Novel lateral shaping mechanism

A new type of side shaping technology, applied in metal processing equipment, safety equipment, manufacturing tools, etc., can solve the problems of easy springback and crushing, poor mold stability, large space occupation, etc., to reduce mold tooling costs and improve castings. Quality, effect of optimizing part structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

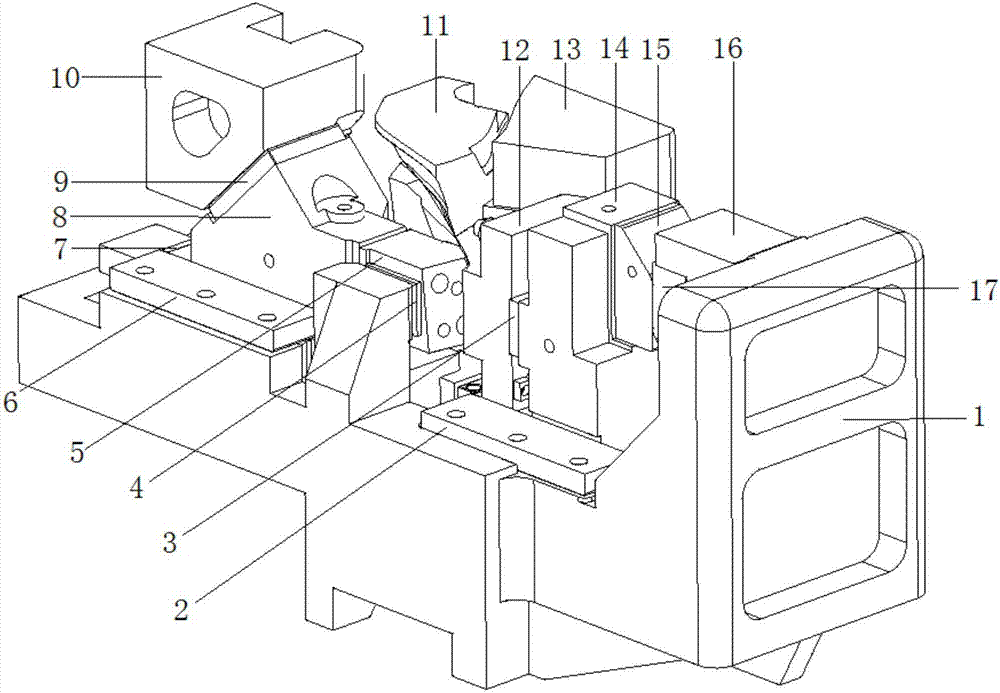

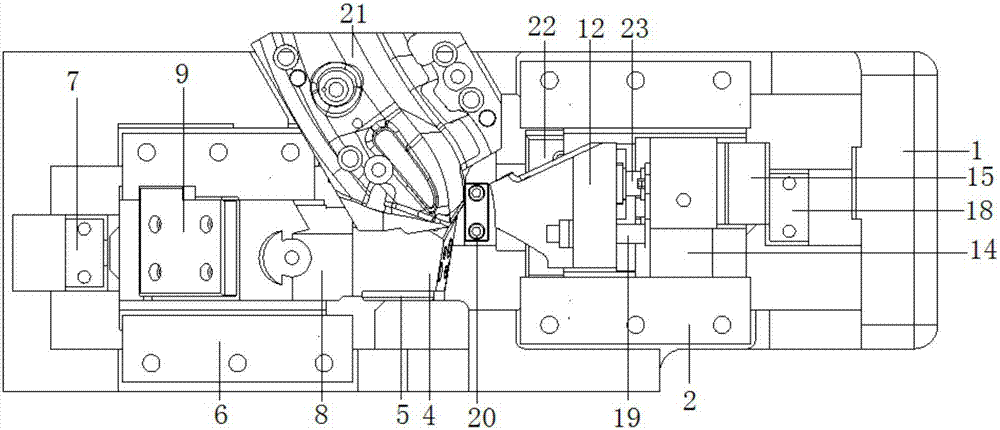

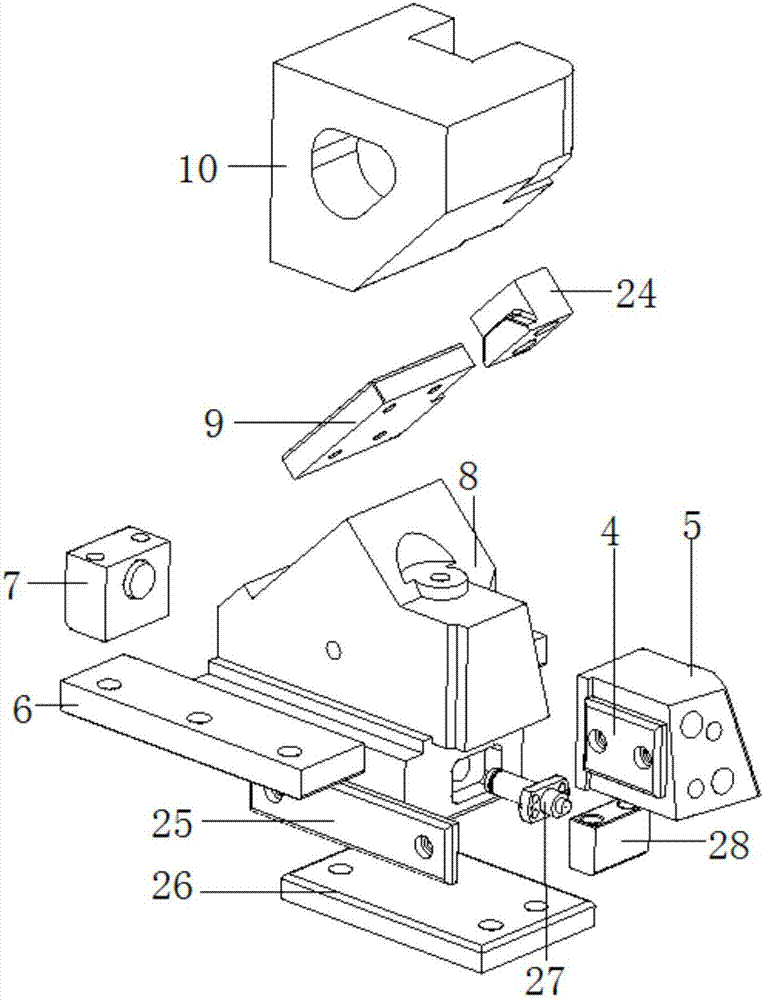

[0011] Such as Figures 1 to 4 As shown, the present invention provides a novel side shaping mechanism, which includes: an upper mold base and a lower mold base 1, the upper mold base is driven and connected with a binder core 11 and a shaping knife block 13, and the lower mold base 1 has 21 on the split punch, and the process parts are arranged on the split punch 21, wherein: at the two lateral ends of the split punch 21, the upper mold base also has respectively: the driving seat 10 and Inserting knife mounting seat 16, described lower mold base 1 also has respectively: pulley module (such as image 3 shown) and side shaping modules (such as Figure 4 As shown), the wedge sliding connection between the driving base 10 and the pulley module, the wedge sliding connection between the inserting knife mounting seat 16 and the side shaping module; and the pulley module includes: a pulley body 8 and the punch slide block 5 connected with the driving end of the block body 8, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com