Floating connector component and floating connector thereof

A floating connector and connector technology, which is used in the installation of connecting parts, the parts of connecting devices, and the connection, etc., can solve the problem of aggravating the mutual wear of the guide column and the guide sleeve, reducing the guide positioning accuracy, and fixing the connector and the floating connector. Re-plug inconvenience and other problems, to achieve the effect of reducing the automatic offset and reducing the requirements of the matching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

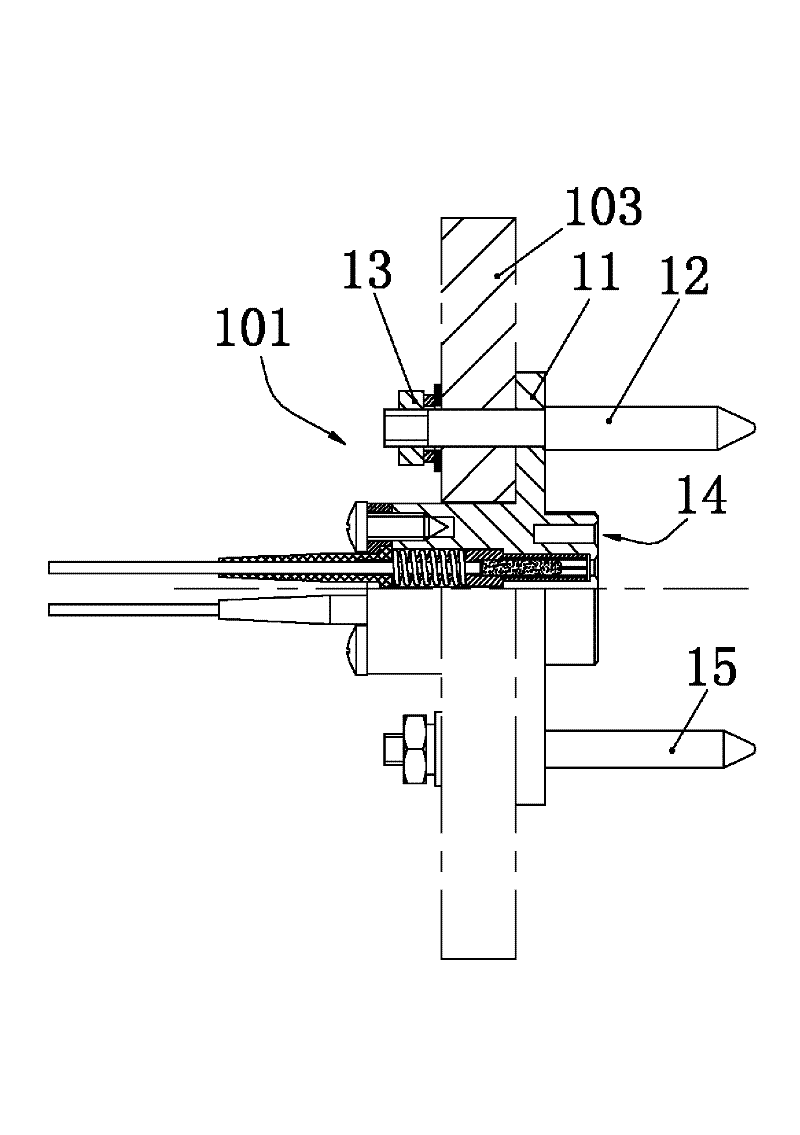

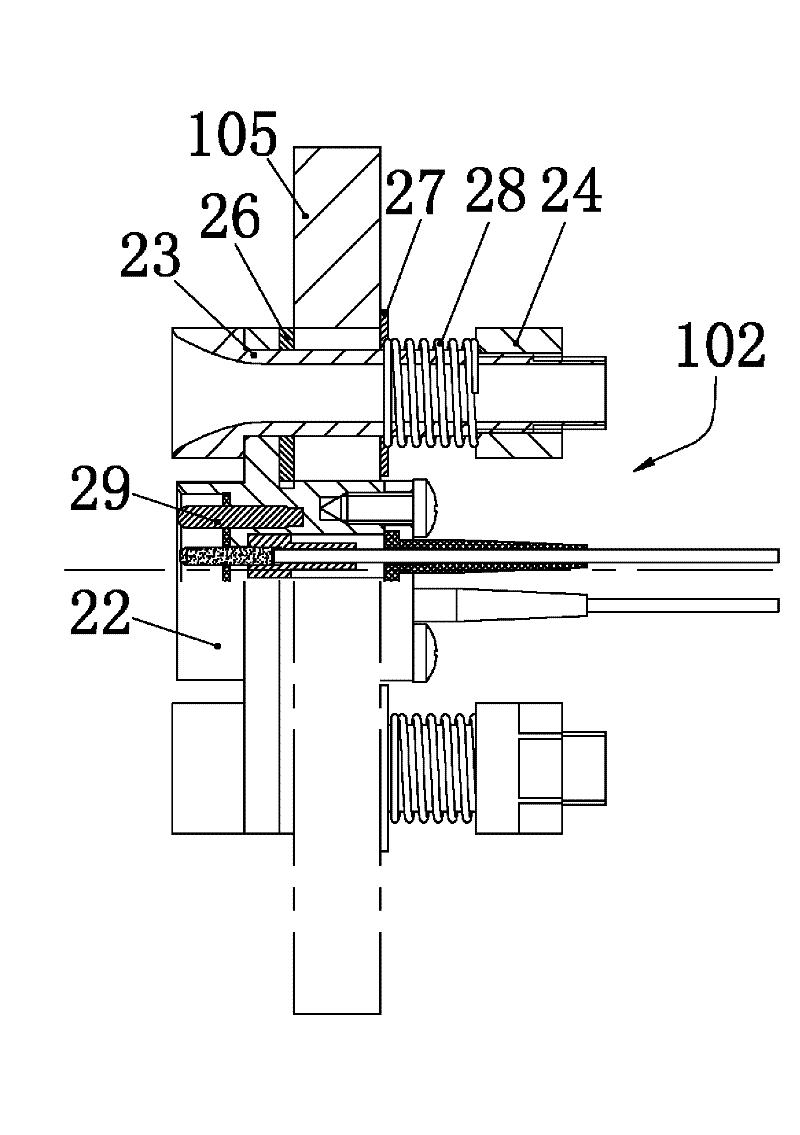

[0020] Embodiment 1 of the floating connector assembly, such as Figure 1-4 As shown, it consists of a fixed connector 101 and a floating connector 102.

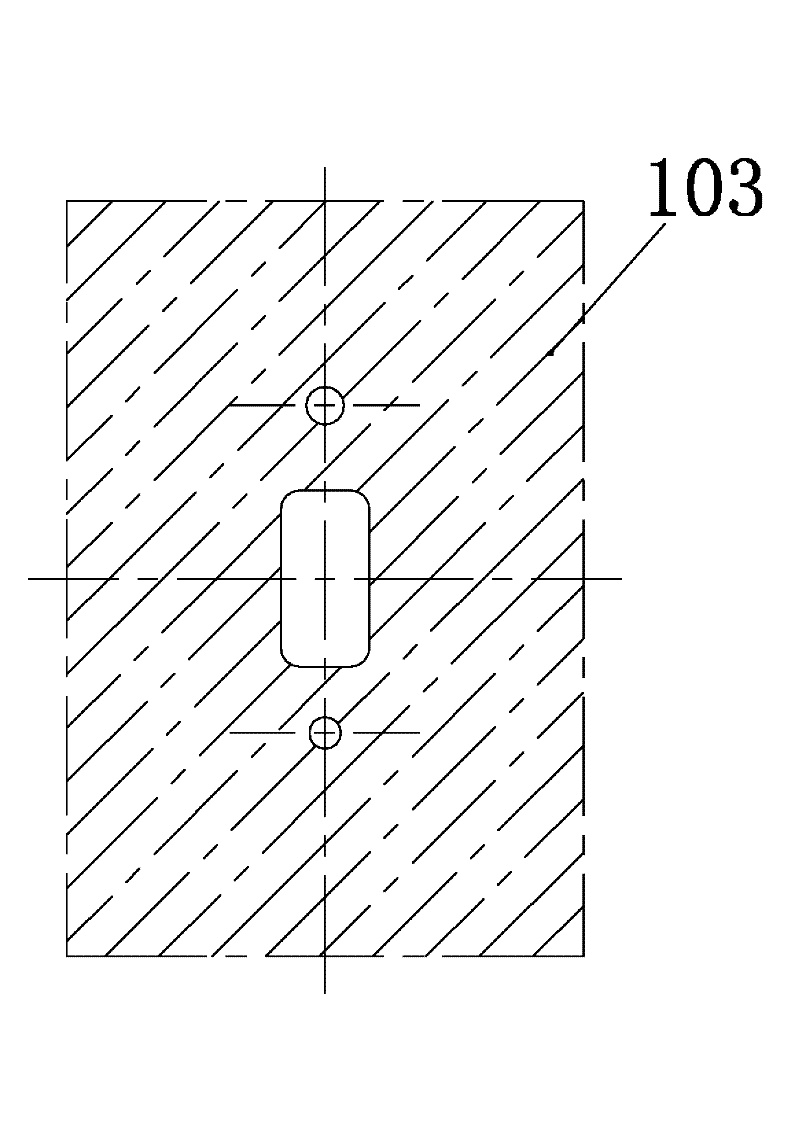

[0021] fixed connector 101 (as figure 1 ) has a fixed connector housing 11, and the fixed connector housing 11 is a square disc housing. The first guide post 15 and the second guide post 12 are equal. The unequal outer diameters of the two guide posts can effectively prevent mis-insertion with the floating connector 102. Both guide posts are stepped shafts with a large diameter section and a small diameter section. structure and form a step surface between their respective large and small diameter sections, the small diameter section of each guide column deviates from the plug-in end of the fixed connector and is provided with an external thread section, and the square plate of the fixed connector housing 11 is provided with two When the fixed connector 101 is in use, the fixed connector housing 11 is first assembled on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com