other through supporting rods, and the wheels are arranged at the bottoms of of supporting rods; the dressing dolly is reasonable in structure and clear in use and is suitable for the orderly placing of medical items such as dressing materials for different chronic wounds and the like to facilitate taking; an operation table is wide and bright, so that dressing of a chronic wound is safe and sterile; medical workers can sterilize and clean hands, and different machinery and rubbishes related to dressing can be recovered. The dressing dolly is convenient to use and complete in functions, comprehensive services can be provided for the medical workers, the structure is not complicated, and the dressing dolly is suitable for industrial production and market popularization and use.

Owner:FIRST AFFILIATED HOSPITAL OF KUNMING MEDICAL UNIV

Preparation method of aluminum alloy profile for high-power LED (light-emitting diode) lamp substrate

The invention discloses a preparation method of an aluminum alloy profile for a high-power LED (light-emitting diode) lamp substrate. The aluminum alloy profile comprises the following elements in percentage by mass: 1.2-1.8% of Si, 2.6-3.4% of Cu, 0.5-1.0% of Ag, 0.3-0.6% of Be, 0.2-0.4% of W, 0.25-0.35% of Mn, 0.1-0.2% of Zn, 0.2-0.3% of Ni, 0.05-0.15% of Fe, 0.03-0.07% of Pd, 0.02-0.04% of Nd, 0.01-0.02% of Tb and the balance of Al. The aluminum alloy profile has the advantages of high heat conductivity, excellent heat dispersion property and sufficient mechanical properties, and thus, is suitable for manufacturing the high-power LED lamp substrate. The aluminum alloy profile can improve the working reliability and service life of the LED lamp, lowers the production cost, and is suitable for industrial production and large-scale popularization.

