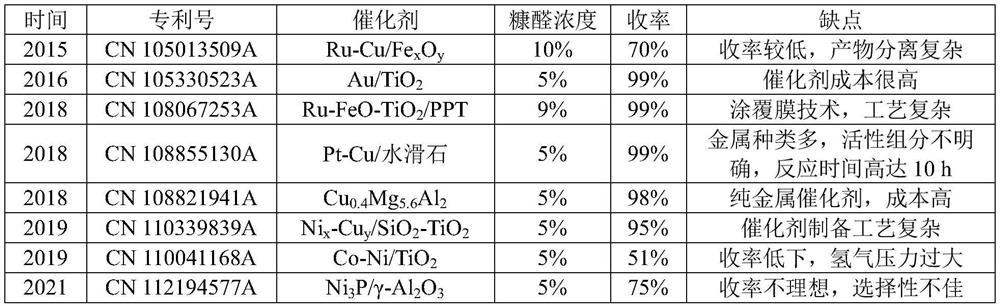

Method for preparing cyclopentanone through furfural water liquid hydrogenation rearrangement

A technology of cyclopentanone and furfural, which is applied in the field of furfural water-liquid hydrogenation rearrangement to prepare cyclopentanone, can solve the problems of complex reaction, large amount of catalyst usage, harsh conditions, etc., achieve good stability and cycle performance, and reduce catalyst cost The effect of reducing and environmental protection in the synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

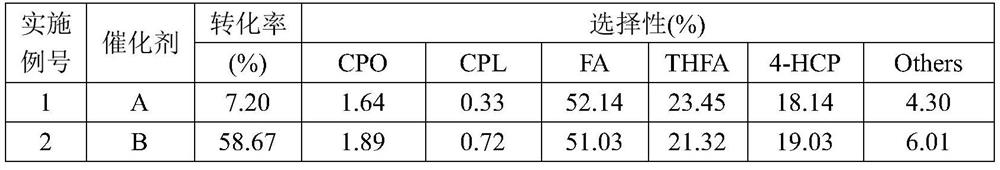

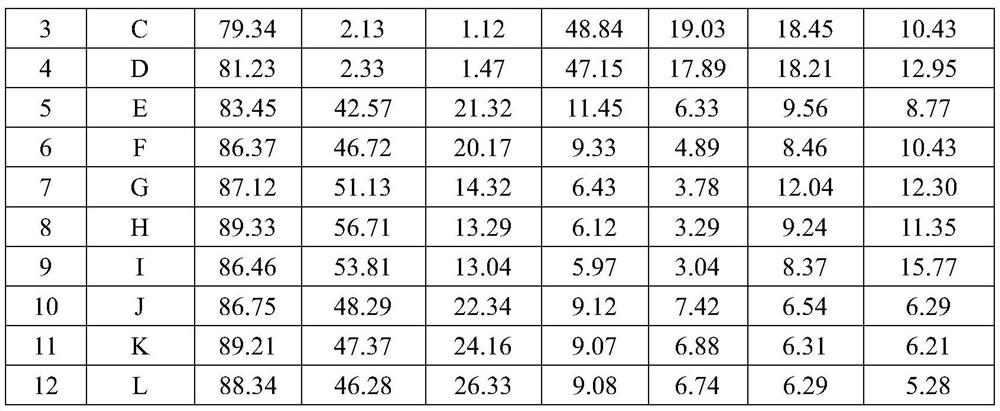

Examples

preparation example Construction

[0034] Catalyst preparation and hydrogenation method:

[0035] Preparation and synthesis of the carrier: Diatomaceous earth was fully dried at 110°C and ground into powder, passed through a 200-mesh sieve and placed in a beaker, adding dilute sulfuric acid with a mass fraction of 40% (solid-liquid mass ratio was 1:4) , transferred to a three-necked flask, placed in an oil bath at 80°C for continuous mechanical stirring for 8 hours, suction filtered after cooling, fully washed with distilled water until the filtrate was neutral, transferred to a drying oven and kept at 110°C for 24 hours, cooled and transferred to Crucible, placed in a muffle furnace and kept at 450 ° C for 4 hours, ground evenly for later use.

[0036] Another 2.70 g of the above solid powder was added to a round bottom flask containing 1.00 NaOH solid and 25.00 mL of distilled water and heated to 80 ° C for 4 h to obtain a sodium silicate precursor. Alkyltrimethylammonium bromide and 50mL distilled water wer...

Embodiment 1

[0039] Embodiment 1: the hydrogenation device is a stainless steel high-pressure electric heating reactor of 50 milliliters, at first the furfural of 2.4 g is added to the distilled water of 17.6 g, utilizes magnet to stir 30min to form uniform mass fraction and is the furfural aqueous liquid of 12wt%, then adds 0.10g of catalyst A, quickly close the autoclave, and replace the air in the autoclave with hydrogen for 3-4 times, start stirring, adjust the pressure of the hydrogen gas introduced to 2.0MPa, raise the temperature to 160°C, continue to react at this temperature for 240min, then cool to At room temperature, after carefully releasing the pressure, take out the product and weigh it, and take the upper liquid and centrifuge it to detect it using the internal standard method of gas chromatography, n-butanol is used as the internal standard, and the calculated conversion and selectivity data of related species are shown in Table 1.

Embodiment 2

[0040] Example 2: Catalyst B is selected, the reaction feeding and hydrogenolysis reaction conditions are the same as in Example 1, and the calculated conversion and selectivity data of related species are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com