Automatic magnetic check valve

A check valve, automatic technology, used in indoor sanitary pipeline installations, water supply installations, buildings, etc., can solve the problems of difficult to ensure tightness, inconvenient valve cleaning, and high production costs, and meet the requirements of reducing matching accuracy. Reasonable cloth design, convenient maintenance and nursing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

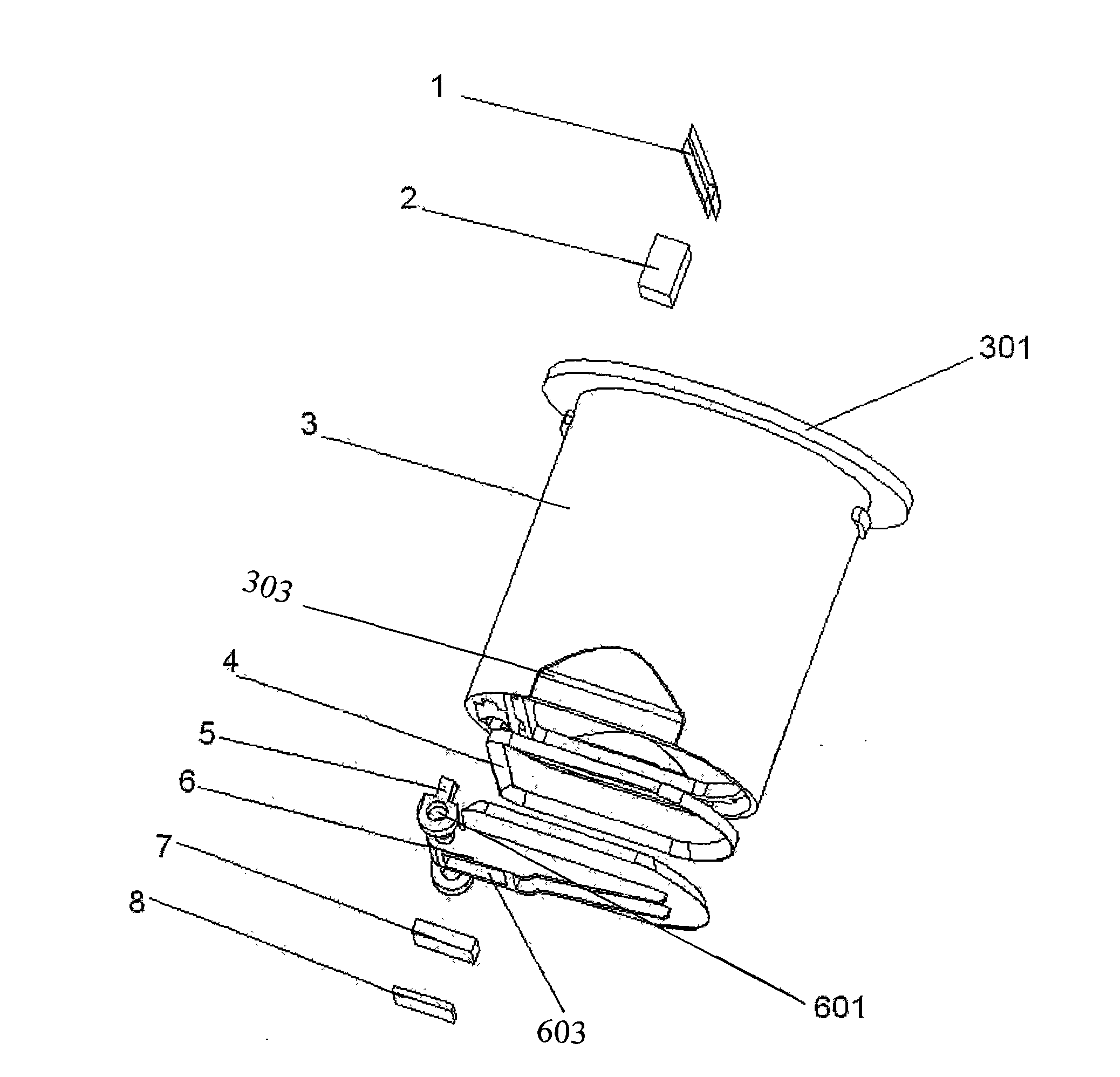

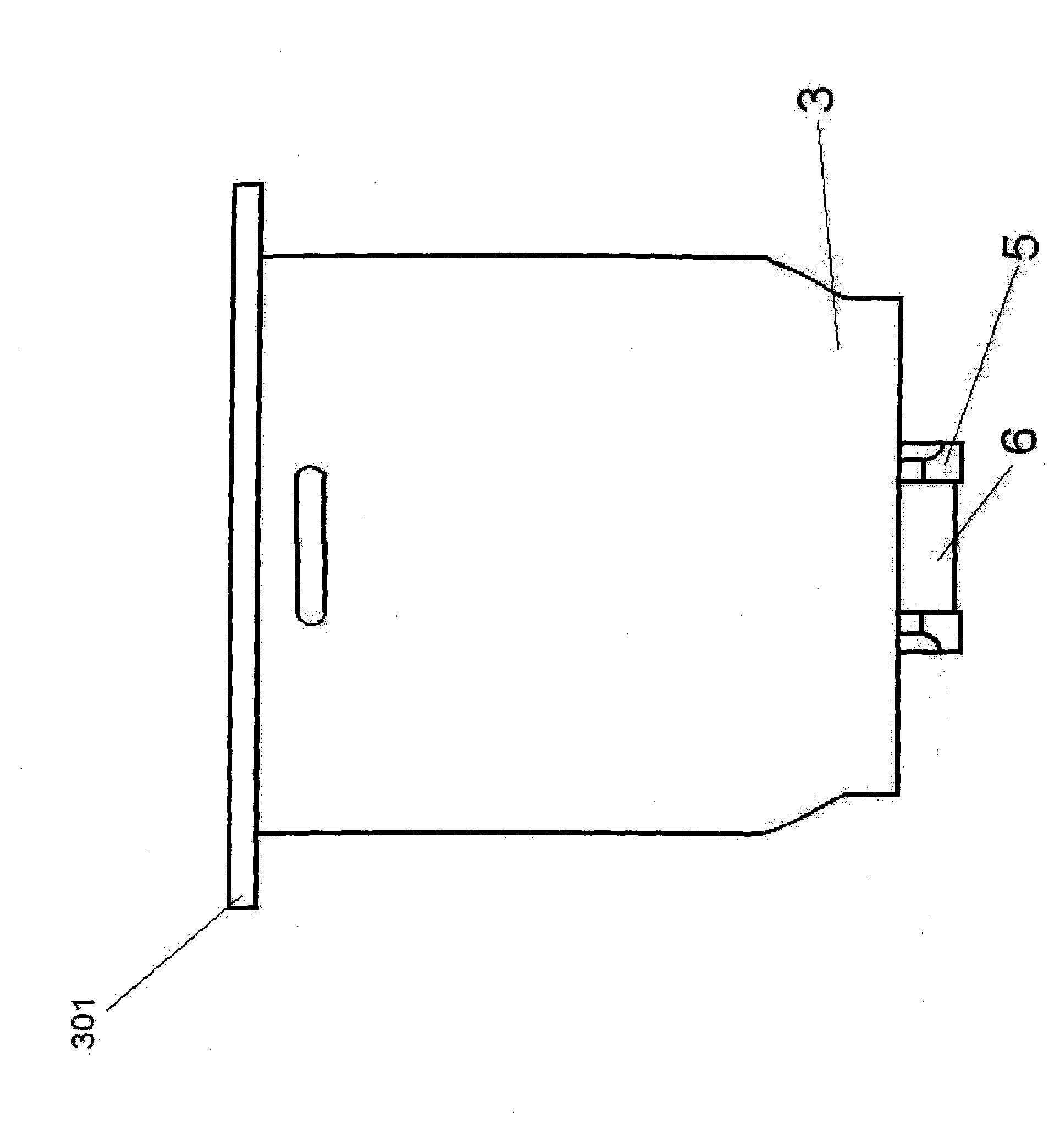

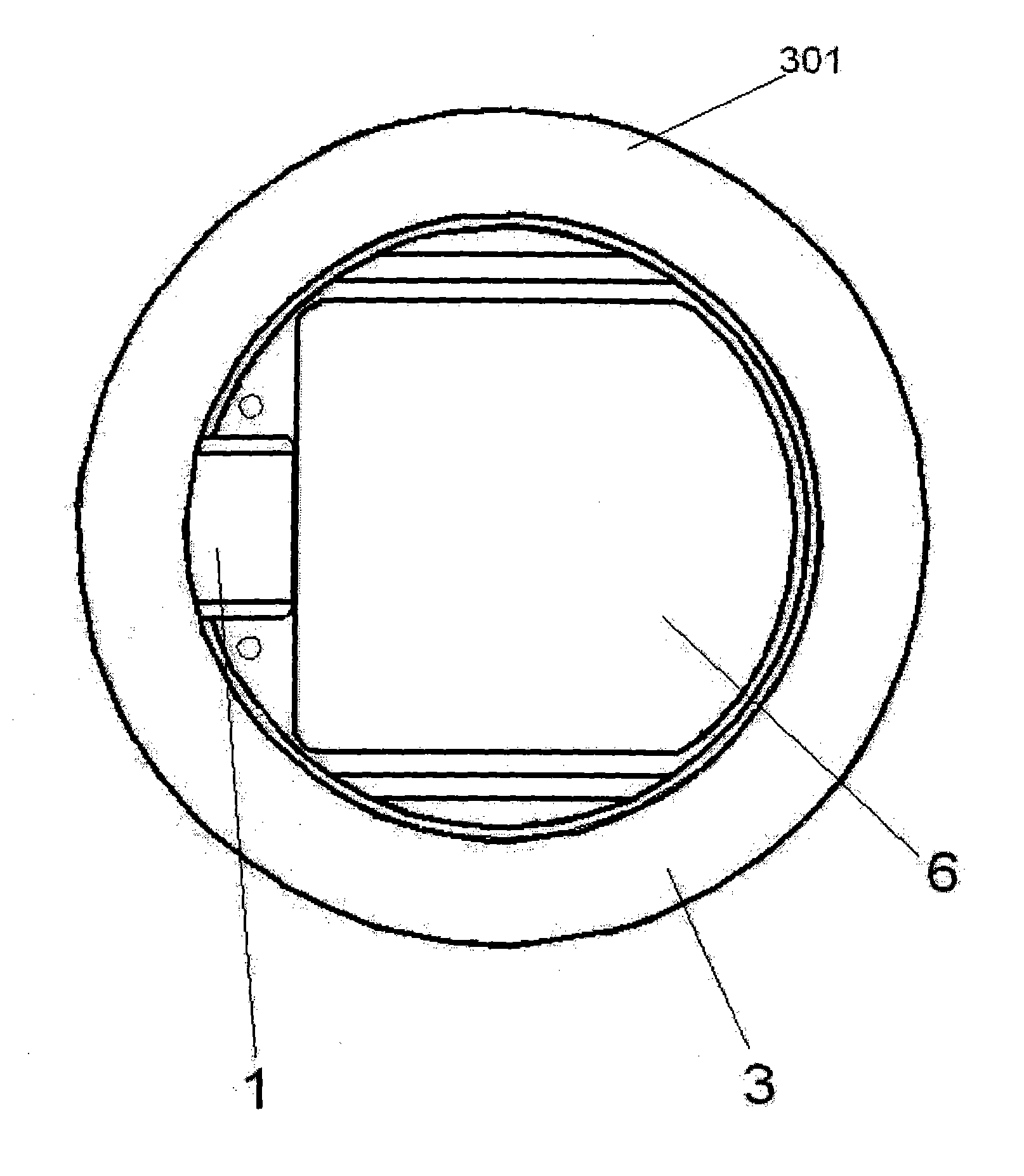

[0035] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a magnetic automatic check valve mainly includes components such as upper cover 1, upper magnet 2, valve body 3, sealing ring 4, shaft seat 5, valve 6, lower magnet 7, lower cover 8; the valve body 3 is cylindrical and has a large