Owner:WUHU WANRUN MACHINERY

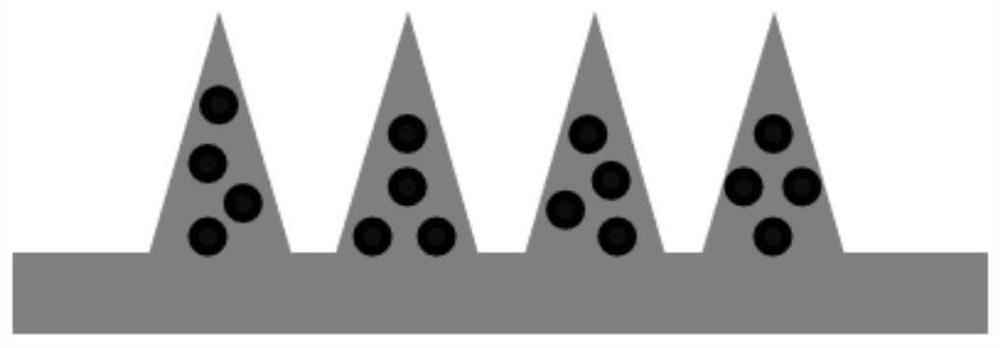

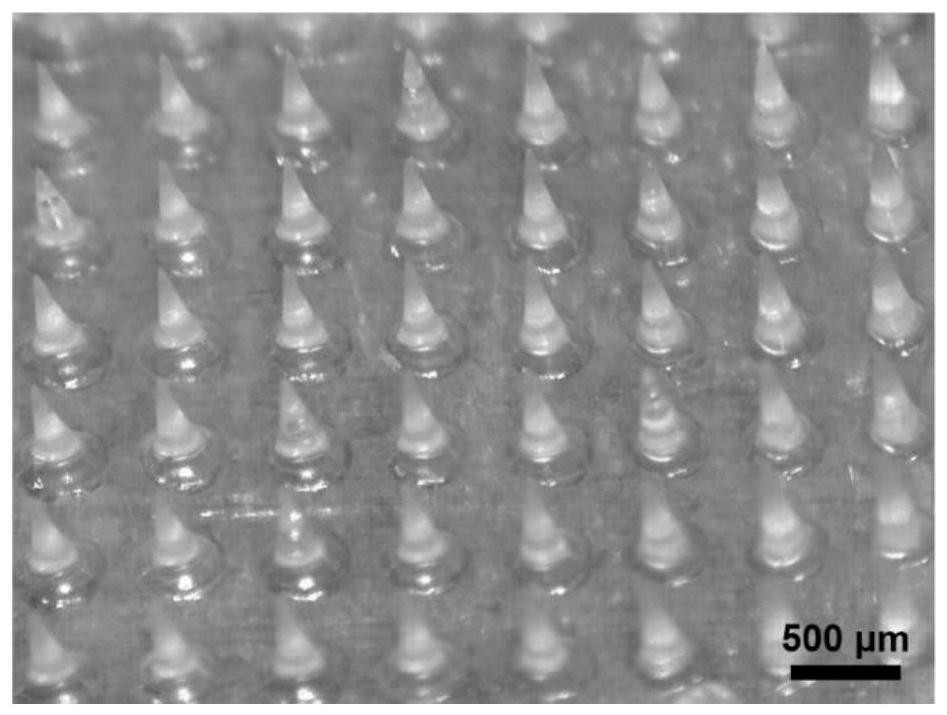

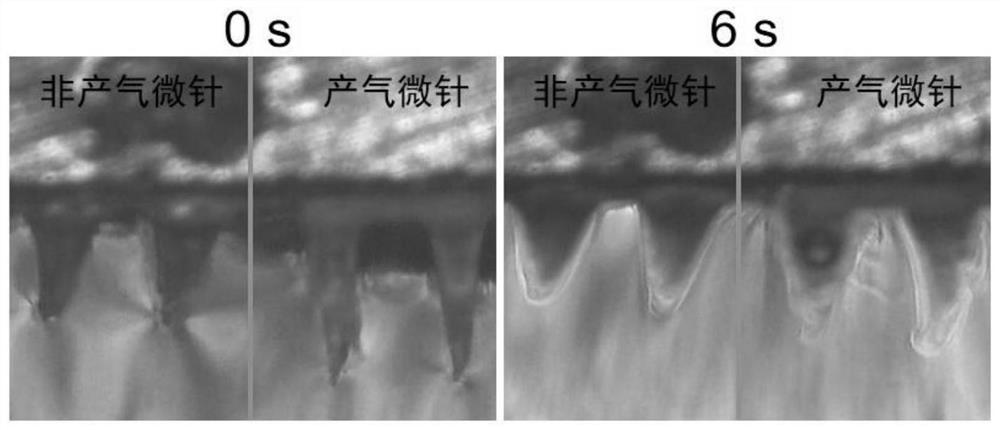

Micro-needle array patch capable of generating gas to take effect quickly and preparation and application thereof

PendingCN113679692AImprove solubilityIncrease the speed of diffusionOrganic active ingredientsPeptide/protein ingredientsTissue fluidBiocompatibility

The invention belongs to the field of biomedical polymer materials, and discloses a micro-needle array patch capable of generating gas to take effect quickly and preparation and application thereof. The micro-needle array patch comprises a substrate and a needle tip located on the substrate, the substrate is composed of a biocompatible matrix, the needle tip is mainly composed of the biocompatible matrix and inorganic particles capable of generating gas, and the inorganic particles capable of generating gas are formed on the surface and / or in the biocompatible matrix of the needle tip; the needle tip part of the micro-needle array patch can interact with skin tissue fluid to generate gas during application, rapid dissolution of micro-needles and diffusion of drugs to a corium layer are promoted, and the drugs can be efficiently and rapidly delivered to subcutaneous parts and take effect without the help of external equipment.

Owner:HUAZHONG UNIV OF SCI & TECH

Porous high-viscoelasticity cake and manufacturing method thereof

The invention provides a porous high-viscoelasticity cake and a manufacturing method thereof. The cake is prepared from the following raw materials in parts by weight: 500-1000 parts of glutinous rice flour, 500-1000 parts of eggs, 30-100 parts of butter, 50-300 parts of white granulated sugar, 1-10 parts of konjaku flour, 1-10 parts of yeast, 1-10 parts of glucose, 0.1-5 parts of table salt and 400-1000 parts of water. The cake prepared with the burdening combination and method is in light yellow and has mellow flavor, favorable viscoelasticity and clear length cutting grain pores; during transection, the cake is in a regularly cellular shape; after being frozen or fried, the product still has favorable viscoelasticity and is elastic. In addition, the scheme of the invention has low manufacturing cost, simple operation and certain market prospect.

