Aluminum alloy cable conductor and manufacturing method thereof

A cable conductor and aluminum alloy technology, which is applied in the field of wire and cable, can solve the problems of equipment operators, large project investment, easy water penetration in the gap of the conductor single line, and low compression coefficient of conductor stranding, so as to improve the current carrying capacity of the cable Performance, improvement of waterproof and anti-oxidation performance, wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

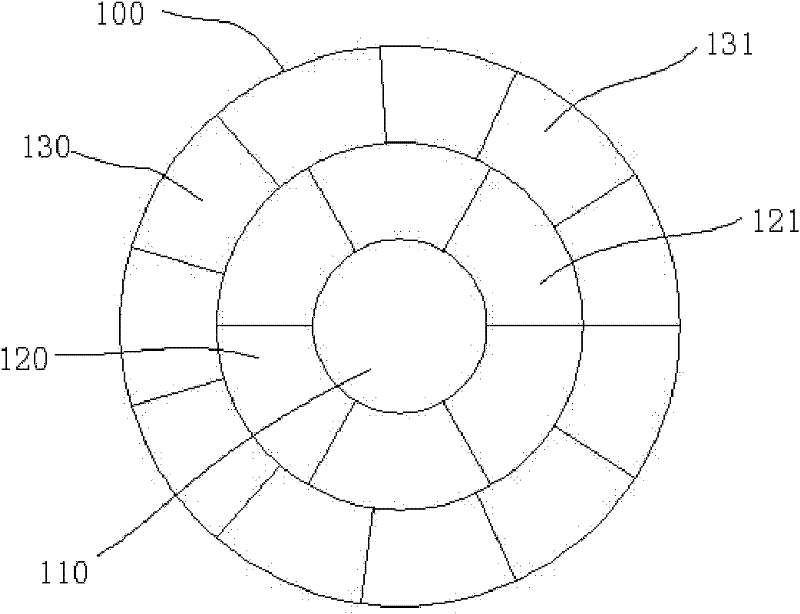

[0023] Such as figure 2 As shown, an aluminum alloy cable conductor includes a conductor body 100 with a circular cross-sectional shape, and the conductor body 100 includes a central part and an outer ring part. The central portion is a circular central circle portion 110 . The central circular part 110 is formed by integral processing.

[0024] The outer ring part is sleeved outside the central part, including an inner ring part 120 and an outer ring part 130. The inner ring part 120 is sleeved outside the central circular part 110 and is adapted to the outer wall of the central circular part. The outer ring part 130 is sleeved Outside the inner ring part 120, and the inner wall of the outer ring part is adapted to the outer wall of the inner ring part; the inner ring part 120 is composed of several inner ring tile-shaped blocks 121 spliced along the circumferential direction; the outer ring part 130 is composed of several outer ring tiles The shape blocks 131 are splice...

Embodiment 2

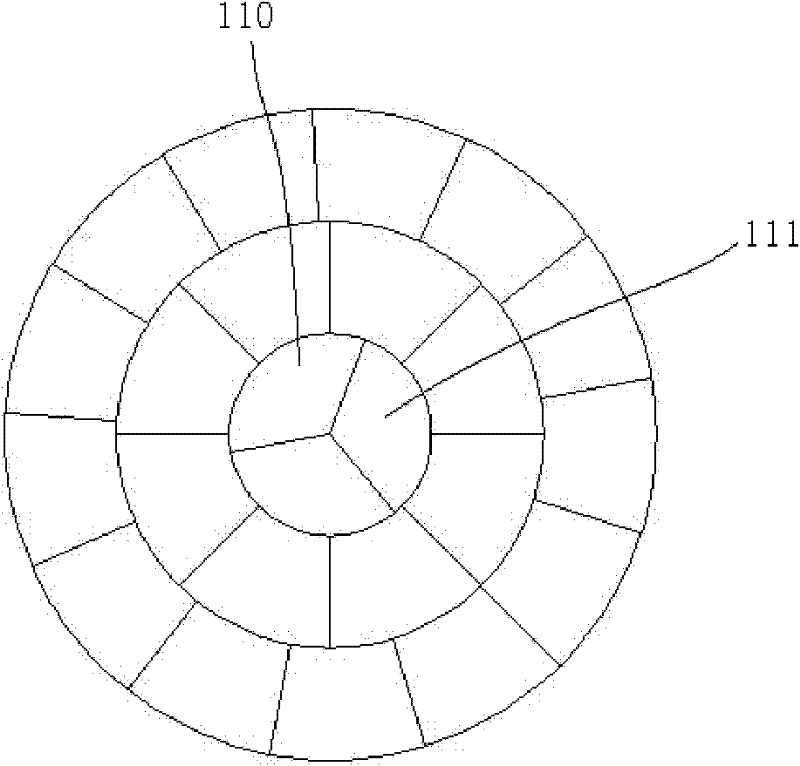

[0028] image 3 The difference between the shown aluminum alloy cable conductor and the aluminum alloy cable conductor in Embodiment 1 is that the central circular part 110 is composed of several fan-shaped blocks 111 spliced together.

[0029] The manufacturing method of aluminum alloy cable conductor of the present invention, comprises the following steps:

[0030] A. The unit components of the center part and the outer circle part are obtained by pre-processing raw materials;

[0031] B. Twisting and splicing the unit assemblies of the center portion and the outer circle portion obtained in step A according to the concentric stranding rule.

[0032] C. After step B is completed, perform compression processing on the stranded splice.

[0033] The aluminum alloy cable conductor of the present invention is prefabricated into unit components (blocks), and then spliced and twisted by the unit components, the seamless splicing of the blocks is realized in the aluminum alloy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com