Electric cable line extruder

A technology of extruder and cable wire, applied in the field of cable wire extruder, can solve the problems of troublesome installation, debugging, easy leakage of glue, difficult coordination of auxiliary machine and co-extrusion head, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below through specific examples.

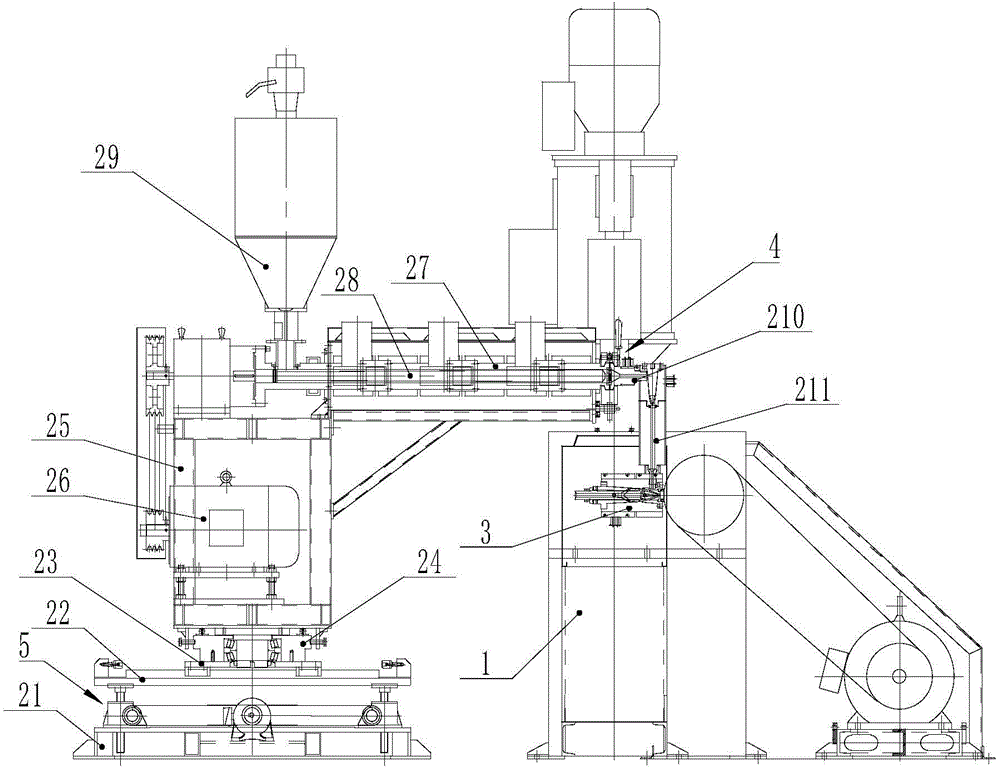

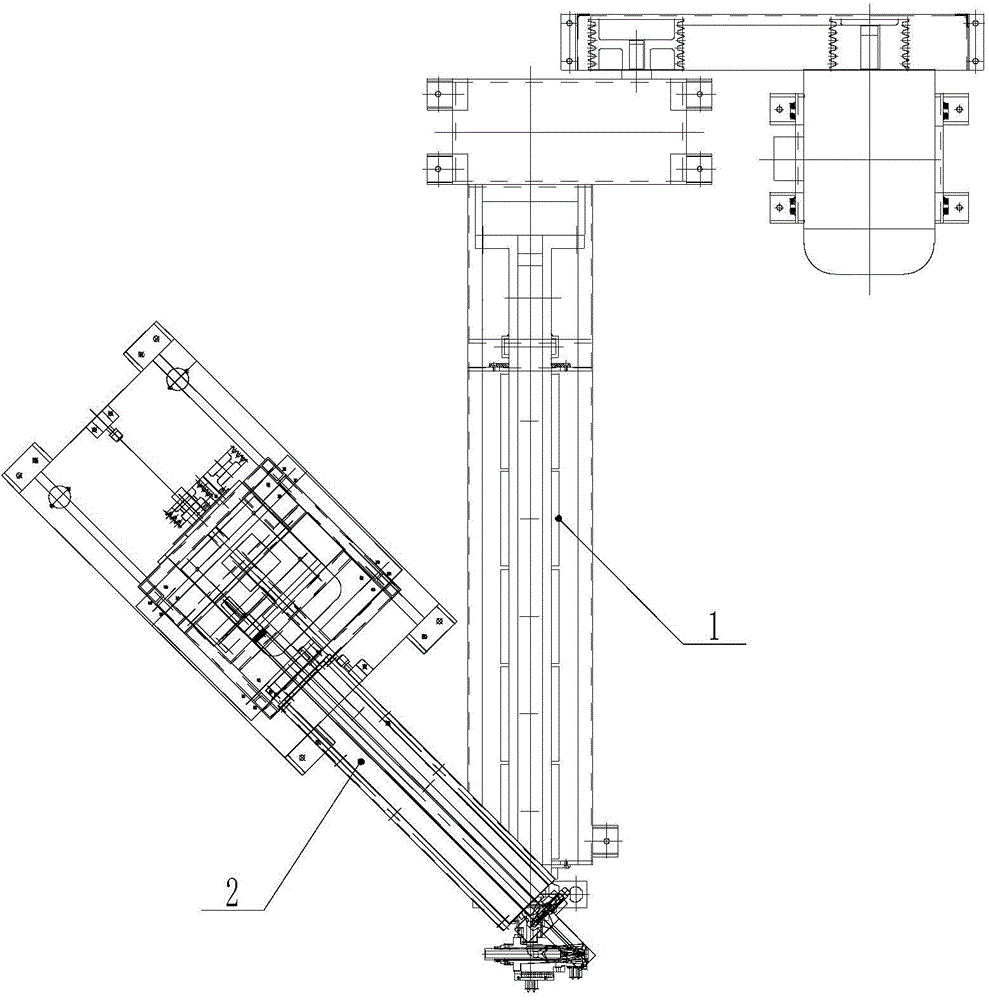

[0027] like Figure 1 to Figure 6 As shown, a cable extruder includes an extruding main machine 1 and at least one extruding auxiliary machine 2. The main machine head of the extruding main machine 1 cooperates with the co-extrusion head 3. The extruding main machine 1 is