Gear wheel precision hot rolling extruding and grinding machine and processing method thereof

A hot rolling and precise technology, applied in the direction of gears, other household appliances, household appliances, etc., can solve the problems of high price of gear grinding machines, application restrictions, and high manufacturing costs, and achieve improved labor productivity, save processing time, and reduce residual Austrian The effect of the number of ingots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

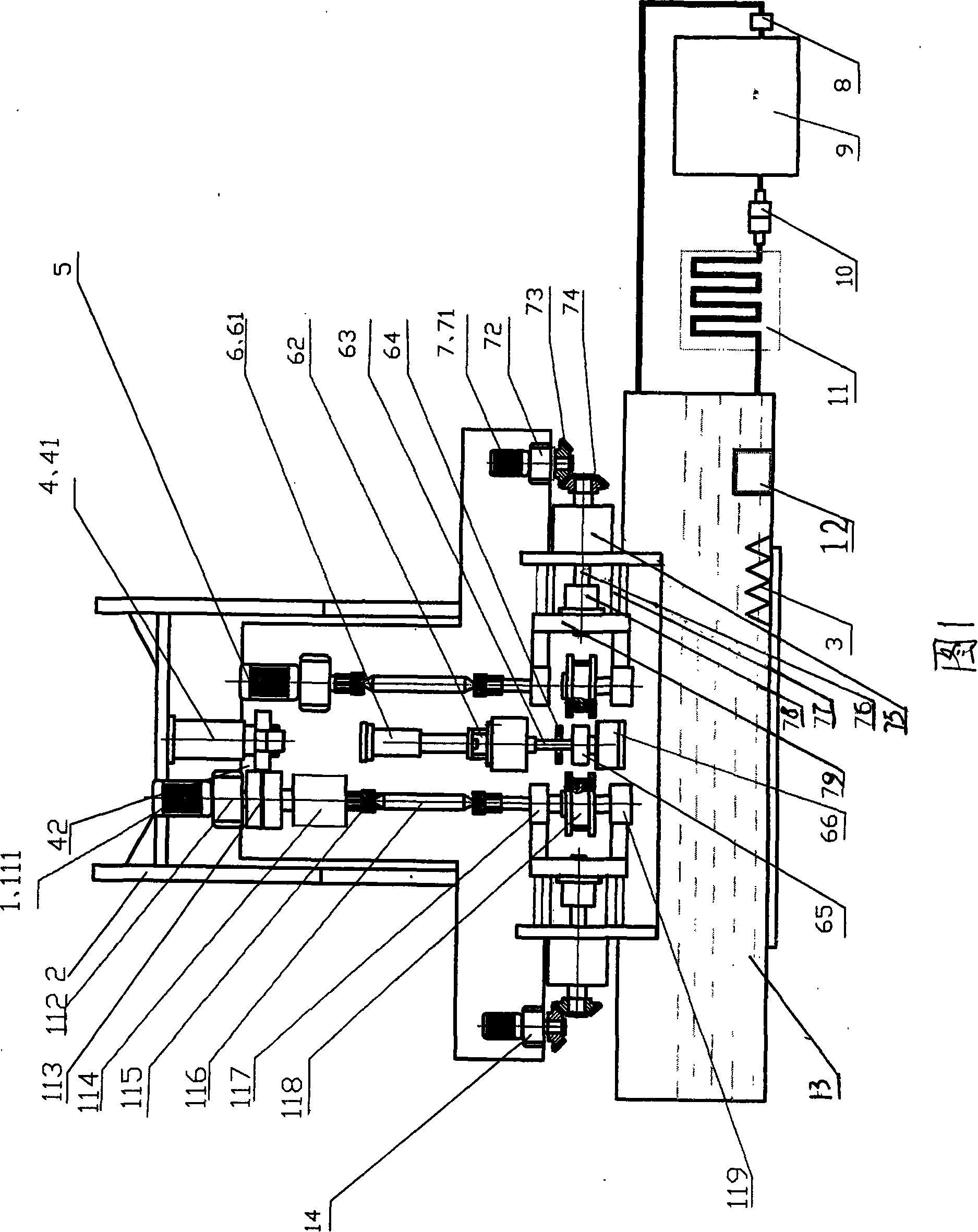

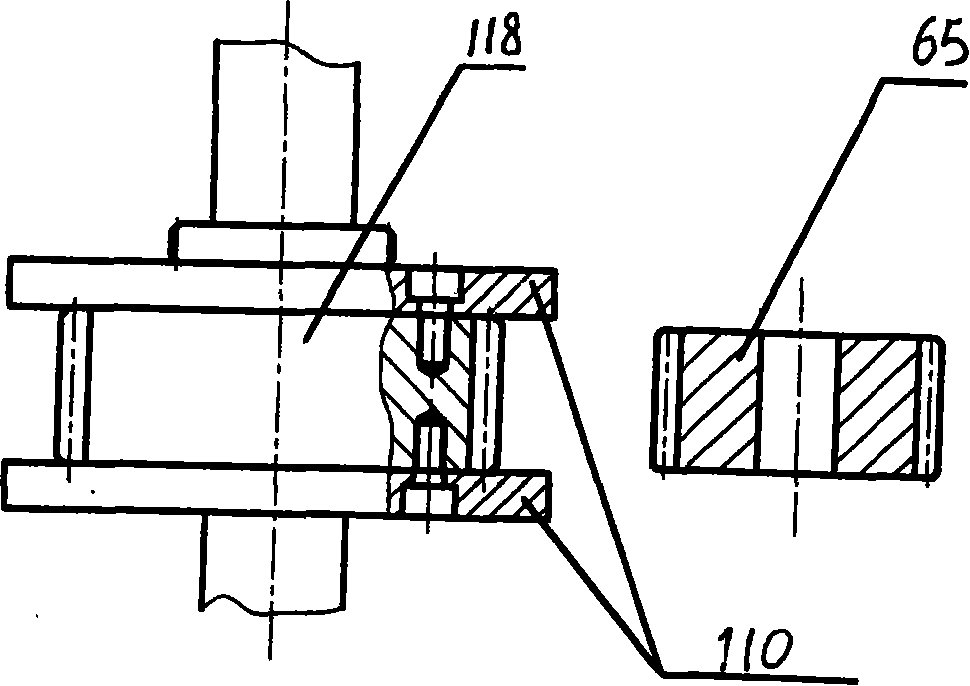

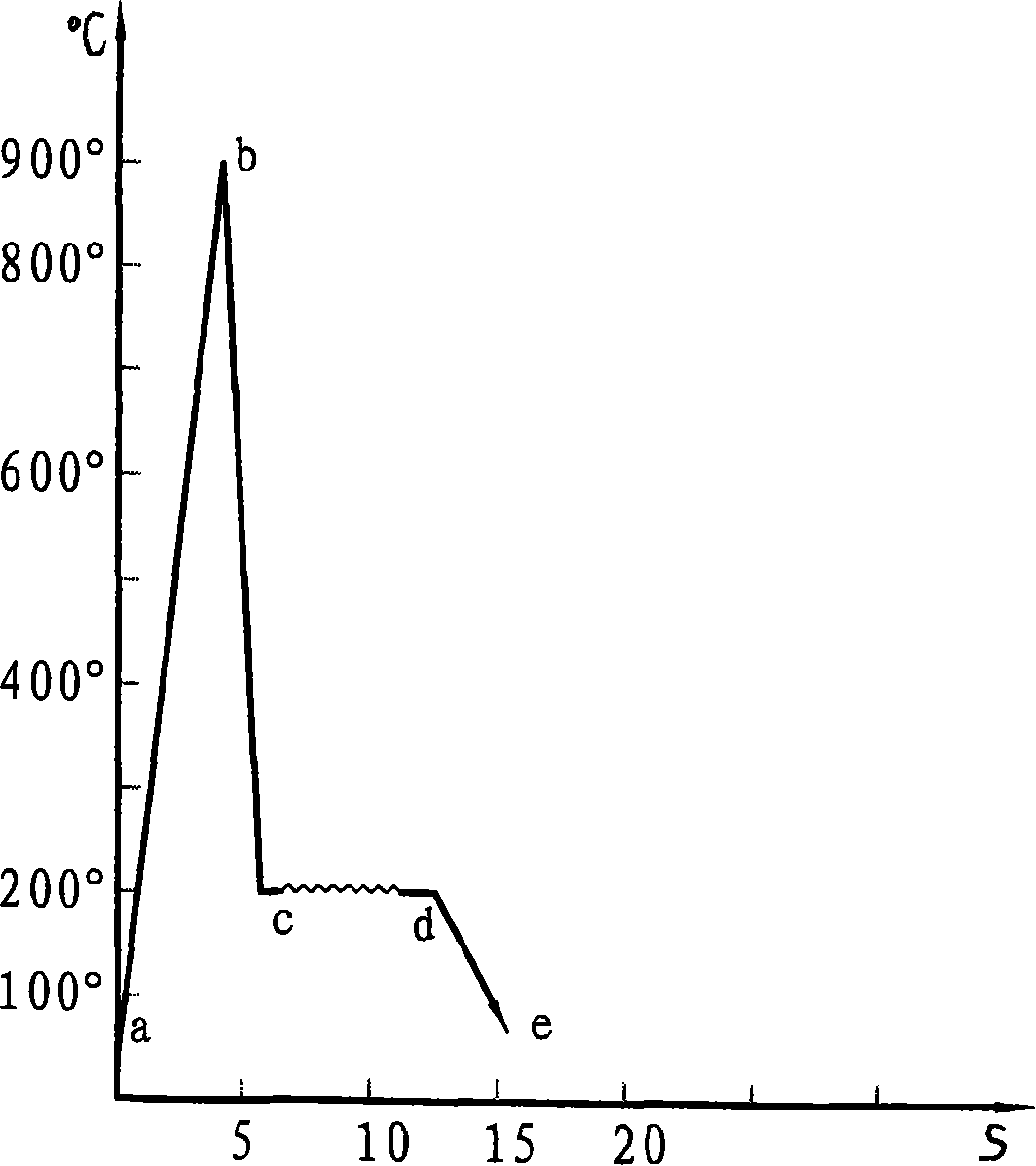

[0025] As shown in Figure 1, a gear precision hot rolling mill is composed of a first hobbing die transmission mechanism 1, a second hobbing die transmission mechanism 5, a workpiece loading and unloading compacting mechanism 6, a lifting mechanism 4, and a first screw rod The propulsion mechanism 7, the second screw mandrel propulsion mechanism 14, the oil tank 13, the temperature control device and the frame 2 are composed. The frame straddles the both sides of the oil tank, and the slide block 42 in the lifting mechanism is installed on the slide block rails provided on both sides of the frame, and is connected with the piston rod of the hydraulic cylinder 41 fixed on the frame. The first hobbing mold transmission mechanism, the workpiece loading and unloading compacting mechanism and the second hobbing mold transmission mechanism are vertically suspended from left to right on the slide block.

[0026] The first hobbing mold transmission mechanism 1 is composed of a servo m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com