Rubber processing aid and preparation method thereof

A processing aid and rubber technology, applied in the field of rubber additives and its preparation, can solve the problems of difficult popularization and application, single function, etc., and achieve the effects of increasing uniformity and stability, reducing pollution, and avoiding dust flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

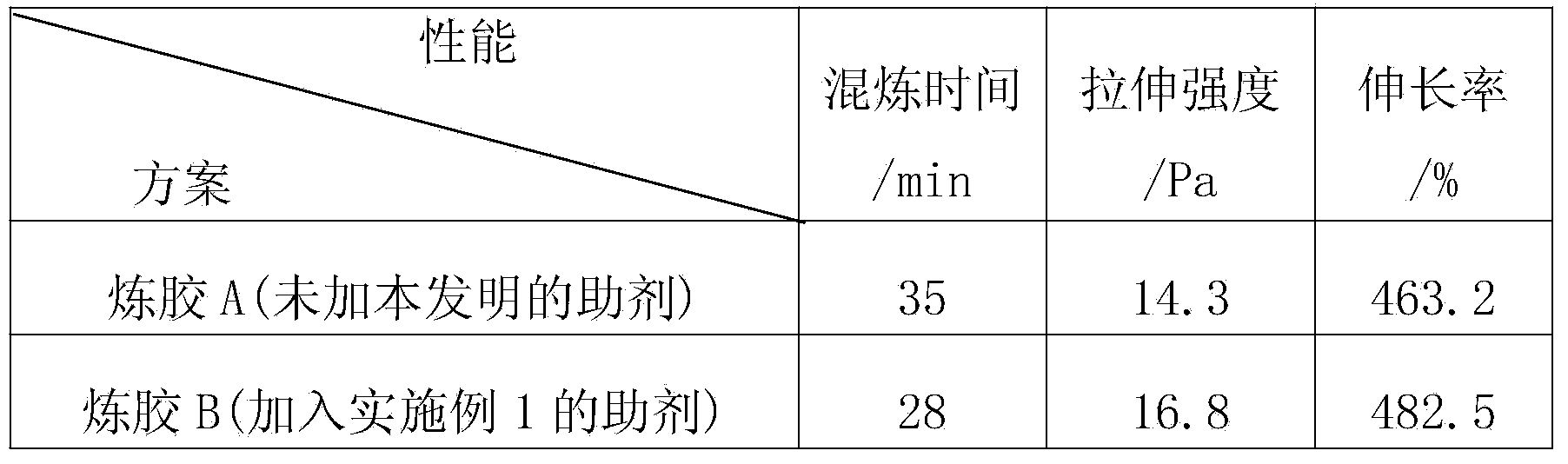

Examples

Embodiment 1

[0013] Embodiment 1: the preparation of auxiliary agent

[0014] 1) Weigh raw materials according to the following parts by weight: stearic acid 756, zinc oxide 27, anhydrous aluminum trichloride 117, zinc oleate 100;

[0015] 2) First put stearic acid into the reaction kettle, heat it to 140°C, then put in anhydrous aluminum trichloride, react for 2.5 hours under constant temperature conditions, then put in zinc oxide, and then put in zinc oleate, under constant temperature conditions Under reaction 40min;

[0016] 3) Send the mixture in the reaction kettle quantitatively to the granulation extruder for granulation to obtain the auxiliary agent.

Embodiment 2

[0017] Embodiment 2: the preparation of auxiliary agent

[0018] 1) Weigh raw materials according to the following parts by weight: 700 stearic acid, 10 zinc oxide, 50 anhydrous aluminum trichloride, 50 zinc oleate;

[0019] 2) First put stearic acid into the reaction kettle, heat it to 125°C, then put in anhydrous aluminum trichloride, react for 3 hours under constant temperature conditions, then put in zinc oxide, and then put in zinc oleate, under constant temperature conditions Reaction 40min;

[0020] 3) Send the mixture in the reaction kettle quantitatively to the granulation extruder for granulation to obtain the auxiliary agent.

Embodiment 3

[0021] Embodiment 3: the preparation of rubber auxiliary agent

[0022] 1) Weigh raw materials according to the following parts by weight: stearic acid 800, zinc oxide 117, anhydrous aluminum trichloride 100, cobalt stearate 200;

[0023] 2) First put stearic acid into the reaction kettle, heat it to 155°C, then put in anhydrous aluminum trichloride, react for 2.5 hours under constant temperature conditions, then put in zinc oxide, and then put in zinc oleate, under constant temperature conditions Under reaction 40min;

[0024] 3) Send the mixture in the reaction kettle quantitatively to the granulation extruder for granulation to obtain the auxiliary agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com