Cleaning method and preparation method of quantum dots

A technology of quantum dots and cations, applied in the field of quantum dots, can solve the problem of low cleaning yield of quantum dots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] The present application also provides a method for preparing quantum dots, which includes: preparing quantum dots, and then cleaning the quantum dots according to the above cleaning method for quantum dots.

[0077] The method for preparing quantum dots is as follows:

[0078] Mix the precursor solution containing cations and the precursor solution containing anions and keep warm at 280-310°C to form a reaction solution with quantum dot nanocrystal nuclei, and stop when the wavelength of quantum dots in the reaction solution moves to the target position react to prepare a solution containing quantum dots, add a non-polar solvent and a polar solvent to the solution of quantum dots, and centrifuge to obtain quantum dots.

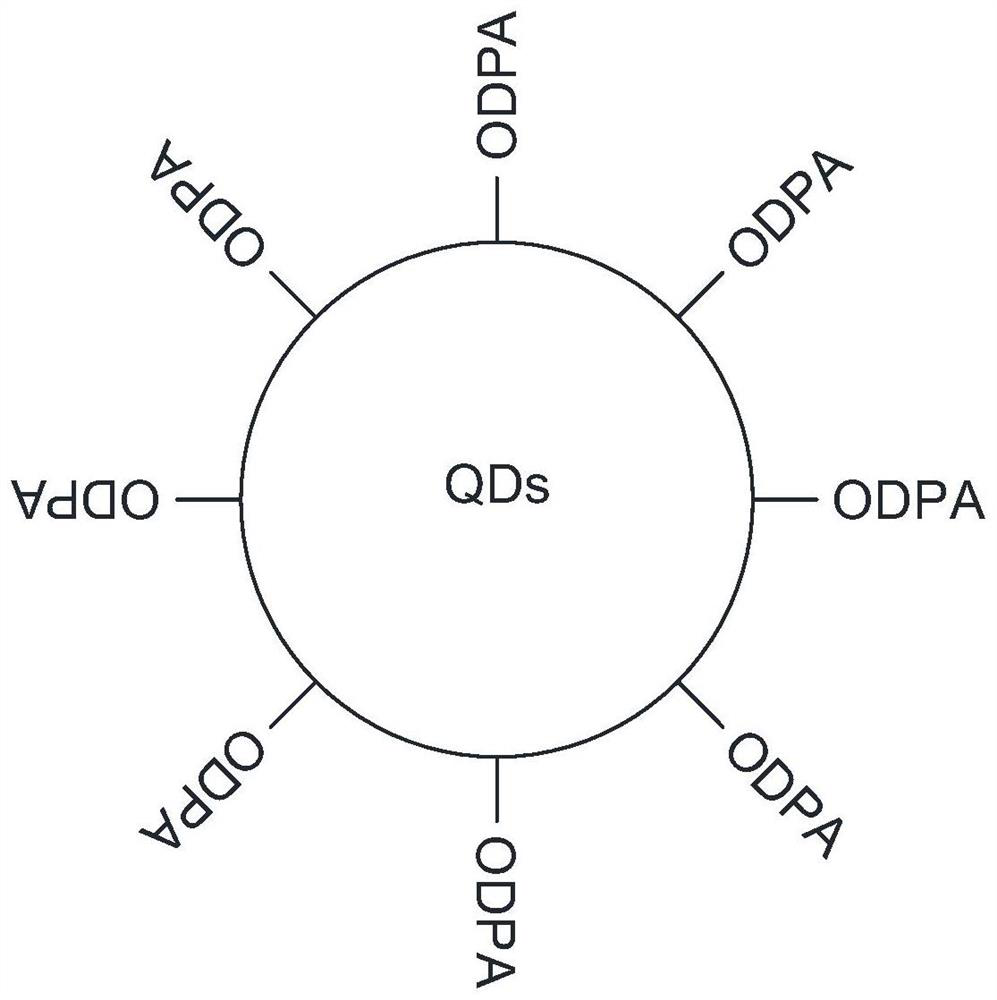

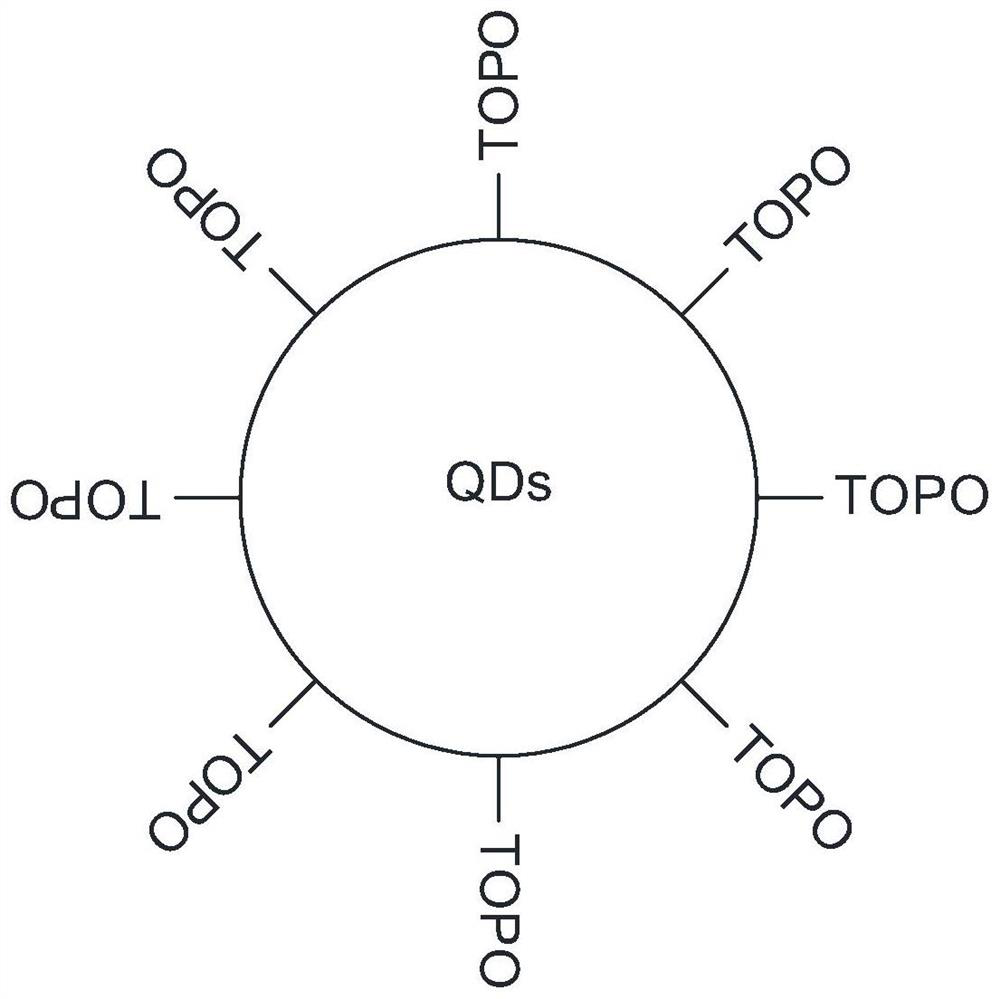

[0079] The precursor solution containing cations includes a second coordination solvent, and the second coordination solvent is tri-n-octylphosphine oxide and / or octadecyl orthophosphate.

[0080] The number of moles of cations in the precursor solutio...

Embodiment 1

[0095] The embodiment of the present application provides a method for preparing quantum dots, which includes:

[0096] 1. Preparation of quantum dots

[0097] Add 1.5mmol of cadmium oxide, 3mmol of octadecyl orthophosphate and 20mL of octadecene into the three-necked flask, and purge the three-necked flask with argon for 20min at room temperature, and heat the three-necked flask at a heating rate of 20°C / min. The flask was heated to 110°C and kept warm for 30 minutes. Then heat up to 300°C, quickly inject 1.0 mmol of selenium element-tri-n-octyl phosphorus solution under the liquid level of the three-necked bottle to form a reaction solution with quantum dot nanocrystal nuclei, and detect the wavelength shift of the quantum dots in the reaction solution The reaction was stopped after reaching 530 nm, and a solution containing quantum dots was prepared.

[0098] After the solution containing quantum dots was cooled to 100°C, the solution containing quantum dots was mixed wit...

