Configuration method of medium and heavy plate roll system with consideration of both rolling stability and cross-section shape

A technology of cross-sectional shape and configuration method, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of rolling stability and cross-sectional shape control difficult to take into account, and achieves suppression of rolling instability and low cost. , the effect of strong feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the embodiments.

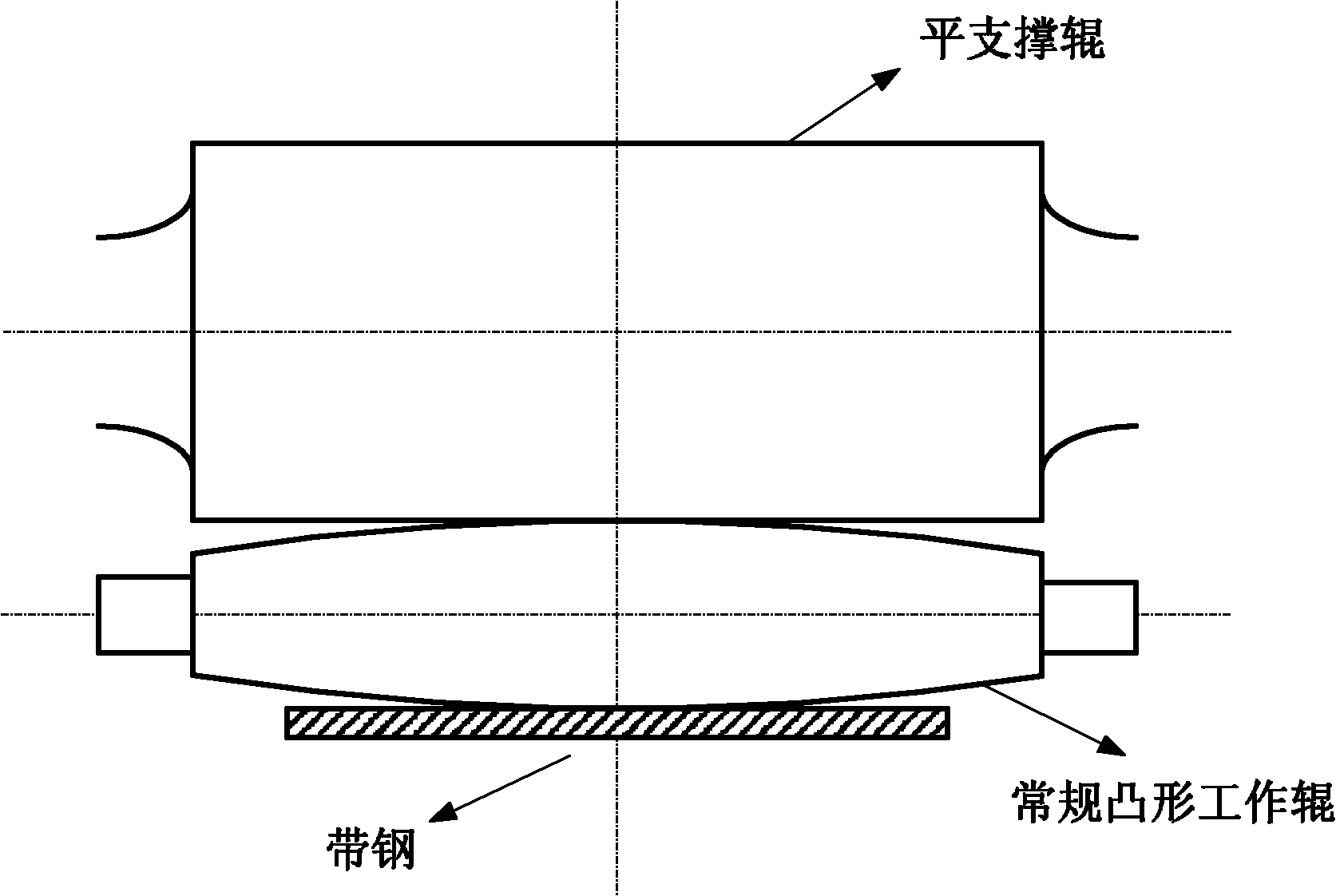

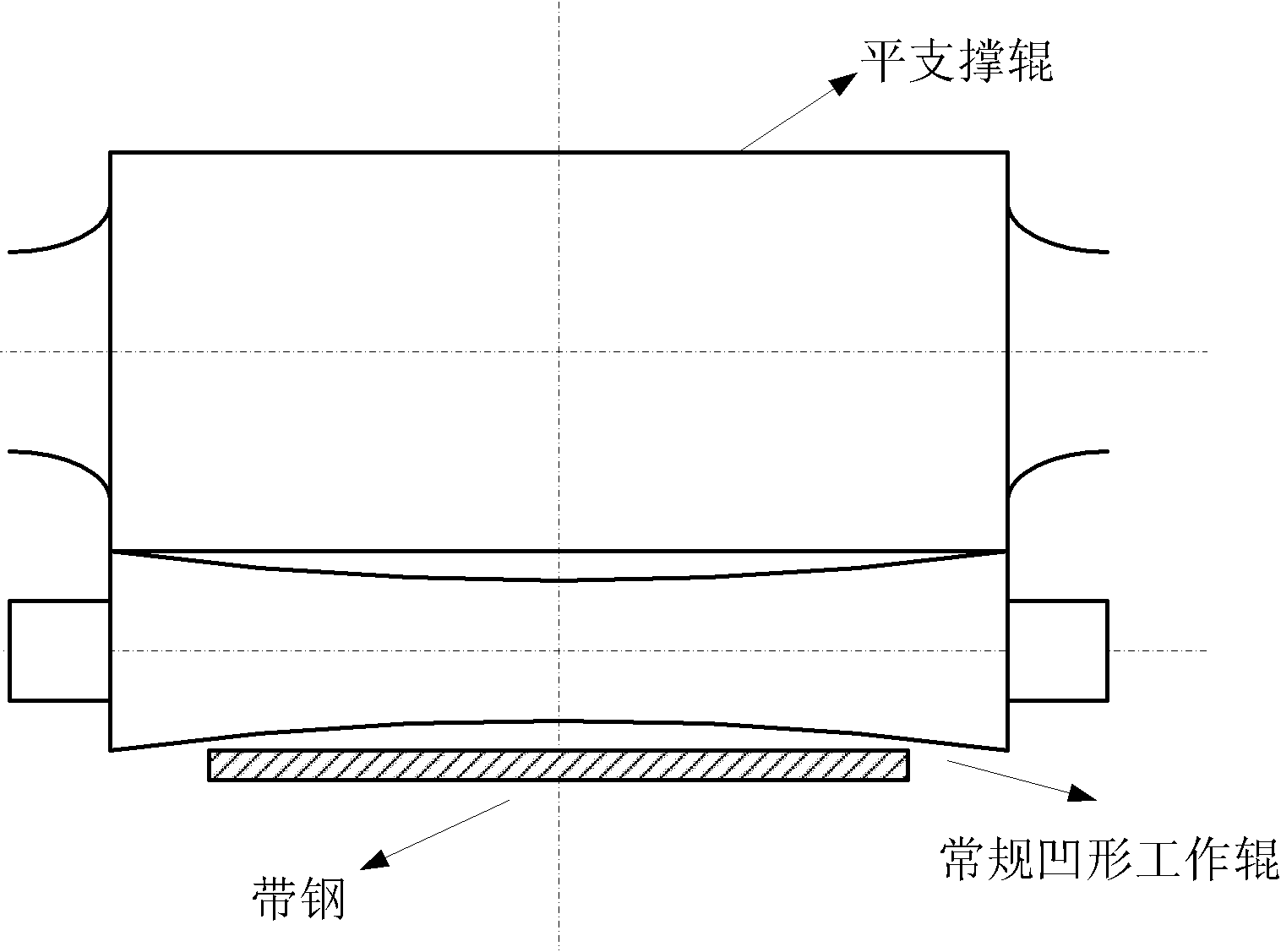

[0029] From the analysis of the background technology, it can be seen that the medium and heavy plate rolling mill has the characteristics of serious roll deflection, the harmful contact zone has a large impact on the roll gap, and the roll gap in each pass is unstable. Therefore, the configuration plan of the backup roll needs to consider how to deal with it. The above characteristics. Introduce two important evaluation indicators: 1) The transverse stiffness of the bearing roll gap, using the variable k g Means, defined as the ratio of the change in rolling pressure to the change in crown of the load roll, k g The larger the value, the more stable the load-bearing roll gap, which can effectively reduce the influence of harmful contact areas and rolling pressure fluctuations on the roll gap in the medium and thick plate; 2) the effect of roll bending forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com