Epoxy resin composition and semiconductor device

A technology of epoxy resin and semiconductor, which is applied in the direction of semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., and can solve problems such as reduced adhesion, excessive compounding amount, and poor reliability of packages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0149] Examples of the present invention are shown below, but the present invention is not limited by these Examples. The compounding ratio is expressed in parts by weight.

[0150] Next, the embodiment series (1) relates to the first aspect, the embodiment series (2) relates to the second aspect, and the embodiment series (3) relates to the third aspect.

[0151] Example series (1)

Embodiment (1

[0153] After mixing each component shown below with a mixer, it kneaded with the twin roll whose surface temperature was 95 degreeC and 25 degreeC, after cooling, it grind|pulverized, and the epoxy resin composition was obtained. The properties of the obtained epoxy resin composition were evaluated by the following methods. The results are shown in Table 1.

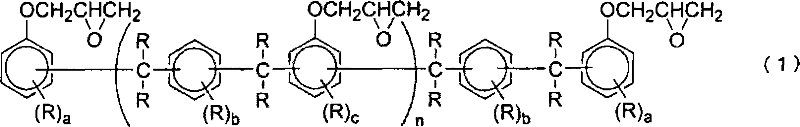

[0154] Epoxy resin 1: Epoxy resin represented by formula (1a) (softening point is 44° C., epoxy equivalent is 234, hereinafter referred to as E-1) 6.21 parts by weight

[0155]

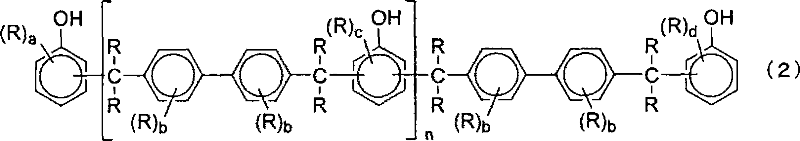

[0156] Phenolic resin 1: phenolic resin represented by formula (2a) (softening point: 107°C, hydroxyl equivalent: 203, hereinafter referred to as H-1) 4.89 parts by weight

[0157]

[0158] 1. 8-diazabicyclo(5,4,0)undecene-7 (hereinafter referred to as DBU)

[0159] 0.20 parts by weight

[0160] Fused spherical silica (average particle size: 25 μm) 88.00 parts by weight

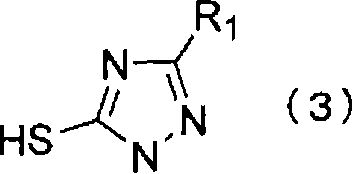

[0161] 1,2,4-triazole-5-...

Embodiment (2

[0194] After mixing each component shown below with a mixer, it kneaded with the twin-roller whose surface temperature was 95 degreeC and 25 degreeC, after cooling, it grind|pulverized, and the epoxy resin composition was obtained. The properties of the obtained epoxy resin composition were evaluated in the following manner. The results are shown in Table 4.

[0195] Epoxy resin 1: Epoxy resin represented by formula (1a) (softening point 44° C., epoxy equivalent 234, hereinafter referred to as E-1) 6.09 parts by weight

[0196]

[0197]Phenolic resin 1: phenolic resin represented by formula (2a) (softening point 107°C, hydroxyl equivalent 203, hereinafter referred to as H-1) 4.41 parts by weight

[0198]

[0199] Organopolysiloxane represented by formula (4a) (hereinafter referred to as organopolysiloxane 1)

[0200] 0.20 parts by weight

[0201]

[0202] Oxidized polyethylene wax 1 (oxidized high-density polyethylene with a dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com