Micro-needle array patch capable of generating gas to take effect quickly and preparation and application thereof

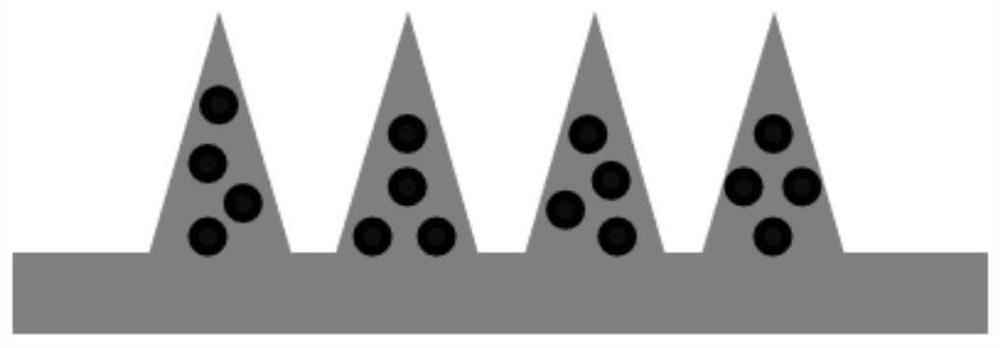

A technology of microneedle array and gas, which is applied in the direction of non-active ingredient medical preparations, medical preparations containing active ingredients, sheet delivery, etc. It can solve the problem of slow transdermal release speed, shortening the time required for drug onset, Long onset time and other issues, to achieve the effect of promoting rapid onset of action, shortening the required time, and accelerating dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Include the following steps:

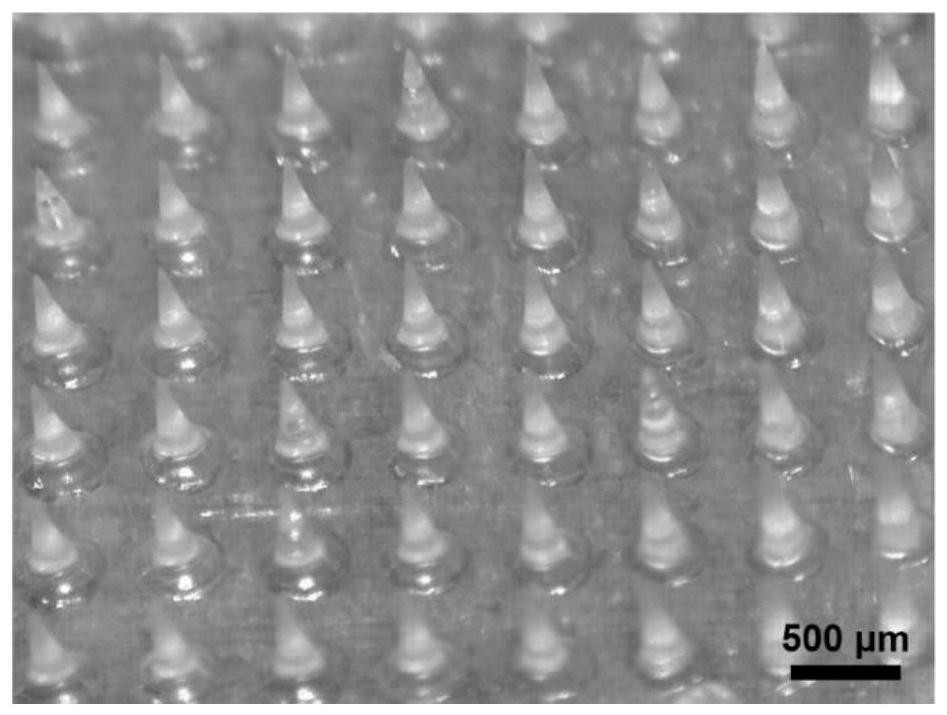

[0029] 1. Use a laser engraving machine to etch out a 10*10 polydimethylsiloxane (PDMS) negative template with a bottom diameter of 200 μm, a height of 850 μm, and a distance between adjacent microneedles of 600 μm;

[0030] 2. Grinding the purchased magnesium metal into granules, sieving, and finally obtaining magnesium metal particles with a size less than 30 μm for later use;

[0031] 3. Prepare a 200mg / mL polyvinylpyrrolidone (PVP) solution containing 0.5wt% magnesium metal particles and an appropriate amount of Aylar with a phosphate buffer solution of pH 9 and stir evenly;

[0032]4. Take an appropriate amount of the solution in step 3 and fill it into the tip of the PDMS mold by vacuuming, scrape off the excess solution with a scraper, place it in a desiccator for 8 hours at room temperature and then take it out. Spread a layer of pure 200mg / mL PVP solution on the dried PDMS mold, remove air bubbles in a vacuum, continue drying for...

Embodiment 7

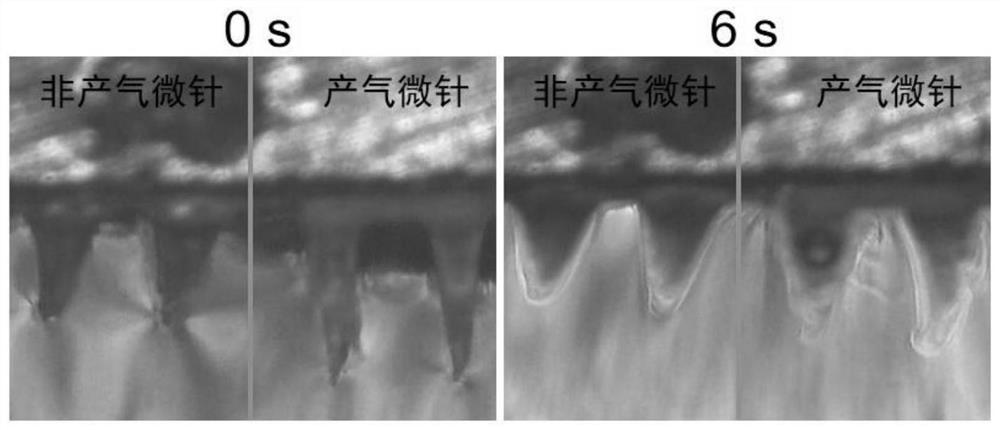

[0037] The gas-generating microneedles obtained in Example 6 and the non-gas-generating microneedles obtained under the same operating conditions were placed in water at the same time, and the dissolution rates of the microneedle tips were compared. It was found that half of the microneedles loaded with sodium percarbonate dissolved within 6 seconds, while only a small part of the non-gas-producing group dissolved, indicating that the gas-producing microneedles can promote the dissolution and release of drugs from the microneedles.

[0038] The specific preparation process of the non-gas-producing microneedle includes the following steps:

[0039] 1. Use a laser engraving machine to etch out a 10*10 polydimethylsiloxane (PDMS) negative template with a base diameter of 300 μm, a height of 650 μm, and a distance between adjacent microneedles of 600 μm;

[0040] 2. Prepare a 200 mg / mL polyvinylpyrrolidone (PVP) solution containing an appropriate amount of chlorin e6 with a phosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com