Process method and application of improving the quality of thick pulp heat-not-burn reconstituted tobacco leaves

A technology for heat-not-burn and reconstituted tobacco leaves, applied in the application, tobacco, preparation of tobacco and other directions, can solve the problems of reduced pungent taste, reduced irritation, etc., and achieves the effects of not easy desorption, strong adsorption, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

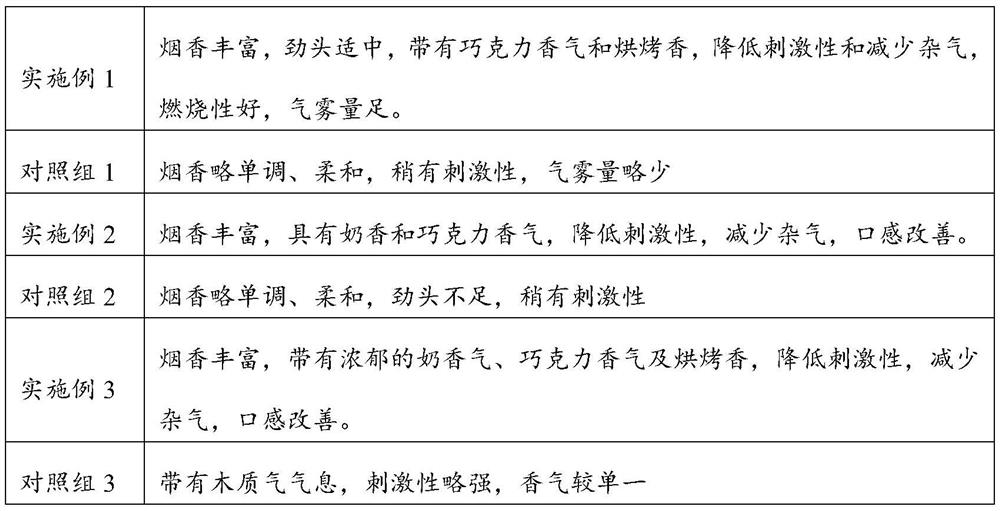

Embodiment 1

[0032] A process for improving the quality of heat-not-burn reconstituted tobacco leaves by the thick slurry method, comprising the following steps:

[0033] (1) Pulverization: pulverize the tobacco raw material to 10 mesh powder;

[0034] (2) Strain activation: add the active solid freeze-dried powder of Saccharomycopsis fibuligera and Armillariella tabescens to 5 times the mass of sterilized 5% corn syrup solution , placed in a 30°C water bath for activation for 30 minutes to obtain a strain activation solution;

[0035] (3) Immobilized adsorption of composite biological agents: wash and dry the tobacco rods and shavings, process the tobacco rods into pieces about 1 cm long, mix them with the shavings at a mass ratio of 1:0.5, and dry them after autoclaving. As a strain immobilization carrier, put it into a filter bag and put it in a container, then add the strain activation solution in step (2), and a certain amount of cellulase and α-L-arabinofuranosidase to obtain the bi...

Embodiment 2

[0046] A process for improving the quality of heat-not-burn reconstituted tobacco leaves by the thick slurry method, comprising the following steps:

[0047] (1) Pulverization: pulverize the tobacco raw material to 100 mesh powder;

[0048] (2) Strain activation: the active solid lyophilized powder of Saccharomycopsis fibuligera and Armillariella tabescens was added to 13 times the mass of the sterilized 16% sucrose solution, Place in a 38°C water bath for activation for 45 minutes to obtain a strain activation solution;

[0049] (3) Immobilized adsorption of compound biological agents: wash and dry the tobacco rods and shavings, process the tobacco rods into pieces about 1 cm long, mix them with the shavings at a mass ratio of 1:1.1, and dry them after autoclaving. As a strain immobilization carrier, put it into a filter bag and put it in a container, then add the strain activation solution in step (2), and a certain amount of cellulase and α-L-arabinofuranosidase to obtain ...

Embodiment 3

[0060] A process for improving the quality of heat-not-burn reconstituted tobacco leaves by the thick slurry method, comprising the following steps:

[0061] (1) Pulverization: pulverize the tobacco raw material to 200 mesh powder;

[0062] (2) Strain activation: the active solid freeze-dried powders of Saccharomycopsis fibuligera and Armillariella tabescens were added to 20 times the mass of sterilized 30% glucose solution, Place in a water bath at 45°C for 60 minutes to obtain the strain activation solution;

[0063] (3) Immobilized adsorption of compound biological agents: wash and dry the tobacco rods and shavings, process the tobacco rods into pieces about 1 cm long, mix them with the shavings at a mass ratio of 1:2, and dry them after autoclaving. As a strain immobilization carrier, put it into a filter bag and put it in a container, then add the strain activation solution in step (2), and a certain amount of cellulase and α-L-arabinofuranosidase to obtain the biologica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com