Plane cambered glass periphery film removal device

A curved glass and film device technology, which is applied in the field of coated glass, can solve the problems of low film removal efficiency, difficult film removal of automotive coated glass, and inability to remove film from flat curved glass, so as to improve product quality, simple action, and realization The effect of clean production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

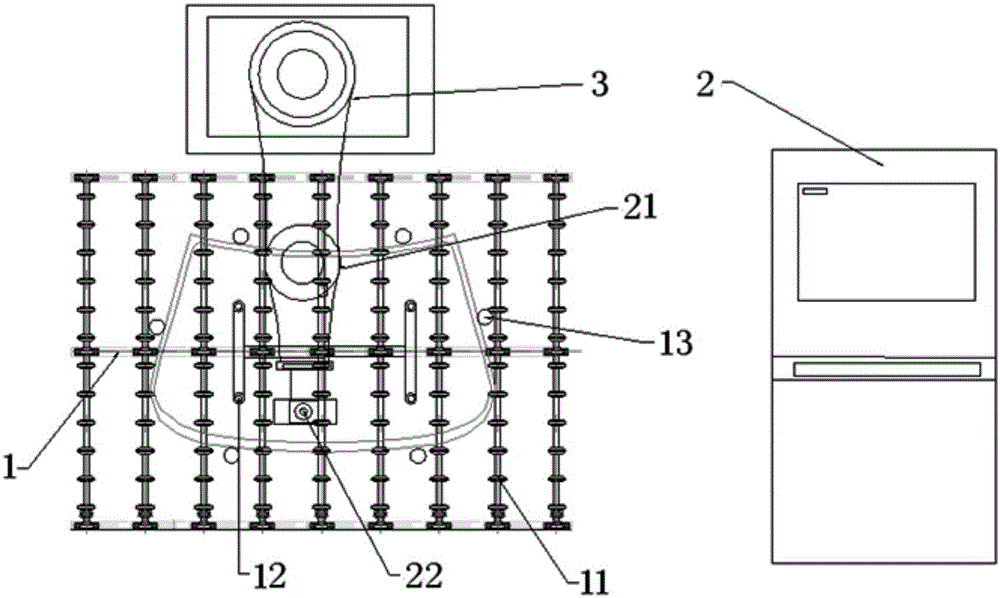

[0043] Such as figure 1 As shown, a film removal device around the plane curved glass includes a film removal platform 1, an electrical control device 2 and a robot arm numerical control platform 3, a laser 22 is located at the free end of the robot arm 21, and the electrical control device 2 is respectively connected to the film removal platform. Table 1 and robot arm numerical control platform 3, film removal table 1 includes frame, glass transmission assembly 11 and liftable glass positioning assembly, robot arm numerical control platform 3 includes robot arm 21 and laser 22, glass transmission assembly 11 is arranged on the frame On the top surface, the liftable glass positioning component is arranged under the glass transmission component 11, and the robot arm 21 is set on one side of the frame. 21 drives the laser 22 to perform laser film removal on the positioned flat curved glass.

[0044] Among them, the robot arm 21 adopts a space six-bar open-chain mechanism compos...

Embodiment 2

[0053] The difference between this embodiment and Embodiment 1 is that it also includes a dust suction assembly connected to the electrical control device 2. The dust suction assembly includes a dust suction fan, an exhaust pipe, and a dust suction port. The flat curved glass is connected with the vacuum fan through the exhaust pipe.

[0054] Film removal process:

[0055] 1) Firstly, the coated glass is transported to the corresponding position of the film removal platform 1 through the glass transmission assembly 11, and the lifting platform 12 rises, so that the positioning part 13 rises, and the positioning part 13 passes through the gap between the transmission rollers, and fixes the side of the flat curved glass side;

[0056] 2) Input the graphics of the film area to be removed into the system control software of the CNC host computer, set the working power of the excitation generator to be 10W-1000W according to the thickness of the film layer, start the automatic cyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com