Method for repairing organic pollutants in polluted soil and underground water

A technology for organic pollutants and groundwater, applied in the field of environmental pollution control, can solve the problems of high cost, complex disposal operation of chlorinated aliphatic hydrocarbon pollutants, and large influence of nature factors, and achieve low cost, safe transportation and use, and long-term retention long time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

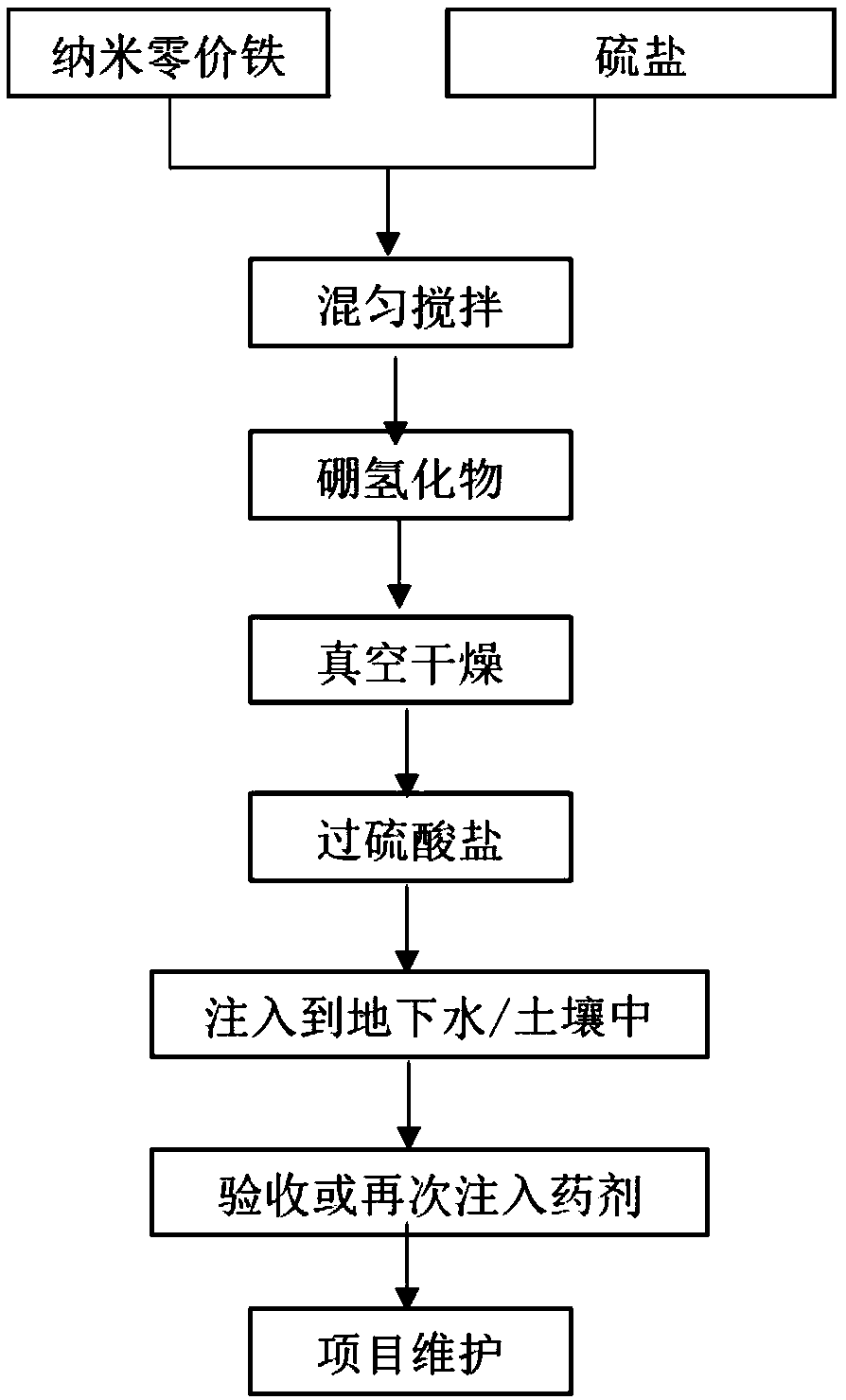

Image

Examples

Embodiment 1

[0047] Embodiment 1: a kind of method for repairing polluted soil and organic pollutant in groundwater, concrete steps are as follows:

[0048] (1) Add 100g of nano-sized zero-valent iron into 500ml of deionized water, ultrasonically clean for 15 minutes, discard the distilled water, and keep the nano-sized zero-valent iron particles; add nano-sized zero-valent iron particles into a certain volume of sodium sulfite solution, the concentration of sodium sulfite solution is 0.01mol / L, to ensure that the molar ratio of sulfur: iron is 1:1;

[0049] (2) Place the above-mentioned mixed solution in an atmosphere furnace, and slowly add a sodium borohydride solution with a concentration of 0.1mol / L to the mixture under the condition of nitrogen protection. The molar ratio of sodium borohydride to sulfur is 1:2, and fully stir until Discard the supernatant when there is no obvious gas evolution;

[0050] (3) Wash the black solid obtained in step (2) with absolute ethanol solution th...

Embodiment 2

[0055] Embodiment 2: a kind of method for remediating organic pollutants in polluted soil and groundwater, concrete steps are as follows:

[0056] (1) Add 100g of nanometer zero-valent iron into 500ml of deionized water, ultrasonically clean for 15 minutes, discard the distilled water, and keep the nanometer zerovalent iron particles; add nanometer zerovalent iron particles into a certain volume of sodium sulfite solution, the concentration of sodium sulfite solution is 0.05mol / L, to ensure that the molar ratio of sulfur: iron is 1:2;

[0057] (2) Slowly add sodium borohydride solution with a concentration of 0.2mol / L to the above mixed solution under the condition of nitrogen protection, the molar ratio of sodium borohydride to sulfur is 1:3, fully stir until no obvious gas is released, then discard supernatant;

[0058] (3) The black solid obtained in step (2) was washed three times with anhydrous methanol solution according to the solid-to-liquid ratio of 1:5, and then va...

Embodiment 3

[0062] Embodiment 3: a kind of method for repairing polluted soil and organic pollutant in groundwater, concrete steps are as follows:

[0063] (1) Add 100g of nanometer zero-valent iron into 500ml of deionized water, and after ultrasonic cleaning for 15 minutes, discard the distilled water and keep the nanometer zerovalent iron particles; add nanometer zerovalent iron particles into a certain volume of sodium dithionite solution, The concentration is 0.1mol / L, and the molar ratio of sulfur: iron is guaranteed to be 1:10;

[0064] (2) Slowly add the potassium borohydride solution that concentration is 0.3mol / L in the above-mentioned mixed solution, the mol ratio of potassium borohydride and sulfur is 1:4, discard the supernatant after fully stirring;

[0065] (3) Wash the black solid obtained in step (2) with absolute ethanol solution three times according to the solid-to-liquid ratio of 1:10, and then vacuum-dry it at 70°C;

[0066] (4) Fully mix the dried solid obtained in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com