Embodiment 2

[0104] The embodiment of the present application provides a method for preparing quantum dots, which includes:

[0105] 1. Preparation of quantum dots

[0106] Add 1.5mmol of cadmium oxide, 3mmol of tri-n-octylphosphine oxide and 20mL of octadecene into the three-necked bottle. The flask was heated to 110°C and kept warm for 30 minutes. Then heat up to 300°C, quickly inject 1.0 mmol of selenium element-tri-n-octyl phosphorus solution under the liquid level of the three-necked bottle to form a reaction solution with quantum dot nanocrystal nuclei, and detect the wavelength shift of the quantum dots in the reaction solution The reaction was stopped after reaching 530 nm, and a solution containing quantum dots was prepared.

[0107] After the solution containing quantum dots was cooled to 100°C, the solution containing quantum dots was mixed with 40 mL of absolute ethanol and 20 mL of n-hexane, and centrifuged to obtain quantum dots.

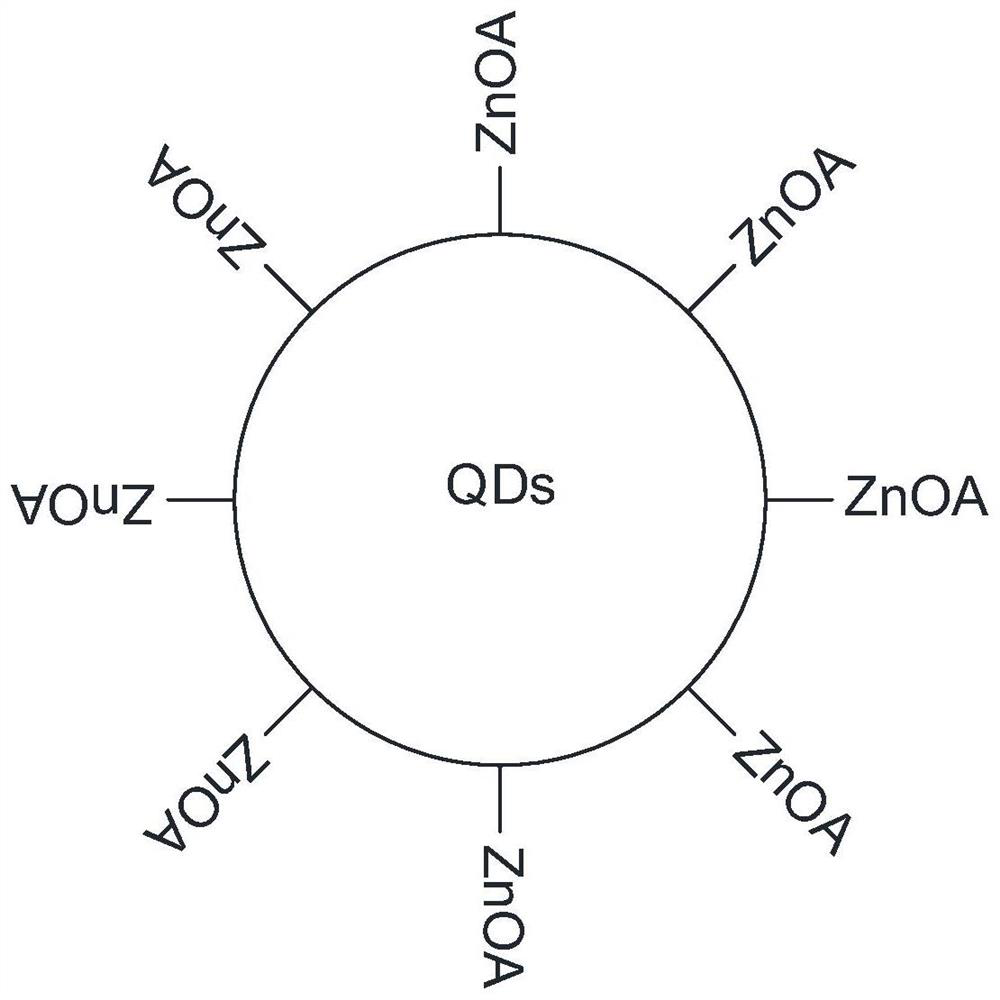

[0108] 2. Ligand exchange for quantum dot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com