Owner:ZHEJIANG UNIV OF TECH

L-Se-methylselenocysteine inclusion compound and preparation method thereof

ActiveCN102846586AGood embedding effectGood taste masking effectOrganic active ingredientsMetabolism disorderOrganic solventL-Se-Methylselenocysteine

The invention discloses an L-Se-methylselenocysteine inclusion compound and a preparation method thereof. The L-Se-methylselenocysteine inclusion compound is prepared from the main raw materials of L-Se-methylselenocysteine, mono- and diglycerides of fatty acids and sucrose fatty acid ester as well as auxiliary materials of microcrystalline cellulose, beta-cyclodextrine and maltodextrin through certain processes. The L-Se-methylselenocysteine inclusion compound has the advantages of good inclusion effect, high uniformity, good taste-masking effect, no objectional odor after being dissolved and no influence on mouth feeling, is simple and safe in process, does not need water or organic solvent or a drying course, is time-saving and labor-saving, consumes few equipment, is simple in operation method, good in repeatability, low in equipment requirement, suitable for large-scale production and industrialization and wide in applicability, can be uniformly dispersed in milk beverage, and is not liable to moisture absorption.

Owner:江西川奇药业有限公司

Plane cambered glass periphery film removal device

InactiveCN105110655ASolve the problem of peripheral film removalPrecise positioningNumerical controlHigh volume manufacturing

The invention relates to a plane cambered glass periphery film removal device which comprises a film removal table and an electrical control gear, wherein the film removal table comprises a machine frame, a glass transmission assembly, a lifting glass positioning assembly and a robot arm numerical control platform; the robot arm numerical control platform comprises a robot arm and a laser device; the laser device is arranged at the free end of the robot arm; the electrical control gear is respectively connected with the film removal table and robot arm numerical control platform; the glass transmission assembly is arranged on the top surface of the machine frame; the lifting glass positioning assembly is arranged below the glass transmission assembly; and the robot arm is arranged on one side of the machine frame. Compared with the prior art, the plane cambered glass periphery film removal device can implement plane cambered glass periphery film removal, has the advantage of small glass ghosting, can implement automation and is suitable for mass production.

Owner:FUYAO GRP SHANGHAI AUTOMOBILE GLASS CO LTD

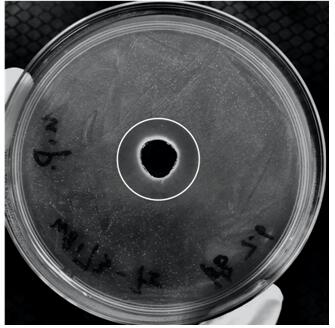

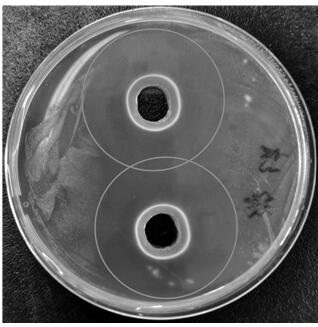

Lactobacillus sp. W8173 and application thereof

ActiveCN113215039AImproves symptoms of rot diseaseEnhanced inhibitory effectAntibacterial agentsBacteriaBiotechnologyMicrobiological culture

The invention discloses lactobacillus sp. W8173 which is preserved in the China General Microbiological Culture Collection Center with the preservation number of CGMCC NO. 21787. The strain can alleviate the symptom of European foulbrood of bees, and in an in-vitro bacteriostasis experiment, the strain can directly inhibit melissococcus pluton; in the in-vivo experiment, single-bacterium bees fed with lactobacillus sp. W8173 have a relatively good inhibition effect on melissococcus pluton; and by separating supernant of a lactobacillus sp. W8173 culture solution, it is found that a secretory product of lactobacillus sp. W8173 has an inhibitory effect on melissococcus pluton. The preparation of the present invention is environmentally friendly, free of pollution, free of influence on bee product quality and suitable for industrial production and market popularization and application.

