Preparation method of InP/ZnS (indium phosphide/zinc sulfide) core-shell structure quantum dots

A technology of core-shell quantum dots and core-shell structure, which is applied in the field of preparation of InP/ZnS core-shell quantum dots, can solve the problems of easily polluting toxic substances, expensive phosphorus sources, etc., and achieve excellent optical purity and brightness, fluorescence Effect of high quantum yield and high film formation yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

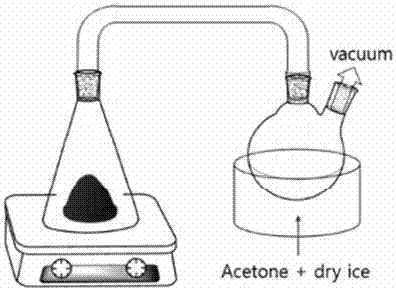

[0029] (1) Preparation of phosphorus source: Take 100g of red phosphorus in an Erlenmeyer flask, one U-shaped tube is connected to the upper port of the Erlenmeyer flask, and the other is connected to a 250ml two-necked round-bottomed flask, and the round-bottomed flask is placed in a container A mixture of acetone and dry ice is used to gasify P4 red phosphorus, heated to 350°C, and kept at the temperature for 4.5 hours under vacuum;

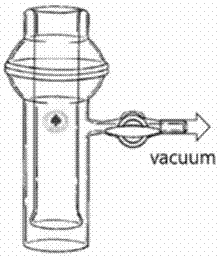

[0030] (2) For further purification, the obtained product is sublimated, slowly heated to 100°C and vacuumed. This sublimation process is used three times to improve the purity of P4; the final P4 solid is obtained; be cautious when P4 is exposed to air It will spontaneously oxidize when exposed to high temperature. Therefore, all synthetic processes to produce P4 must be carried out in a glove box in an inert atmosphere; moreover, to synthesize P4, after P4 conversion, it should be stored in the dark; when exposed to light, it slowly turns yel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com