a conventional design at present. Therefore, the structure of the extrusion host 1 will not be described in detail.

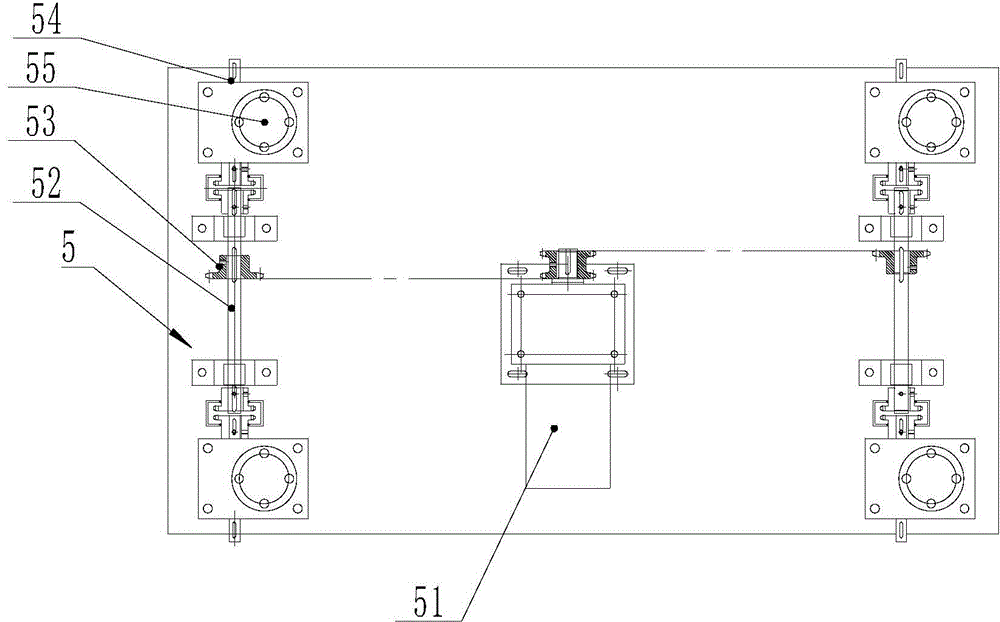

[0028]And this extruding auxiliary machine 2 comprises the base 21 that is arranged on extruding host 1 side, on this base 21 vertical lift is installed with lift seat 22, between this lift seat 22 and base 21 is provided with lift adjusting device 5, so The sliding seat 23 is horizontally slidably installed on the lifting seat 22, and a slide rail is installed on the upper surface of the lifting seat 22. device. The limit device adopts a limit screw, and the sliding seat 23 is fixed with a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com