Owner:CHINA AGRI UNIV

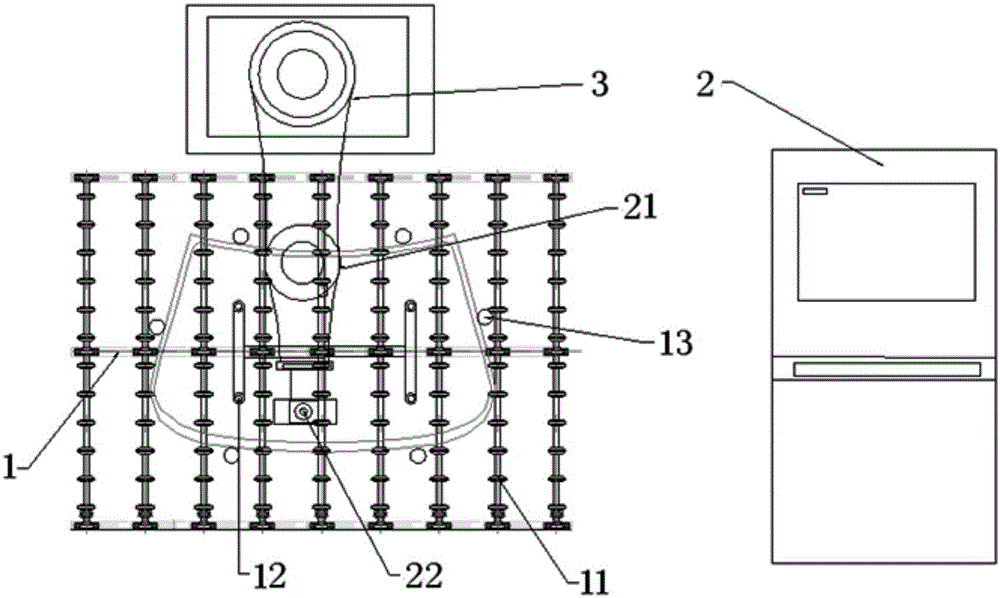

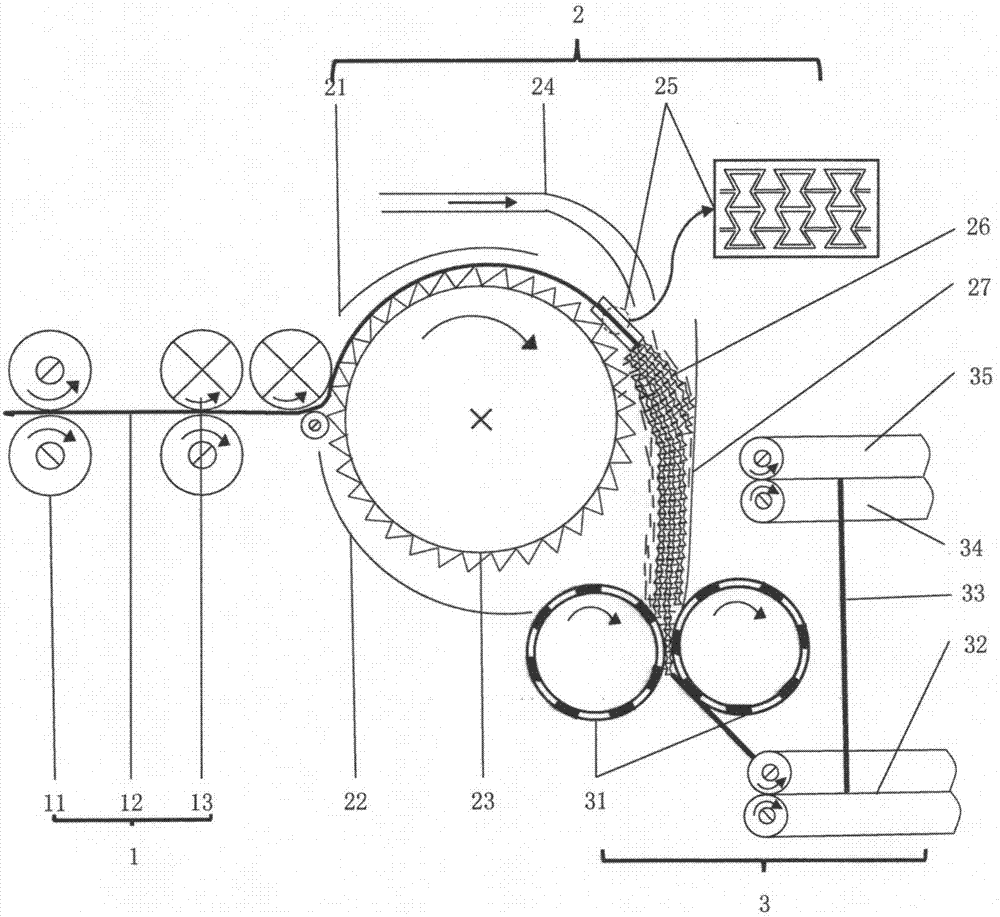

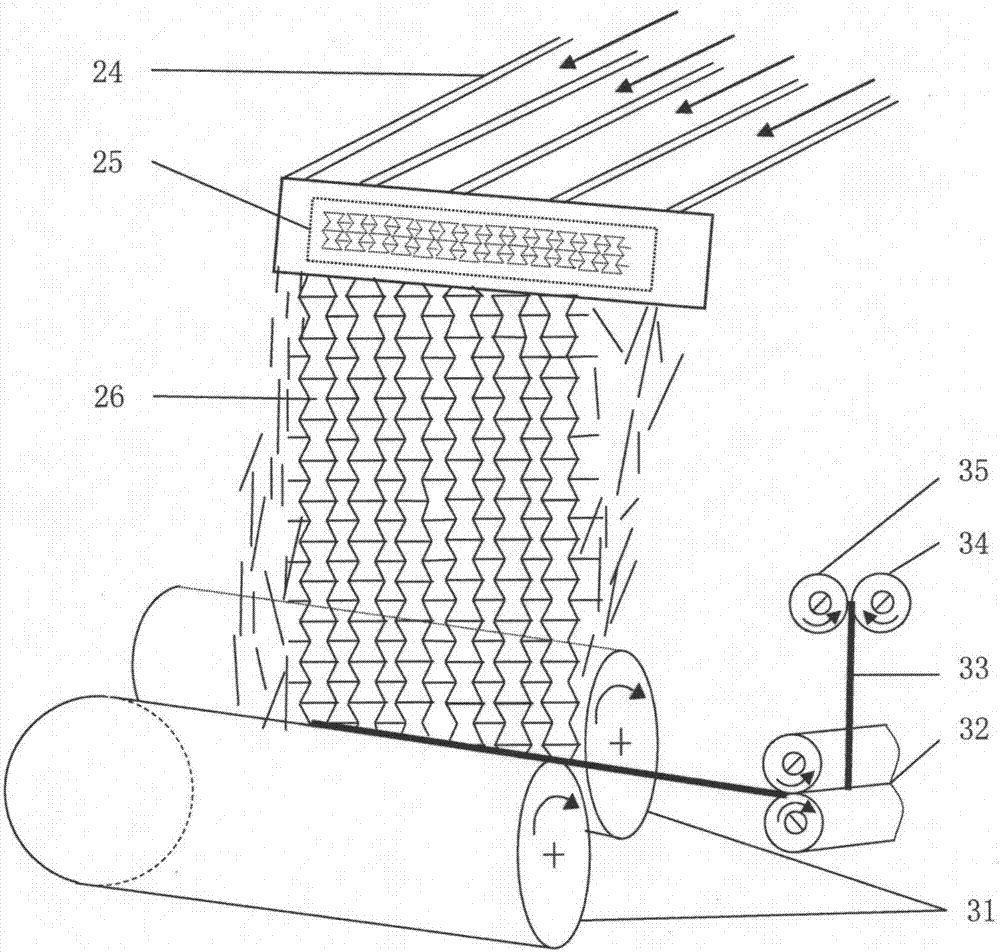

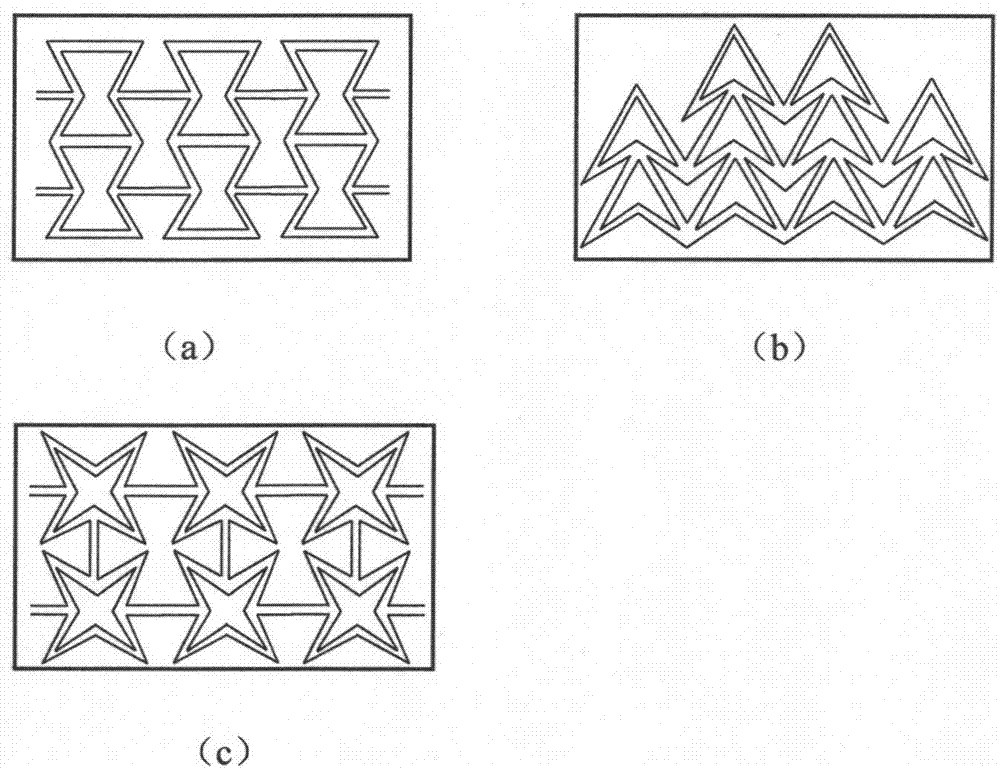

Processing method and device of friction spinning negative Poisson's ratio yarn of front tension structure

ActiveCN107988674AWide applicabilityRealize recyclingContinuous wound-up machinesOpen-end spinning machinesYarnFiber

The invention provides a processing method and device of friction spinning negative Poisson's ratio yarn of a front tension structure. The processing device comprises a short fiber yarn feeding and drafting mechanism used for feeding short fiber coarse yarn and drafting and carding the short fiber coarse yarn to make the cohesive force of the fiber increased; a tension structure forming mechanismused for carding the short fiber coarse yarn after being drafted and opened, also utilizing a shaping mechanism template to form the shape of the tension structure and shaping the short fiber coarse yarn under the thermal effect to form the tension structure of the short fiber coarse yarn and a twisting and winding mechanism used for twisting the tension short fiber yarn and winding the tension short fiber yarn on a spool. The method can used for spinning short fiber, recycled, opened or recycled fiber of waste fabric or blended fiber of the recycled, opened or recycled fiber of waste fabric.The processing method and device have the advantages that the formed yarn has an obvious tension effect and is stable in structure, and meanwhile, the raw material is low in uniformity requirement, wide in selection range, convenient to implement, low in cost and applicable to continuous production and application and popularization.

