Heat stabilizer for processing soft transparent PVC (polyvinyl chloride) and preparation method of heat stabilizer

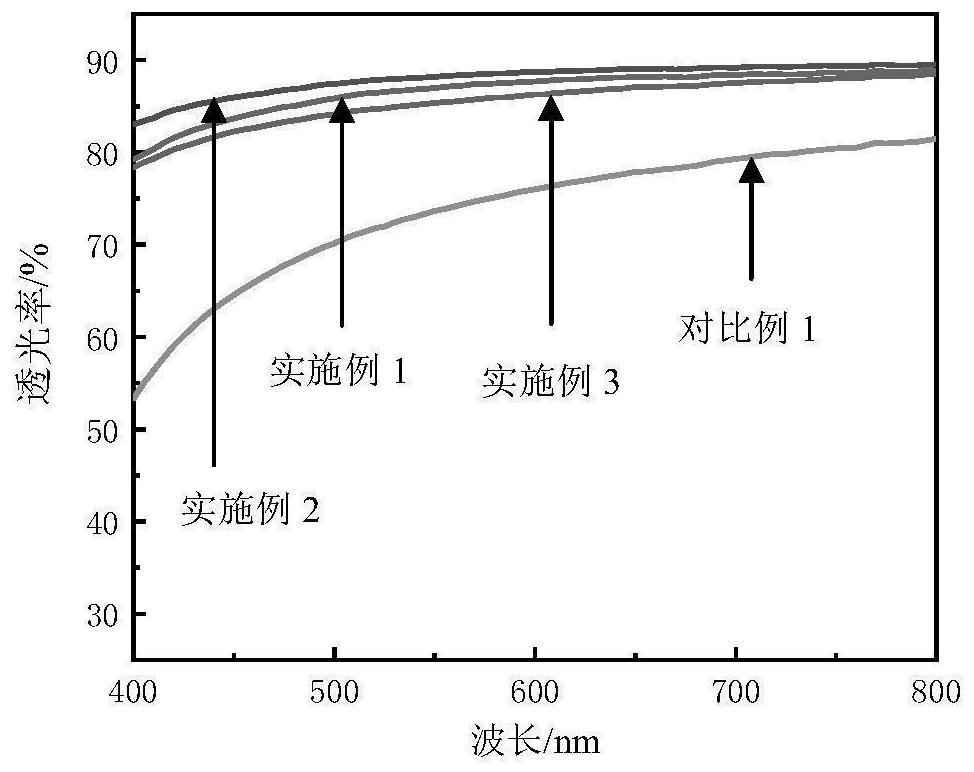

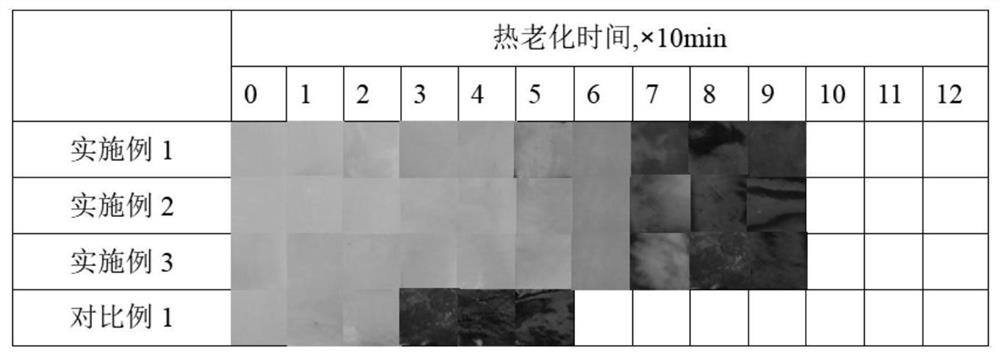

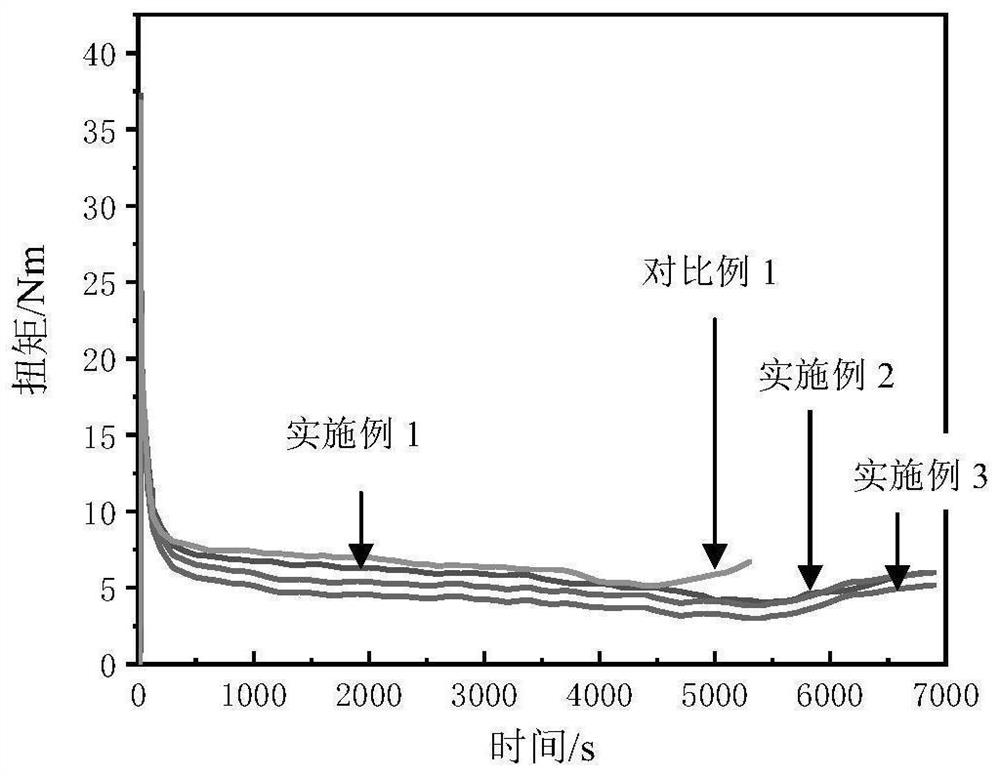

A heat stabilizer, soft and transparent technology, which is applied in the field of heat stabilizer for processing soft and transparent PVC and its preparation, can solve the problems of coloring and long-term heat stability cannot be taken into account, and achieves the reduction of initial coloring and zinc burning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method provided by the invention is used to process the thermal stabilizer of soft transparent PVC, comprises the following steps:

[0037] Step 1, mixing zinc oleate, amino metal organic framework compound, auxiliary heat stabilizer, lubricant, antioxidant and ultraviolet absorber to obtain the first mixture, heating the first mixture, wherein the heating temperature is 60-90 ℃;

[0038] Step 2, adding a plasticizer to the heated first mixture to obtain a second mixture, heating, stirring, and granulating the second mixture in sequence to obtain a heat stabilizer for processing soft transparent PVC, wherein the heated The temperature is 100-120°C, and the granulation is obtained by a granulator.

Embodiment 1

[0040] A heat stabilizer for processing soft transparent PVC, which consists of the following components in mass ratio: 30 parts of zinc oleate, 15 parts of amino metal organic framework compound, 10 parts of uracil, 5 parts of β-diketone, 10 parts of diisononyl cyclohexane 1,2-dicarboxylate, 4 parts of polyethylene wax (AC-6A), 1 part of antioxidant 618, and 1 part of UV531, wherein the amino metal organic framework compound contains a mass ratio of 1:1 organic ligand and metal salt, wherein the organic ligand is aminoterephthalic acid, aminonaphthalene dicarboxylic acid or 2-aminoimidazole;

