Patents

Literature

39 results about "ZINC OLEATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

It is a light tan color powder containing about 8.5-10.5% zinc. Zinc oleate may appear as bloom on the surface of oil or alkyd paints when it is formed by the reaction of oleic acid with zinc white pigment. Zinc oleate is also used as a drier in paints, resins and varnishes.

Performance Grade Asphalt Composition and Method of Production Thereof

InactiveUS20090012214A1Low viscosityBuilding insulationsBituminous coatingsPolymer modifiedWater insoluble

An asphalt material having improved paving characteristics and processes for its preparation. An asphalt base material is heated in a mixing chamber to a temperature sufficient to melt the asphalt so that it can be stirred. A water-insoluble heavy metal soap is incorporated into the chamber in an amount effective to reduce the PAV-DSR temperature of the asphalt base material by an incremental amount of at least 1° C. Thereafter, the asphalt material is recovered from the mixing chamber to provide an asphalt product containing the heavy metal soap which exhibits a PAV-DSR temperature which is less than the PAV-DSR temperature for the corresponding base material without the addition of the heavy metal soap. The water-insoluble soap is a C14-C18 heavy metal soap such as a C16-C18 zinc- or calcium-based soap including zinc stearate, zinc oleate and zinc palmitate. The heavy metal soap is added to the mixing chamber in an amount within the range of 0.05-3.0 wt. % of the amount of asphalt based material in the mixing chamber. A thermoplastic polymer may be added to the asphalt based material to provide a polymer-modified asphalt blend. An asphalt paving composition comprising an asphalt base material and a water-insoluble heavy metal soap in an amount to provide a PAV-DSR temperature lower than the PAV-DSR temperature of the corresponding asphalt material without the addition of the heavy metal soaps.

Owner:FINA TECH

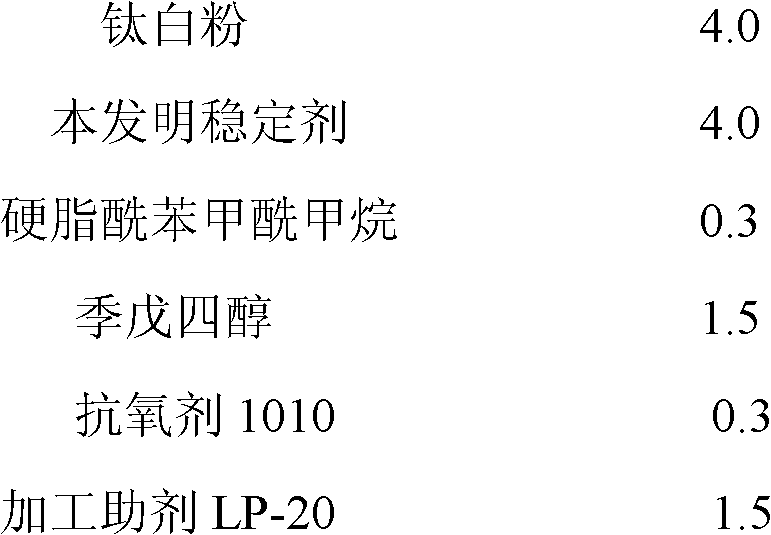

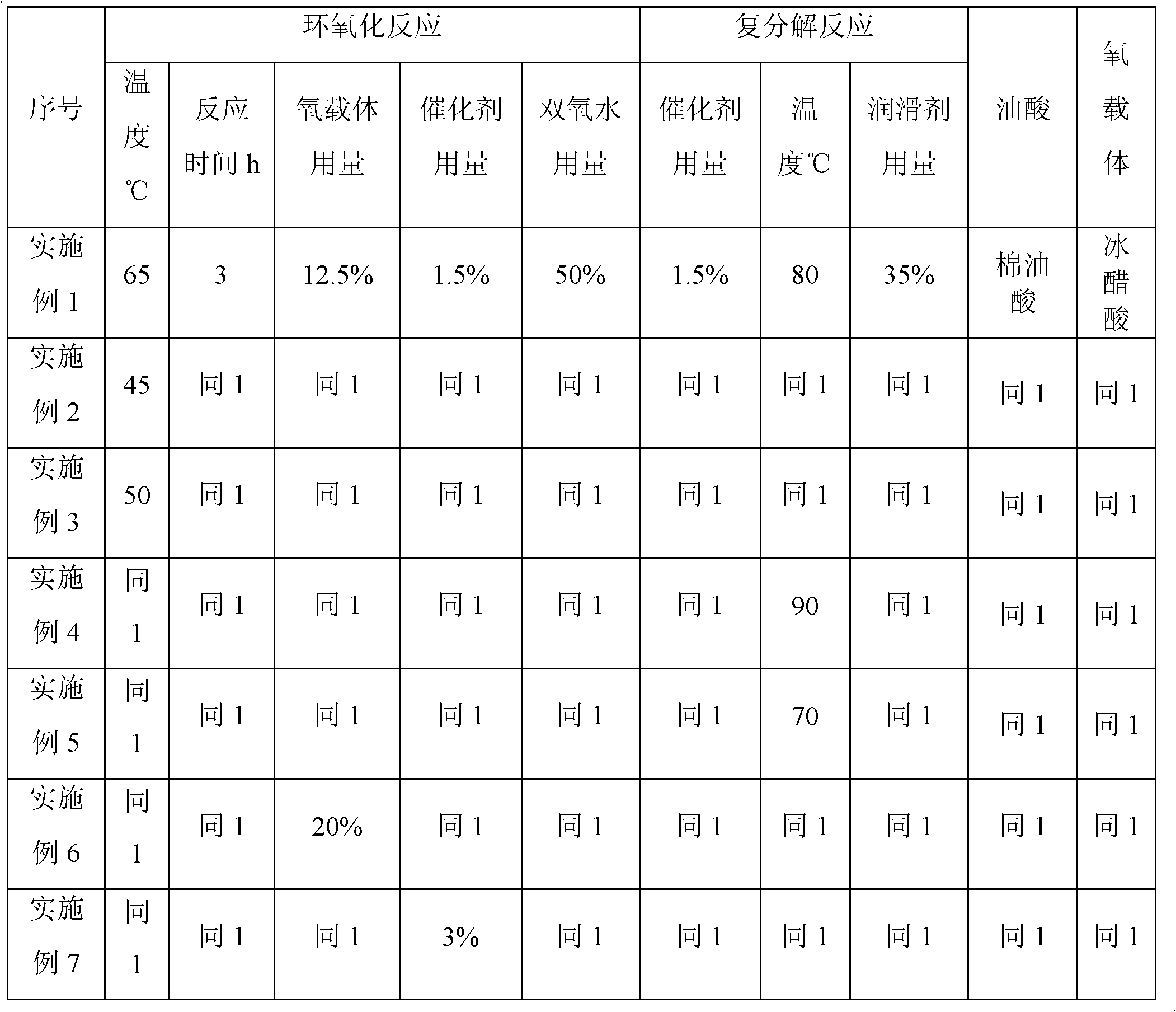

Epoxidized calcium-zinc oleate compound stabilizer and preparation method thereof

ActiveCN102504443AEasy to keepGood dispersibility in flakesOrganic chemistryDistillationReaction temperature

The invention relates to epoxidized calcium-zinc oleate compound stabilizer and a preparation method thereof, and belongs to the technical field of PVC processing agent. The stabilizer is prepared by the following steps that: oleic acid, glacial acetic acid or formic acid, concentrated sulfuric acid or p-toluene sulfo acid, and hydrogen peroxide are added into a reactor to conduct epoxidation reaction so as to obtain epoxidized oleic acid, wherein the reaction temperature is 45-65 DEG C, and the reaction time is 2-3 hours; alkali wash is carried out, that is, the prepared epoxidized oleic acid is subjected to alkali wash by diluted sodium bicarbonate solution and is then washed by water to the PH of 6-8, then reduced pressure distillation is conducted to remove water; metal ions and catalyst are added into the epoxidized oleic acid which is subjected to alkali wash for reaction, finally lubricant is added into the mixture, and then the mixture is discharged and cut into slices after being stirred uniformly so as to prepare the epoxidized calcium-zinc oleate compound stabilizer. The stabilizer has excellent plasticizer and stability, and the preparation method provided by the invention is excellent instability and is easy to operate.

Owner:SHANDONG RUIFENG CHEM

Zinc oxide pre-dispersed masterbatch particle and preparation method and applications thereof

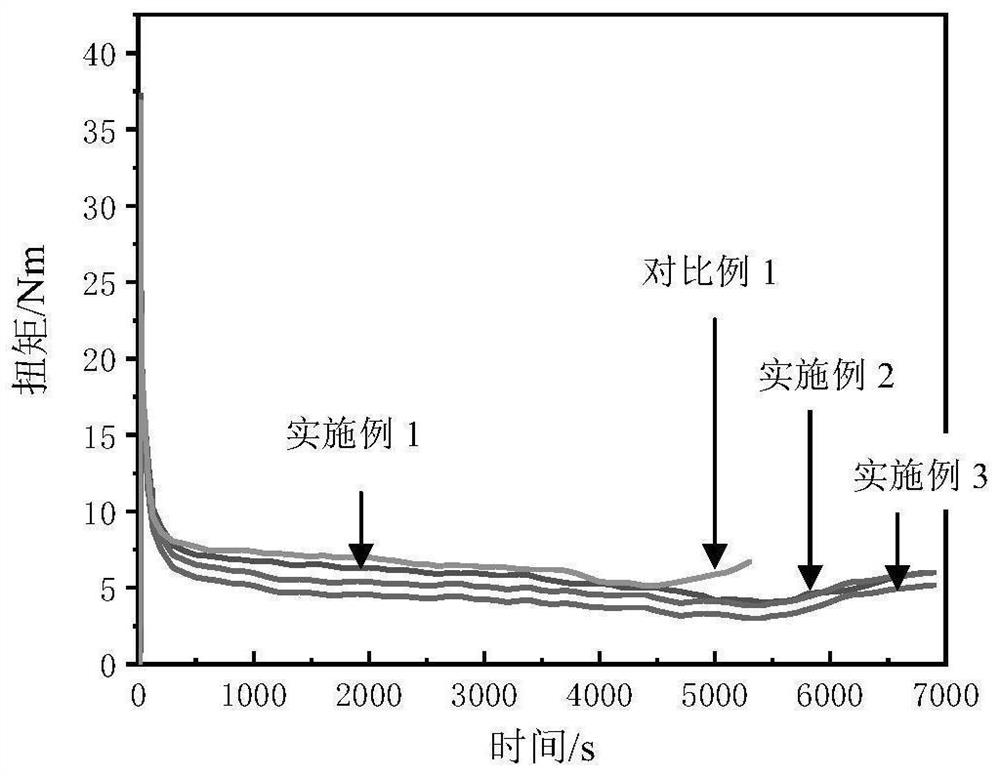

The invention provides a zinc oxide pre-dispersed masterbatch particle, which comprises the following components in parts by mass: 75-85 parts of zinc oxide powder, 6-14 parts of a matrix material, 7-11 parts of a dispersant and 1-3 parts of a plasticizer, wherein the matrix material comprises an ethylene propylene diene monomer EPDM and butadiene rubber BR, the dispersant is composed of a zinc fatty acid and zinc dioleate, and the plasticizer is sulfurized isobutylene. Due to the mutual cooperation of the materials and the mutual influence of molecules, the hardness of the masterbatch particle is reduced, the ash content is increased, and in the process of practical application, the interfusion speed, dispersion speed and dispersion uniformity of the masterbatch particle are significantly increased, the vulcanizing time is short, the vulcanizing effect is good, the energy consumption for blending is reduced, and the production cost is saved.