cross-sectional area. The upper part is provided with a flanging 301, and the bottom side is provided with a shaft seat 5. The shaft seat 5 and the valve body 3 can be integrally formed, or can be formed separately and fixedly connected with the valve body 3. Together, the valve 6 is hinged on the two shaft seats 5 through the valve shaft 601, and the valve shaft 601 rotates in the inner hole of the shaft seat 5 to drive the valve 6 to open at 90 degrees in the circular pipe; the upper magnet 2 is arranged on the valve body 3, The lower magnet 7 is arranged on the valve 6, and a groove 302 is integrally formed on the side of the valve body 3 close to the bottom outl...

Embodiment 2

[0039] refer to Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 As shown, a notch 304 with a three-dimensional curved surface shape is provided on the side wall of the bottom of the valve body 3, or a notch 304 with a three-dimensional curved surface shape corresponding to each other is provided on the two side walls; one side of the valve body 6 Or both sides are provided with a three-dimensional curved surface shape flange 604 that matches the three-dimensional curved surface shape of the notch 304 at the bottom of the valve body 3. When the valve 6 is closed, under the mutual attraction of the upper magnet 2 and the lower magnet 7, the The flange 604 of the valve 6 is tightly combined with the notch 304 of the valve body 3, and a sealing ring 4 is installed between the valve 6 and the valve body 3. The arc shape of the inner wall of the pipeline is compatible; the rest of the structure is the same as that of Embodiment 1.

[0040] refer to Figure 11 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com