Whole-type bearing high-speed spinning spindle with detachable and washable spindle feet

A spinning spindle and integral technology, which is applied in the field of high-speed spinning spindles with integral bearings, can solve the problems of difficult processing, radial unilateral force on the rod and disc, and unilateral wear of parts, etc., and achieve the reduction of matching accuracy requirements , uniform radial force on the hole, and the effect of reducing vibration energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

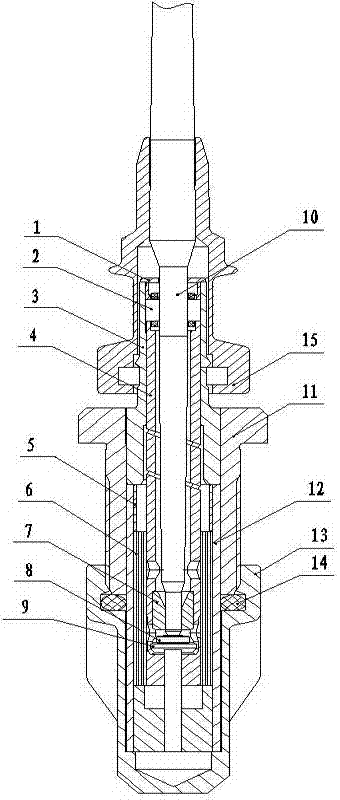

[0008] Now, the present invention will be described in detail in conjunction with the embodiments shown in the accompanying drawings.

[0009] Such as figure 1 As shown, a high-speed spinning spindle with an integral bearing with detachable and washable spindle feet includes a spindle seat and a rod disc. The spindle seat is composed of a spindle foot and a spindle liner. The sealing ring 14, the oil storage cup 13, the upper inner wall of the oil storage cup 13 has an outwardly protruding step, the sealing ring 14 is placed on the step, the lower part of the vibration-damping sleeve 12 is inserted into the oil storage cup 13 through the sealing ring 14, and the ingot The lower inner wall of the leg pipe 11 is mated with the upper outer wall of the vibration-damping sleeve 12, and the outer periphery is threaded with the inner wall of the upper end of the oil storage cup 13. Ingot gall includes bearing housing 3, elastic tube 4, oil-proof cap 1, ingot backsheet 8, ingot botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com