Owner:PANJIN XINANYUAN CHEM IND

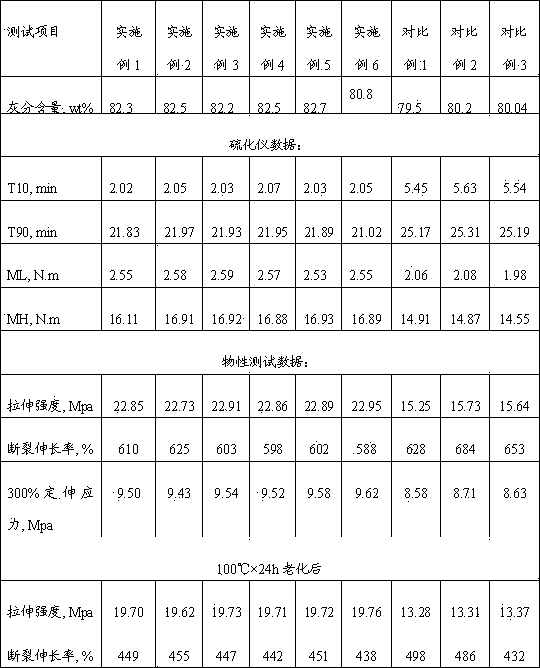

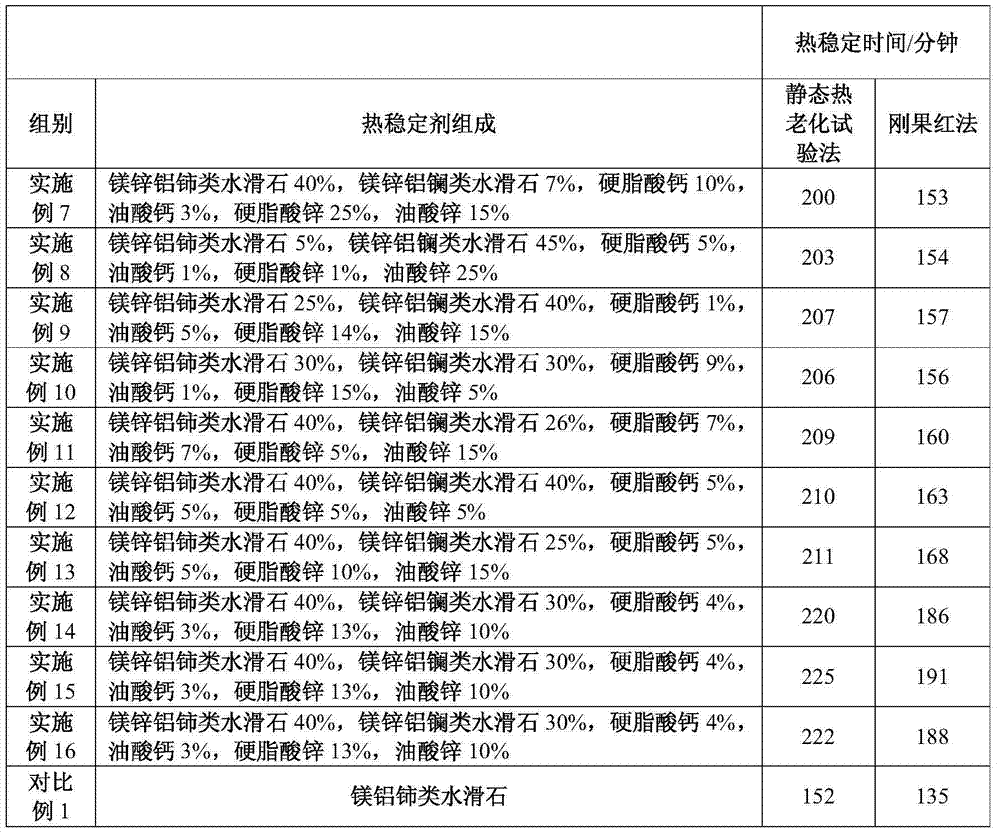

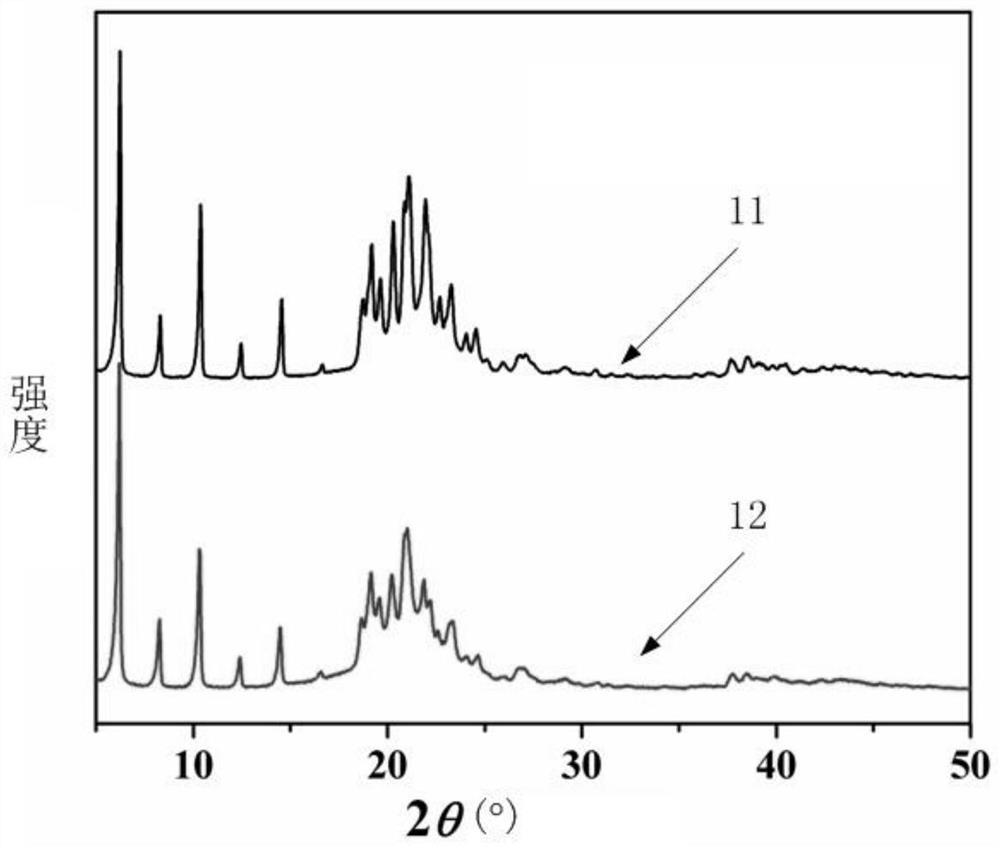

Rare earth type hydrotalcite composite heat stabilizer and heat-stable polyvinyl chloride

The invention discloses a rare earth type hydrotalcite composite heat stabilizer and heat-stable polyvinyl chloride. The rare earth type hydrotalcite composite heat stabilizer comprises the following raw materials in percentage by mass: 5-40% of modified Mg-Zn-Al-Ce hydrotalcite, 7-45% of modified Mg-Zn-Al-La hydrotalcite, 1-10% of calcium stearate, 1-10% of calcium oleate, 1-25% of zinc stearate and 1-25% of zinc oleate. The rare earth type hydrotalcite composite heat stabilizer is prepared by kneading and stirring the above raw materials for 20 minutes and is obtained by compounding two raw materials, namely two kinds of four-element rare earth type hydrotalcite which are the modified Mg-Zn-Al-Ce hydrotalcite and the modified Mg-Zn-Al-La hydrotalcite respectively. The rare earth type hydrotalcite composite heat stabilizer disclosed by the invention is good in compatibility with polyvinyl chloride, the synergistic effect of the components is good, and the heat stability of polyvinyl chloride is improved. The heat-stable polyvinyl chloride disclosed by the invention is good in heat stability.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

Performance grade asphalt composition and method of production thereof

InactiveUS20060122292A1Reduce Brookfield viscosityLow viscosityBuilding insulationsBituminous coatingsPolymer modifiedWater insoluble

An asphalt material having improved paving characteristics and processes for its preparation. An asphalt base material is heated in a mixing chamber to a temperature sufficient to melt the asphalt so that it can be stirred. A water-insoluble heavy metal soap is incorporated into the chamber in an amount effective to reduce the PAV-DSR temperature of the asphalt base material by an incremental amount of at least 1° C. Thereafter, the asphalt material is recovered from the mixing chamber to provide an asphalt product containing the heavy metal soap which exhibits a PAV-DSR temperature which is less than the PAV-DSR temperature for the corresponding base material without the addition of the heavy metal soap. The water-insoluble soap is a C14-C18 heavy metal soap such as a C16-C18 zinc- or calcium-based soap including zinc stearate, zinc oleate and zinc palmitate. The heavy metal soap is added to the mixing chamber in an amount within the range of 0.05-3.0 wt. % of the amount of asphalt based material in the mixing chamber. A thermoplastic polymer may be added to the asphalt based material to provide a polymer-modified asphalt blend. An asphalt paving composition comprising an asphalt base material and a water-insoluble heavy metal soap in an amount to provide a PAV-DSR temperature lower than the PAV-DSR temperature of the corresponding asphalt material without the addition of the heavy metal soaps.

Owner:FINA TECH

Application of scrap tire rubber powder and scrap polystyrene (PS) foam to modified production of CPVC (chlorinated polyvinyl chloride) and PVC (polyvinyl chloride) products

The invention relates to an application of scrap tire rubber powder and scrap polystyrene (PS) foam to production of PVC (polyvinyl chloride) or vinylidene chloride or CPVC (chlorinated polyvinyl chloride) laminates or other sections and appliances. Plenty of cheap black pollutants-scrap tire rubber powder and white pollutants-scrap PS foam are simultaneously adopted as the main modifiers, thus the processability can be improved, the impact strength can be improved and the released hydrogen chloride can be simultaneously absorbed, and the scrap tire rubber powder and the scrap PS foam are matched with defined amount of zinc oleate and barium oleate thermal lubricating stabilizers which can absorb hydrogen chloride and conventional processing aids to produce the CPVC and PVC materials with low prices and excellent properties through the production processes such as preheating, mixing, laminating and the like or produce such sections as bars, sheets, pipes and the like or plastic appliances by adopting plastic extruders and plastic injection moulding machines.

