Treatment method of zinc oleate-containing waste residues produced by synthesis of quantum dots

A treatment method and technology of quantum dots, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve problems such as difficult to treat waste residue and environmental pollution, and achieve the effect of convenient treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

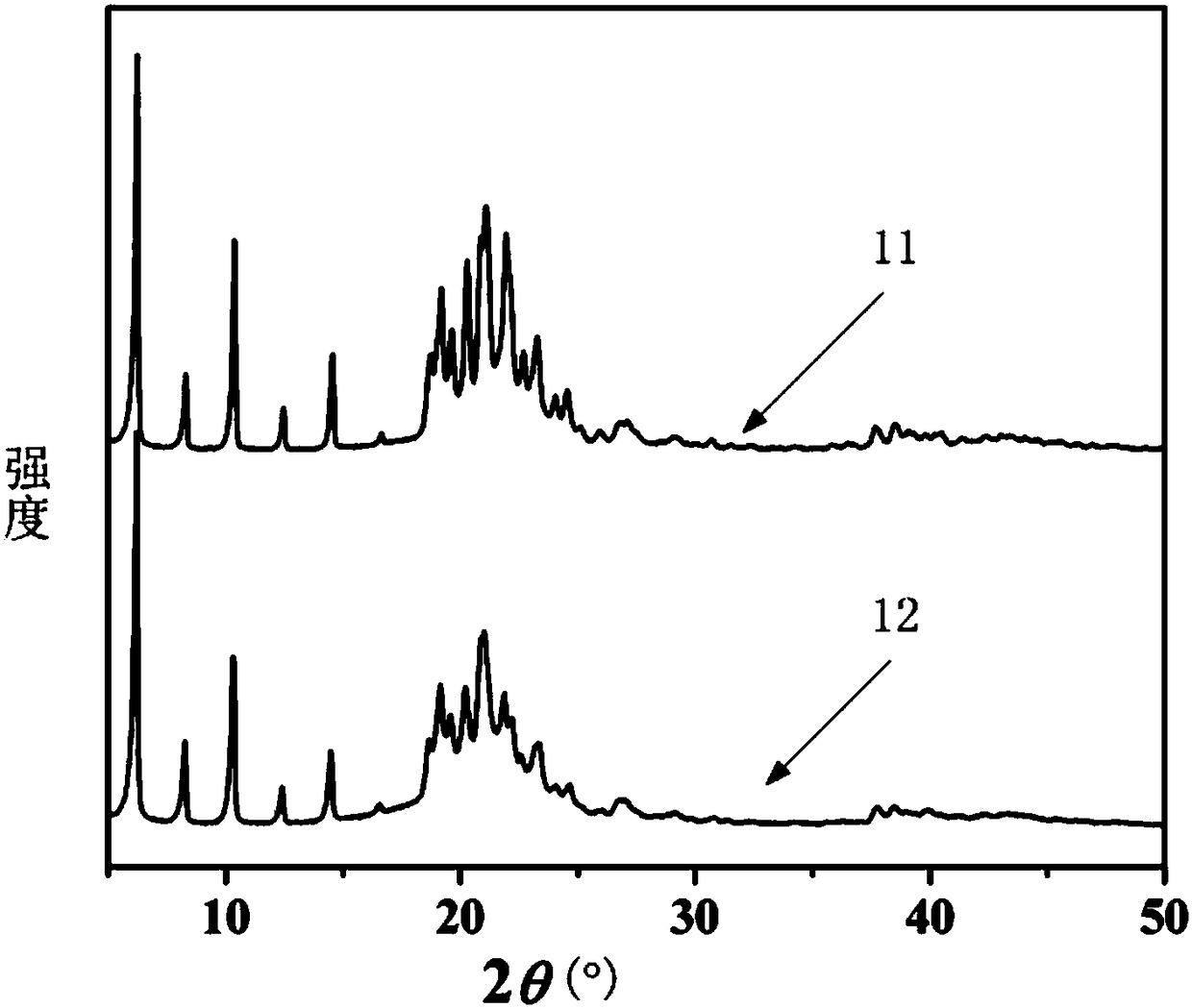

Image

Examples

Embodiment 1

[0017] At the first temperature of 90° C., 100 g of waste residue and 500 ml of n-heptane were mixed and subjected to steam reflux treatment, so that the waste residue was dispersed in n-heptane to form a first dispersion system. The zinc oleate in the waste residue is dispersed into the first dispersion system in the form of small droplets; the quantum dots are dissolved in the liquid phase.

[0018] 500 ml of ethanol was added to the first dispersion to form a second dispersion. In this way, the quantum dots are precipitated to form an insoluble solid. Zinc oleate is still dispersed into the second dispersion in the form of small droplets. The second dispersion was centrifuged at 50° C., the centrifugation speed was 4500 rpm, and the centrifugation time was 3 minutes. In this way, the quantum dots are separated from the second dispersion, and the zinc oleate is in the liquid.

[0019] The centrifuged liquid was left standing at 4°C, and zinc oleate was precipitated from t...

Embodiment 2

[0021] At the first temperature of 100° C., 150 g of waste residue and 500 ml of n-octane were mixed and subjected to steam reflux treatment, so that the waste residue was dispersed in n-octane to form a first dispersion system. The zinc oleate in the waste residue is dispersed into the first dispersion system in the form of small droplets; the quantum dots are dissolved in the liquid phase.

[0022] 800 ml of ethanol was added to the first dispersion to form a second dispersion. In this way, the quantum dots are precipitated to form an insoluble solid. Zinc oleate is still dispersed into the second dispersion in the form of small droplets. The second dispersion was centrifuged at 50° C., the centrifugation speed was 4500 rpm, and the centrifugation time was 3 minutes. In this way, the quantum dots are separated from the second dispersion, and the zinc oleate is in the liquid.

[0023] The centrifuged liquid was left standing at 4°C, and zinc oleate was precipitated from th...

Embodiment 3

[0025] At the first temperature of 110°C, 100g of waste residue and 200ml of 2,2,2-trimethylpentane were mixed and subjected to steam reflux treatment, so that the waste residue was dispersed in 2,2,2-trimethylpentane to form The first dispersion system. The zinc oleate in the waste residue is dispersed into the first dispersion system in the form of small droplets; the quantum dots are dissolved in the liquid phase.

[0026] 600 ml of isopropanol was added to the first dispersion to form a second dispersion. In this way, the quantum dots are precipitated to form an insoluble solid. Zinc oleate is still dispersed into the second dispersion in the form of small droplets. The second dispersion was centrifuged at 60°C with a centrifugation speed of 4500 rpm and a centrifugation time of 3 minutes. In this way, the quantum dots are separated from the second dispersion, and the zinc oleate is in the liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com