Treatment method of oleic acid zinc waste residue produced by synthesis of quantum dots

A treatment method and technology of quantum dots, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve problems such as difficult to treat waste residue and environmental pollution, and achieve the effect of convenient treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

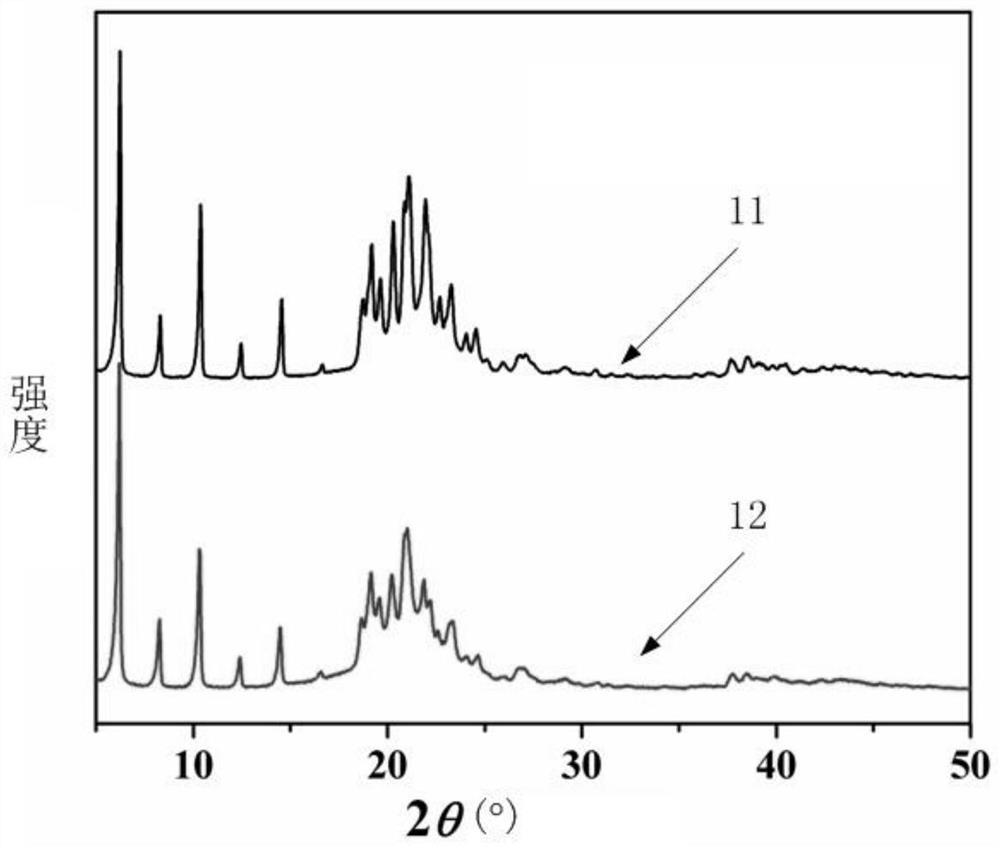

Examples

Embodiment 1

[0016] Take 200g waste and 500 ml of ethanol, mix it. The mixture was heated to 75 ° C and the steam reflux treatment was carried out such that the waste residue was dispersed into the alcohol to form a first dispersion system. The zinc in the waste residue is dispersed in a small droplet to the first dispersion system; the quantum dots are present in the form of precipitation; other organic materials are mutually solved with ethanol.

[0017] Next, the first dispersion system was separated at 65 ° C, the centrifugal speed was 4500 rpm, and the centrifugal time was 3 minutes. Thus, the quantum dot is separated from the first dispersion system, and the zinc oleic acid is in the liquid.

[0018] The centrifugal liquid was allowed to stand at 4 ° C, and zinc olerate was precipitated from the liquid. The liquid was centrifuged at 4 ° C and the centrifugal speed was 4500 rpm, centrifugal time was 5 minutes, resulting in zinc acid zinc and a small amount of waste liquid.

Embodiment 2

[0020] Take 100G waste and 800 ml of n-butanol, mix it. The mixture was heated to 75 ° C under reduced pressure, and the steam reflux treatment was carried out such that the waste residue was dispersed into the alcohol to form a first dispersion system. The zinc in the waste residue is dispersed in a small droplet to the first dispersion system; the quantum dots are present in the form of precipitation; other organic materials are mutually solved with n-butanol.

[0021] Next, the first dispersion system was separated at 60 ° C, the centrifugal speed was 5000 rpm, and the centrifugal time was 4 minutes. Thus, the quantum dot is separated from the first dispersion system, and the zinc oleic acid is in the liquid.

[0022] The centrifugal liquid was allowed to stand at 4 ° C, and zinc olerate was precipitated from the liquid. The liquid was centrifuged at 4 ° C and the centrifugal speed was 5000 rpm, centrifugal time was 5 minutes, resulting in zinc acid zinc and a small amount of w...

Embodiment 3

[0024] The 200g waste residue was taken with 360 mL of ethanol, 40 ml of water. The mixture was heated to 78 ° C and the steam reflux treatment was carried out such that the waste residue was dispersed into the alcohol to form a first dispersion system. The zinc in the waste residue is dispersed in a small droplet to the first dispersion system; the quantum dots are present in the form of precipitation; other organic materials are mutually solved with n-butanol.

[0025] Next, the first dispersion system was separated at 60 ° C, the centrifugal speed was 3500 rpm, and the centrifugal time was 4 minutes. Thus, the quantum dot is separated from the first dispersion system, and the zinc oleic acid is in the liquid.

[0026] The centrifugal liquid was allowed to stand at -10 ° C, and the zinc oleate was precipitated from the liquid. The liquid was centrifuged at -10 ° C, centrifugal speed of 5000 rpm, centrifugal time was 5 minutes, resulting in zinc acid zinc and a small amount of wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com