Owner:HUANGSHI HUAYI PLASTIC +1

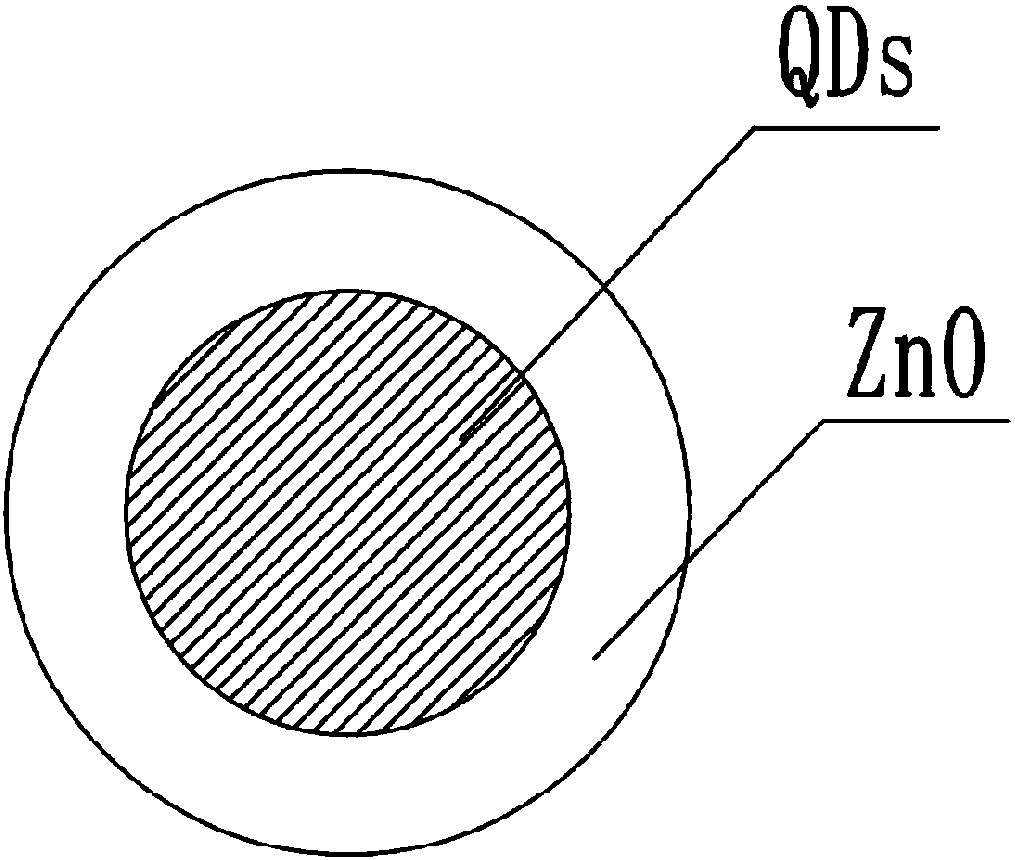

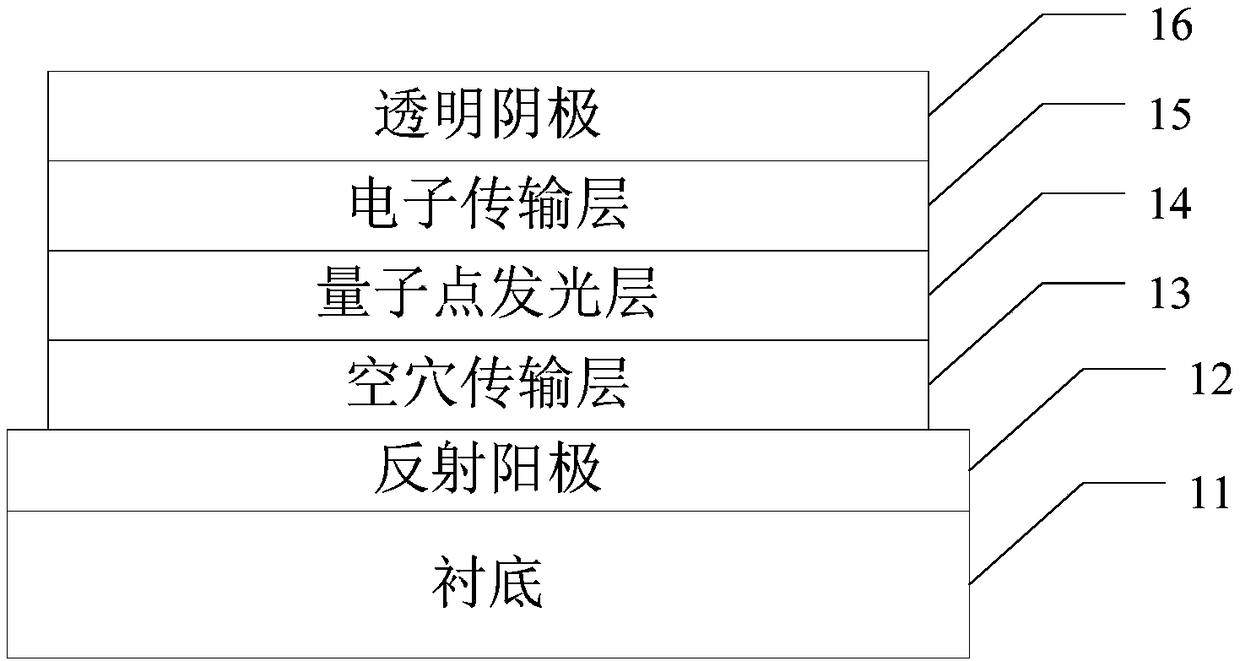

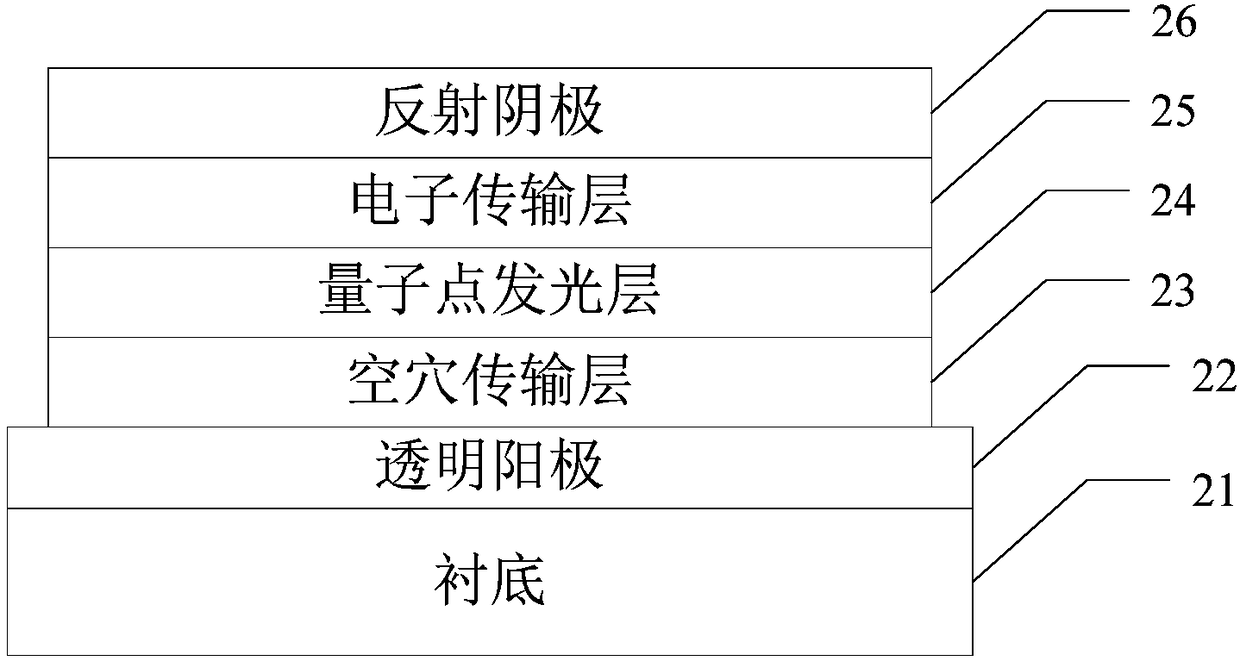

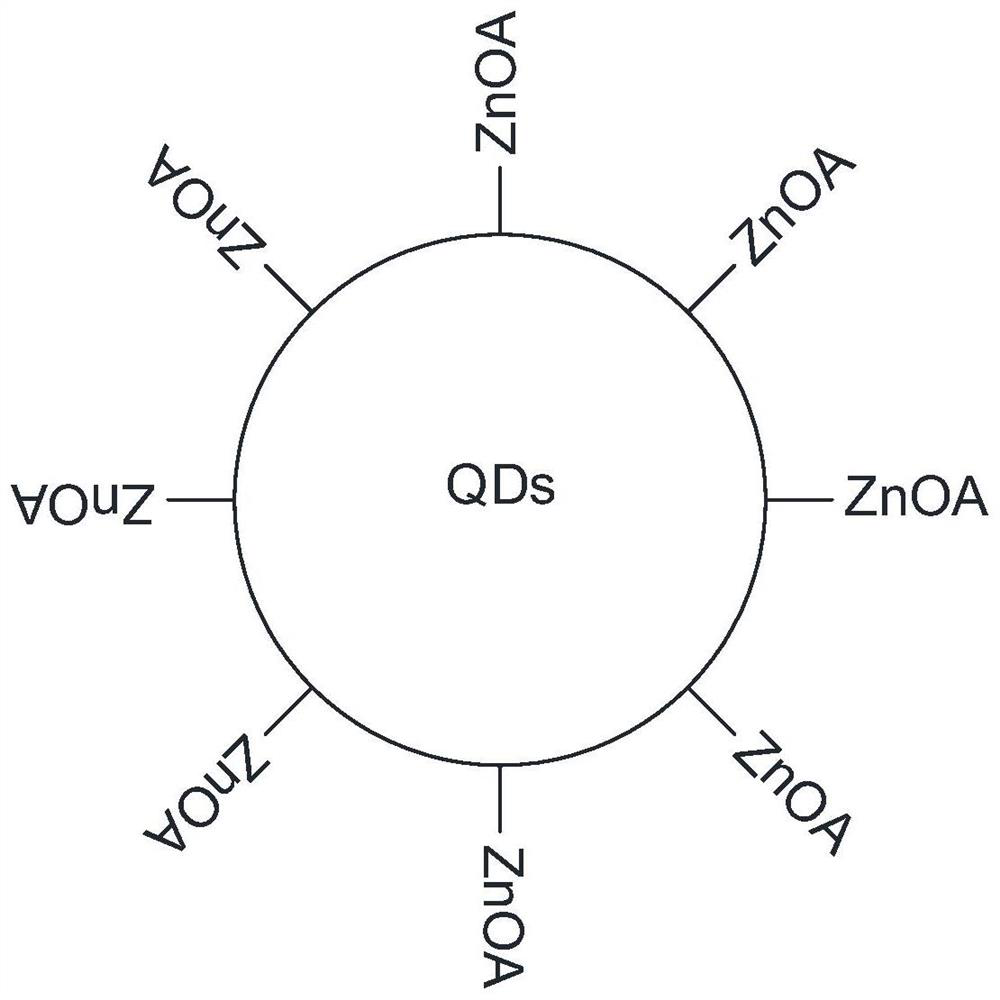

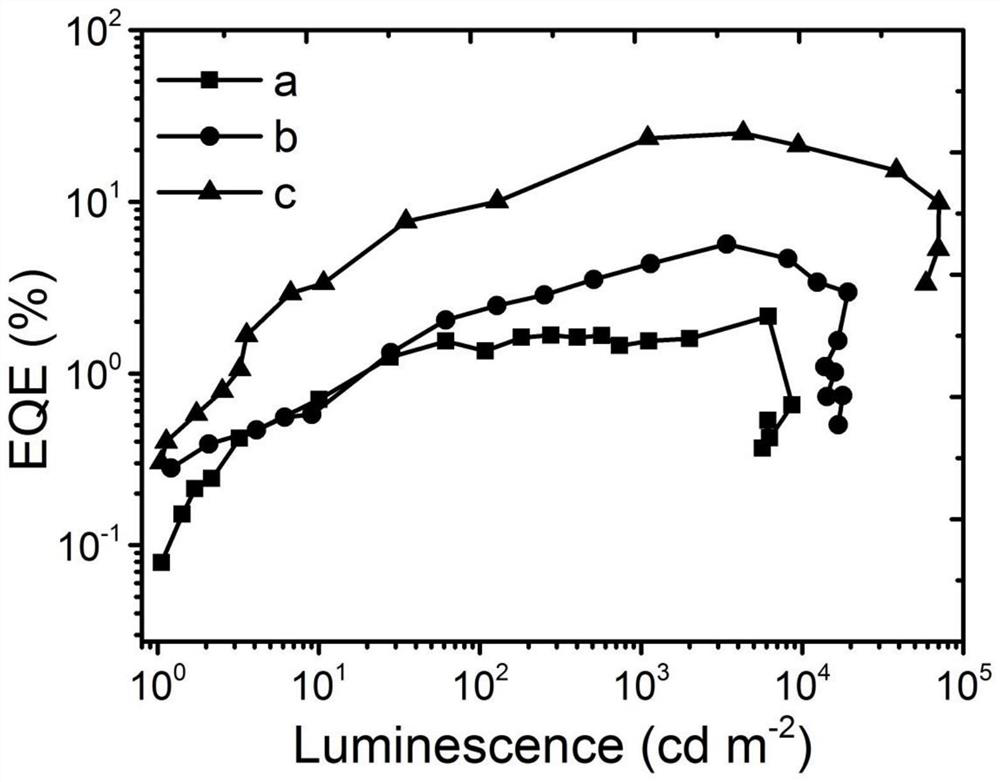

Preparation method of quantum dot/zinc oxide core shell structure and semiconductor device of quantum dot/zinc oxide core shell structure

