Manifold and manufacturing process thereof

A manufacturing process and branch pipe technology, applied in the field of branch pipes, can solve the problems of uneven weld deposit, easy bursting and poor fastness at the welding place, and achieve the effect of good roundness, smooth inside and outside of the pipe, and uniform welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

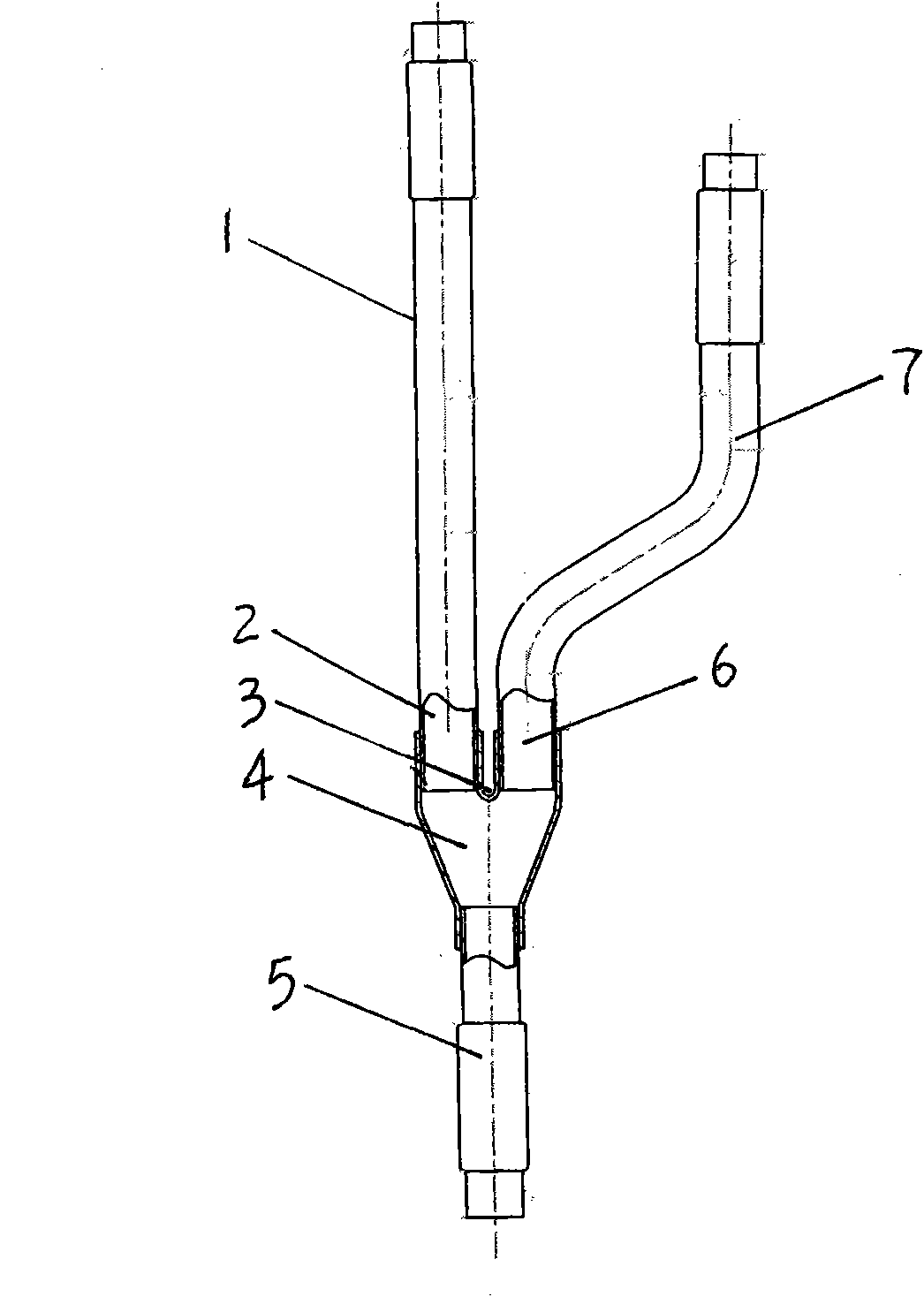

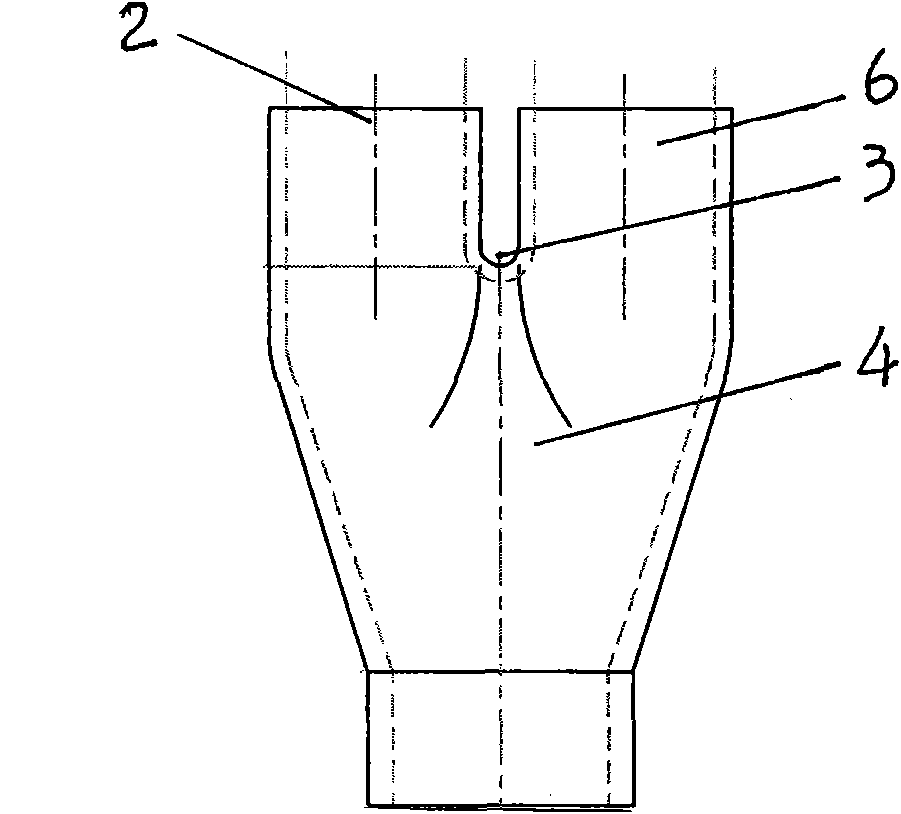

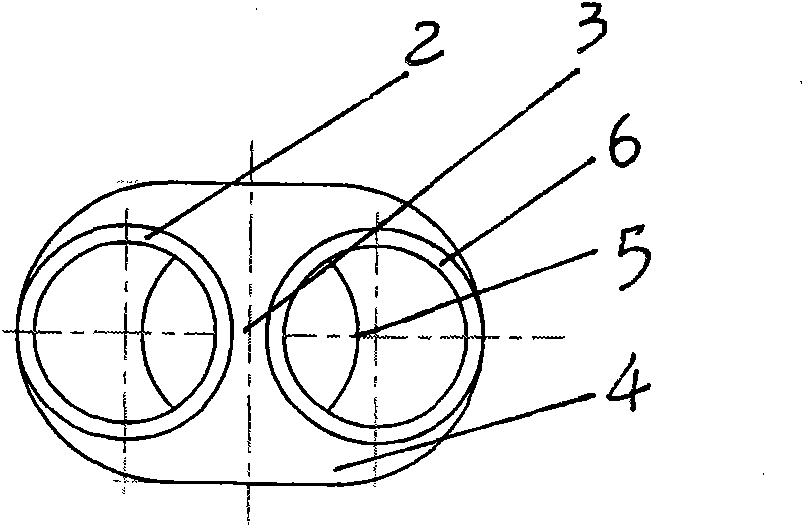

[0012] Such as figure 1 As shown, the present invention mainly consists of a straight pipe 5 and a long straight pipe 1 located at the end of the straight pipe 5 and bifurcated welding sockets 2 and 6 of the bent pipe 7 to form a trousers tee 4. The bifurcated welding socket 2 and 6 are independent seamless nozzles. The trousers tee is provided with a bifurcated opening 3, which is arc-shaped. on flat surface.

[0013] Such as figure 2 , image 3 As shown, the bifurcated welding sockets 2 and 6 on the trousers tee 4 of the present invention are independent seamless nozzles. The sockets 2, 6 are parallel to the center line of the straight pipe 5 and are on the same plane.

[0014] The manufacturing process of the present invention adopts the hydraulic extrusion process technology, and the copper pipe is passed through a special trousers tee mold, and the welded sockets of the straight pipe and the bent pipe are extruded into independent seamless pipe trousers tees.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com