Method for preparing beta-Al2O3 ceramic electrolyte separator for sodium battery

A ceramic electrolyte and sodium battery technology, which is applied in ceramic molding machines, battery components, circuits, etc., can solve the problem of difficulty in realizing special-shaped, complex structure electrolyte diaphragm preparation, affecting electrolyte conductivity and mechanical properties, and difficult densification of ceramic diaphragms and other problems to achieve the effect of low matching precision requirements, ensuring consistency and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Preparation of beta-Al for sodium batteries of the present invention 2 o 3 The method for the ceramic electrolyte membrane includes step (1): respectively synthesizing Na-Z powder and Li-Z powder as precursor powder based on an Al source and a Na source, and an Al source and a Li source.

[0033] In one embodiment of the present invention, in this step (1), alpha-Al can be used 2 o 3 as Al source. and can use Na 2 CO 3 、Na 2 C 2 o 4 Any one of NaOH and NaOH is used as Na source. and can adopt Li 2 CO 3 , Li 2 C 2 o 4 and any one of LiOH as the Li source. Thereby, desired Na-Z powder and Li-Z powder which are precursor powders can be efficiently synthesized. However, the present invention is not limited thereto, and other sources of Al, Na and Li can also be used.

[0034] Further, in this step (1), after the Al source is mixed with the Na source and the Li source according to the specified molar ratio, the planetary ball mill is used for 2-6h, Preferabl...

Embodiment 1

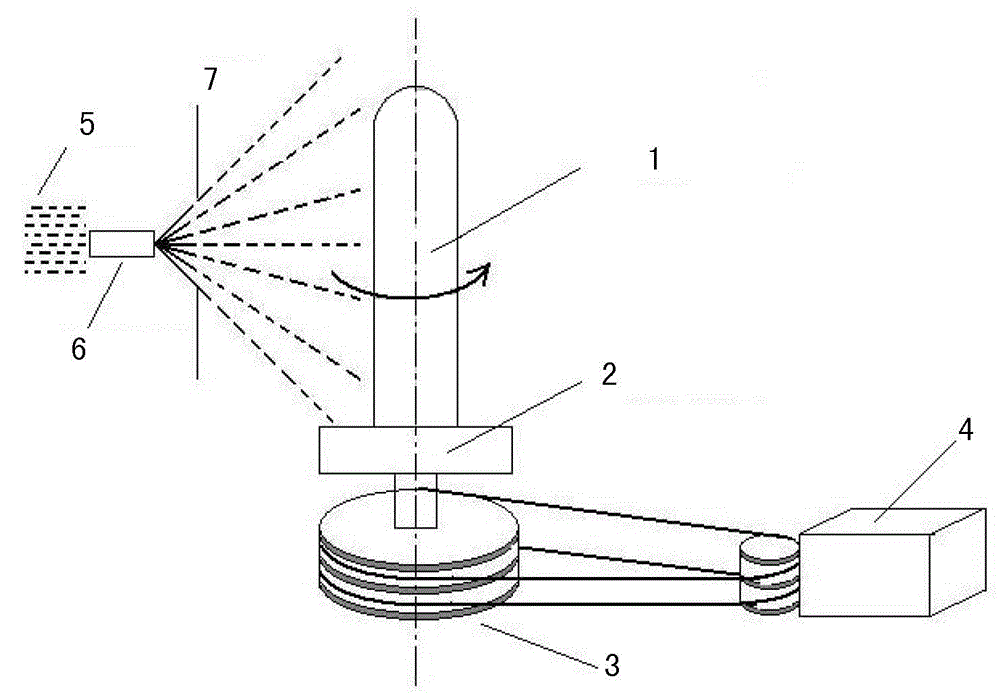

[0052] Weigh a certain amount of alpha-Al respectively 2 o 3 、Na 2 C 2 o 4 , Li 2 C 2 o 4 , according to the molar ratio Al 2 o 3 : Na 2 O=5:1, Al 2 o 3 : Li 2O=5:1 for batching, with absolute ethanol as the medium, planetary ball mill for 4 hours, dried and sieved, pre-calcined at 700°C for 4 hours, and then sintered at 1250°C for 2 hours to obtain Na-Z powder and Li-Z Powder. According to molar ratio Na-Z:Li-Z=6:1 batching, and the PVB that adds 2wt% is made binder, is solvent with dehydrated alcohol, prepares slurry 5, controls the consumption of dehydrated alcohol, makes slurry 5 had a solids content of 36 wt%. Fix the hemispherical tubular metal mandrel 1 on the fastening device 2, and turn on the motor of the driving device 4, and drive the forming mandrel 1 to rotate through the pulley 3, and the speed is controlled to 100r / min; the solid content is 36wt%. The slurry 5 is carried by a 3MPa high-pressure gas, and is sprayed from the high-pressure nozzle 6 ...

Embodiment 2

[0054] Weigh a certain amount of alpha-Al respectively 2 o 3 、Na 2 C 2 o 4 , Li 2 C 2 o 4 , according to the molar ratio Al 2 o 3 : Na 2 O=4.5:1, Al 2 o 3 : Li 2 O=4.5:1 for batching, with absolute ethanol as the medium, planetary ball mill for 4 hours, dried and sieved, pre-calcined at 700°C for 4 hours, and then sintered at 1250°C for 2 hours to obtain Na-Z powder and Li-Z Powder. According to molar ratio Na-Z:Li-Z=6:1 batching, and the PVB that adds 3wt% is made binder, is solvent with dehydrated alcohol, prepares slurry 5, controls the consumption of dehydrated alcohol, makes slurry 5 had a solids content of 36 wt%. Fix the four-leaf clover-shaped metal mandrel 1 on the fastening device 2, and turn on the motor of the driving device 4, and drive the forming mandrel 1 to rotate through the pulley 3, and the speed is controlled at 100r / min; the slurry with a solid content of 36wt% 5. Through the 5MPa high-pressure gas carrier, spray from the high-pressure nozz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com