Owner:DONGHUA UNIV

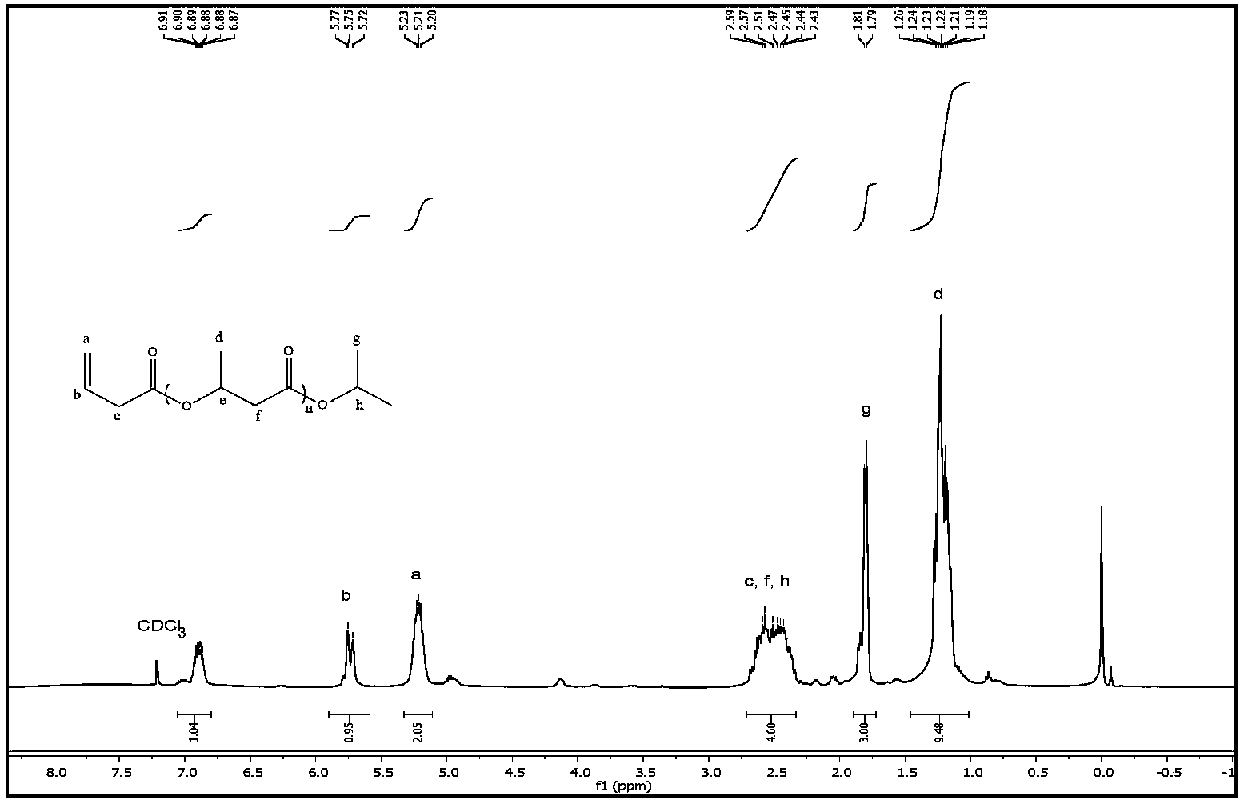

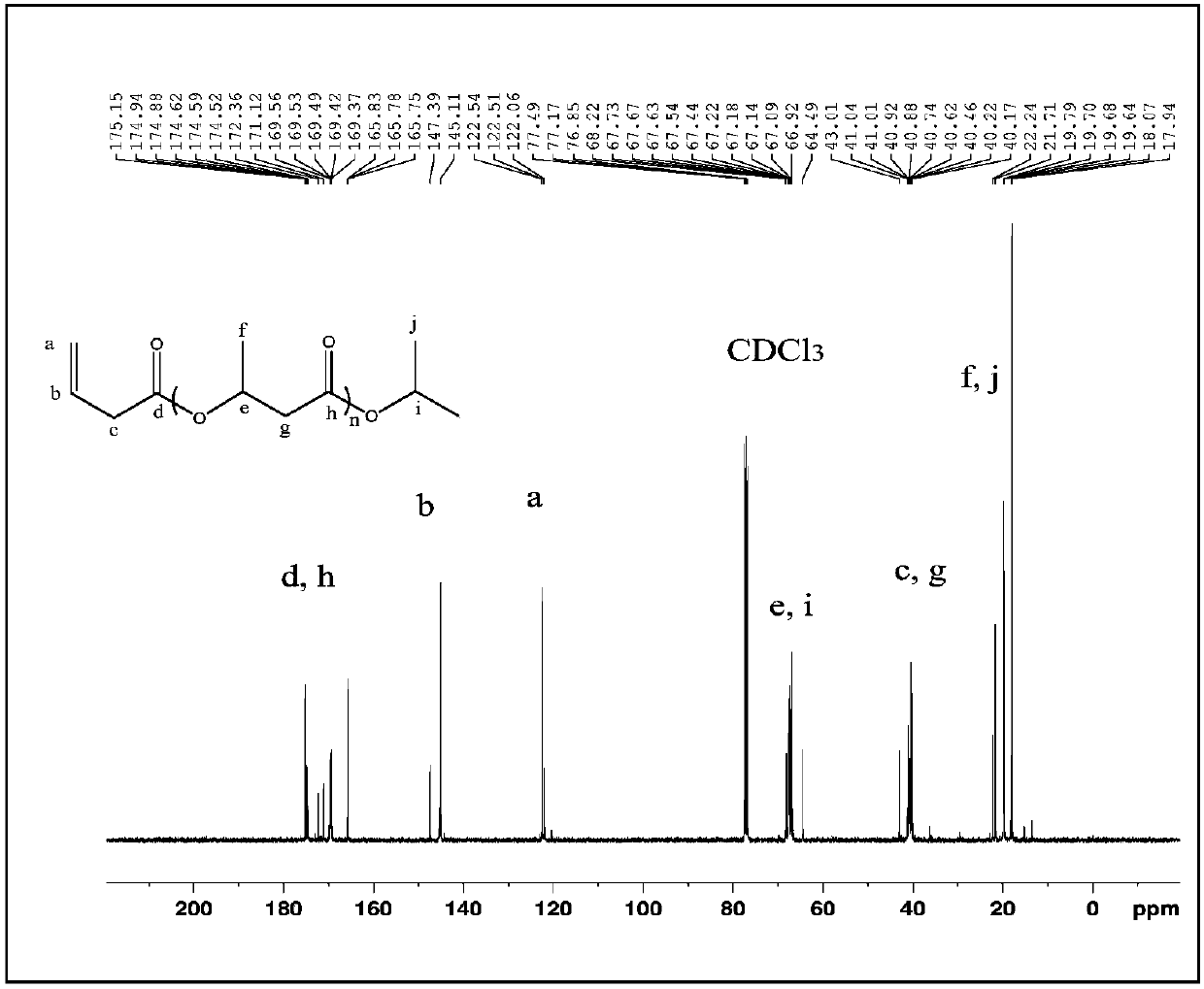

Synthetic method for poly(3-hydroxybutyrate) oligomers, product obtained by method and application of oligomers

ActiveCN110452115ASmall molecular weightExcellent and stable antibacterial activityAntibacterial agentsBiocideOligomerSynthesis methods

The invention provides a synthetic method for poly(3-hydroxybutyrate) oligomers. The method comprises the step of performing a reaction by using one lactone as a raw material in the presence of alkoxyaluminum Al(OR)3 and pyridine to prepare one oligomer. The invention also provides the poly(3-hydroxybutyrate) oligomers and an application of the oligomers in preparation of an antimicrobial material. The synthetic method provided by the invention can prepare the poly(3-hydroxybutyrate) oligomers having a lower molecular weight, and the oligomers have excellent and stable antimicrobial activity,and is very suitable to be used as the antimicrobial material; and the synthetic method has mild reaction conditions and a greatly-simplified purification process, and is suitable for industrial production and large-scale use.

Owner:THE HONG KONG RES INST OF TEXTILES & APPAREL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com