InactiveCN108376750AImprove quantum efficiencyImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingFluorescenceDissolution

The invention relates to the quantum dot synthesis field and particularly relates to a preparation method of the quantum dot / zinc oxide core shell structure and a semiconductor device of the quantum dot / zinc oxide core shell structure. The method comprises steps that S1, the zinc precursor is dissolved in oleic acid and oleylamine to obtain the zinc oleate precursor mixture; S2, quantum dots are added to the zinc oleate precursor mixture of the S1 step, NaHCO3 is further added, and reaction under the 180-270 DEG C for 1 hour is further carried out; and S3, repeated dissolution in toluene and absolute ethanol, deposition and centrifugation are carried out, and the quantum dot / zinc oxide core shell structure is acquired. The method is advantaged in that through the quantum dot / zinc oxide core shell structure, quantum efficiency of QLED devices and photobleaching resistance can be enhanced, fluorescence emission flickering at the single particle level is reduced, for quantum dot electroluminescent devices, 1), high-efficiency charge injection, 2), high light emitting brightness, 3), a low driving voltage and 4) high device efficiency can be realized.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA +1

Clean fuel oil antiknock additive

InactiveCN104711053AEliminate strong activityWeaken cold flame intensityLiquid carbonaceous fuelsFuel additivesSide effectOil additive

The invention belongs to the technical field of fuel oil additives, and specifically relates to a clean fuel oil antiknock additive. The antiknock additive is characterized by being composed of the following raw materials in parts by weight: 35 to 45 parts of low-carbon alcohol, 10 to 20 parts of bis-succinamide, 7 to 9 parts of hexahydrobenzoic acid, 1 to 3 parts of 2,6-di-tert-butyl mixed phenol, 1 to 2 parts of trimethyl phosphate, 5 to 7 parts of benzotriazole derivatives, 2 to 4 parts of sodium hydroxide, 9 to 11 parts of zinc oleate, and 1 to 3 parts of tert-butyl benzene. The provided antiknock additive can effectively improve the antiknock performance of fuel oil, is harmless and non-toxic, is capable of prominently improving the octane value of gasoline, can improve the octane value by 8 to 20 units, and does not have any side effect on the engine or storage tank. The using conditions of the antiknock additive are the same as those of the gasoline. The antiknock additive has the advantages of simple technology, low cost, and user-friendliness.

Owner:张希顺

Transparent powder calcium-zinc composite heat stabilizer for PVC and preparation method thereof

The invention provides a transparent powder calcium-zinc composite heat stabilizer for PVC and a preparation method thereof. The transparent powder calcium-zinc composite heat stabilizer comprises the following raw materials in parts by weight: 30-35 parts of a calcium-zinc composite main heat stabilizer, 25-30 parts of an auxiliary heat stabilizer, 10-20 parts of hydrotalcite, 5-10 parts of silicon dioxide, 5 parts of an antioxidant and 5 parts of an ultraviolet light absorber. The calcium-zinc composite main heat stabilizer is formed by compounding epoxy zinc oleate and epoxy calcium oleate, the auxiliary heat stabilizer is formed by magnesium acetylacetonate, the hydrotalcite is formed by modified ternary hydrotalcite, and the silicon dioxide is formed by fumed silica. The calcium-zinc composite main heat stabilizer, the magnesium acetylacetonate auxiliary heat stabilizer and the modified ternary hydrotalcite and fumed silica are used as fillers to be combined according to the proportion, and the transparency of the heat stabilizer is effectively improved according to the efficient coloring inhibition characteristic of the heat stabilizer.

Owner:黄山佳宝新材料科技有限公司

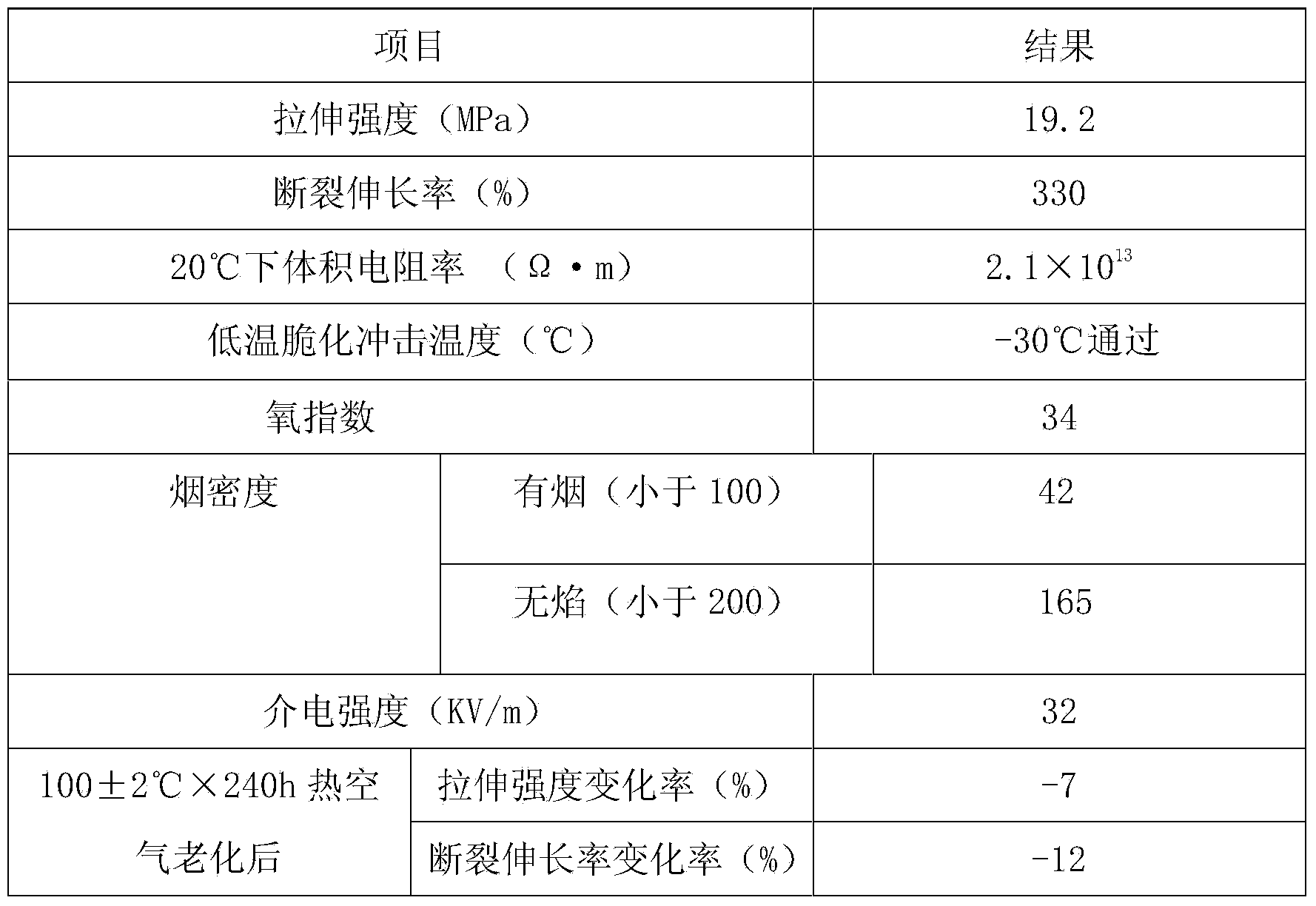

Cold resistant PVC cable material and preparation method thereof

ActiveCN103524940AImprove low temperature resistanceLow smokePlastic/resin/waxes insulatorsPhosphateGlycerol

The invention provides a cold resistant PVC cable material. The cold resistant PVC cable material is prepared by using the following raw materials, by weight, 75-80 parts of a PVC resin, 20-25 parts of a vinyl chloride-vinyl acetate copolymer, 1-3 parts of o-hydroxycinnamic acid, 0.2-0.3 parts of zinc oleate, 0.1-0.2 parts of glycerol, 4-6 parts of an MBS resin, 10-15 parts of calcium carbonate powder, 5-10 parts of a modification filler, 0.3-0.8 parts of epoxidized soybean oil, 0.2-0.3 parts of stearic acid, 1.0-2.0 parts of titanium dioxide, 1.0-2 parts of ACR, 10-15 parts of aluminum hypophosphite, 1-2 parts of organic phosphate, 1.0-3.0 parts of PE wax and 1-2 parts of ethyl acrylate. The cable material has a very good low temperature resistance, has a brittle temperature with low temperature impact reaching -50DEG C, has a lower making cost than routine low temperature resistant cable materials, and can resistant a temperature of -50DEG C. The cold resistant PVC cable material can be widely used in low temperature environment and has a low price.

Owner:台山市万安电线电缆有限公司

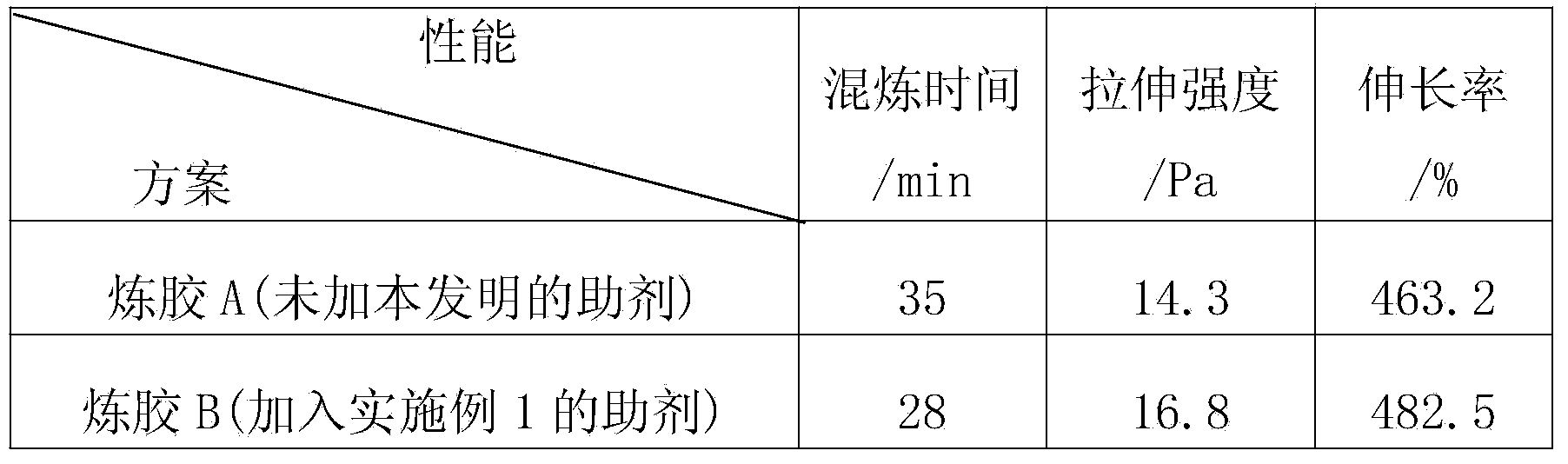

Rubber processing aid and preparation method thereof

The invention firstly discloses a rubber processing aid. The rubber processing aid is prepared by mixing and granulating the following raw materials in parts by weight: 700-800 parts of stearic acid, 0-100 parts of zinc oxide, 10-150 parts of anhydrous aluminum trichloride and 0-200 parts of zinc oleate. The invention secondly discloses a preparation method of the rubber processing aid. The preparation method comprises the steps of 1) firstly adding the stearic acid to a reaction kettle, heating to 125 to 155 DEG C, next, adding the anhydrous aluminum trichloride, reacting for 2-3 hours under a constant temperature condition, and then adding zinc oxide and reacting for 1.5-5 hours under the constant temperature condition; 2) adding zinc oleate to the reaction kettle, mixing evenly and reacting for 35-45 minutes under the constant temperature condition; and 3) quantificationally feeding the mixture in the reaction kettle to a granulation extruder for granulation, thereby obtaining the aid. The rubber aid is capable of improving the fluidity of the rubber material, increasing the extrusion speed of the rubber material, accelerating quick dispersion of fillers added to the rubber material such as an anti-aging agent, a vulcanizing agent, an accelerant, carbon black and calcium carbonate, and thus improving the uniformity and the stability of the rubber material.

