Processing method and device of friction spinning negative Poisson's ratio yarn of front tension structure

A negative Poisson's ratio and processing device technology, which is applied in the field of processing devices for negative Poisson's ratio yarns, can solve the problems of thick yarns and difficult to obtain high-quality favors, and achieve stable structure, suitable for continuous production and promotion Low cost of application and implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

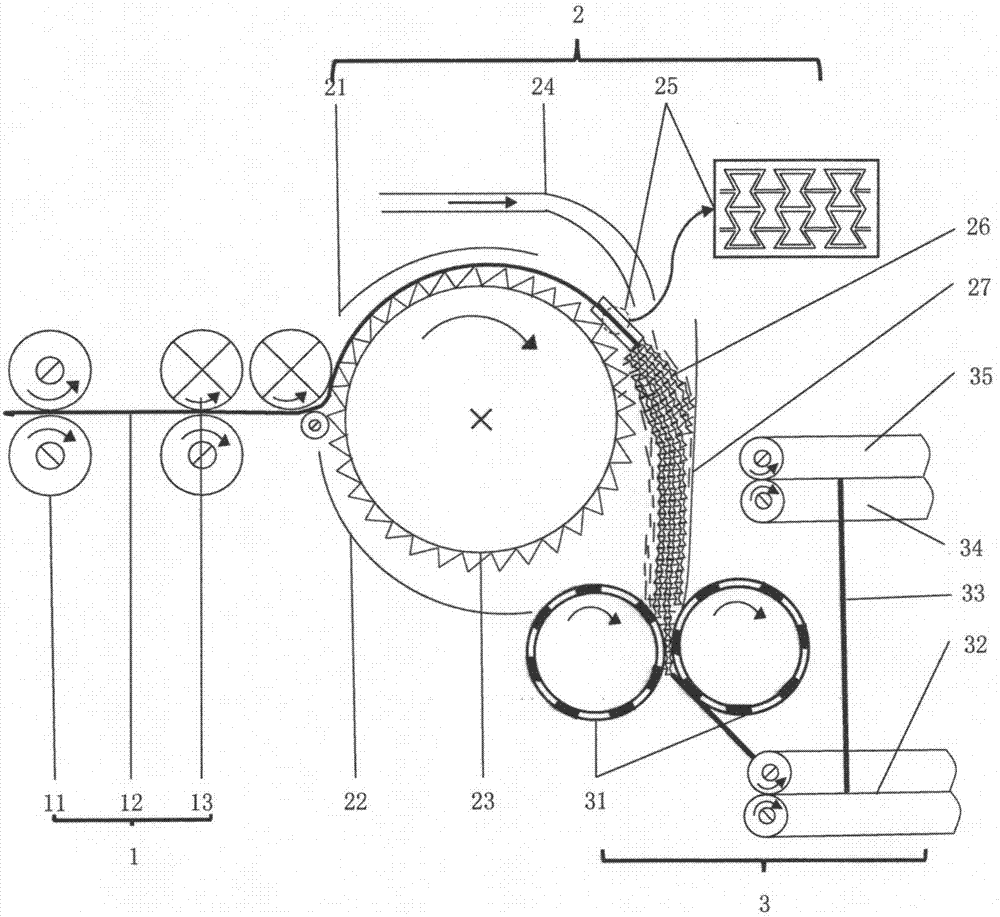

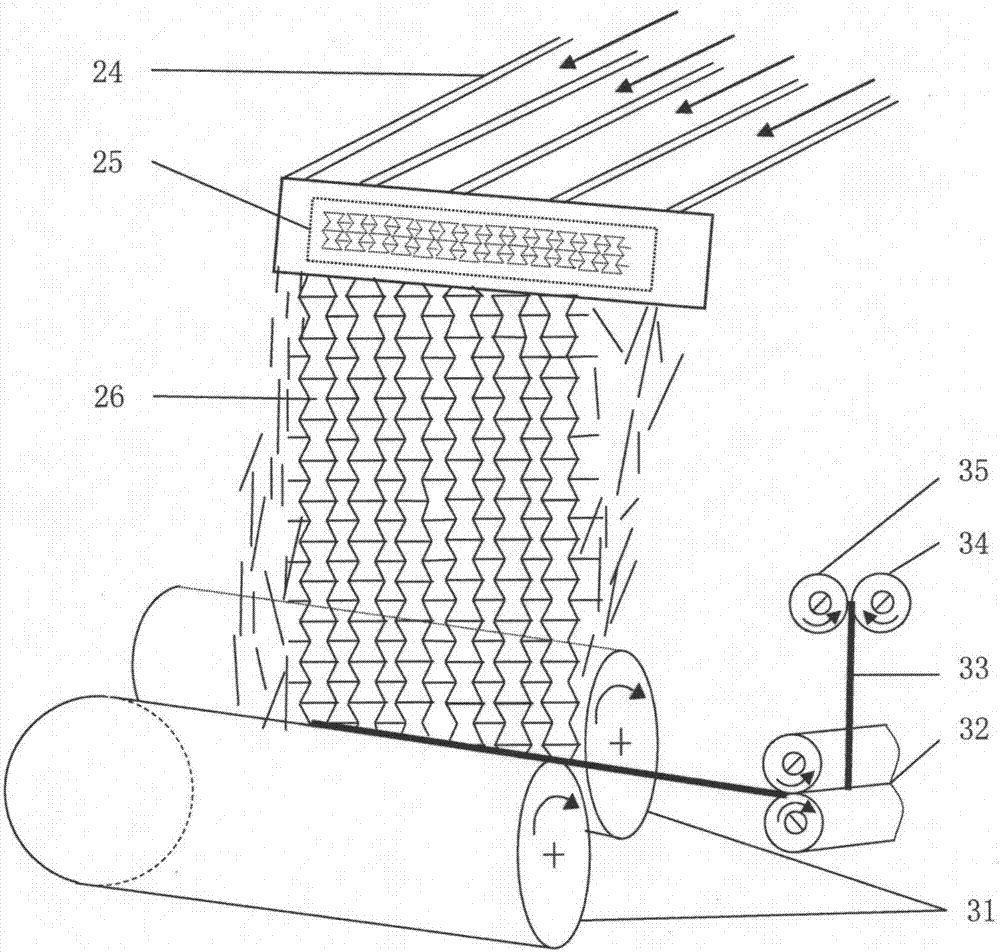

[0047] The preparation of embodiment 1 concave hexagon-negative Poisson's ratio cotton fiber yarn

