Metal organic framework material, synthetic method and application thereof

A metal-organic framework and framework material technology, applied in the field of materials, can solve the problems of few types of metal-organic framework materials, no practical application prospect, difficult industrial application, etc., and achieve excellent water stability, low cost, high porosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Synthesis of Metal Organic Frameworks

[0029] Dissolve 0.048g of copper nitrate trihydrate in 1mL of water, dissolve 0.025g of pyromellitic acid in 4mL of water, mix the obtained copper nitrate trihydrate aqueous solution and pyromellitic acid aqueous solution, and stand for reaction at 60°C for 3 days, and then the obtained The reaction product was cooled to room temperature and subjected to suction filtration. During the suction filtration, 5 ml of ethanol was used to wash three times. The resulting filter cake was dried at 60° C. for 24 hours to obtain 0.031 g of the product, with a yield of 67.4%.

[0030] Structural characterization and performance tests were performed on the product obtained in Example 1.

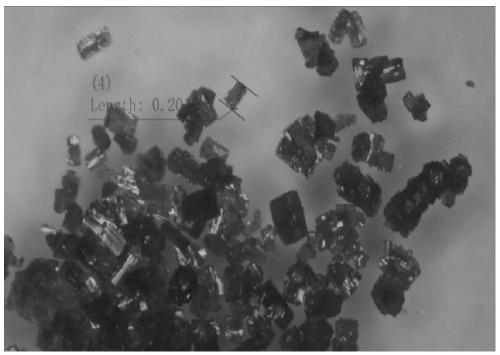

[0031] refer to figure 1 , figure 1 This is the shape of the product under a microscope. It can be seen through observation that the product is a dark green crystal with a crystal length of about 0.201 mm.

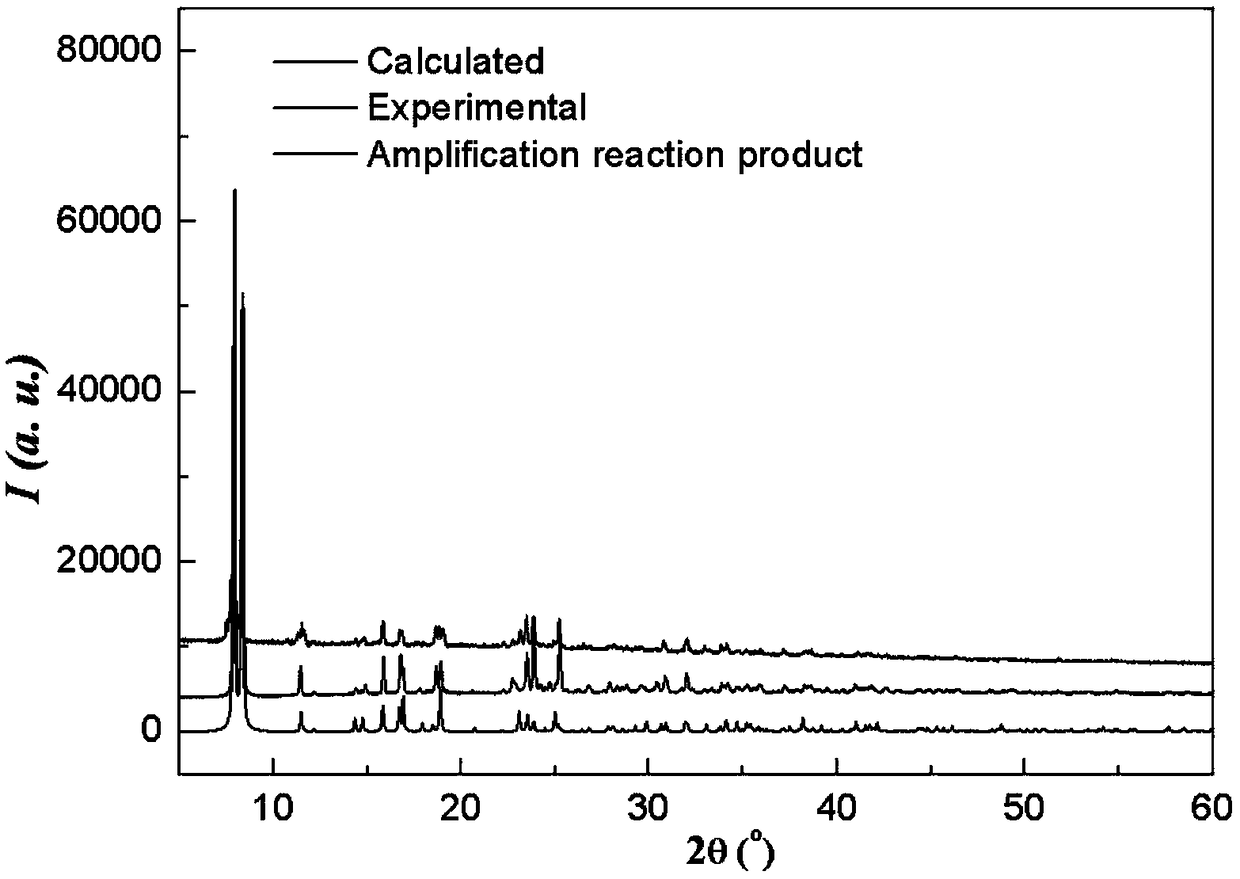

[0032] refer to figure 2 , figure ...

Embodiment 2

[0051] Example 2: Synthesis of Metal Organic Frameworks

[0052] Dissolve 0.960g of copper nitrate trihydrate with 2mL of water, dissolve 0.600g of pyromellitic acid with 8mL of DMF, mix the obtained copper nitrate trihydrate aqueous solution and pyromellitic acid DMF solution, and let it stand for reaction at 60°C for 3 days, and then dissolve the obtained The reaction product was cooled to room temperature and subjected to suction filtration. During the suction filtration, 5 ml of ethanol was used to wash three times. The resulting filter cake was dried at 60° C. for 24 hours to obtain 0.628 g of the product, with a yield of 71.0%.

Embodiment 3

[0053] Example 3: Synthesis of Metal Organic Frameworks

[0054] Dissolve 192g of copper nitrate trihydrate in 400mL of water, dissolve 100g of pyromellitic acid in 800mL of DMF, mix the obtained aqueous solution of copper nitrate trihydrate and aqueous solution of pyromellitic acid, let it stand for a reaction at 60°C for 3 days, and then cool the resulting reaction product Return to room temperature and perform suction filtration. During the suction filtration, 50 ml of ethanol was used to wash three times. The resulting filter cake was dried at 60° C. for 24 hours to obtain 89.4 g of the product, with a yield of 54.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com