Potassium niobate sodium-based multi-layer piezoelectric ceramic element and preparing method thereof

A piezoelectric ceramic element, potassium sodium niobate-based technology, applied in the manufacture/assembly of electrical components, piezoelectric/electrostrictive/magnetostrictive devices, magnetostrictive devices, etc., can solve the problem of reducing the piezoelectric performance of ceramics , Alkali metals are easy to volatilize, product performance decline and other problems, to achieve the effect of increasing the phase ratio, improving the uniformity and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

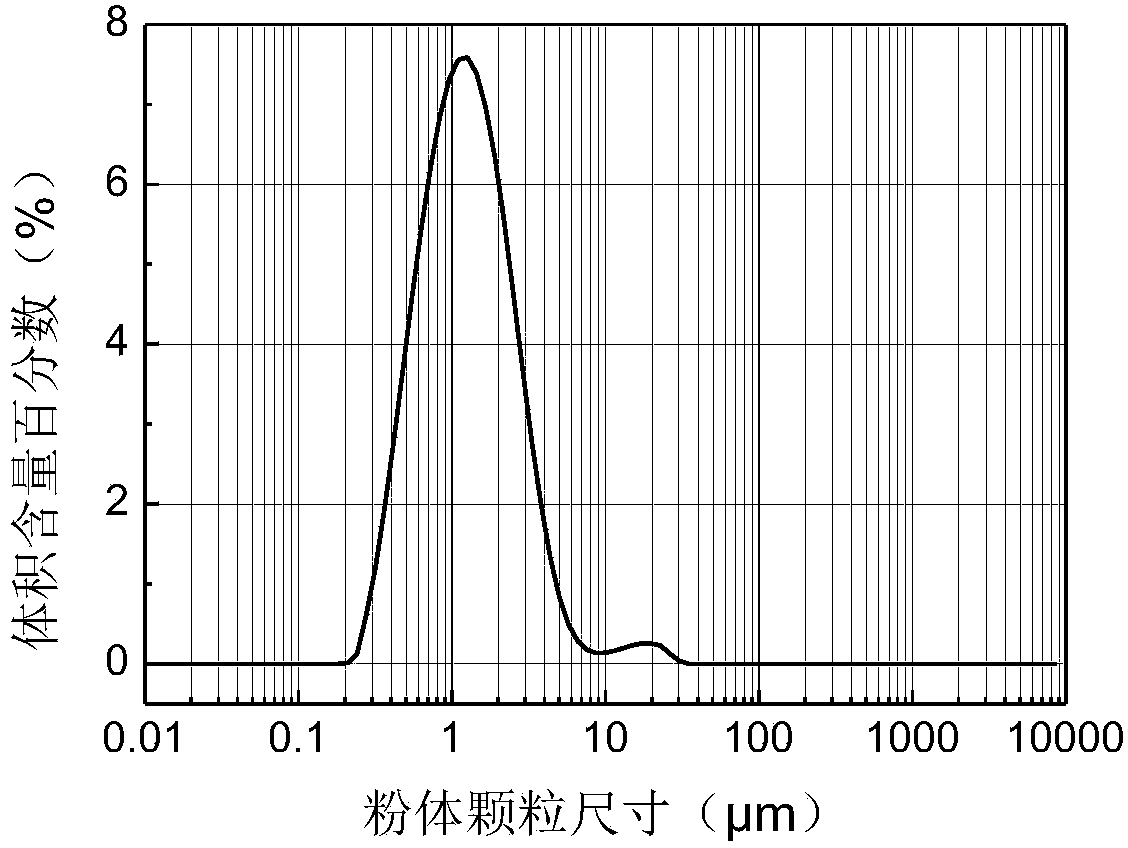

Image

Examples

Embodiment 1

[0045] The formula stoichiometric formula of the potassium sodium niobate-based multilayer piezoelectric ceramic element in this embodiment is:

[0046] (Na 0.52 K 0.44 Li 0.04 )(Nb 0.91 Sb 0.07 Ta 0.02 )O 3

[0047] The method for preparing the above-mentioned potassium sodium niobate-based multilayer piezoelectric ceramic element includes the following steps:

[0048] (1) Raw material preparation and ingredients

[0049] Li 2 CO 3 , Na 2 CO 3 , K 2 CO 3 These alkali metal carbonates are easy to absorb water and be damp, so they must be dried at 60°C for 12 hours before use. According to the stoichiometric ratio of the formula general formula, first weigh: Li 2 CO 3 , Na 2 CO 3 , K 2 CO 3 ; Then weigh Nb 2 O 5 , Ta 2 O 5 , Sb 2 O 3 .

[0050] (2) Ball milling compound

[0051] Add the prepared raw materials to absolute ethanol as the dispersant, use zirconia balls as the ball milling medium, and mill the planetary ball mill for 4 hours (please provide the manufacturer model of the plan...

Embodiment 2

[0065] The formula stoichiometric formula of the potassium sodium niobate-based multilayer piezoelectric ceramic element in this embodiment is:

[0066] (Na 0.52 K 0.44 Li 0.04 )(Nb 0.87 Sb 0.07 Ta 0.06 )O 3

[0067] (1) Raw material preparation and ingredients

[0068] Li 2 CO 3 , Na 2 CO 3 , K 2 CO 3 These alkali metal carbonates are easy to absorb water and become damp, so they must be dried at 80°C for 8 hours before use. According to the stoichiometric ratio of the formula general formula, first weigh: Li 2 CO 3 , Na 2 CO 3 , K 2 CO 3 ; Then weigh Nb 2 O 5 , Ta 2 O 5 , Sb 2 O 3 .

[0069] (2) Ball milling compound

[0070] Add the prepared raw materials to absolute ethanol as dispersant, zirconia ball as the ball milling medium, and use a planetary ball mill for 4 hours or an ordinary tank mill for 24 hours.

[0071] (3) Initial calcination and ball milling

[0072] The slurry obtained after ball milling and mixing is dried to obtain a mixed powder. The mixed powder is crushed and s...

Embodiment 3

[0084] The formula stoichiometric formula of the potassium sodium niobate-based multilayer piezoelectric ceramic element in this embodiment is:

[0085] (Na 0.52 K 0.44 Li 0.04 )(Nb 0.90 Sb 0.07 Ta 0.03 )O 3

[0086] (1) Raw material preparation and ingredients

[0087] Li 2 CO 3 , Na 2 CO 3 , K 2 CO 3 These alkali metal carbonates are easy to absorb water and become damp, so they must be dried at 70°C for 10 hours before use. According to the stoichiometric ratio of the formula general formula, first weigh: Li 2 CO 3 , Na 2 CO 3 , K 2 CO 3 ; Then weigh Nb 2 O 5 , Ta 2 O 5 , Sb 2 O 3 .

[0088] (2) Ball mill mixture

[0089] Add the prepared raw materials to absolute ethanol as dispersant, zirconia balls as ball milling medium, and planetary ball mill for 4 hours.

[0090] (3) Initial calcination and ball milling

[0091] The slurry obtained after ball milling and mixing is dried to obtain mixed powder. The mixed powder is crushed and sieved. After passing through a 60-mesh standard siev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| electromechanical coupling coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com