Owner:安徽瑞邦橡塑助剂集团有限公司

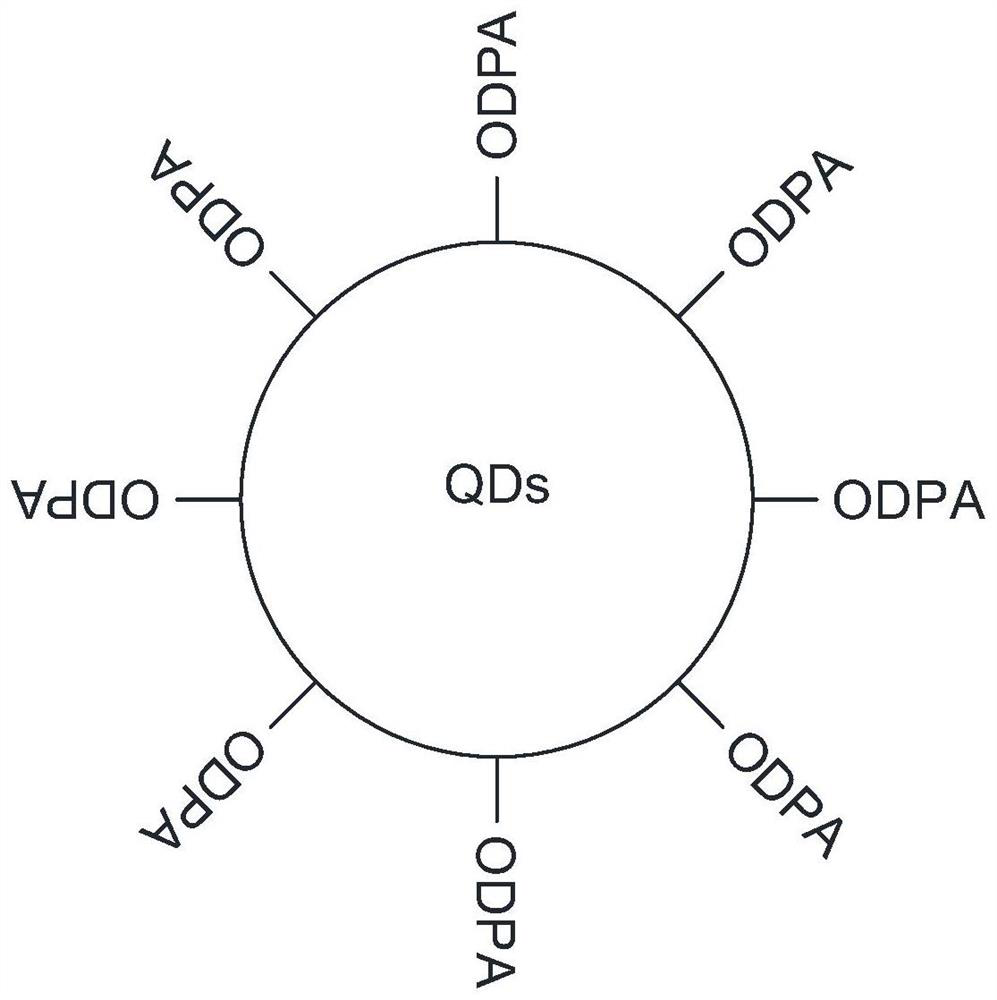

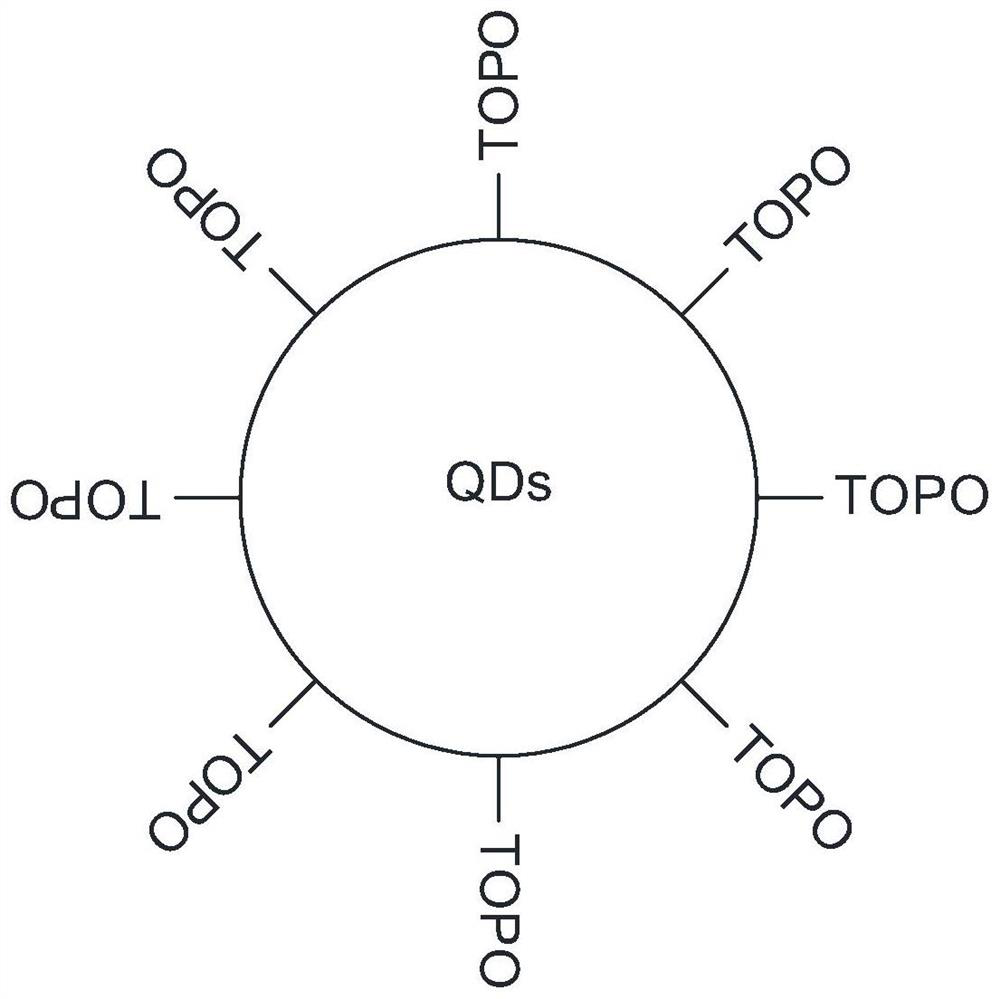

Cleaning method and preparation method of quantum dots

The invention provides a cleaning method and a preparation method of quantum dots, and belongs to the technical field of quantum dots. The cleaning method of the quantum dots comprises the steps that: the quantum dots are dispersed in a first non-coordination solvent, a first coordination solvent is added, and stirring reaction is conducted for 20-40 min at the temperature of 80-120 DEG C; and ligands of the quantum dots are tri-n-octylphosphine oxide and / or octadecyl orthophosphate. The mole number of the first coordination solvent is 2-3 times of the mole number of cations of the quantum dots. The first coordination solvent is oleic acid and / or zinc oleate. For the quantum dots with tri-n-octylphosphine oxide and / or octadecyl orthophosphate as ligands, according to the cleaning method of the quantum dots, oleic acid and / or zinc oleate are / is adopted for exchanging the ligands on the surfaces of the quantum dots, the ligands on the surfaces of the quantum dots are changed into oleic acid and / or zinc oleate, and in the subsequent cleaning process, the cleaning yield of the quantum dots can be increased.

Owner:合肥福纳科技有限公司

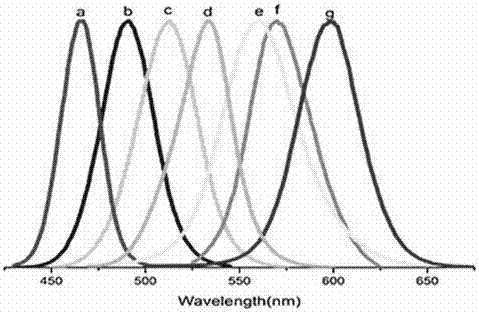

Preparation method of InP/ZnS (indium phosphide/zinc sulfide) core-shell structure quantum dots

InactiveCN107502352AUniform particle size distributionHigh fluorescence yieldNanoopticsLuminescent compositionsIndiumIodide

The invention discloses a preparation method of InP / ZnS (indium phosphide / zinc sulfide) core-shell structure quantum dots. The preparation method comprises a preparation method of InP-series core-shell quantum dots and a synthesis method of the InP / ZnS core-shell structure quantum dots; the preparation method of InP-series core-shell quantum dots is used for preparation of a phosphorus source; the synthesis method is used for preparing an indium precursor with indium iodide as a quantum dot, and the InP / ZnS core-shell structure quantum dots are obtained with P4 as the phosphorus source, dodecanethiol as an S source, 1-octodecene as a stabilizer, oleylamine as a solvent reactant and a ligand as well as zinc oleate as a zinc source of a coated shell structure; centrifugal separation and purification are performed after the reaction is performed; pure InP / ZnS core-shell structure quantum dots are dispersed in octane again; the purified quantum dots are assembled into a QLED (quantum dot light-emitting diode) light emitting device. The preparation method has the advantages as follows: the yield of organic phase synthesized quantum dots is high, the fluorescent yield of a film is high, the quantum dots have uniformly distributed sizes, luminescent spectra are symmetric and narrow, and the cost is greatly reduced by use of the cheap phosphorus source.

