Method for refining, metamorphosing and casting cold roll steel by casting instead of forging

A technology for cold-rolled roll steel and cold-rolled work rolls, which is applied to the improvement of process efficiency, furnace type, furnace, etc., can solve the problems of shallow hardening depth, large processing volume, low fatigue strength, etc., and achieves alloy content and carbon content. Reasonable, high hardness and fatigue strength, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

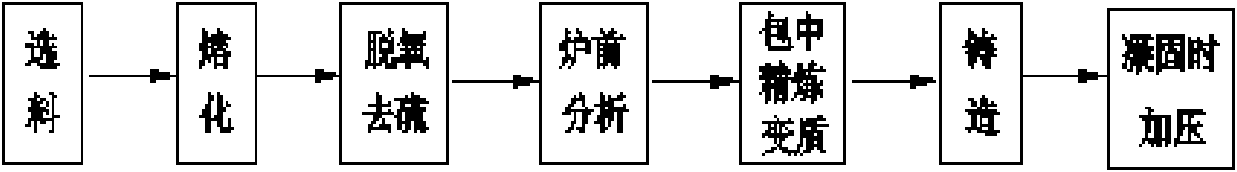

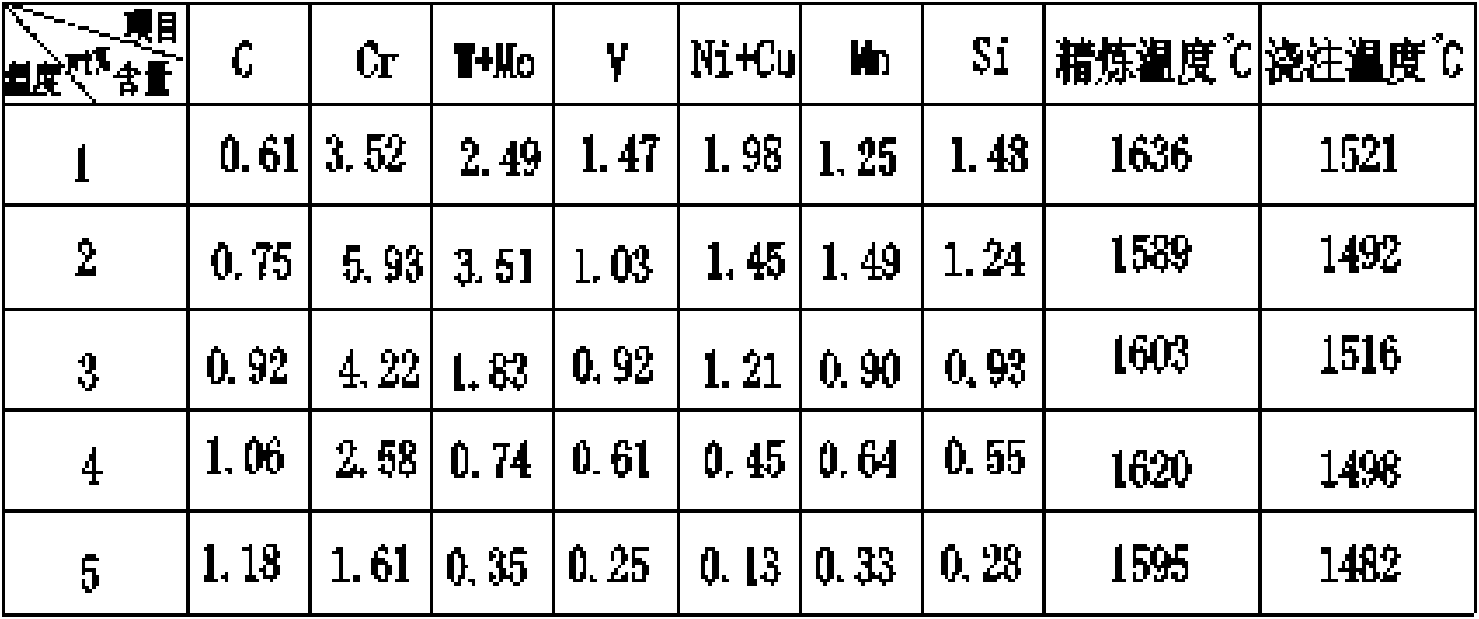

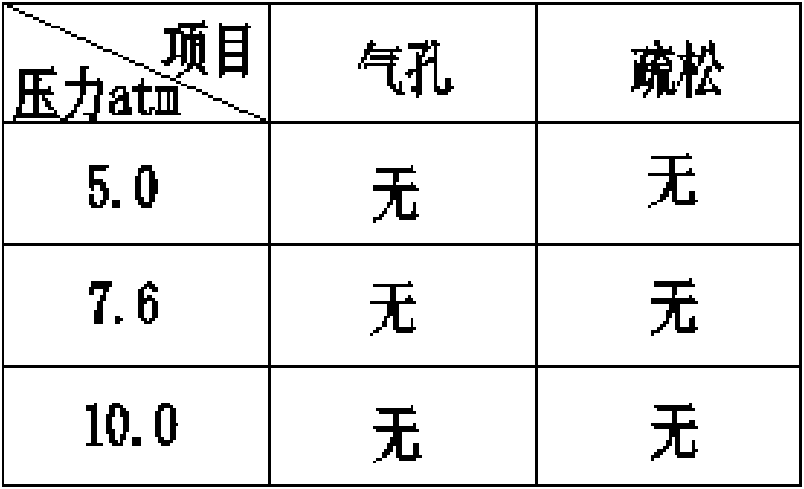

[0025] by attached figure 1 , figure 2 , image 3 As shown, a cold-rolled roll steel is refined, modified and cast by casting instead of forging, including the weight percentages of the chemical composition of the cold-rolled work roll sleeve: C: 0.6%-1.2%, Si: 0.2%-1.5%, Mn: 0.3%-1.5%, Cr: 1.6%-6.0%, W+Mo≤3.5%, Ni+Cu≤1.5%, V≤1.5%, Re≤0.15%, Ba+Mg≤0.10%, K+Na ≤0.05%, S≤0.015%, O≤0.002%, the rest is iron and unfathomable trace impurities; the weight percentage of the chemical composition of the backup roll sleeve is: C: 0.4%-1.0%, Si: 0.3%-2.0% , Mn: 0.6%-2.5%, Cr: 1.0%-4.5%, W+Mo≤1.5%, Ni+Cu≤1.5%, V≤1.0%, Re≤0.15%, Ba+Mg≤0.10%, K+ Na≤0.05%, S≤0.02%, O≤0.003%, the rest is iron and trace impurities; figure 2 Five examples of the weight percentage content of the chemical components of the main elements of the work roll sleeve or working layer steel, all of which meet the national standard GB / T155471995 for cold-rolled forging billets, and adopt different quenching and tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com