[0041] 30 parts of zinc oleate, 15 parts of amino metal organic framework compound, 10 parts of uracil, 5 parts of β-diketone, 10 parts of diisononyl cyclohexane 1,2-dicarboxylate, polyethylene wax (AC- 6A) Mix 4 parts, 6181 parts of antioxidant and 1 part of UV531 to obtain the first mixture, heat the first mixture to 60°C, then add plasticizer to the heated first mixture to obtain the...

Embodiment 2

[0043]A heat stabilizer for processing soft transparent PVC, which consists of the following components in mass ratio: 25 parts of zinc oleate, 18 parts of amino metal organic framework compound, 10 parts of uracil, 5 parts of pentaerythritol, epoxy resin 10 parts of soybean oil, 6 parts of polyethylene wax (AC-6A), 1 part of antioxidant 1010, 1 part of UV326, wherein the amino metal organic framework compound contains an organic ligand and a metal salt with a mass ratio of 1:1, wherein, The organic ligand is aminoterephthalic acid, aminonaphthalene dicarboxylic acid or 2-aminoimidazole;

[0044] 30 parts of zinc oleate, 15 parts of amino metal organic framework compound, 10 parts of uracil, 5 parts of β-diketone, 10 parts of diisononyl cyclohexane 1,2-dicarboxylate, polyethylene wax (AC- 6A) Mix 4 parts, 6181 parts of antioxidant and 1 part of UV531 to obtain the first mixture, heat the first mixture to 90°C, then add plasticizer to the heated first mixture to obtain the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com