Owner:NANCHANG HANGKONG UNIVERSITY

Environment-friendly antistatic anti-corrosion paint and preparation method thereof

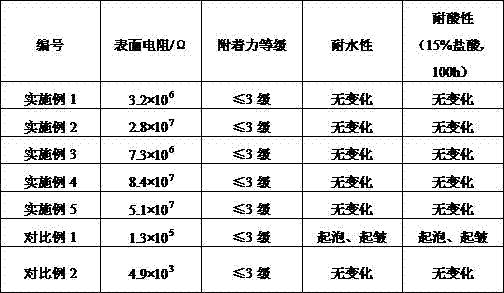

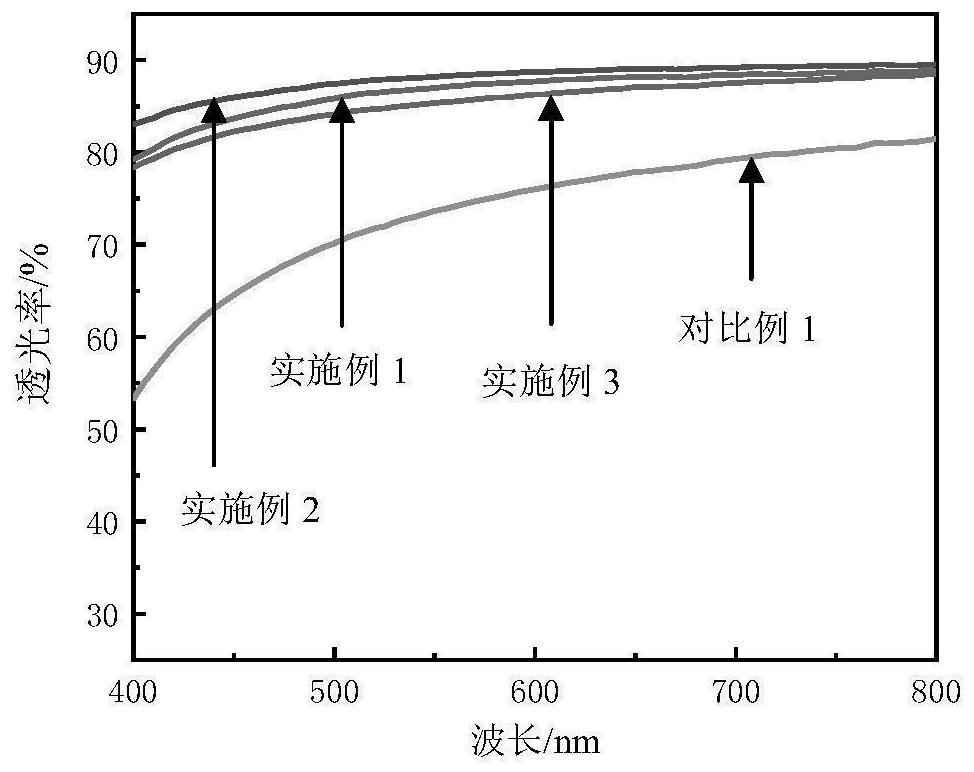

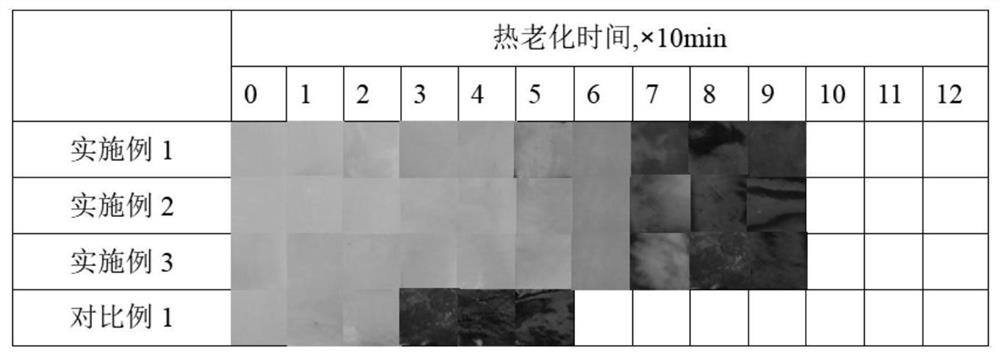

InactiveCN105176359AHigh surface resistanceImprove antistatic performanceAnti-corrosive paintsPolyurea/polyurethane coatingsEnvironmental resistanceAcrylic resin

The invention discloses environment-friendly antistatic anti-corrosion paint and a preparation method thereof. The environment-friendly antistatic anti-corrosion paint is prepared from, by weight, 40-65 parts of waterborne polyurethane emulsion, 30-45 parts of waterborne acrylic resin, 5-15 parts of copper sulphide, 5-15 parts of montmorillonite, 3-12 parts of conductive mica powder, 10-20 parts of potassium titanate whiskers, 10-20 parts of zinc oxide whiskers, 3-12 parts of calcium carbonate, 3-8 parts of zinc oleate, 3-8 parts of poly[oxy(methyl-1,2-ethanediyl)], 3-6 parts of lauryl sodium sulfate, 1-2 parts of flatting agents, 0.3-2 parts of defoaming agents, 10-25 parts of ethyl alcohol and 80-100 parts of deionized water. The surface resistance of the prepared paint is large, and good anti-static capacity is displayed. Besides, the conductive mica powder and the copper sulphide are low in cost of raw materials, easy to obtain and suitable for being widely used. The prepared paint has good water resistance and acid resistance, shows excellent corrosion resistance, and is long in actual service life and stable.

Owner:刘广利

Molding sand for hand molding and preparation method thereof

InactiveCN104525844AImprove breathabilityGood dispersionFoundry mouldsFoundry coresZINC OLEATEStearate

Molding sand for hand molding is prepared from the following raw materials in parts by weight: 0.5-0.8 part of glycervl triacetate, 4-5 parts of phenolic resin, 0.8-1.1 parts of zinc oleate, 1-1.3 parts of zinc isoocatanoate, 2-2.4 parts of barium stearate, 2-3 parts of sodium humate, 20-25 parts of zinc oxide, 130-160 parts of clay, a proper amount of water, and 20-30 parts of an auxiliary agent. Through adopting the clay for sintering granulation, the molding sand has good air permeability and good dispersion and can be recycled; and with use of zinc oleate, barium stearate, sodium humate and zinc oxide, the molding sand is good in plasticity, and easy for hand molding.

Owner:FANCHANG COUNTY HENGXIN AUTO PARTS

High-strength plastic flooring and manufacture method thereof

The invention discloses high-strength plastic flooring and a manufacture method thereof. The high-strength plastic flooring is made from, by weight part, 50-70 of PVC resin, 24-38 of polyether-type thermoplastic polyurethane elastomer, 15-20 of dioctyl isophthalate, 10-15 of ultrafine alumina, 5-10 of graphene aerogel, 17-29 of poly(arylene ether ether nitrile), 2-3 of zinc oleate, 1-2 of magnesium oleate, 5-7 of palm wax, 18-26 of quartz powder, 10-15 of chloro-methoxy fatty acid methyl ester, and 10-15 of polyacrylonitrile-based carbon fibers. The polyacrylonitrile-based carbon fibers and graphene aerogel which are light in weight and high in strength are used to improve the mechanical strength of plastic flooring. The manufactured plastic flooring is relatively high in mechanical strength, particularly in tensile strength and bending strength, is excellent in wear resistance, heat resistance and corrosion resistance, and adapts to the situation that requires high strength.

Owner:JIANGYIN ZHIYUAN AUTOMOBILE DECORATION PARTS CO LTD

Polyurethane anticorrosive paint

InactiveCN109504272AImprove performanceImprove adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsDiacetone alcoholPetroleum ether

The invention discloses polyurethane anticorrosive paint, which comprises the following ingredients in parts by weight: 18-25 parts of waterborne polyurethane acrylic ester, 15-20 parts of waterborneepoxy acrylate, 8-18 parts of a silicon acrylic emulsion, 8-18 parts of waterborne polyurethane, 3-8 parts of triethylamine, 4-15 parts of copper sulphide, 3-15 parts of montmorillonoid, 5-12 parts ofelectric conduction mica powder, 8-12 parts of kaolin, 2-6 parts of xylene, 3-8 parts of calcium carbonate, 5-10 parts of zinc oleate, 5-10 parts of diacetone alcohol, 2-8 parts of aluminium triphosphate, 2-8 parts of tetrachloromethane and 2-8 parts of petroleum ether. The paint has the advantages of high adhesive force, very high anti-corrosion performance and good water resistance, and meanwhile, harm on the human body and environment is reduced.

Owner:徐州聚友信息技术有限公司

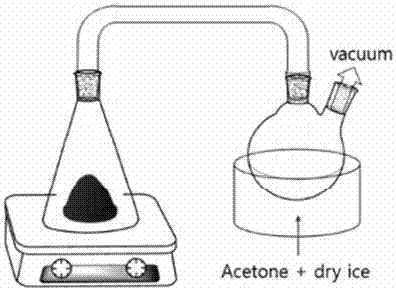

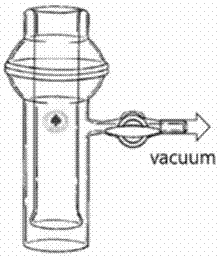

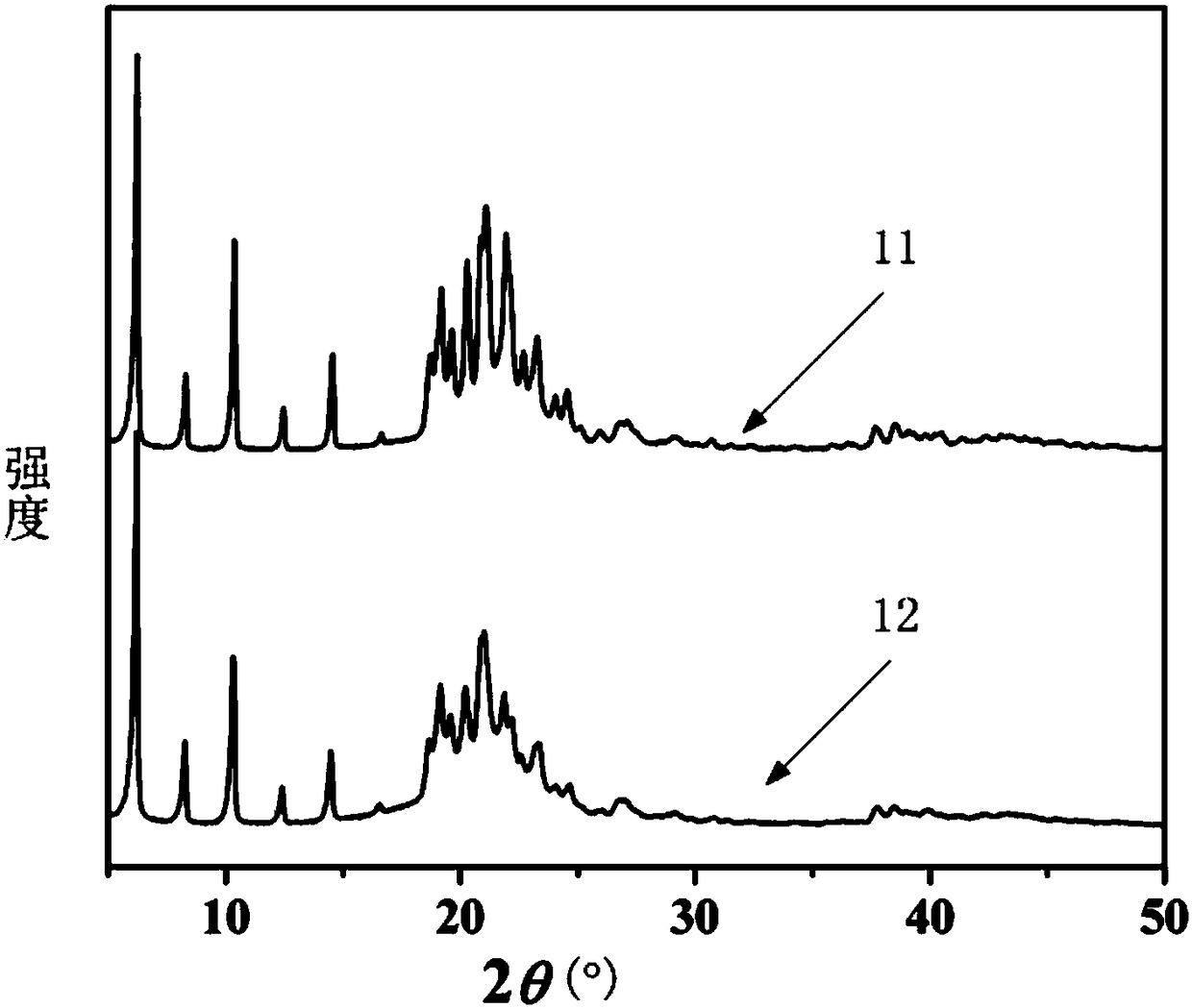

Method for preparing zinc oleate

InactiveCN109251141APrevent oxidationHigh reaction yieldOrganic compound preparationCarboxylic acid salt preparationAcetic acidZINC OLEATE

