Environment-friendly antistatic polyurethane anticorrosion coating and preparation method thereof

An anti-corrosion coating and anti-static technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, conductive coatings, etc., can solve problems such as carcinogenicity, toxic volatiles, and impact on people's health, and achieve long service life, easy cost, and excellent performance. The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

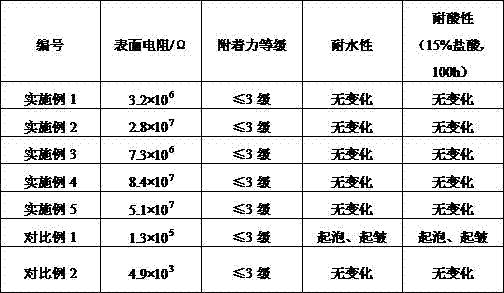

Examples

Embodiment 1

[0017] The preparation method of the environment-friendly antistatic polyurethane anticorrosion coating, the specific preparation steps include:

[0018] Step 1: Weigh raw materials according to certain parts by weight: according to parts by weight: 36 parts of water-based polyurethane emulsion, 28 parts of water-based acrylic resin, 4 parts of copper sulfide, 3 parts of montmorillonite, 2 parts of conductive mica powder, 2 parts of calcium carbonate 1 part, 2 parts of zinc oleate, 1 part of polyoxypropylene laurate, 1 part of sodium lauryl sulfate, 1 part of leveling agent, 0.2 part of defoamer, 12 parts of ethanol and an appropriate amount of deionized water;

[0019] Step 2: Dissolve sodium lauryl sulfate in deionized water, then add copper sulfide, montmorillonite, conductive mica powder, calcium carbonate and ethanol, stir and mix for 1 hour, then grind and disperse the slurry to 2500 Mesh fineness;

[0020] Step 3: Add water-based polyurethane emulsion, water-based acry...

Embodiment 2

[0023] The preparation method of the environment-friendly antistatic polyurethane anticorrosion coating, the specific preparation steps include:

[0024] Step 1: Weigh raw materials according to certain parts by weight: according to parts by weight: 60 parts of water-based polyurethane emulsion, 43 parts of water-based acrylic resin, 13 parts of copper sulfide, 12 parts of montmorillonite, 9 parts of conductive mica powder, 10 parts of calcium carbonate 5 parts of zinc oleate, 6 parts of polyoxypropylene laurate, 3 parts of sodium lauryl sulfate, 2 parts of leveling agent, 2 parts of defoamer, 25 parts of ethanol and appropriate amount of deionized water;

[0025] Step 2: Dissolve sodium lauryl sulfate in deionized water, then add copper sulfide, montmorillonite, conductive mica powder, calcium carbonate and ethanol, stir and mix for 4 hours, then grind and disperse the slurry to 2500 Mesh fineness;

[0026] Step 3: Add water-based polyurethane emulsion, water-based acrylic r...

Embodiment 3

[0029] The preparation method of the environment-friendly antistatic polyurethane anticorrosion coating, the specific preparation steps include:

[0030] Step 1: Weigh raw materials according to certain parts by weight: according to parts by weight: 48 parts of water-based polyurethane emulsion, 35 parts of water-based acrylic resin, 8 parts of copper sulfide, 7 parts of montmorillonite, 5 parts of conductive mica powder, 6 parts of calcium carbonate 4 parts of zinc oleate, 3 parts of polyoxypropylene laurate, 2 parts of sodium lauryl sulfate, 1.4 parts of leveling agent, 1 part of defoamer, 18 parts of ethanol and appropriate amount of deionized water;

[0031] Step 2: Dissolve the sodium lauryl sulfate in the raw material in deionized water, then add copper sulfide, montmorillonite, conductive mica powder, calcium carbonate and ethanol, stir and mix for 2.5 hours, then grind and disperse the slurry to 2500 mesh fineness;

[0032] Step 3: Add water-based polyurethane emulsio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com