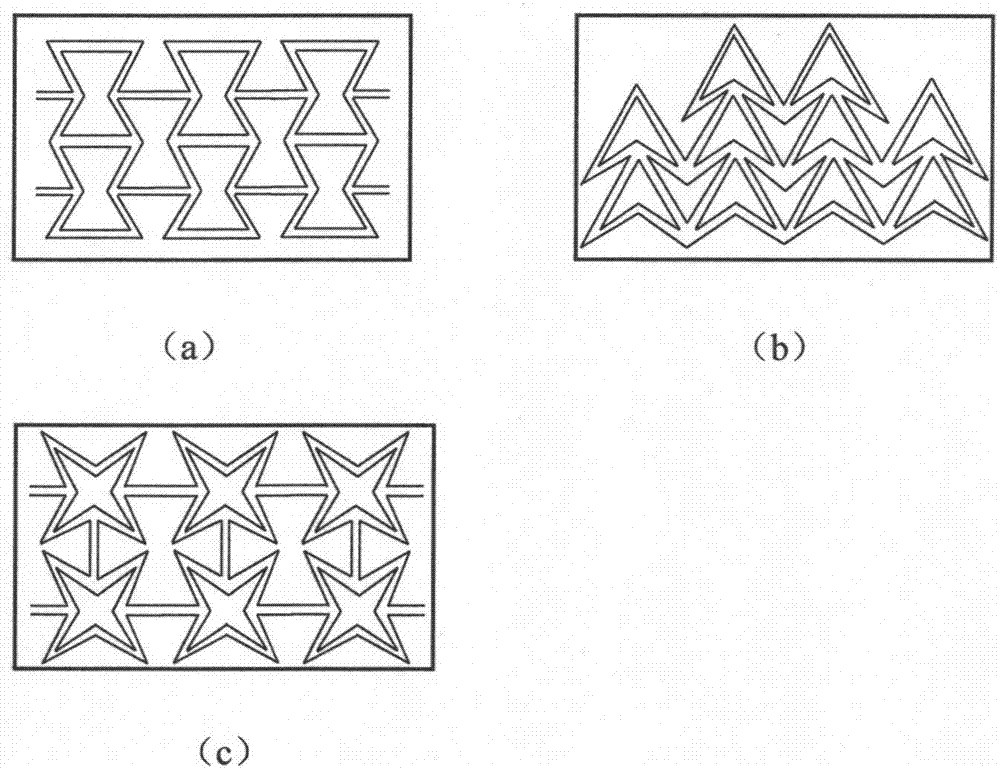

[0048] The shape of the surface grooves on the upper and lower templates of the stereotyped template 25 is a concave hexagon, such as image 3 (a) shown.

[0049] Select cotton staple roving 12 whiskers as raw material, cotton staple roving is fed to delivery roller 11, after passing through the draft zone that delivery roller 11 and draft roller 13 form, output from the front nip of draft roller 13; The short fiber roving 12 is fed to the carding roller 23 after preliminary drafting and carding, and enters the shaping template 25 after being carded by the carding roller 23 to form the shape of the auxetic structure and is synchronized under the action of the hot steam containing the sizing agent blown by the blowing pipe 24 Output after sizing; the auxetic spun yarn 26 output by the carding roller 23 and the sizing template 25 is delivered to the surface of the dust cage 31 wi...

Embodiment 2

[0051] The preparation of embodiment 2 double arrow shape-negative Poisson's ratio cotton fiber yarn

[0052] The shape of the surface grooves on the upper and lower templates of the stereotyped template 25 is a double arrow shape, such as image 3 (b) shown.

[0053] Select cotton staple roving 12 whiskers as raw material, cotton staple roving is fed to delivery roller 11, after passing through the draft zone that delivery roller 11 and draft roller 13 form, output from the front nip of draft roller 13; The short fiber roving 12 is fed to the carding roller 23 after preliminary drafting and carding, and enters the shaping template 25 after being carded by the carding roller 23 to form the shape of the auxetic structure and is synchronized under the action of the hot steam containing the sizing agent blown by the blowing pipe 24 Output after sizing; the auxetic spun yarn 26 output by the carding roller 23 and the sizing template 25 is delivered to the surface of the dust cage...

Embodiment 3

[0055] The preparation of embodiment 3 star-negative Poisson's ratio cotton fiber yarn

[0056] The surface groove shape on the sizing template 25 upper and lower templates is star-shaped, as image 3 (c) shown.

[0057] Select spun roving 12 strands as raw materials, feed the spun roving to the conveying roller 11, pass through the drafting zone formed by the conveying roller 11 and the drafting roller 13, and output it from the front jaw of the drafting roller 13; 12 After preliminary drawing and carding, it is fed to the carding roller 23, and after being carded by the carding roller 23, it enters the shaping template 25 to form the shape of the auxetic structure and is synchronously shaped by the hot steam containing the sizing agent blown in by the blowing pipe 24 and then output The auxetic spun yarn 26 output by the carding roller 23 and the sizing template 25 is delivered to the surface of the dust cage 31 with air suction channels and built-in air suction devices on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com