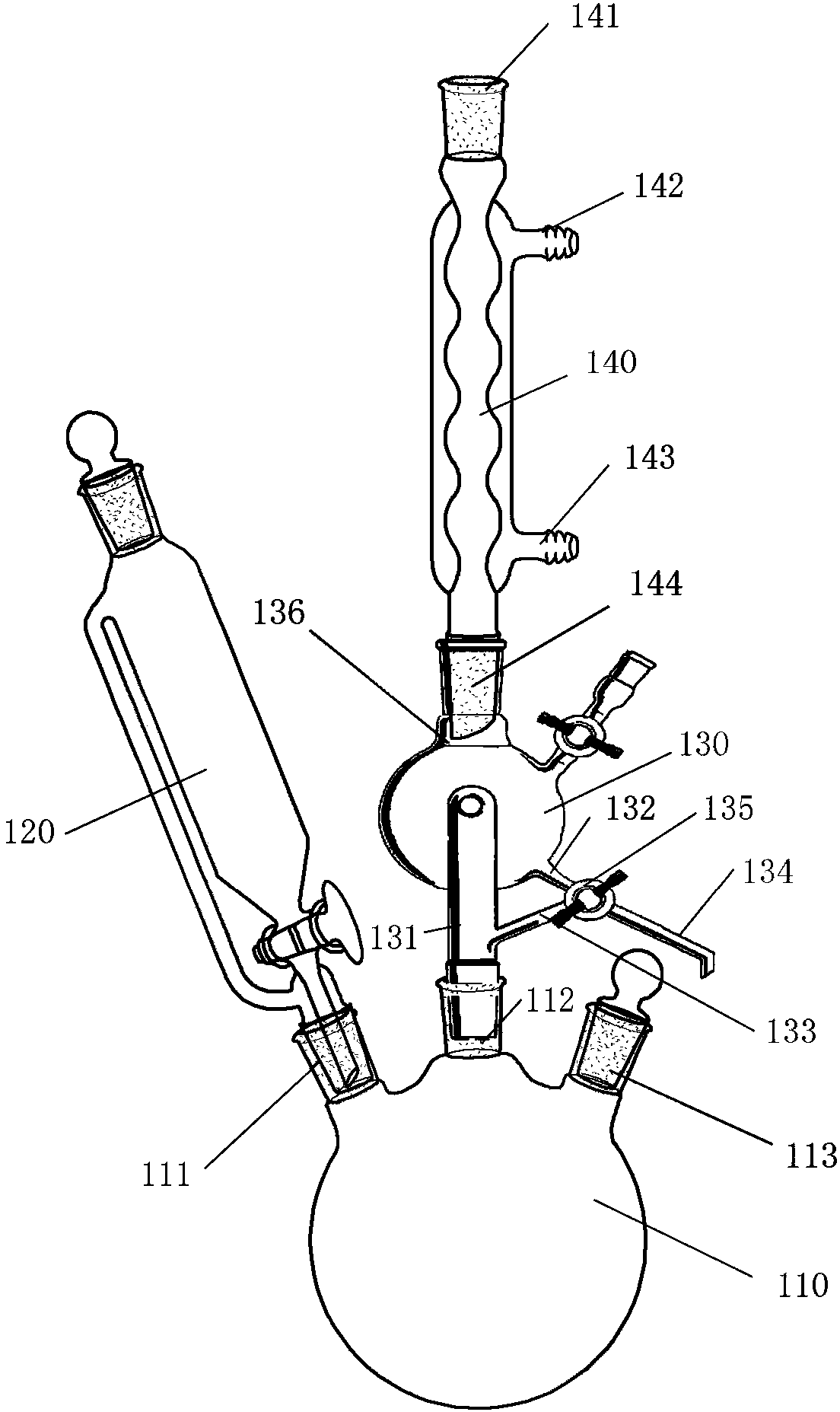

The invention relates to a method for preparing zinc oleate. The method comprises the following steps: S1, adding zinc acetate and oleic acid in a molar ratio of 1: (1-3) into a reaction unit; S2, replacing air in the reaction unit with protective gas; S3, performing refluxing at 100-180 DEG C for 1-4 h; S4, distilling off acetic acid; S5, extracting residual acetic acid in the reaction unit, carrying out cooling to 50-100 DEG C, adding n-hexane into the reaction unit, performing cooling after sufficient dissolving, and allowing a crude zinc oleate product to be precipitated; S6, subjecting the crude zinc oleate product to filtering and washing so as to remove residual zinc acetate in the crude zinc oleate product, then washing away oleic acid in the crude zinc oleate product by using n-hexane or acetone, and then performing vacuum drying to obtain a finished zinc oleate product. The preparation method for the zinc oleate in the invention adopts the protective gas for protection so asto avoid the oxidation of oleic acid and zinc oleate in a high-temperature reaction process; most of the acetic acid can be separated and recovered as a by-product, and n-hexane and the like can alsobe recycled and reused; and the method is high in reaction yield, simple in process and easy to achieve industrial production.

Owner:FIRST RARE MATERIALS CO LTD

Preparation method of epoxidized calcium zinc oleate for PVC heat stabilizer

The invention discloses a preparation method of epoxidized calcium zinc oleate for a PVC heat stabilizer. The method comprises the following steps: S1, adding oleic acid, a solid metal oxide catalyst, formic acid and hydrogen peroxide into a reactor to obtain epoxidized oleic acid liquid; S2, adding an alkaline solution and a surfactant into the epoxidized oleic acid liquid reactor to obtain epoxidized sodium oleate saponification liquid; S3, neutralizing the epoxidized sodium oleate saponification liquid with dilute acid, adding a calcium / zinc ion-containing solution, cooling to normal temperature, discharging and filtering; and S4, drying a filter cake to constant weight to obtain an epoxidized calcium zinc oleate finished product. The prepared epoxidized calcium zinc oleate has high thermal stability and plasticizing performance, the epoxy value is obviously increased by adopting the solid metal oxide catalyst compared with common concentrated sulfuric acid and p-toluenesulfonic acid catalysts, and the catalyst is a metal compound and can be directly changed into a corresponding PVC stabilizer, a synergistic effect is achieved with epoxidized calcium zinc oleate, and the reaction rate is increased.

Owner:广东鑫达新材料科技有限公司

Synthesis method of low-cadmium quantum dots

InactiveCN111378452AHigh activityImprove stabilityLuminescent compositionsCarbamateHeat conservation

The invention discloses a synthesis method of low-cadmium quantum dots. The method comprises the following steps of dissolving cadmium oleate in a solvent to form a solution A for later use, dissolving zinc dialkyl diseleno carbamate in oleylamine to form a solution B for later use, and dissolving zinc oleate and octyl mercaptan in a solvent to form a solution C for later use. The synthesis process comprises the following steps of (1) heating the solution A to 150-250 DEG C, then injecting the solution B, carrying out heat preservation for reaction, taking out a trace reaction solution througha needle head, and monitoring the wavelength by using an optical fiber spectrometer, (2) after the monitored wavelength reaches the expected wavelength, raising the temperature to 250-300 DEG C, injecting the solution C, and after injection is completed, continuing to carry out a heat preservation reaction for 30-90 minutes to obtain a quantum dot solution, and (3) drying the quantum dot solutionto obtain the quantum dots. The activity of zinc is improved, the core preparation temperature is reduced, a cadmium-free alloy shell structure is formed, the optical performance is adjustable, the quantum dot stability is excellent, and the cadmium content of the quantum dot is relatively low.

Owner:NINGBO DXC NEW MATERIAL TECH

High-thermal-stability liquid calcium-potassium-zinc stabilizer for producing foamed PVC material

The invention discloses a high-thermal-stability liquid calcium-potassium-zinc stabilizer for producing a foamed PVC material, and relates to the technical field of plastic additives. The high-thermal-stability liquid calcium-potassium-zinc stabilizer for producing a foamed PVC material is prepared from the following components in percentage by weight: 45-55 parts of stearyl epoxy potassium oleate, 27-33 parts of stearyl epoxy zinc oleate, 8-12 parts of a calcium component additive, 2-3 parts of an auxiliary heat stabilizer, 10-12 parts of a catalyst and 18-24 parts of a solvent. The stearyl epoxy potassium oleate is synthesized from stearic acid, epoxy oleic acid and potassium oxide through a one-step method, and the stearyl epoxy zinc oleate is synthesized from stearic acid, epoxy oleic acid and zinc oxide through a one-step method. According to the high-thermal-stability liquid calcium-potassium-zinc stabilizer for producing a foamed PVC material, based on the characteristic that a potassium-zinc stabilizer is insufficient in thermal stability, a calcium component additive is added on the basis of the liquid potassium-zinc stabilizer to greatly improve the thermal stability of the liquid calcium-potassium-zinc stabilizer, and the raw materials are wide in source and easy to synthesize, have no adverse effect on the environment and meet the national requirement for green development.

Owner:黄山佳宝新材料科技有限公司

A zinc ion antibacterial cloud blanket

ActiveCN107557985BEvenly dispersedGood hygroscopicityWarp knittingFilament/thread formingMoisture absorptionAntibacterial agent

The invention discloses a zinc-ion antibacterial cloud blanket. The cloud blanket is woven by zinc-ion warp yarns, zinc-ion weft yarns and ultrafine plush yarns on a warp knitting machine, wherein each ultrafine plush yarn consists of 30-60 ultrafine synthetic fibers with the fineness of 0.1-0.3 D obtained by high-temperature high-pressure extrusion and nitrogen hydrogen plasma treatment at room temperature. According to the zinc-ion antibacterial cloud blanket, with the assistance of ultrasonic waves, zinc-ion antibacterial agent is subjected to organic surface modification by means of zinc oleate, and the modified zinc-ion antibacterial agent can evenly disperse in fused liquid of a polymer; an antibacterial layer is used as the surface layer of the warp yarns and the weft yarns, compared with traditional prepared antibacterial fibers, little antibacterial agent is used, and a good and enduring antibacterial effect is achieved; besides, by means of the high-temperature high-pressureextrusion and the nitrogen hydrogen plasma treatment at the room temperature, the moisture absorption performance of the plush yarns is improved, and the use comfort of the cloud blanket is improved.

Owner:ZHEJIANG TRUELOVE CARPET IND SCI & TECH

Environment-friendly antistatic polyurethane anticorrosion coating and preparation method thereof

ActiveCN105199582BHigh surface resistanceImprove antistatic performanceAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylic resinDefoamer

The invention discloses environment-friendly anti-static polyurethane anticorrosion paint and a preparation method thereof. The environment-friendly anti-static polyurethane anticorrosion paint comprises the following raw materials in parts by weight: 36-60 parts of aqueous polyurethane emulsion, 28-43 parts of aqueous acrylic resin, 4-13 parts of copper sulphide, 3-12 parts of montmorillonite, 2-9 parts of conductive mica powder, 2-10 parts of calcium carbonate, 2-5 parts of zinc oleate, 1-6 parts of PPG-n Laurate, 1-3 parts of sodium dodecyl sulfate, 1-2 parts of a levelling agent, 0.2-2 parts of an antifoaming agent, 12-25 parts of ethanol, and proper amount of deionized water. The prepared paint is large in surface resistance, shows good antistatic capability, and further, the conductive mica powder and copper sulphide raw materials are low in cost and easy to obtain and suitable for wide application. The prepared paint possesses good water proofness and acid resistance, displays excellent anticorrosion performance, and is long in practical service life and stable.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Heat stabilizer for processing soft transparent PVC (polyvinyl chloride) and preparation method of heat stabilizer

The invention belongs to the technical field of PVC (polyvinyl chloride) heat stabilizers, particularly relates to a heat stabilizer for processing soft transparent PVC and a preparation method of the heat stabilizer, and can solve the technical problem that the existing heat stabilizer technology cannot give consideration to both initial coloring and long-term heat stability in PVC processing. The heat stabilizer for processing the soft transparent PVC is characterized by comprising the following raw materials: zinc oleate, an amino metal organic framework compound, an auxiliary heat stabilizer, a plasticizer, a lubricant, an antioxidant and an ultraviolet light absorber. Zinc oleate and an amino metal organic framework compound are used as main stabilizers, necessary auxiliary stabilizers are matched, and compared with traditional zinc stearate, the transparent PVC material has excellent transparency and initial coloring and is suitable for transparent PVC products.

