Optical repeater used for long distance seabed optical cable communication system

A submarine optical cable and optical repeater technology, which is applied in the direction of electromagnetic repeaters, etc., can solve the problems of photoelectric unit structure design, complex material selection, increased difficulty of marine construction and burial, and large volume and weight of optical repeaters. , to achieve the effect of facilitating marine construction operations, reducing the difficulty of marine construction and embedding, and reducing the difficulty of mechanical design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

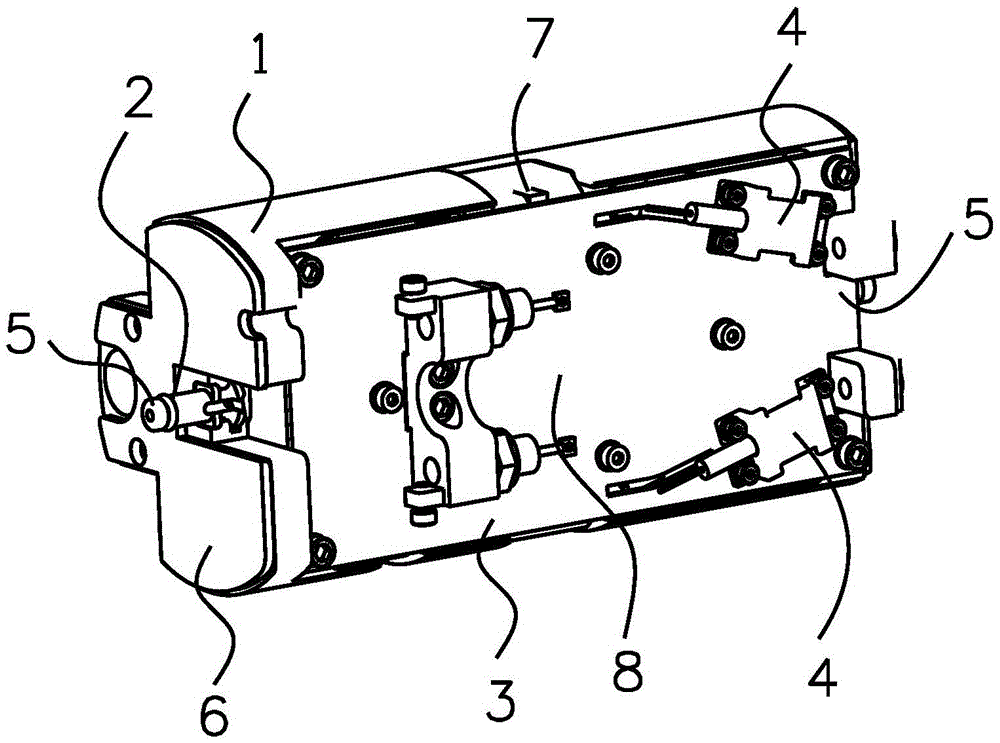

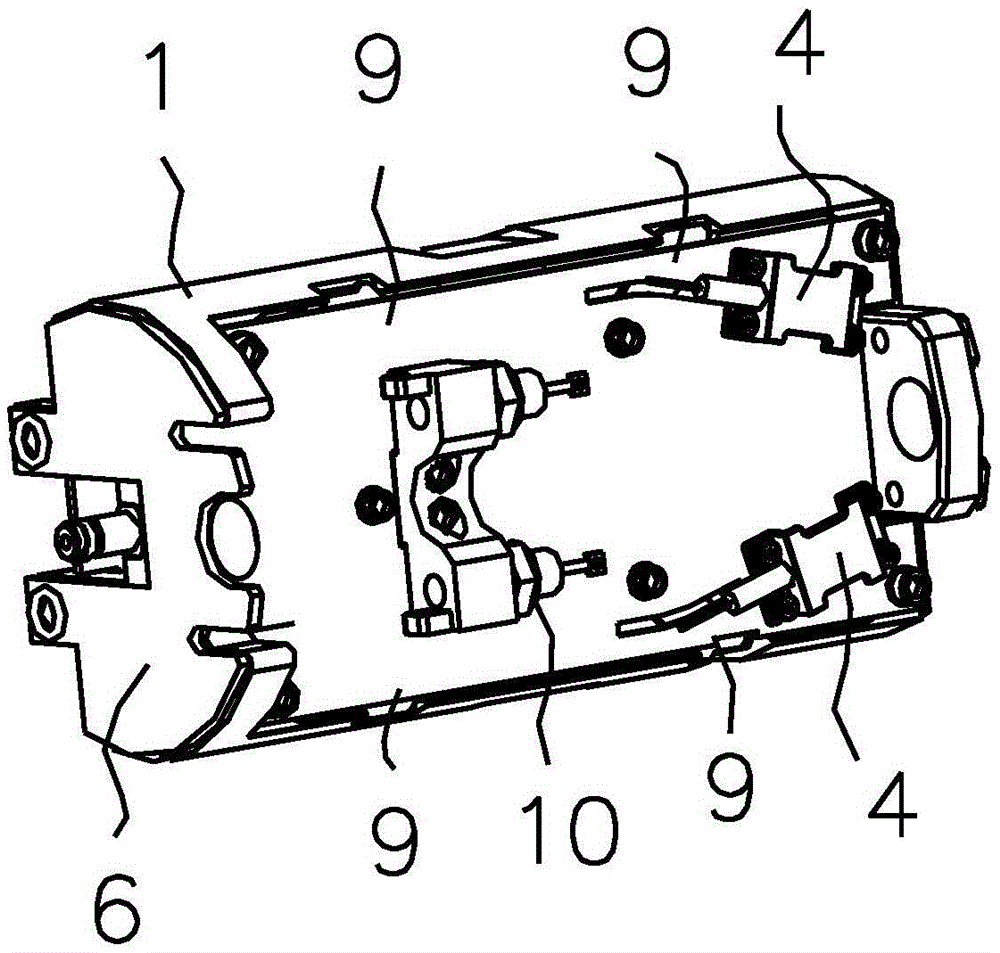

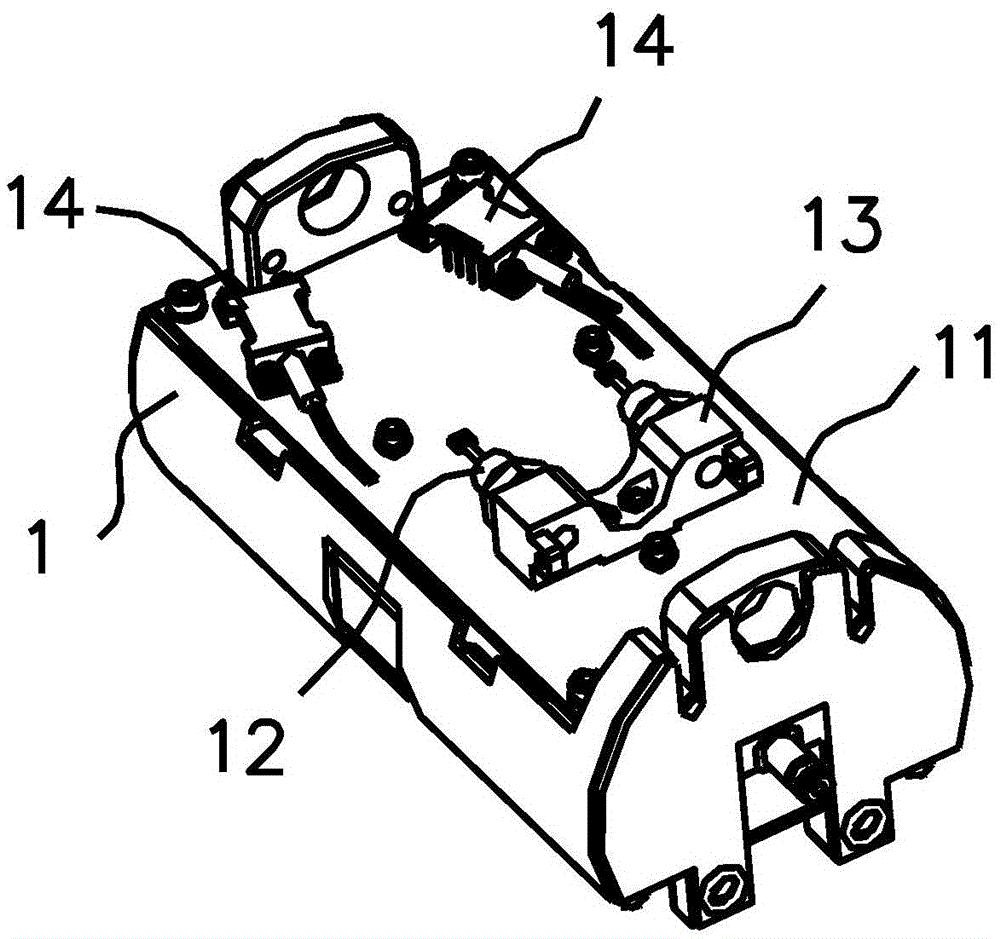

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0042] An embodiment of the present invention provides an optical repeater for a long-distance submarine optical cable communication system. The optical repeater is integrated in an optimized submarine optical cable connector. The structure of the optimized submarine optical cable connector is as follows: The longitudinal center line grows and the outer diameter remains unchanged, and the optimized submarine optical cable connector is obtained, which realizes the deployment and integration of optical repeaters in the inner space of the optimized submarine optical cable connector, and the exterior of the optimized submarine optical cable connector adopts an integral injection molding process, The entire optical repeater is wrapped inside the PE (polyethylene) insulating layer and isolated from seawater.

[0043] The optical repeater in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com