Owner:CHANGAN UNIV

Treatment method of oleic acid zinc waste residue produced by synthesis of quantum dots

ActiveCN108484389BEasy to separateEasy to handleCarboxylic compound separation/purificationZINC OLEATEN-Butyl Alcohol

The invention discloses a method for treating waste residue containing zinc oleate produced by synthesizing quantum dots. The method comprises the following steps: step 1): at a first temperature, disperse the waste residue in alcohol to form a first dispersion system; step 2): separate the first dispersion system at a second temperature, and the oil Zinc acid is separated from the first dispersion, and the second temperature is lower than the first temperature. According to the treatment method of the oleic zinc waste residue produced by the synthesis of quantum dots of the present invention, the use of alcohol, such as ethanol or n-butanol, can easily separate most of the oleic zinc in the waste residue, and then the waste company can handle it conveniently remaining waste.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

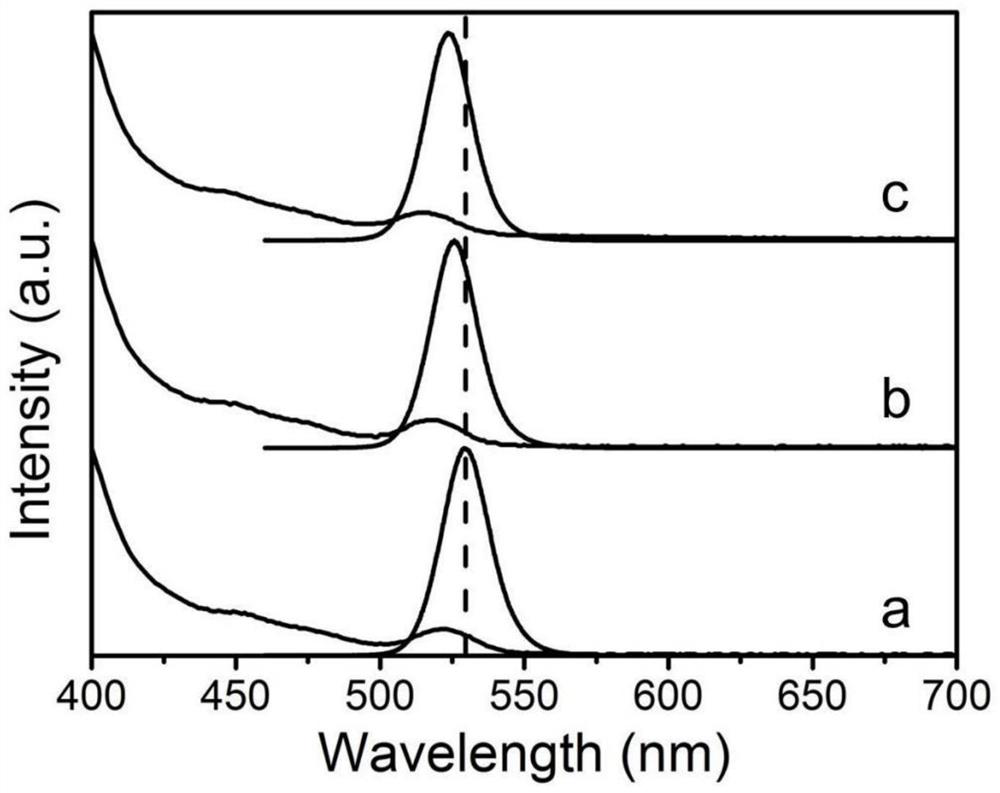

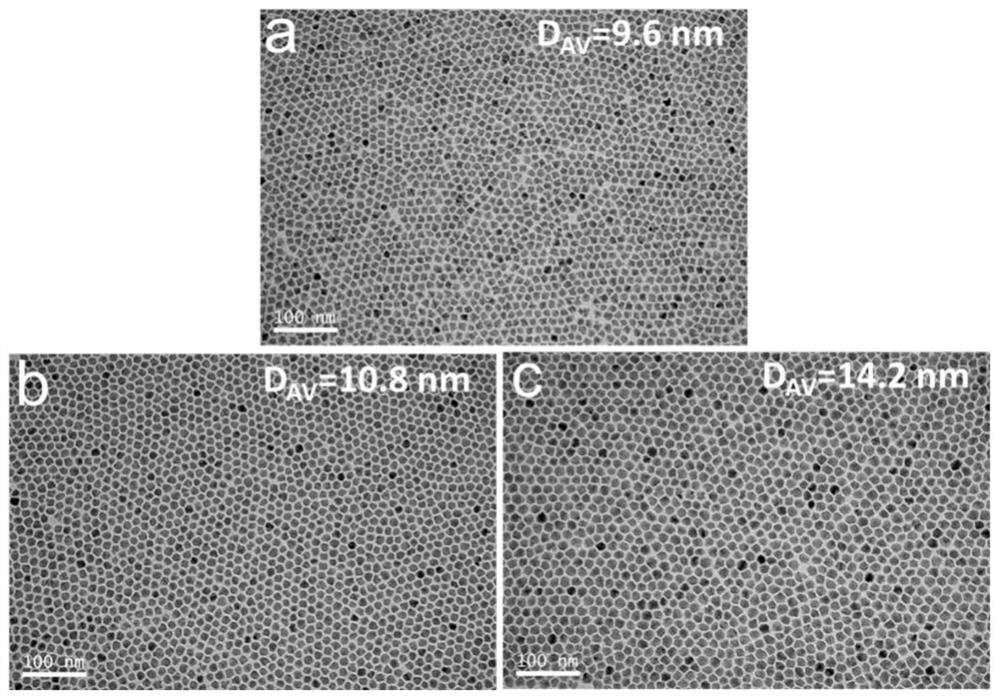

Preparation of cdsezns/zns/zns core/shell/shell quantum dots

ActiveCN110129055BImprove stabilityExtend your lifeMaterial nanotechnologyNanoopticsFluorescenceTrioctylphosphine

The invention provides preparation of a CdSeZnS / ZnS / ZnS core / shell / core quantum dot. The preparation comprises following steps: reacting a cadmium source and a zinc source with oleic acid and 1-octadecene to prepare a cation precursor; reacting a selenium source and a sulfur source with trioetyl phosphine to prepare an anion precursor; rapidly injecting the anion precursor into the cation precursor at a certain temperature to carry out reactions to obtain a quantum dot core; using an injection pump, controlling the shell growth temperature, the shell precursor injection amount, and injection speed, growing a first layer prepared from zinc oleate and octyl mercaptan, and growing a second layer prepared from oleylamine zinc and oleylamine sulfur to obtain the CdSeZnS / ZnS / ZnS green light core / shell / core quantum dot. The prepared quantum dot has the advantages of uniform size and morphology, low half-width, high fluorescence efficiency, and low cadmium content, is widely applied to the fields of illumination and display, is especially suitable for a full solution inverted device structure, and is capable of largely improving the device efficiency and prolonging the service life.

Owner:SHANGHAI JIAOTONG UNIV

A plastic turnover tube for chemical fiber spinning instead of paper tube and preparation method thereof

The invention discloses a plastic turnover pipe replacing a paper tube for chemical fiber spinning. The plastic turnover pipe is prepared from the following raw materials in parts by weight: 60-90 parts of matrix resin, 10-40 parts of a flexibilizer, 0.2-0.5 part of an antioxidant, 0-5 parts of color master batch, 1-2 parts of zinc borate, 0.4-1 part of calcium ricinoleate, 1-2 parts of barium stearate, 0.5-1 part of 2-mercapto benzimidazole, 2-3 parts of polytetrafluoroethylene wax, 7-9 parts of aluminum isopropoxide, 4-10 parts of carbon nano tubes, 0.8-1 part of fatty acid diethanol amide and 0.06-0.1 part of zinc oleate. According to the invention, the matrix resin is used as a main ingredient; the prepared plastic turnover pipe is used for replacing the traditional paper tube; the plastic turnover pipe has the advantages of long service life, high stability, high compressive strength and excellent fire resistance.

Owner:四川久远科技股份有限公司

Novel high-efficient fuel oil emission reducing additive

InactiveCN104711052AReduce carbon depositionExtended service lifeLiquid carbonaceous fuelsCombustion chamberRare earth

The invention belongs to the technical field of fuel oil additives, and specifically relates to a novel high-efficient fuel oil emission reducing additive. The additive is characterized by being composed of the following raw materials in parts by weight: 10 to 20 parts of nano rare earth, 10 to 14 parts of fatty acid iron, 15 to 25 parts of dinitrogen ethane, 9 to 11 parts of 2,6-ditert-buytyl mixed phenol, 3 to 5 parts of acetone, 6 to 8 parts of polyisobutylene succinimide, 9 to 11 parts of alkyl benzene, 1 to 3 parts of zinc oleate, and 2 to 3 parts of tert-butyl benzene. The additive can reduce carbon precipitation in the combustion chamber of a diesel engine, thus can prolong the service life of engine, reduces the hearth coking and corrosion of an oil-burning boiler, and prolongs the decoking period and boiler service life.

Owner:张希顺

Plastic turnover pipe replacing paper tube for chemical fiber spinning and preparation method thereof

The invention discloses a plastic turnover pipe replacing a paper tube for chemical fiber spinning. The plastic turnover pipe is prepared from the following raw materials in parts by weight: 60-90 parts of matrix resin, 10-40 parts of a flexibilizer, 0.2-0.5 part of an antioxidant, 0-5 parts of color master batch, 1-2 parts of zinc borate, 0.4-1 part of calcium ricinoleate, 1-2 parts of barium stearate, 0.5-1 part of 2-mercapto benzimidazole, 2-3 parts of polytetrafluoroethylene wax, 7-9 parts of aluminum isopropoxide, 4-10 parts of carbon nano tubes, 0.8-1 part of fatty acid diethanol amide and 0.06-0.1 part of zinc oleate. According to the invention, the matrix resin is used as a main ingredient; the prepared plastic turnover pipe is used for replacing the traditional paper tube; the plastic turnover pipe has the advantages of long service life, high stability, high compressive strength and excellent fire resistance.

Owner:四川久远科技股份有限公司

Treatment method of zinc oleate-containing waste residues produced by synthesis of quantum dots

ActiveCN108558648AEasy to separateEasy to handleCarboxylic compound separation/purificationAlkaneAlcohol

The invention discloses a treatment method of zinc oleate-containing waste residues produced by synthesis of quantum dots. The method comprises the following steps: step 1), dispersing the waste residues into liquid-state alkane at first temperature to form a first dispersion system; step 2), adding alcohol to the first dispersion system to form a second dispersion system; and step 3), separatingthe second dispersion system at second temperature, wherein zinc oleate is separated from the second dispersion system, and the second temperature is lower than the first temperature. According to themethod disclosed by the invention, by using liquid-state alkane and alcohol, most of zinc oleate in the waste residues can be conveniently separated out, so that waste treatment companies can conveniently treat residual wastes.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com